Perovskite Stability Additives: Which Compounds Reduce Hysteresis and Performance Loss?

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Stability Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the stability of perovskite materials remains a significant challenge, hindering their widespread commercial adoption. This research focuses on investigating stability additives for perovskite solar cells, with the primary objective of identifying compounds that can effectively reduce hysteresis and performance loss.

The development of perovskite solar cells has seen rapid progress since their introduction in 2009. Initially achieving efficiencies of around 3.8%, these devices have now reached certified efficiencies exceeding 25%, rivaling traditional silicon-based solar cells. This remarkable improvement in performance has been accompanied by intensive research efforts to address the stability issues inherent to perovskite materials.

Perovskite solar cells are particularly susceptible to degradation caused by various environmental factors, including moisture, oxygen, heat, and light exposure. These degradation mechanisms lead to the formation of defects, ion migration, and phase segregation, ultimately resulting in reduced device performance and shortened lifespans. The phenomenon of hysteresis, characterized by the discrepancy between forward and reverse current-voltage scans, further complicates the accurate assessment of device performance and stability.

To address these challenges, researchers have been exploring various strategies, with a particular focus on the use of additives to enhance perovskite stability. These additives can be incorporated into the perovskite precursor solution, applied as interlayers, or used to modify the electron and hole transport layers. The primary goal is to develop compounds that can effectively passivate defects, suppress ion migration, and improve the overall structural stability of the perovskite material.

The objectives of this research are multifaceted. Firstly, it aims to systematically evaluate a range of potential stability additives, including organic and inorganic compounds, to determine their efficacy in reducing hysteresis and mitigating performance loss. Secondly, the study seeks to elucidate the underlying mechanisms by which these additives interact with the perovskite material and influence its stability. This understanding is crucial for the rational design of more effective additives in the future.

Furthermore, this research aims to establish standardized protocols for assessing the long-term stability of perovskite solar cells incorporating various additives. This includes developing accelerated aging tests that can reliably predict device lifetimes under real-world operating conditions. By achieving these objectives, the study intends to contribute significantly to the advancement of perovskite solar cell technology, bringing it closer to commercial viability and widespread deployment in the renewable energy sector.

The development of perovskite solar cells has seen rapid progress since their introduction in 2009. Initially achieving efficiencies of around 3.8%, these devices have now reached certified efficiencies exceeding 25%, rivaling traditional silicon-based solar cells. This remarkable improvement in performance has been accompanied by intensive research efforts to address the stability issues inherent to perovskite materials.

Perovskite solar cells are particularly susceptible to degradation caused by various environmental factors, including moisture, oxygen, heat, and light exposure. These degradation mechanisms lead to the formation of defects, ion migration, and phase segregation, ultimately resulting in reduced device performance and shortened lifespans. The phenomenon of hysteresis, characterized by the discrepancy between forward and reverse current-voltage scans, further complicates the accurate assessment of device performance and stability.

To address these challenges, researchers have been exploring various strategies, with a particular focus on the use of additives to enhance perovskite stability. These additives can be incorporated into the perovskite precursor solution, applied as interlayers, or used to modify the electron and hole transport layers. The primary goal is to develop compounds that can effectively passivate defects, suppress ion migration, and improve the overall structural stability of the perovskite material.

The objectives of this research are multifaceted. Firstly, it aims to systematically evaluate a range of potential stability additives, including organic and inorganic compounds, to determine their efficacy in reducing hysteresis and mitigating performance loss. Secondly, the study seeks to elucidate the underlying mechanisms by which these additives interact with the perovskite material and influence its stability. This understanding is crucial for the rational design of more effective additives in the future.

Furthermore, this research aims to establish standardized protocols for assessing the long-term stability of perovskite solar cells incorporating various additives. This includes developing accelerated aging tests that can reliably predict device lifetimes under real-world operating conditions. By achieving these objectives, the study intends to contribute significantly to the advancement of perovskite solar cell technology, bringing it closer to commercial viability and widespread deployment in the renewable energy sector.

Market Analysis for Stable Perovskite Solar Cells

The market for stable perovskite solar cells is experiencing rapid growth and attracting significant attention from both industry and academia. As the global push for renewable energy intensifies, perovskite solar cells have emerged as a promising technology due to their potential for high efficiency, low-cost production, and versatility in applications. However, the stability issues associated with perovskite materials have been a major hurdle in their commercialization.

