How to Test Perovskite Stability Under Thermal and Humidity Stress (Standard Protocols)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Stability Testing Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the stability of perovskite materials under various environmental stresses remains a critical challenge that must be addressed for their widespread commercial adoption. The primary objective of stability testing is to evaluate and improve the long-term performance and durability of perovskite solar cells under real-world operating conditions.

The development of standardized protocols for testing perovskite stability under thermal and humidity stress is crucial for several reasons. Firstly, it allows for consistent and comparable results across different research groups and institutions, facilitating collaborative efforts and accelerating progress in the field. Secondly, it provides a reliable benchmark for assessing the effectiveness of various stability enhancement strategies, such as compositional engineering, interface modifications, and encapsulation techniques.

Thermal stress testing aims to simulate the temperature fluctuations that solar cells experience during daily and seasonal cycles. These tests typically involve subjecting the perovskite devices to controlled temperature variations, ranging from sub-zero temperatures to elevated temperatures exceeding 85°C. The primary goal is to assess the impact of thermal cycling on the structural integrity, phase stability, and overall performance of the perovskite materials.

Humidity stress testing, on the other hand, focuses on evaluating the moisture sensitivity of perovskite solar cells. Perovskite materials are known to be particularly susceptible to degradation in the presence of moisture, which can lead to the formation of hydrated phases and ultimately result in performance deterioration. Standard protocols for humidity testing often involve exposing the devices to controlled relative humidity levels, typically ranging from 50% to 85%, for extended periods.

The development of these testing protocols has evolved significantly over the past decade, with researchers and industry stakeholders working towards establishing consensus on best practices. International organizations, such as the International Electrotechnical Commission (IEC) and the International Summit on Organic Photovoltaic Stability (ISOS), have played crucial roles in defining and refining these standards.

As the field progresses, there is a growing emphasis on combining multiple stress factors to more accurately simulate real-world conditions. This approach, often referred to as combined accelerated stress testing, involves subjecting perovskite solar cells to simultaneous thermal, humidity, and light stress. The ultimate goal is to develop comprehensive testing protocols that can reliably predict the long-term stability and performance of perovskite solar cells in various climatic conditions and deployment scenarios.

The development of standardized protocols for testing perovskite stability under thermal and humidity stress is crucial for several reasons. Firstly, it allows for consistent and comparable results across different research groups and institutions, facilitating collaborative efforts and accelerating progress in the field. Secondly, it provides a reliable benchmark for assessing the effectiveness of various stability enhancement strategies, such as compositional engineering, interface modifications, and encapsulation techniques.

Thermal stress testing aims to simulate the temperature fluctuations that solar cells experience during daily and seasonal cycles. These tests typically involve subjecting the perovskite devices to controlled temperature variations, ranging from sub-zero temperatures to elevated temperatures exceeding 85°C. The primary goal is to assess the impact of thermal cycling on the structural integrity, phase stability, and overall performance of the perovskite materials.

Humidity stress testing, on the other hand, focuses on evaluating the moisture sensitivity of perovskite solar cells. Perovskite materials are known to be particularly susceptible to degradation in the presence of moisture, which can lead to the formation of hydrated phases and ultimately result in performance deterioration. Standard protocols for humidity testing often involve exposing the devices to controlled relative humidity levels, typically ranging from 50% to 85%, for extended periods.

The development of these testing protocols has evolved significantly over the past decade, with researchers and industry stakeholders working towards establishing consensus on best practices. International organizations, such as the International Electrotechnical Commission (IEC) and the International Summit on Organic Photovoltaic Stability (ISOS), have played crucial roles in defining and refining these standards.

As the field progresses, there is a growing emphasis on combining multiple stress factors to more accurately simulate real-world conditions. This approach, often referred to as combined accelerated stress testing, involves subjecting perovskite solar cells to simultaneous thermal, humidity, and light stress. The ultimate goal is to develop comprehensive testing protocols that can reliably predict the long-term stability and performance of perovskite solar cells in various climatic conditions and deployment scenarios.

Market Demand for Stable Perovskite Solar Cells

The market demand for stable perovskite solar cells has been steadily increasing in recent years, driven by the growing need for efficient and cost-effective renewable energy solutions. Perovskite solar cells have emerged as a promising technology due to their high power conversion efficiency, low production costs, and potential for flexible and lightweight applications. However, the long-term stability of perovskite solar cells remains a significant challenge, limiting their widespread commercial adoption.

