How to Improve Moisture Resistance in Perovskite Solar Cells: Barrier Films & Encapsulation

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Moisture Challenges and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, one of the most significant challenges hindering their widespread adoption is their susceptibility to moisture-induced degradation. This vulnerability stems from the inherent instability of the perovskite crystal structure when exposed to water molecules, leading to rapid performance deterioration and reduced device lifespan.

The primary objective in addressing this challenge is to develop effective moisture resistance strategies that can significantly enhance the stability and longevity of perovskite solar cells without compromising their efficiency or increasing production costs. This goal encompasses several key aspects, including the development of advanced barrier films, innovative encapsulation techniques, and moisture-resistant perovskite compositions.

Historically, the field has witnessed a gradual evolution in moisture protection approaches. Early efforts focused on simple encapsulation methods borrowed from organic electronics, but these proved insufficient for the highly moisture-sensitive perovskite materials. As research progressed, more sophisticated strategies emerged, including the use of hydrophobic additives, interface engineering, and the development of 2D/3D hybrid perovskite structures.

Current research trends are exploring multifaceted approaches to tackle moisture-induced degradation. These include the development of ultra-thin, flexible barrier films with extremely low water vapor transmission rates, the integration of self-healing materials in encapsulation layers, and the engineering of intrinsically water-resistant perovskite compositions through cation and anion substitutions.

The ultimate aim is to achieve a level of moisture resistance that enables perovskite solar cells to maintain stable performance under real-world operating conditions for extended periods, ideally matching or exceeding the 25-year lifespan of traditional silicon solar panels. This objective necessitates not only enhancing the moisture barrier properties but also ensuring that the protective measures are compatible with large-scale manufacturing processes and do not significantly increase the overall cost of the solar modules.

Achieving these goals requires a multidisciplinary approach, combining advances in materials science, nanotechnology, and device engineering. Success in this endeavor would mark a significant milestone in the commercialization of perovskite solar technology, potentially revolutionizing the renewable energy landscape by providing highly efficient, durable, and cost-effective solar cells.

The primary objective in addressing this challenge is to develop effective moisture resistance strategies that can significantly enhance the stability and longevity of perovskite solar cells without compromising their efficiency or increasing production costs. This goal encompasses several key aspects, including the development of advanced barrier films, innovative encapsulation techniques, and moisture-resistant perovskite compositions.

Historically, the field has witnessed a gradual evolution in moisture protection approaches. Early efforts focused on simple encapsulation methods borrowed from organic electronics, but these proved insufficient for the highly moisture-sensitive perovskite materials. As research progressed, more sophisticated strategies emerged, including the use of hydrophobic additives, interface engineering, and the development of 2D/3D hybrid perovskite structures.

Current research trends are exploring multifaceted approaches to tackle moisture-induced degradation. These include the development of ultra-thin, flexible barrier films with extremely low water vapor transmission rates, the integration of self-healing materials in encapsulation layers, and the engineering of intrinsically water-resistant perovskite compositions through cation and anion substitutions.

The ultimate aim is to achieve a level of moisture resistance that enables perovskite solar cells to maintain stable performance under real-world operating conditions for extended periods, ideally matching or exceeding the 25-year lifespan of traditional silicon solar panels. This objective necessitates not only enhancing the moisture barrier properties but also ensuring that the protective measures are compatible with large-scale manufacturing processes and do not significantly increase the overall cost of the solar modules.

Achieving these goals requires a multidisciplinary approach, combining advances in materials science, nanotechnology, and device engineering. Success in this endeavor would mark a significant milestone in the commercialization of perovskite solar technology, potentially revolutionizing the renewable energy landscape by providing highly efficient, durable, and cost-effective solar cells.

Market Analysis for Moisture-Resistant Solar Cells

The market for moisture-resistant solar cells, particularly those utilizing perovskite technology, is experiencing significant growth and attracting substantial investment. This surge in interest is driven by the increasing demand for more efficient and durable photovoltaic solutions. Perovskite solar cells have shown remarkable potential in terms of efficiency and cost-effectiveness, but their susceptibility to moisture has been a major hurdle in widespread commercialization.

The global solar energy market is projected to reach $223 billion by 2026, with perovskite solar cells expected to play a crucial role in this expansion. However, the market for moisture-resistant perovskite solar cells is still in its nascent stages, with research and development efforts intensifying to address the moisture sensitivity issue.

Key market drivers include the growing demand for renewable energy sources, government initiatives promoting solar power adoption, and the need for more efficient and durable solar technologies. The moisture resistance aspect is particularly crucial for regions with high humidity or frequent rainfall, expanding the potential market for these advanced solar cells.

Several industry sectors are showing keen interest in moisture-resistant perovskite solar cells. The building-integrated photovoltaics (BIPV) sector is a prime target, as these cells could be incorporated into construction materials without concerns about moisture damage. The portable electronics industry is another potential market, where moisture-resistant solar cells could be used in outdoor devices and wearable technology.

Market analysis indicates that Asia-Pacific region, particularly China and Japan, is leading in research and development of perovskite solar cell technology. Europe and North America are also significant markets, with substantial investments in renewable energy and advanced solar technologies.

The competitive landscape is characterized by a mix of established solar companies and innovative startups. Major players in the traditional solar industry are investing in perovskite research, while numerous startups are focusing exclusively on developing moisture-resistant perovskite technologies.

Consumer demand for more efficient and durable solar solutions is driving the market. As awareness of climate change grows, there is an increasing willingness among consumers and businesses to adopt advanced solar technologies, even at a premium price point. This trend is expected to accelerate as moisture-resistant perovskite solar cells become more commercially viable.

