How to Design Outdoor Field Tests for Perovskite Module Reliability

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Module Testing Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering the potential for high efficiency, low-cost manufacturing, and versatile applications. As the technology advances from laboratory-scale devices to commercial-sized modules, the need for comprehensive outdoor field testing becomes increasingly critical. The primary objective of designing outdoor field tests for perovskite module reliability is to evaluate and validate the long-term performance, stability, and durability of these modules under real-world environmental conditions.

The development of perovskite solar technology has progressed rapidly over the past decade, with power conversion efficiencies surpassing 25% for small-scale devices. However, the transition from laboratory success to commercial viability requires rigorous testing to address concerns about long-term stability and performance degradation. Outdoor field tests play a crucial role in this transition, as they expose perovskite modules to the complex interplay of environmental factors that cannot be fully replicated in controlled laboratory settings.

The design of outdoor field tests for perovskite modules must consider several key factors that influence their reliability. These include temperature fluctuations, humidity levels, UV radiation exposure, mechanical stress from wind and snow loads, and potential chemical interactions with atmospheric pollutants. Additionally, the unique properties of perovskite materials, such as their sensitivity to moisture and potential ion migration, necessitate specialized testing protocols that may differ from those used for traditional silicon-based photovoltaics.

The objectives of outdoor field testing for perovskite modules encompass both short-term and long-term goals. In the short term, these tests aim to identify immediate failure modes, assess initial degradation rates, and validate the module's ability to withstand typical outdoor conditions. Long-term objectives include determining the modules' operational lifespan, quantifying performance losses over time, and evaluating the effectiveness of encapsulation and protective measures.

Furthermore, outdoor field tests serve to bridge the gap between accelerated laboratory testing and real-world performance. While accelerated aging tests provide valuable insights into potential degradation mechanisms, they may not accurately represent the complex and often synergistic effects of outdoor exposure. Field tests allow researchers and manufacturers to correlate accelerated test results with actual outdoor performance, refining predictive models and improving the overall understanding of perovskite module behavior in diverse climatic conditions.

Ultimately, the design of outdoor field tests for perovskite module reliability aims to generate comprehensive data sets that can inform further technological improvements, guide the development of industry standards, and build confidence among potential adopters of perovskite solar technology. By systematically evaluating the performance and durability of perovskite modules in real-world environments, these tests pave the way for the successful commercialization and widespread deployment of this promising photovoltaic technology.

The development of perovskite solar technology has progressed rapidly over the past decade, with power conversion efficiencies surpassing 25% for small-scale devices. However, the transition from laboratory success to commercial viability requires rigorous testing to address concerns about long-term stability and performance degradation. Outdoor field tests play a crucial role in this transition, as they expose perovskite modules to the complex interplay of environmental factors that cannot be fully replicated in controlled laboratory settings.

The design of outdoor field tests for perovskite modules must consider several key factors that influence their reliability. These include temperature fluctuations, humidity levels, UV radiation exposure, mechanical stress from wind and snow loads, and potential chemical interactions with atmospheric pollutants. Additionally, the unique properties of perovskite materials, such as their sensitivity to moisture and potential ion migration, necessitate specialized testing protocols that may differ from those used for traditional silicon-based photovoltaics.

The objectives of outdoor field testing for perovskite modules encompass both short-term and long-term goals. In the short term, these tests aim to identify immediate failure modes, assess initial degradation rates, and validate the module's ability to withstand typical outdoor conditions. Long-term objectives include determining the modules' operational lifespan, quantifying performance losses over time, and evaluating the effectiveness of encapsulation and protective measures.

Furthermore, outdoor field tests serve to bridge the gap between accelerated laboratory testing and real-world performance. While accelerated aging tests provide valuable insights into potential degradation mechanisms, they may not accurately represent the complex and often synergistic effects of outdoor exposure. Field tests allow researchers and manufacturers to correlate accelerated test results with actual outdoor performance, refining predictive models and improving the overall understanding of perovskite module behavior in diverse climatic conditions.