The global solar energy market is projected to experience substantial growth in the coming years, with a particular focus on emerging technologies like perovskite solar cells. As governments and industries worldwide push for cleaner energy sources to combat climate change, the demand for innovative solar technologies continues to rise. Perovskite solar cells offer the potential to revolutionize the photovoltaic industry by providing higher efficiency at lower costs compared to traditional silicon-based solar cells.

The stability of perovskite solar cells under thermal and humidity stress is a critical factor influencing market demand. Consumers and industries require solar panels that can maintain their performance over extended periods, typically 20-25 years, under various environmental conditions. Currently, the limited stability of perovskite solar cells hinders their large-scale deployment and market penetration. Addressing this challenge through improved testing protocols and enhanced stability would significantly boost market demand and investor confidence.

Several key market segments are particularly interested in stable perovskite solar cells. The building-integrated photovoltaics (BIPV) sector sees great potential in perovskite technology due to its versatility and aesthetic appeal. The automotive industry is exploring perovskite solar cells for integration into electric vehicles to extend their range. Additionally, the aerospace sector is investigating perovskite solar cells for satellite and space applications, where stability under extreme conditions is crucial.

The development of standard protocols for testing perovskite stability under thermal and humidity stress is essential for market growth. Reliable and reproducible testing methods would enable accurate comparisons between different perovskite compositions and device architectures, accelerating research and development efforts. Furthermore, standardized testing protocols would provide investors and end-users with confidence in the long-term performance of perovskite solar cells, potentially unlocking significant market opportunities.

As the renewable energy sector continues to expand, the demand for stable perovskite solar cells is expected to grow substantially. Market analysts predict that once stability issues are adequately addressed, perovskite solar cells could capture a significant share of the global solar market. This potential market growth underscores the importance of developing robust testing protocols to evaluate and improve the stability of perovskite solar cells under thermal and humidity stress.

The global solar energy market is projected to experience substantial growth in the coming years, with a particular focus on emerging technologies like perovskite solar cells. As governments and industries worldwide push for cleaner energy sources to combat climate change, the demand for innovative solar technologies continues to rise. Perovskite solar cells offer the potential to revolutionize the photovoltaic industry by providing higher efficiency at lower costs compared to traditional silicon-based solar cells.

The stability of perovskite solar cells under thermal and humidity stress is a critical factor influencing market demand. Consumers and industries require solar panels that can maintain their performance over extended periods, typically 20-25 years, under various environmental conditions. Currently, the limited stability of perovskite solar cells hinders their large-scale deployment and market penetration. Addressing this challenge through improved testing protocols and enhanced stability would significantly boost market demand and investor confidence.

Several key market segments are particularly interested in stable perovskite solar cells. The building-integrated photovoltaics (BIPV) sector sees great potential in perovskite technology due to its versatility and aesthetic appeal. The automotive industry is exploring perovskite solar cells for integration into electric vehicles to extend their range. Additionally, the aerospace sector is investigating perovskite solar cells for satellite and space applications, where stability under extreme conditions is crucial.

The development of standard protocols for testing perovskite stability under thermal and humidity stress is essential for market growth. Reliable and reproducible testing methods would enable accurate comparisons between different perovskite compositions and device architectures, accelerating research and development efforts. Furthermore, standardized testing protocols would provide investors and end-users with confidence in the long-term performance of perovskite solar cells, potentially unlocking significant market opportunities.

As the renewable energy sector continues to expand, the demand for stable perovskite solar cells is expected to grow substantially. Market analysts predict that once stability issues are adequately addressed, perovskite solar cells could capture a significant share of the global solar market. This potential market growth underscores the importance of developing robust testing protocols to evaluate and improve the stability of perovskite solar cells under thermal and humidity stress.

Current Challenges in Perovskite Stability Testing

Perovskite solar cells have shown remarkable potential in the field of photovoltaics, but their long-term stability remains a significant challenge. Current testing protocols for perovskite stability under thermal and humidity stress face several critical issues that hinder accurate assessment and comparison of different perovskite compositions and device architectures.

One of the primary challenges is the lack of standardized testing conditions across research groups. Different laboratories often employ varying temperature ranges, humidity levels, and exposure durations, making it difficult to compare results and draw meaningful conclusions. This inconsistency in testing parameters leads to discrepancies in reported stability data and impedes the development of reliable benchmarks for perovskite performance.

Another major hurdle is the absence of universally accepted accelerated aging protocols. While accelerated testing is crucial for predicting long-term stability within reasonable timeframes, there is no consensus on how to correlate accelerated test results with real-world performance. This gap in understanding limits the ability to make accurate projections about the operational lifespan of perovskite solar cells under various environmental conditions.