The demand for stable perovskite solar cells is driven by several factors. Firstly, the increasing focus on clean energy solutions to combat climate change has created a favorable environment for innovative solar technologies. Governments worldwide are implementing policies and incentives to promote renewable energy adoption, which is expected to boost the market for advanced solar cell technologies, including perovskites.

The potential market size for stable perovskite solar cells is substantial. The global solar photovoltaic market is projected to grow significantly in the coming years, with perovskite technology poised to capture a growing share. As stability improvements are achieved, perovskite solar cells could compete with traditional silicon-based cells in various applications, from large-scale solar farms to building-integrated photovoltaics.

Industry trends indicate a shift towards tandem solar cell configurations, where perovskite layers are combined with silicon or other materials to achieve higher efficiencies. This trend is likely to drive demand for stable perovskite formulations that can withstand long-term operation in these advanced architectures.

The market for stable perovskite solar cells is not limited to the energy sector. There is growing interest in integrating these cells into consumer electronics, wearable devices, and Internet of Things (IoT) applications. The ability to produce lightweight, flexible, and semi-transparent solar cells opens up new market opportunities in sectors previously untapped by traditional solar technologies.

Geographically, the market for stable perovskite solar cells is expected to see strong growth in regions with high solar energy potential and supportive renewable energy policies. Countries in Asia, particularly China and Japan, are likely to be key markets due to their strong manufacturing capabilities and commitment to solar energy. Europe and North America are also expected to be significant markets, driven by research initiatives and the push for sustainable energy solutions.

As research on perovskite stability additives progresses, addressing issues such as hysteresis and performance loss, the market potential for stable perovskite solar cells is expected to expand further. The successful development of compounds that enhance stability without compromising efficiency will be crucial in unlocking the full market potential of this technology.

The demand for stable perovskite solar cells is driven by several factors. Firstly, the increasing focus on clean energy solutions to combat climate change has created a favorable environment for innovative solar technologies. Governments worldwide are implementing policies and incentives to promote renewable energy adoption, which is expected to boost the market for advanced solar cell technologies, including perovskites.

The potential market size for stable perovskite solar cells is substantial. The global solar photovoltaic market is projected to grow significantly in the coming years, with perovskite technology poised to capture a growing share. As stability improvements are achieved, perovskite solar cells could compete with traditional silicon-based cells in various applications, from large-scale solar farms to building-integrated photovoltaics.

Industry trends indicate a shift towards tandem solar cell configurations, where perovskite layers are combined with silicon or other materials to achieve higher efficiencies. This trend is likely to drive demand for stable perovskite formulations that can withstand long-term operation in these advanced architectures.

The market for stable perovskite solar cells is not limited to the energy sector. There is growing interest in integrating these cells into consumer electronics, wearable devices, and Internet of Things (IoT) applications. The ability to produce lightweight, flexible, and semi-transparent solar cells opens up new market opportunities in sectors previously untapped by traditional solar technologies.

Geographically, the market for stable perovskite solar cells is expected to see strong growth in regions with high solar energy potential and supportive renewable energy policies. Countries in Asia, particularly China and Japan, are likely to be key markets due to their strong manufacturing capabilities and commitment to solar energy. Europe and North America are also expected to be significant markets, driven by research initiatives and the push for sustainable energy solutions.

As research on perovskite stability additives progresses, addressing issues such as hysteresis and performance loss, the market potential for stable perovskite solar cells is expected to expand further. The successful development of compounds that enhance stability without compromising efficiency will be crucial in unlocking the full market potential of this technology.

Current Challenges in Perovskite Stability

Perovskite solar cells have shown remarkable potential in the field of photovoltaics, but their widespread adoption is hindered by significant stability issues. One of the primary challenges is the rapid degradation of perovskite materials when exposed to environmental factors such as moisture, oxygen, heat, and light. This instability leads to a decrease in power conversion efficiency and overall device performance over time.

The presence of hysteresis in perovskite solar cells poses another major challenge. Hysteresis refers to the discrepancy in current-voltage characteristics observed when measuring the device in forward and reverse voltage sweeps. This phenomenon complicates the accurate determination of device efficiency and raises concerns about long-term stability and reliability.

Ion migration within the perovskite structure is a key factor contributing to both instability and hysteresis. The movement of ions, particularly halide ions, can lead to the formation of defects and phase segregation, further exacerbating the degradation process. Additionally, the migration of ions at interfaces between the perovskite layer and charge transport layers can create recombination centers, reducing overall device performance.