Ultimately, the design of outdoor field tests for perovskite module reliability aims to generate comprehensive data sets that can inform further technological improvements, guide the development of industry standards, and build confidence among potential adopters of perovskite solar technology. By systematically evaluating the performance and durability of perovskite modules in real-world environments, these tests pave the way for the successful commercialization and widespread deployment of this promising photovoltaic technology.

Market Demand for Reliable Perovskite Solar Modules

The market demand for reliable perovskite solar modules has been steadily increasing in recent years, driven by the growing global focus on renewable energy and the potential of perovskite technology to revolutionize the solar industry. Perovskite solar cells have shown remarkable progress in efficiency, reaching over 25% in laboratory settings, surpassing many traditional silicon-based technologies. This high efficiency, coupled with the potential for low-cost manufacturing, has sparked significant interest from both the scientific community and industry players.

The global solar photovoltaic market is projected to grow substantially in the coming years, with perovskite technology poised to capture a significant portion of this growth. As countries worldwide set ambitious renewable energy targets to combat climate change, the demand for more efficient and cost-effective solar solutions continues to rise. Perovskite modules, with their potential for higher power conversion efficiencies and lower production costs, are well-positioned to meet this demand.

However, the market's enthusiasm for perovskite technology is tempered by concerns about long-term stability and reliability, particularly in outdoor conditions. This is where the critical need for reliable perovskite modules becomes apparent. Potential customers, including utility-scale solar farm operators, commercial building owners, and residential consumers, are hesitant to adopt new technology without assurances of its durability and performance over time.

The demand for reliable perovskite modules is further driven by the industry's push towards building-integrated photovoltaics (BIPV) and other innovative applications. These emerging markets require solar modules that can withstand various environmental stresses while maintaining consistent performance. As such, demonstrating the reliability of perovskite modules through rigorous outdoor field testing is crucial for market acceptance and widespread adoption.

Investors and policymakers are also closely watching the development of reliable perovskite modules. The potential for perovskite technology to significantly reduce the levelized cost of electricity (LCOE) from solar power is a major driver of market interest. However, this potential can only be realized if the modules prove to be durable and reliable under real-world conditions, highlighting the importance of comprehensive outdoor field testing.

In conclusion, the market demand for reliable perovskite solar modules is strong and growing. The technology's promise of high efficiency and low cost is attractive, but it must be balanced with proven reliability to gain widespread market acceptance. As such, the development of effective outdoor field tests for perovskite module reliability is not just a technical challenge, but a critical step in meeting market demands and unlocking the full potential of this promising solar technology.

The global solar photovoltaic market is projected to grow substantially in the coming years, with perovskite technology poised to capture a significant portion of this growth. As countries worldwide set ambitious renewable energy targets to combat climate change, the demand for more efficient and cost-effective solar solutions continues to rise. Perovskite modules, with their potential for higher power conversion efficiencies and lower production costs, are well-positioned to meet this demand.

However, the market's enthusiasm for perovskite technology is tempered by concerns about long-term stability and reliability, particularly in outdoor conditions. This is where the critical need for reliable perovskite modules becomes apparent. Potential customers, including utility-scale solar farm operators, commercial building owners, and residential consumers, are hesitant to adopt new technology without assurances of its durability and performance over time.

The demand for reliable perovskite modules is further driven by the industry's push towards building-integrated photovoltaics (BIPV) and other innovative applications. These emerging markets require solar modules that can withstand various environmental stresses while maintaining consistent performance. As such, demonstrating the reliability of perovskite modules through rigorous outdoor field testing is crucial for market acceptance and widespread adoption.

Investors and policymakers are also closely watching the development of reliable perovskite modules. The potential for perovskite technology to significantly reduce the levelized cost of electricity (LCOE) from solar power is a major driver of market interest. However, this potential can only be realized if the modules prove to be durable and reliable under real-world conditions, highlighting the importance of comprehensive outdoor field testing.