The complex nature of degradation mechanisms in perovskites further complicates stability testing. Perovskites are susceptible to multiple degradation pathways, including moisture-induced decomposition, thermal instability, and light-induced degradation. Current testing methods often struggle to isolate and quantify the individual contributions of these factors, making it challenging to develop targeted strategies for improving stability.

Moreover, the interaction between different stress factors, such as combined thermal and humidity stress, is not well understood or adequately addressed in many testing protocols. This oversight can lead to underestimation of degradation rates and overly optimistic stability projections. Developing methods to accurately simulate and assess the synergistic effects of multiple stressors remains a significant challenge in the field.

The lack of standardized metrics for quantifying stability is another critical issue. While parameters such as T80 (time to 80% of initial efficiency) are commonly used, there is no uniform agreement on which metrics best represent the overall stability of perovskite devices. This ambiguity makes it difficult to establish clear benchmarks and compare the effectiveness of different stabilization strategies across studies.

Additionally, the reproducibility of stability tests is often compromised by variations in sample preparation, encapsulation methods, and measurement techniques. These inconsistencies can lead to significant discrepancies in reported stability data, even for nominally identical perovskite compositions. Addressing this challenge requires the development of robust, standardized protocols for device fabrication and characterization.

One of the primary challenges is the lack of standardized testing conditions across research groups. Different laboratories often employ varying temperature ranges, humidity levels, and exposure durations, making it difficult to compare results and draw meaningful conclusions. This inconsistency in testing parameters leads to discrepancies in reported stability data and impedes the development of reliable benchmarks for perovskite performance.

Another major hurdle is the absence of universally accepted accelerated aging protocols. While accelerated testing is crucial for predicting long-term stability within reasonable timeframes, there is no consensus on how to correlate accelerated test results with real-world performance. This gap in understanding limits the ability to make accurate projections about the operational lifespan of perovskite solar cells under various environmental conditions.

The complex nature of degradation mechanisms in perovskites further complicates stability testing. Perovskites are susceptible to multiple degradation pathways, including moisture-induced decomposition, thermal instability, and light-induced degradation. Current testing methods often struggle to isolate and quantify the individual contributions of these factors, making it challenging to develop targeted strategies for improving stability.

Moreover, the interaction between different stress factors, such as combined thermal and humidity stress, is not well understood or adequately addressed in many testing protocols. This oversight can lead to underestimation of degradation rates and overly optimistic stability projections. Developing methods to accurately simulate and assess the synergistic effects of multiple stressors remains a significant challenge in the field.

The lack of standardized metrics for quantifying stability is another critical issue. While parameters such as T80 (time to 80% of initial efficiency) are commonly used, there is no uniform agreement on which metrics best represent the overall stability of perovskite devices. This ambiguity makes it difficult to establish clear benchmarks and compare the effectiveness of different stabilization strategies across studies.

Additionally, the reproducibility of stability tests is often compromised by variations in sample preparation, encapsulation methods, and measurement techniques. These inconsistencies can lead to significant discrepancies in reported stability data, even for nominally identical perovskite compositions. Addressing this challenge requires the development of robust, standardized protocols for device fabrication and characterization.

Existing Thermal and Humidity Stress Test Protocols

01 Compositional engineering for perovskite stability

Modifying the composition of perovskite materials by incorporating specific elements or compounds can enhance their stability. This approach involves fine-tuning the chemical structure to improve resistance against environmental factors such as moisture, heat, and light exposure. Techniques may include cation substitution, halide mixing, or the addition of stabilizing agents to the perovskite structure.- Compositional engineering for perovskite stability: Modifying the composition of perovskite materials by incorporating specific elements or compounds can enhance their stability. This approach may involve doping, substitution, or the use of mixed-cation or mixed-halide perovskites to improve resistance against environmental factors and degradation.

- Encapsulation and protective layers: Implementing encapsulation techniques or adding protective layers to perovskite devices can significantly improve their stability. These methods shield the perovskite material from moisture, oxygen, and other environmental factors that contribute to degradation.

- Interface engineering: Optimizing the interfaces between the perovskite layer and adjacent layers in the device structure can enhance stability. This may involve the use of specific interlayers, passivation techniques, or surface treatments to reduce defects and improve charge transport.

- Crystallization and grain boundary control: Improving the crystallization process and controlling grain boundaries in perovskite films can lead to enhanced stability. Techniques such as solvent engineering, additive incorporation, or post-treatment processes can be employed to achieve larger grain sizes and reduce defects.