The choice of hole and electron transport materials also plays a crucial role in device stability. Many commonly used transport materials are susceptible to degradation themselves or can accelerate the degradation of the perovskite layer. Finding transport materials that are both efficient and stable under various environmental conditions remains a significant challenge.

Encapsulation techniques have been explored to protect perovskite devices from external factors, but current methods often fall short in providing long-term protection while maintaining device performance. Developing effective, scalable, and cost-efficient encapsulation strategies is essential for improving the stability of perovskite solar cells.

The intrinsic instability of certain perovskite compositions, particularly those containing volatile organic components like methylammonium, presents another hurdle. While more stable formulations using inorganic cations have been developed, they often come at the cost of reduced efficiency or increased fabrication complexity.

Lastly, the lack of standardized stability testing protocols makes it difficult to compare results across different research groups and assess the real-world viability of various stability enhancement strategies. Establishing universally accepted testing procedures is crucial for advancing the field and translating laboratory successes into commercial applications.

The presence of hysteresis in perovskite solar cells poses another major challenge. Hysteresis refers to the discrepancy in current-voltage characteristics observed when measuring the device in forward and reverse voltage sweeps. This phenomenon complicates the accurate determination of device efficiency and raises concerns about long-term stability and reliability.

Ion migration within the perovskite structure is a key factor contributing to both instability and hysteresis. The movement of ions, particularly halide ions, can lead to the formation of defects and phase segregation, further exacerbating the degradation process. Additionally, the migration of ions at interfaces between the perovskite layer and charge transport layers can create recombination centers, reducing overall device performance.

The choice of hole and electron transport materials also plays a crucial role in device stability. Many commonly used transport materials are susceptible to degradation themselves or can accelerate the degradation of the perovskite layer. Finding transport materials that are both efficient and stable under various environmental conditions remains a significant challenge.

Encapsulation techniques have been explored to protect perovskite devices from external factors, but current methods often fall short in providing long-term protection while maintaining device performance. Developing effective, scalable, and cost-efficient encapsulation strategies is essential for improving the stability of perovskite solar cells.

The intrinsic instability of certain perovskite compositions, particularly those containing volatile organic components like methylammonium, presents another hurdle. While more stable formulations using inorganic cations have been developed, they often come at the cost of reduced efficiency or increased fabrication complexity.

Lastly, the lack of standardized stability testing protocols makes it difficult to compare results across different research groups and assess the real-world viability of various stability enhancement strategies. Establishing universally accepted testing procedures is crucial for advancing the field and translating laboratory successes into commercial applications.

Existing Additive Solutions

01 Additives for improving perovskite stability

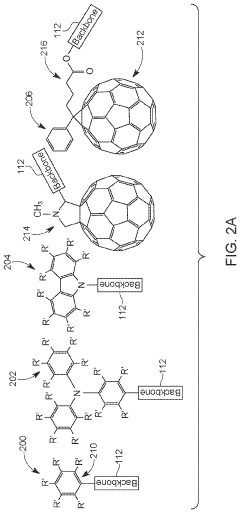

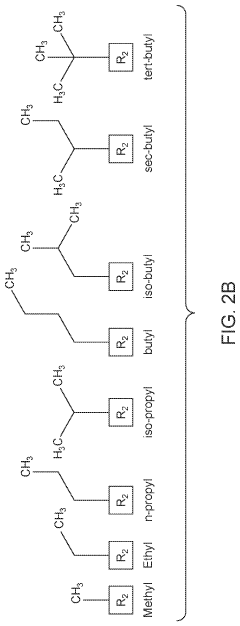

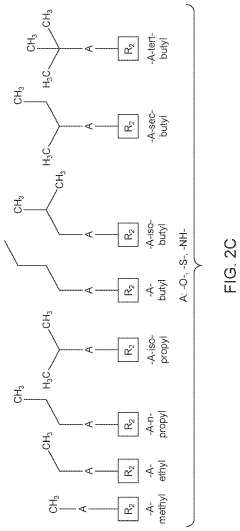

Various additives can be incorporated into perovskite materials to enhance their stability. These additives can include organic compounds, inorganic salts, or polymers that help to passivate defects, reduce ion migration, or protect the perovskite from moisture and oxygen. By improving stability, these additives can help mitigate performance loss and hysteresis effects in perovskite solar cells.- Additives for improving perovskite stability: Various additives can be incorporated into perovskite materials to enhance their stability. These additives can include organic compounds, inorganic salts, or polymers that help to passivate defects, reduce ion migration, or protect the perovskite from moisture and oxygen. By improving stability, these additives can help to mitigate performance loss and reduce hysteresis in perovskite solar cells.