In conclusion, the market demand for reliable perovskite solar modules is strong and growing. The technology's promise of high efficiency and low cost is attractive, but it must be balanced with proven reliability to gain widespread market acceptance. As such, the development of effective outdoor field tests for perovskite module reliability is not just a technical challenge, but a critical step in meeting market demands and unlocking the full potential of this promising solar technology.

Current Challenges in Outdoor Perovskite Module Testing

Outdoor field testing of perovskite solar modules presents several significant challenges that researchers and manufacturers must address to ensure reliable performance assessment. One of the primary obstacles is the inherent instability of perovskite materials when exposed to environmental factors such as moisture, heat, and UV radiation. These elements can rapidly degrade the perovskite layer, leading to accelerated performance loss and potentially inaccurate long-term reliability predictions.

Another major challenge is the lack of standardized testing protocols specifically designed for perovskite modules. Unlike traditional silicon-based photovoltaics, which have well-established testing procedures, perovskite technology is relatively new and requires tailored approaches to account for its unique characteristics and degradation mechanisms. This absence of standardization makes it difficult to compare results across different studies and institutions, hindering the collective advancement of the field.

The variability of outdoor conditions poses an additional hurdle in perovskite module testing. Factors such as temperature fluctuations, humidity levels, and solar irradiance can vary significantly across different geographical locations and seasons. This variability complicates the process of isolating specific degradation factors and extrapolating results to predict long-term performance in diverse climates.

Furthermore, the rapid pace of perovskite technology development introduces challenges in outdoor testing. As new perovskite compositions and device architectures are continually being developed, outdoor testing protocols must be flexible enough to accommodate these advancements while still providing meaningful, comparable results. This requires a delicate balance between standardization and adaptability in testing methodologies.

The time-intensive nature of outdoor field tests also presents a significant challenge, particularly for an emerging technology like perovskites. While accelerated indoor testing can provide quick insights, real-world outdoor testing often requires months or years to gather comprehensive data. This extended timeframe can be at odds with the fast-paced development cycle of perovskite technology, potentially leading to a lag between laboratory innovations and field-validated results.

Lastly, the challenge of accurately measuring and attributing performance changes in perovskite modules during outdoor testing is considerable. Distinguishing between reversible and irreversible degradation, identifying specific failure modes, and correlating observed changes with environmental factors require sophisticated monitoring equipment and data analysis techniques. The complex interplay of various degradation mechanisms in perovskite modules further complicates this task, necessitating advanced characterization methods and modeling approaches to fully understand the outdoor behavior of these devices.

Another major challenge is the lack of standardized testing protocols specifically designed for perovskite modules. Unlike traditional silicon-based photovoltaics, which have well-established testing procedures, perovskite technology is relatively new and requires tailored approaches to account for its unique characteristics and degradation mechanisms. This absence of standardization makes it difficult to compare results across different studies and institutions, hindering the collective advancement of the field.

The variability of outdoor conditions poses an additional hurdle in perovskite module testing. Factors such as temperature fluctuations, humidity levels, and solar irradiance can vary significantly across different geographical locations and seasons. This variability complicates the process of isolating specific degradation factors and extrapolating results to predict long-term performance in diverse climates.

Furthermore, the rapid pace of perovskite technology development introduces challenges in outdoor testing. As new perovskite compositions and device architectures are continually being developed, outdoor testing protocols must be flexible enough to accommodate these advancements while still providing meaningful, comparable results. This requires a delicate balance between standardization and adaptability in testing methodologies.

The time-intensive nature of outdoor field tests also presents a significant challenge, particularly for an emerging technology like perovskites. While accelerated indoor testing can provide quick insights, real-world outdoor testing often requires months or years to gather comprehensive data. This extended timeframe can be at odds with the fast-paced development cycle of perovskite technology, potentially leading to a lag between laboratory innovations and field-validated results.