- Novel perovskite formulations: Developing new perovskite formulations or structures, such as 2D/3D hybrid perovskites or lead-free alternatives, can address stability issues. These novel materials may offer improved resistance to environmental factors while maintaining or enhancing the desired optoelectronic properties.

02 Encapsulation and protective layers

Implementing effective encapsulation techniques and protective layers can significantly improve the stability of perovskite materials. This involves creating barrier layers that shield the perovskite from environmental factors such as moisture and oxygen. Various materials and deposition methods can be used to create these protective layers, including hydrophobic coatings, metal oxides, or polymer-based encapsulants.Expand Specific Solutions03 Interface engineering for enhanced stability

Optimizing the interfaces between the perovskite layer and adjacent layers in devices can improve overall stability. This involves designing and implementing interlayers or modifying existing interfaces to reduce charge recombination, prevent ion migration, and enhance the adhesion between layers. Techniques may include the use of self-assembled monolayers, buffer layers, or surface treatments.Expand Specific Solutions04 Defect passivation and grain boundary engineering

Addressing defects and optimizing grain boundaries in perovskite materials can lead to improved stability. This approach focuses on reducing the density of defects within the perovskite structure and at grain boundaries, which are often sites for degradation initiation. Techniques may include post-treatment processes, additive engineering, or controlled crystallization methods to achieve larger grain sizes and fewer defects.Expand Specific Solutions05 Novel perovskite formulations and architectures

Developing new perovskite formulations or device architectures can inherently improve stability. This may involve exploring 2D or quasi-2D perovskite structures, mixed-dimensional systems, or entirely new compositions that offer improved stability while maintaining desirable optoelectronic properties. Additionally, innovative device designs that better protect the perovskite layer or manage stress within the structure can enhance overall stability.Expand Specific Solutions

Key Players in Perovskite Stability Research

The perovskite stability testing market is in a growth phase, driven by increasing research and commercialization efforts in perovskite solar cells. The global market size for perovskite solar cell testing equipment is expected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with various protocols being developed to assess thermal and humidity stability. Key players like Centre National de la Recherche Scientifique, Huazhong University of Science & Technology, and LONGi Green Energy Technology are at the forefront of research and development. Companies such as Wuxi UtmoLight Technology and ExxonMobil Chemical Patents are also contributing to technological advancements. While standardization efforts are ongoing, there is still a need for universally accepted testing protocols to ensure consistent evaluation of perovskite stability across the industry.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has established a robust protocol for evaluating perovskite stability under thermal and humidity stress. Their approach combines accelerated aging tests with advanced in-situ characterization techniques. The protocol includes exposing perovskite solar cells to controlled temperature and humidity conditions in environmental chambers, with temperatures ranging from 25°C to 100°C and relative humidity levels up to 90%[1]. They have developed a unique method for real-time monitoring of perovskite degradation using in-situ X-ray diffraction and photoluminescence spectroscopy[2]. The university's researchers also employ electrochemical impedance spectroscopy to investigate charge transport dynamics during stress testing[3]. Additionally, their protocol incorporates machine learning algorithms to predict long-term stability based on short-term stress test data, potentially reducing the time required for stability assessments[4].

Strengths: Advanced in-situ characterization techniques, real-time degradation monitoring, innovative use of machine learning for stability prediction. Weaknesses: Potential limitations in accurately predicting very long-term stability, high initial investment in specialized equipment.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed a comprehensive protocol for testing perovskite stability under thermal and humidity stress. Their approach combines standardized stress tests with advanced analytical techniques. The protocol includes exposing perovskite solar cells to controlled temperature and humidity conditions in environmental chambers, with temperatures ranging from 25°C to 85°C and relative humidity levels up to 85%[1]. NTU researchers have implemented a unique method for in-situ monitoring of perovskite degradation using synchrotron-based X-ray diffraction and X-ray absorption spectroscopy[2]. They also employ transient photocurrent and photovoltage decay measurements to investigate charge carrier dynamics during stress testing[3]. Additionally, their protocol incorporates accelerated light soaking tests combined with thermal cycling to simulate real-world operating conditions more accurately[4]. NTU has also developed a novel encapsulation technique using atomic layer deposition to enhance device resilience against moisture ingress[5].

Strengths: Advanced in-situ characterization techniques, comprehensive stress testing, innovative encapsulation methods. Weaknesses: Potential high costs associated with synchrotron-based techniques, complexity in data interpretation from multiple analytical methods.