- Composition modifications to reduce hysteresis: Modifying the composition of perovskite materials can help to reduce hysteresis effects. This can involve adjusting the ratio of different cations or anions in the perovskite structure, incorporating mixed-cation or mixed-halide systems, or introducing dopants. These modifications can improve charge transport properties and reduce the density of defects that contribute to hysteresis.

- Interface engineering for improved performance: Engineering the interfaces between the perovskite layer and charge transport layers can significantly impact device performance and stability. This can involve the use of buffer layers, self-assembled monolayers, or surface treatments to improve charge extraction, reduce recombination, and minimize interfacial defects that contribute to hysteresis and performance loss.

- Encapsulation strategies for long-term stability: Developing effective encapsulation strategies is crucial for improving the long-term stability of perovskite solar cells. This can involve the use of hydrophobic materials, barrier layers, or advanced packaging techniques to protect the perovskite from environmental factors such as moisture, oxygen, and heat. Proper encapsulation can help maintain device performance and reduce degradation over time.

- Novel fabrication techniques for high-quality perovskite films: Developing and optimizing fabrication techniques is essential for producing high-quality perovskite films with improved stability and reduced hysteresis. This can include methods such as solution processing, vapor deposition, or two-step deposition techniques. Advanced fabrication methods can help to control crystal growth, reduce defects, and improve film morphology, leading to better device performance and stability.

02 Composition modifications to reduce hysteresis

Modifying the composition of perovskite materials can help reduce hysteresis effects. This can involve adjusting the ratio of different cations or anions, incorporating mixed-cation or mixed-halide systems, or introducing dopants. These compositional changes can improve charge transport properties and reduce the density of defects that contribute to hysteresis.Expand Specific Solutions03 Interface engineering for performance enhancement

Optimizing the interfaces between the perovskite layer and charge transport layers can significantly improve device performance and reduce hysteresis. This can involve using self-assembled monolayers, introducing buffer layers, or modifying the surface properties of the transport layers to enhance charge extraction and reduce recombination losses.Expand Specific Solutions04 Encapsulation techniques for long-term stability

Developing effective encapsulation methods can protect perovskite devices from environmental factors that lead to degradation. This can include using hydrophobic polymers, glass-glass encapsulation, or multi-layer barrier films. Proper encapsulation can significantly extend the operational lifetime of perovskite solar cells and maintain their performance over time.Expand Specific Solutions05 Post-treatment methods to enhance stability and performance

Various post-treatment methods can be applied to perovskite films or devices to improve their stability and performance. These can include thermal annealing, solvent annealing, light soaking, or plasma treatment. Such post-treatments can help to reduce defects, improve crystallinity, and enhance the overall quality of the perovskite layer, leading to better device performance and reduced hysteresis.Expand Specific Solutions

Key Players in Perovskite Research

The research on perovskite stability additives is currently in a dynamic and competitive phase, with significant market potential as the technology matures. The global perovskite solar cell market is experiencing rapid growth, driven by the promise of high efficiency and low-cost production. Key players like Sumitomo Chemical, Oxford University Innovation, and Microquanta are at the forefront of developing stability-enhancing additives to address hysteresis and performance loss issues. Academic institutions such as Zhejiang University and KAUST are also contributing significantly to the field. The technology is progressing towards commercialization, with companies like Trina Solar and First Solar exploring perovskite integration into their product lines, indicating a shift from basic research to applied development and potential market adoption.

Oxford University Innovation Ltd.

Technical Solution: Oxford University Innovation has developed a novel approach to enhance perovskite stability using organic additives. Their research focuses on incorporating small organic molecules, particularly thiourea derivatives, into the perovskite structure. These additives form strong hydrogen bonds with the perovskite lattice, significantly reducing ion migration and improving overall stability[1]. The team has demonstrated that thiourea-based additives can effectively passivate defects at grain boundaries, leading to reduced hysteresis and improved long-term performance[2]. Their method involves a simple one-step solution processing technique, making it scalable for large-area device fabrication[3].