Lastly, the challenge of accurately measuring and attributing performance changes in perovskite modules during outdoor testing is considerable. Distinguishing between reversible and irreversible degradation, identifying specific failure modes, and correlating observed changes with environmental factors require sophisticated monitoring equipment and data analysis techniques. The complex interplay of various degradation mechanisms in perovskite modules further complicates this task, necessitating advanced characterization methods and modeling approaches to fully understand the outdoor behavior of these devices.

Existing Outdoor Field Test Protocols for Perovskites

01 Encapsulation techniques for improved reliability

Advanced encapsulation methods are employed to enhance the stability and longevity of perovskite solar modules. These techniques involve using specialized materials and processes to protect the sensitive perovskite layer from environmental factors such as moisture and oxygen, which can degrade performance over time. Improved encapsulation contributes significantly to the overall reliability of perovskite solar modules.- Encapsulation techniques for improved reliability: Advanced encapsulation methods are employed to enhance the stability and longevity of perovskite solar modules. These techniques involve using specialized materials and processes to protect the sensitive perovskite layer from environmental factors such as moisture and oxygen, which can degrade performance over time. Improved encapsulation contributes significantly to the overall reliability of perovskite solar modules.

- Interface engineering for enhanced stability: Interface engineering focuses on optimizing the layers between the perovskite material and the electrodes. This approach aims to reduce charge recombination, improve charge extraction, and enhance the overall stability of the device. By carefully designing and modifying these interfaces, researchers can significantly improve the long-term reliability and performance of perovskite solar modules.

- Compositional modifications for increased durability: Researchers are exploring various compositional modifications to the perovskite material itself to enhance its intrinsic stability. This includes incorporating additives, dopants, or altering the perovskite formulation to create more robust and resilient structures. These modifications aim to address issues such as phase instability and ion migration, which can affect the long-term reliability of perovskite solar modules.

- Tandem and multi-junction architectures: Tandem and multi-junction architectures are being developed to combine perovskite solar cells with other photovoltaic technologies. These designs aim to leverage the strengths of different materials while mitigating their individual weaknesses. By integrating perovskites into such structures, researchers can potentially improve overall module reliability and efficiency, addressing some of the stability concerns associated with single-junction perovskite devices.

- Environmental stress testing and reliability assessment: Comprehensive environmental stress testing and reliability assessment protocols are being developed specifically for perovskite solar modules. These tests simulate various real-world conditions and accelerated aging processes to evaluate the long-term stability and performance of the modules. By identifying failure modes and degradation mechanisms, researchers can refine module designs and manufacturing processes to enhance overall reliability.

02 Interface engineering for enhanced stability

Interface engineering focuses on optimizing the layers between the perovskite material and the electrodes. This approach aims to reduce charge recombination, improve charge extraction, and enhance the overall stability of the device. By carefully designing and modifying these interfaces, researchers can significantly improve the long-term reliability and performance of perovskite solar modules.Expand Specific Solutions03 Composition tuning for improved durability

Researchers are exploring various compositions and additives to enhance the intrinsic stability of perovskite materials. This includes incorporating inorganic components, mixed cations, or halides to create more robust perovskite structures. These compositional modifications aim to improve the material's resistance to degradation factors such as heat, light, and humidity, thereby increasing the overall reliability of perovskite solar modules.Expand Specific Solutions04 Advanced manufacturing processes for reliability

Innovative manufacturing techniques are being developed to improve the consistency and quality of perovskite solar modules. These processes focus on precise control of film formation, crystallization, and device assembly. Advanced manufacturing methods can reduce defects, improve uniformity, and enhance the overall reliability and scalability of perovskite solar technology.Expand Specific Solutions05 Testing and characterization methods for reliability assessment

Developing standardized testing protocols and advanced characterization techniques is crucial for assessing and improving the reliability of perovskite solar modules. These methods include accelerated aging tests, in-situ monitoring, and non-destructive evaluation techniques. By accurately measuring and predicting long-term performance and degradation mechanisms, researchers can identify areas for improvement and validate the reliability of perovskite solar modules.Expand Specific Solutions

Key Players in Perovskite Module Testing Industry

The development of outdoor field tests for perovskite module reliability is in its early stages, with the market showing significant growth potential due to the increasing interest in perovskite solar technology. The competitive landscape is characterized by a mix of academic institutions, research centers, and industry players collaborating to advance the technology. Key players like Zhejiang University, Xiamen University, and the Industrial Technology Research Institute are at the forefront of research, while companies such as Toshiba Corp. and Panasonic are exploring commercial applications. The technology's maturity is still evolving, with ongoing efforts to improve long-term stability and performance under real-world conditions.