Core Innovations in Perovskite Stability Assessment

Apparatus and method for stability test of compound of perovskite structure

PatentActiveKR1020230131577A

Innovation

- A stability evaluation device for perovskite structural compounds, comprising a reaction unit with a perovskite structure compound, electrolyte, and organic solvent, along with an electrode unit including a reference, counter, and working electrode, measures current intensity to assess stability and predict the efficiency of optoelectronic devices.

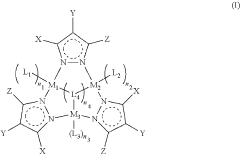

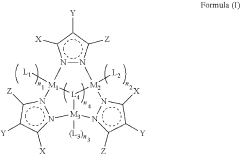

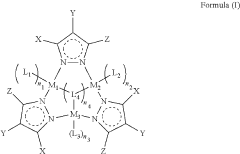

Metal organic framework and use thereof for generating h2

PatentPendingUS20240024861A1

Innovation

- MOFs with trimetallic centers linked to pyrazole units act as ligands, coordinating with metal nodes to facilitate photocatalytic water splitting into hydrogen and oxygen using sunlight, eliminating the need for noble metals and enhancing efficiency by leveraging visible or near-IR radiation.

Environmental Impact of Perovskite Solar Cell Production

The production of perovskite solar cells has garnered significant attention due to their potential as a highly efficient and cost-effective alternative to traditional silicon-based photovoltaics. However, the environmental impact of their production process is a crucial consideration that must be thoroughly examined.

One of the primary concerns in perovskite solar cell production is the use of lead-based compounds. Lead is a toxic heavy metal that poses serious risks to human health and the environment. The manufacturing process may result in lead emissions and contamination of soil and water sources if proper precautions are not taken. This necessitates stringent safety measures and waste management protocols to mitigate potential environmental hazards.

The synthesis of perovskite materials often involves the use of organic solvents, such as dimethylformamide (DMF) and dimethyl sulfoxide (DMSO). These solvents can contribute to air pollution and have adverse effects on human health if not properly handled and disposed of. Additionally, the production of these solvents requires energy-intensive processes, further contributing to the overall environmental footprint of perovskite solar cell manufacturing.

Energy consumption during the production process is another significant factor to consider. While perovskite solar cells can be manufactured at lower temperatures compared to silicon-based cells, the energy requirements for material synthesis, deposition, and annealing processes still contribute to greenhouse gas emissions. The source of this energy, whether from renewable or non-renewable sources, plays a crucial role in determining the overall environmental impact.

Water usage in perovskite solar cell production is relatively low compared to traditional silicon-based cells. However, the potential for water contamination during the manufacturing process and the disposal of waste materials must be carefully managed to prevent negative impacts on local ecosystems and water resources.

The end-of-life considerations for perovskite solar cells also present environmental challenges. The presence of lead and other potentially harmful materials necessitates the development of effective recycling and disposal methods to prevent environmental contamination. Research into lead-free perovskite alternatives and improved recycling technologies is ongoing to address these concerns.

Despite these challenges, it is important to note that the high efficiency and potentially lower production costs of perovskite solar cells could lead to a net positive environmental impact when compared to traditional energy sources. The rapid progress in perovskite technology may result in more environmentally friendly production methods and materials in the future, further improving their sustainability profile.

One of the primary concerns in perovskite solar cell production is the use of lead-based compounds. Lead is a toxic heavy metal that poses serious risks to human health and the environment. The manufacturing process may result in lead emissions and contamination of soil and water sources if proper precautions are not taken. This necessitates stringent safety measures and waste management protocols to mitigate potential environmental hazards.

The synthesis of perovskite materials often involves the use of organic solvents, such as dimethylformamide (DMF) and dimethyl sulfoxide (DMSO). These solvents can contribute to air pollution and have adverse effects on human health if not properly handled and disposed of. Additionally, the production of these solvents requires energy-intensive processes, further contributing to the overall environmental footprint of perovskite solar cell manufacturing.

Energy consumption during the production process is another significant factor to consider. While perovskite solar cells can be manufactured at lower temperatures compared to silicon-based cells, the energy requirements for material synthesis, deposition, and annealing processes still contribute to greenhouse gas emissions. The source of this energy, whether from renewable or non-renewable sources, plays a crucial role in determining the overall environmental impact.

Water usage in perovskite solar cell production is relatively low compared to traditional silicon-based cells. However, the potential for water contamination during the manufacturing process and the disposal of waste materials must be carefully managed to prevent negative impacts on local ecosystems and water resources.