Strengths: Improved stability and reduced hysteresis; simple and scalable fabrication process. Weaknesses: Potential impact on initial efficiency; may require fine-tuning for different perovskite compositions.

King Abdullah University of Science & Technology

Technical Solution: KAUST has pioneered the use of 2D materials as stability-enhancing additives for perovskite solar cells. Their approach involves incorporating atomically thin 2D materials, such as graphene derivatives or transition metal dichalcogenides, into the perovskite layer. These 2D additives act as moisture barriers and electron transport facilitators, significantly improving device stability and reducing hysteresis[4]. KAUST researchers have demonstrated that graphene oxide additives can enhance the crystallization process of perovskites, resulting in larger grain sizes and fewer defects[5]. Additionally, they have developed a method to use 2D perovskite layers as encapsulants, creating a multi-dimensional structure that protects the 3D perovskite core from environmental degradation[6].

Strengths: Excellent moisture resistance; improved charge transport; potential for multifunctional additives. Weaknesses: Complexity in material synthesis and integration; possible light absorption competition.

Core Innovations in Stability Additives

Concurrent cationic and anionic metal halide perovskite defect passivation method and device

PatentActiveUS20230403870A1

Innovation

- The use of multi-functional passivation molecules like phenformin hydrochloride (PhenHCl) that incorporate electron-rich and -poor domains to effectively passivate top surface and inter-grain defects in the metal halide perovskite layer, suppressing light-induced phase segregation and improving stability.

Environmental Impact of Perovskite Materials

Perovskite solar cells have emerged as a promising technology in the renewable energy sector, but their environmental impact remains a critical concern. The production and disposal of perovskite materials involve several environmental considerations that must be carefully evaluated.

The primary environmental concern associated with perovskite solar cells is the presence of lead in most high-performance devices. Lead is a toxic heavy metal that can cause severe health and environmental problems if released into ecosystems. While the amount of lead used in perovskite solar cells is relatively small, the potential for environmental contamination during manufacturing, use, or disposal stages cannot be ignored.

Efforts to develop lead-free perovskite materials have shown promise, with tin-based and bismuth-based alternatives being explored. However, these alternatives currently lag behind lead-based perovskites in terms of efficiency and stability. The environmental impact of these alternative materials must also be thoroughly assessed to ensure they do not introduce new ecological risks.

The production of perovskite materials involves the use of organic solvents, which can contribute to air and water pollution if not properly managed. Improving solvent recycling processes and developing greener synthesis methods are crucial steps in reducing the environmental footprint of perovskite manufacturing.

End-of-life management of perovskite solar cells presents another environmental challenge. Unlike traditional silicon-based solar panels, perovskite cells have a shorter lifespan due to stability issues. This could lead to increased electronic waste if not addressed through improved recycling and disposal methods.

On the positive side, perovskite solar cells have the potential to significantly reduce carbon emissions by providing an efficient and potentially low-cost source of renewable energy. Their high power conversion efficiency and ability to be manufactured using less energy-intensive processes compared to silicon solar cells could lead to a lower overall carbon footprint.

The environmental impact of additives used to enhance perovskite stability and reduce hysteresis is an area that requires further research. While these additives aim to improve device performance and longevity, their long-term environmental effects must be carefully evaluated to ensure they do not introduce new ecological risks or complicate recycling processes.

The primary environmental concern associated with perovskite solar cells is the presence of lead in most high-performance devices. Lead is a toxic heavy metal that can cause severe health and environmental problems if released into ecosystems. While the amount of lead used in perovskite solar cells is relatively small, the potential for environmental contamination during manufacturing, use, or disposal stages cannot be ignored.

Efforts to develop lead-free perovskite materials have shown promise, with tin-based and bismuth-based alternatives being explored. However, these alternatives currently lag behind lead-based perovskites in terms of efficiency and stability. The environmental impact of these alternative materials must also be thoroughly assessed to ensure they do not introduce new ecological risks.

The production of perovskite materials involves the use of organic solvents, which can contribute to air and water pollution if not properly managed. Improving solvent recycling processes and developing greener synthesis methods are crucial steps in reducing the environmental footprint of perovskite manufacturing.