Zhejiang University

Technical Solution: Zhejiang University has developed a comprehensive approach to outdoor field testing for perovskite solar modules, focusing on long-term stability and performance optimization. Their methodology includes:

1. Multi-location testing: Establishing test sites across various climatic regions in China to assess module performance under diverse environmental conditions[1].

2. In-situ degradation analysis: Utilizing portable characterization tools for on-site analysis of degradation mechanisms without removing modules from the field[2].

3. Stress-specific accelerated testing: Designing custom outdoor acceleration chambers that can simulate specific environmental stresses while maintaining real-world conditions[3].

4. Performance recovery studies: Implementing controlled recovery periods to assess the self-healing capabilities of perovskite modules under different environmental conditions[4].

5. Big data analytics: Employing machine learning algorithms to analyze large datasets from multiple test sites, identifying correlations between environmental factors and module degradation[5].

Strengths: Diverse climatic testing locations, in-situ degradation analysis, and focus on performance recovery studies.

Weaknesses: May face challenges in standardizing test procedures across multiple sites and integrating diverse datasets.

University of Florida

Technical Solution: The University of Florida has developed a novel approach to outdoor field testing for perovskite solar modules, focusing on rapid assessment and correlation with indoor testing methods. Their methodology includes:

1. Accelerated outdoor testing: Using specially designed mounting systems that maximize solar exposure and environmental stresses[1].

2. Multi-parameter monitoring: Implementing advanced sensors to track temperature, humidity, UV exposure, and electrical performance in real-time[2].

3. Spectral analysis: Utilizing spectroradiometers to measure the impact of varying light spectra on module performance throughout the day and seasons[3].

4. Degradation mapping: Employing imaging techniques such as electroluminescence and infrared thermography to identify and track degradation patterns over time[4].

5. Machine learning integration: Developing algorithms to predict long-term performance based on short-term outdoor exposure data and correlations with indoor testing results[5].

Strengths: Rapid assessment techniques, advanced monitoring systems, and integration of machine learning for predictive modeling.

Weaknesses: May require validation across diverse geographic locations and climates for comprehensive reliability assessment.

Core Innovations in Perovskite Module Reliability Testing

Solar cell module

PatentWO2021251048A1

Innovation

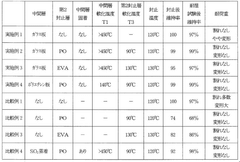

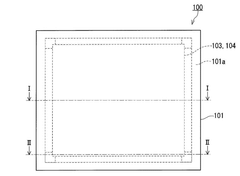

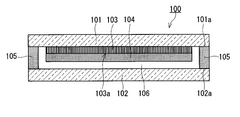

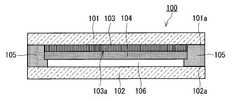

- A solar cell module design featuring a laminated structure with a first substrate, a second substrate, a solar cell, an intermediate layer, and a first sealing layer, where the intermediate layer is not fixed to the solar cell's surface but is positioned between the substrates, and the material of the intermediate layer has a higher softening temperature than the sealing layer, enhancing mechanical strength and preventing interfacial peeling.