The end-of-life considerations for perovskite solar cells also present environmental challenges. The presence of lead and other potentially harmful materials necessitates the development of effective recycling and disposal methods to prevent environmental contamination. Research into lead-free perovskite alternatives and improved recycling technologies is ongoing to address these concerns.

Despite these challenges, it is important to note that the high efficiency and potentially lower production costs of perovskite solar cells could lead to a net positive environmental impact when compared to traditional energy sources. The rapid progress in perovskite technology may result in more environmentally friendly production methods and materials in the future, further improving their sustainability profile.

Regulatory Framework for Solar Cell Certification

The regulatory framework for solar cell certification plays a crucial role in ensuring the quality, safety, and performance of photovoltaic technologies, including perovskite solar cells. As perovskite technology advances, it is essential to establish standardized protocols for testing stability under thermal and humidity stress.

Currently, the International Electrotechnical Commission (IEC) provides the primary standards for photovoltaic module certification. The IEC 61215 series, particularly IEC 61215-1 and IEC 61215-2, outlines the general requirements and test procedures for terrestrial photovoltaic modules. These standards cover various aspects of module performance, including thermal cycling, humidity-freeze, and damp heat tests.

However, the existing regulatory framework may not fully address the unique characteristics of perovskite solar cells, especially concerning their stability under thermal and humidity stress. To bridge this gap, several initiatives are underway to develop specific protocols for perovskite stability testing.

The International Summit on Organic Photovoltaic Stability (ISOS) has proposed a set of protocols for testing the stability of perovskite solar cells. These protocols, known as ISOS-P, include guidelines for assessing thermal stability, light stability, and humidity stability. The ISOS-P protocols aim to provide a standardized approach for evaluating perovskite solar cell performance under various environmental conditions.

In addition to ISOS-P, other organizations and research institutions are working on developing standardized testing procedures for perovskite stability. The European Commission's Joint Research Centre (JRC) has been actively involved in establishing protocols for assessing the long-term stability of perovskite solar cells. Their efforts focus on creating accelerated aging tests that can accurately predict the performance of perovskite modules over extended periods.

As the regulatory framework evolves, it is likely that new standards specific to perovskite solar cells will be incorporated into existing certification processes. This may include modifications to current IEC standards or the development of entirely new standards tailored to the unique properties of perovskite materials.

To ensure the widespread adoption and commercialization of perovskite solar technology, it is crucial for regulatory bodies, research institutions, and industry stakeholders to collaborate in developing comprehensive and standardized certification protocols. These protocols should address the specific challenges associated with perovskite stability under thermal and humidity stress, while also considering other factors such as light-induced degradation and environmental impact.

Currently, the International Electrotechnical Commission (IEC) provides the primary standards for photovoltaic module certification. The IEC 61215 series, particularly IEC 61215-1 and IEC 61215-2, outlines the general requirements and test procedures for terrestrial photovoltaic modules. These standards cover various aspects of module performance, including thermal cycling, humidity-freeze, and damp heat tests.

However, the existing regulatory framework may not fully address the unique characteristics of perovskite solar cells, especially concerning their stability under thermal and humidity stress. To bridge this gap, several initiatives are underway to develop specific protocols for perovskite stability testing.

The International Summit on Organic Photovoltaic Stability (ISOS) has proposed a set of protocols for testing the stability of perovskite solar cells. These protocols, known as ISOS-P, include guidelines for assessing thermal stability, light stability, and humidity stability. The ISOS-P protocols aim to provide a standardized approach for evaluating perovskite solar cell performance under various environmental conditions.

In addition to ISOS-P, other organizations and research institutions are working on developing standardized testing procedures for perovskite stability. The European Commission's Joint Research Centre (JRC) has been actively involved in establishing protocols for assessing the long-term stability of perovskite solar cells. Their efforts focus on creating accelerated aging tests that can accurately predict the performance of perovskite modules over extended periods.

As the regulatory framework evolves, it is likely that new standards specific to perovskite solar cells will be incorporated into existing certification processes. This may include modifications to current IEC standards or the development of entirely new standards tailored to the unique properties of perovskite materials.

To ensure the widespread adoption and commercialization of perovskite solar technology, it is crucial for regulatory bodies, research institutions, and industry stakeholders to collaborate in developing comprehensive and standardized certification protocols. These protocols should address the specific challenges associated with perovskite stability under thermal and humidity stress, while also considering other factors such as light-induced degradation and environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!