End-of-life management of perovskite solar cells presents another environmental challenge. Unlike traditional silicon-based solar panels, perovskite cells have a shorter lifespan due to stability issues. This could lead to increased electronic waste if not addressed through improved recycling and disposal methods.

On the positive side, perovskite solar cells have the potential to significantly reduce carbon emissions by providing an efficient and potentially low-cost source of renewable energy. Their high power conversion efficiency and ability to be manufactured using less energy-intensive processes compared to silicon solar cells could lead to a lower overall carbon footprint.

The environmental impact of additives used to enhance perovskite stability and reduce hysteresis is an area that requires further research. While these additives aim to improve device performance and longevity, their long-term environmental effects must be carefully evaluated to ensure they do not introduce new ecological risks or complicate recycling processes.

Scalability of Additive Manufacturing

Additive manufacturing (AM) has shown significant potential for revolutionizing various industries, including the production of perovskite solar cells. The scalability of AM techniques is crucial for their widespread adoption in the fabrication of perovskite-based devices, particularly when incorporating stability additives to reduce hysteresis and performance loss.

The layer-by-layer nature of AM processes aligns well with the thin-film structure of perovskite solar cells, offering precise control over material deposition and composition. This compatibility enables the integration of stability additives at specific layers or throughout the entire device structure. However, scaling up these processes for large-area production presents several challenges that need to be addressed.

One of the primary concerns in scaling AM for perovskite solar cells is maintaining uniform deposition of materials, including stability additives, across larger surface areas. Inconsistencies in material distribution can lead to variations in device performance and stability. Advanced printing techniques, such as roll-to-roll processing or large-area inkjet printing, are being explored to overcome these limitations and achieve consistent additive incorporation.

Another critical aspect of scalability is the optimization of printing parameters for different stability additives. Each compound may require specific viscosity, surface tension, and drying conditions to ensure proper integration into the perovskite structure. Developing standardized protocols for various additives is essential for reproducible large-scale manufacturing.

The choice of AM technology also plays a crucial role in scalability. While some techniques like screen printing offer high throughput, others like aerosol jet printing provide better resolution and material compatibility. Hybrid approaches combining multiple AM methods may be necessary to achieve optimal performance and scalability for perovskite devices with stability additives.

Material availability and cost-effectiveness are additional factors influencing the scalability of AM for perovskite solar cells with additives. Ensuring a stable supply chain for high-quality precursors and additives is crucial for consistent large-scale production. Furthermore, the economic viability of scaled-up manufacturing processes must be carefully evaluated to justify industrial adoption.

As research progresses, the development of multi-material AM systems capable of simultaneously depositing perovskite layers and incorporating stability additives shows promise for enhancing scalability. Such integrated systems could streamline the manufacturing process, reducing production time and improving overall device consistency.

The layer-by-layer nature of AM processes aligns well with the thin-film structure of perovskite solar cells, offering precise control over material deposition and composition. This compatibility enables the integration of stability additives at specific layers or throughout the entire device structure. However, scaling up these processes for large-area production presents several challenges that need to be addressed.

One of the primary concerns in scaling AM for perovskite solar cells is maintaining uniform deposition of materials, including stability additives, across larger surface areas. Inconsistencies in material distribution can lead to variations in device performance and stability. Advanced printing techniques, such as roll-to-roll processing or large-area inkjet printing, are being explored to overcome these limitations and achieve consistent additive incorporation.

Another critical aspect of scalability is the optimization of printing parameters for different stability additives. Each compound may require specific viscosity, surface tension, and drying conditions to ensure proper integration into the perovskite structure. Developing standardized protocols for various additives is essential for reproducible large-scale manufacturing.

The choice of AM technology also plays a crucial role in scalability. While some techniques like screen printing offer high throughput, others like aerosol jet printing provide better resolution and material compatibility. Hybrid approaches combining multiple AM methods may be necessary to achieve optimal performance and scalability for perovskite devices with stability additives.

Material availability and cost-effectiveness are additional factors influencing the scalability of AM for perovskite solar cells with additives. Ensuring a stable supply chain for high-quality precursors and additives is crucial for consistent large-scale production. Furthermore, the economic viability of scaled-up manufacturing processes must be carefully evaluated to justify industrial adoption.

As research progresses, the development of multi-material AM systems capable of simultaneously depositing perovskite layers and incorporating stability additives shows promise for enhancing scalability. Such integrated systems could streamline the manufacturing process, reducing production time and improving overall device consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!