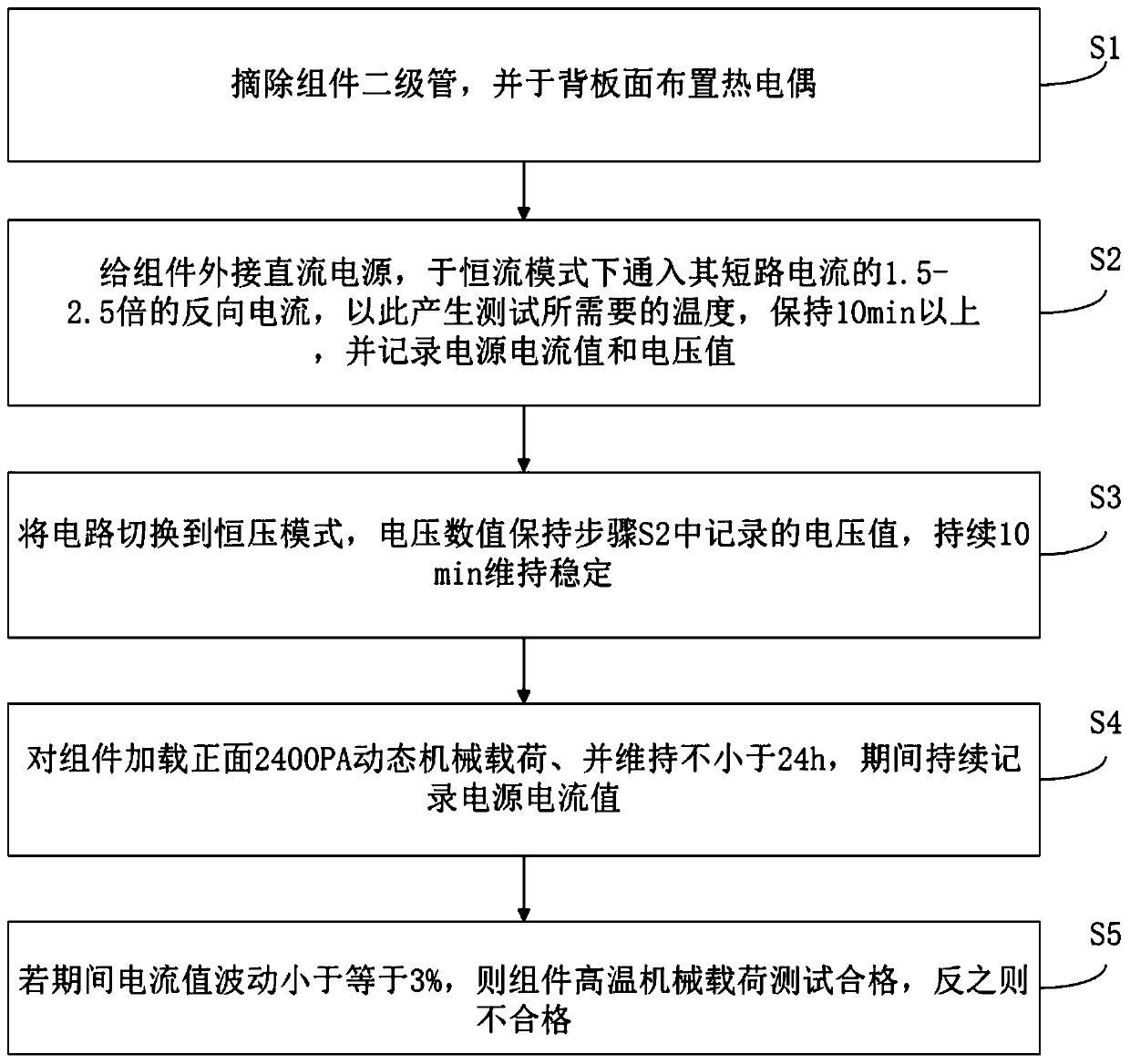

Photovoltaic module reliability detection method

PatentActiveCN110492844A

Innovation

- A photovoltaic module reliability testing method is adopted, which includes arranging thermocouples on the backplane of the module, external DC power supply to generate high temperature, combined with dynamic mechanical load testing, and recording current values to determine the module's high temperature mechanical load test eligibility. The test cycle is short and cost-effective Low.

Environmental Factors Affecting Perovskite Module Performance

Perovskite solar modules are highly sensitive to various environmental factors, which can significantly impact their performance and long-term reliability. Understanding these factors is crucial for designing effective outdoor field tests and improving module durability.

Temperature fluctuations play a critical role in perovskite module performance. Extreme heat can accelerate degradation processes, while rapid temperature changes may induce thermal stress and mechanical failures. Conversely, low temperatures can affect charge carrier mobility and extraction efficiency. Outdoor field tests must account for these temperature variations to accurately assess module behavior under real-world conditions.

Humidity is another major environmental factor affecting perovskite modules. Moisture ingress can lead to decomposition of the perovskite material, causing rapid performance degradation. High humidity environments pose a significant challenge to module encapsulation and sealing technologies. Field tests should evaluate the effectiveness of moisture barriers and assess module performance across different humidity levels.

Solar irradiation intensity and spectral distribution directly influence module efficiency and degradation rates. Prolonged exposure to high-intensity sunlight can accelerate photo-induced degradation processes. Additionally, the UV component of solar radiation can cause damage to both the perovskite layer and encapsulation materials. Outdoor tests must consider seasonal and geographical variations in solar irradiation to provide comprehensive performance data.

Atmospheric pollutants and particulate matter can accumulate on module surfaces, reducing light transmission and overall efficiency. In coastal areas, salt spray corrosion poses a unique challenge to module durability. Field tests should incorporate methods to evaluate the impact of these environmental contaminants on module performance and assess the effectiveness of protective coatings or self-cleaning technologies.

Wind and precipitation are important factors to consider in outdoor testing. Strong winds can subject modules to mechanical stress and vibrations, potentially leading to microcracks or delamination. Rainfall and snow accumulation can affect module temperature, create non-uniform shading, and introduce additional moisture-related challenges. Test designs must account for these weather conditions to ensure comprehensive reliability assessment.

Diurnal and seasonal cycles introduce complex variations in environmental conditions. The interplay between temperature, humidity, and irradiation throughout the day and across seasons can reveal unique degradation patterns and performance characteristics. Long-term field tests should capture these cyclic variations to provide insights into module behavior under diverse environmental scenarios.

Temperature fluctuations play a critical role in perovskite module performance. Extreme heat can accelerate degradation processes, while rapid temperature changes may induce thermal stress and mechanical failures. Conversely, low temperatures can affect charge carrier mobility and extraction efficiency. Outdoor field tests must account for these temperature variations to accurately assess module behavior under real-world conditions.

Humidity is another major environmental factor affecting perovskite modules. Moisture ingress can lead to decomposition of the perovskite material, causing rapid performance degradation. High humidity environments pose a significant challenge to module encapsulation and sealing technologies. Field tests should evaluate the effectiveness of moisture barriers and assess module performance across different humidity levels.

Solar irradiation intensity and spectral distribution directly influence module efficiency and degradation rates. Prolonged exposure to high-intensity sunlight can accelerate photo-induced degradation processes. Additionally, the UV component of solar radiation can cause damage to both the perovskite layer and encapsulation materials. Outdoor tests must consider seasonal and geographical variations in solar irradiation to provide comprehensive performance data.

Atmospheric pollutants and particulate matter can accumulate on module surfaces, reducing light transmission and overall efficiency. In coastal areas, salt spray corrosion poses a unique challenge to module durability. Field tests should incorporate methods to evaluate the impact of these environmental contaminants on module performance and assess the effectiveness of protective coatings or self-cleaning technologies.

Wind and precipitation are important factors to consider in outdoor testing. Strong winds can subject modules to mechanical stress and vibrations, potentially leading to microcracks or delamination. Rainfall and snow accumulation can affect module temperature, create non-uniform shading, and introduce additional moisture-related challenges. Test designs must account for these weather conditions to ensure comprehensive reliability assessment.

Diurnal and seasonal cycles introduce complex variations in environmental conditions. The interplay between temperature, humidity, and irradiation throughout the day and across seasons can reveal unique degradation patterns and performance characteristics. Long-term field tests should capture these cyclic variations to provide insights into module behavior under diverse environmental scenarios.

Standardization of Perovskite Module Field Test Procedures

The standardization of perovskite module field test procedures is crucial for ensuring consistent and reliable evaluation of perovskite solar technology performance in real-world conditions. This process involves establishing uniform protocols for outdoor testing, data collection, and analysis across different research institutions and industry players.

A key aspect of standardization is defining the specific environmental conditions under which tests should be conducted. This includes specifying acceptable ranges for temperature, humidity, solar irradiance, and other relevant factors. By establishing these parameters, researchers can ensure that results from different locations and time periods are comparable and reproducible.

Another important element is the development of standardized measurement techniques and equipment. This encompasses the selection of appropriate sensors, data logging systems, and calibration procedures. Uniformity in these areas helps minimize discrepancies between different testing sites and allows for more accurate cross-comparison of results.

The duration and frequency of measurements also require standardization. Long-term stability is a critical factor for perovskite modules, so field tests must be designed to capture performance data over extended periods. Establishing guidelines for test durations, sampling intervals, and data reporting formats ensures that all relevant information is captured consistently across different studies.

Standardized procedures for module preparation and installation are equally important. This includes guidelines for handling, transportation, and mounting of perovskite modules in outdoor environments. Proper installation techniques are crucial for accurately assessing real-world performance and durability.

Data analysis and reporting methods also need to be standardized to facilitate meaningful comparisons between different studies. This involves establishing common metrics for evaluating module performance, degradation rates, and failure modes. Standardized reporting formats and data visualization techniques can help in effectively communicating results across the research community.

Collaboration between research institutions, industry partners, and regulatory bodies is essential for developing and implementing these standardized procedures. International organizations such as the International Electrotechnical Commission (IEC) can play a crucial role in coordinating efforts and establishing globally recognized standards for perovskite module field testing.

By implementing standardized field test procedures, the perovskite solar community can accelerate the development and commercialization of this promising technology. Consistent and reliable outdoor performance data will build confidence among investors and end-users, paving the way for wider adoption of perovskite solar modules in various applications.

A key aspect of standardization is defining the specific environmental conditions under which tests should be conducted. This includes specifying acceptable ranges for temperature, humidity, solar irradiance, and other relevant factors. By establishing these parameters, researchers can ensure that results from different locations and time periods are comparable and reproducible.

Another important element is the development of standardized measurement techniques and equipment. This encompasses the selection of appropriate sensors, data logging systems, and calibration procedures. Uniformity in these areas helps minimize discrepancies between different testing sites and allows for more accurate cross-comparison of results.

The duration and frequency of measurements also require standardization. Long-term stability is a critical factor for perovskite modules, so field tests must be designed to capture performance data over extended periods. Establishing guidelines for test durations, sampling intervals, and data reporting formats ensures that all relevant information is captured consistently across different studies.

Standardized procedures for module preparation and installation are equally important. This includes guidelines for handling, transportation, and mounting of perovskite modules in outdoor environments. Proper installation techniques are crucial for accurately assessing real-world performance and durability.

Data analysis and reporting methods also need to be standardized to facilitate meaningful comparisons between different studies. This involves establishing common metrics for evaluating module performance, degradation rates, and failure modes. Standardized reporting formats and data visualization techniques can help in effectively communicating results across the research community.

Collaboration between research institutions, industry partners, and regulatory bodies is essential for developing and implementing these standardized procedures. International organizations such as the International Electrotechnical Commission (IEC) can play a crucial role in coordinating efforts and establishing globally recognized standards for perovskite module field testing.

By implementing standardized field test procedures, the perovskite solar community can accelerate the development and commercialization of this promising technology. Consistent and reliable outdoor performance data will build confidence among investors and end-users, paving the way for wider adoption of perovskite solar modules in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!