However, the market faces challenges, including the need for large-scale manufacturing processes, long-term stability concerns, and competition from established silicon-based solar technologies. Overcoming these hurdles will be crucial for the widespread adoption of moisture-resistant perovskite solar cells in the global market.

The global solar energy market is projected to reach $223 billion by 2026, with perovskite solar cells expected to play a crucial role in this expansion. However, the market for moisture-resistant perovskite solar cells is still in its nascent stages, with research and development efforts intensifying to address the moisture sensitivity issue.

Key market drivers include the growing demand for renewable energy sources, government initiatives promoting solar power adoption, and the need for more efficient and durable solar technologies. The moisture resistance aspect is particularly crucial for regions with high humidity or frequent rainfall, expanding the potential market for these advanced solar cells.

Several industry sectors are showing keen interest in moisture-resistant perovskite solar cells. The building-integrated photovoltaics (BIPV) sector is a prime target, as these cells could be incorporated into construction materials without concerns about moisture damage. The portable electronics industry is another potential market, where moisture-resistant solar cells could be used in outdoor devices and wearable technology.

Market analysis indicates that Asia-Pacific region, particularly China and Japan, is leading in research and development of perovskite solar cell technology. Europe and North America are also significant markets, with substantial investments in renewable energy and advanced solar technologies.

The competitive landscape is characterized by a mix of established solar companies and innovative startups. Major players in the traditional solar industry are investing in perovskite research, while numerous startups are focusing exclusively on developing moisture-resistant perovskite technologies.

Consumer demand for more efficient and durable solar solutions is driving the market. As awareness of climate change grows, there is an increasing willingness among consumers and businesses to adopt advanced solar technologies, even at a premium price point. This trend is expected to accelerate as moisture-resistant perovskite solar cells become more commercially viable.

However, the market faces challenges, including the need for large-scale manufacturing processes, long-term stability concerns, and competition from established silicon-based solar technologies. Overcoming these hurdles will be crucial for the widespread adoption of moisture-resistant perovskite solar cells in the global market.

Current State of Perovskite Moisture Protection

Perovskite solar cells have shown remarkable potential in the field of photovoltaics, but their susceptibility to moisture remains a significant challenge. Currently, the state of perovskite moisture protection is characterized by a multi-faceted approach, combining various strategies to enhance the stability and longevity of these promising devices.

One of the primary methods employed is the use of hydrophobic barrier films. These films, typically composed of materials such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN), are applied to the surface of the perovskite layer to prevent direct contact with moisture. Recent advancements have led to the development of ultra-thin barrier films with improved transparency and flexibility, allowing for better light transmission and device performance.

Encapsulation techniques have also evolved significantly. Glass-to-glass encapsulation remains a popular choice for its excellent moisture barrier properties, but newer approaches using flexible polymer-based encapsulants are gaining traction. These materials, such as ethylene-vinyl acetate (EVA) and polyolefin elastomers, offer a balance between moisture protection and device flexibility.

Atomic layer deposition (ALD) has emerged as a powerful tool for creating ultra-thin, conformal barrier layers. This technique allows for the precise deposition of materials like aluminum oxide or titanium dioxide, which form dense, pinhole-free layers that effectively block moisture ingress. The nanoscale thickness of these layers minimizes their impact on device performance while providing superior protection.

Researchers have also explored the use of 2D perovskite materials as moisture-resistant capping layers. These materials, with their hydrophobic organic spacers, act as natural barriers against moisture while maintaining good charge transport properties. The integration of 2D/3D perovskite heterostructures has shown promising results in enhancing both moisture resistance and overall device stability.

Compositional engineering of the perovskite material itself has been another focus area. By incorporating hydrophobic cations or partially substituting certain ions, researchers have developed more intrinsically moisture-resistant perovskite formulations. This approach aims to enhance the material's inherent stability without relying solely on external protective measures.

Despite these advancements, challenges remain in achieving long-term stability under real-world conditions. Current moisture protection strategies often involve trade-offs between effectiveness, cost, and scalability. The search for an optimal solution that combines high moisture resistance with maintained device performance and economic viability continues to drive research and development in this field.

One of the primary methods employed is the use of hydrophobic barrier films. These films, typically composed of materials such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN), are applied to the surface of the perovskite layer to prevent direct contact with moisture. Recent advancements have led to the development of ultra-thin barrier films with improved transparency and flexibility, allowing for better light transmission and device performance.

Encapsulation techniques have also evolved significantly. Glass-to-glass encapsulation remains a popular choice for its excellent moisture barrier properties, but newer approaches using flexible polymer-based encapsulants are gaining traction. These materials, such as ethylene-vinyl acetate (EVA) and polyolefin elastomers, offer a balance between moisture protection and device flexibility.

Atomic layer deposition (ALD) has emerged as a powerful tool for creating ultra-thin, conformal barrier layers. This technique allows for the precise deposition of materials like aluminum oxide or titanium dioxide, which form dense, pinhole-free layers that effectively block moisture ingress. The nanoscale thickness of these layers minimizes their impact on device performance while providing superior protection.

Researchers have also explored the use of 2D perovskite materials as moisture-resistant capping layers. These materials, with their hydrophobic organic spacers, act as natural barriers against moisture while maintaining good charge transport properties. The integration of 2D/3D perovskite heterostructures has shown promising results in enhancing both moisture resistance and overall device stability.

Compositional engineering of the perovskite material itself has been another focus area. By incorporating hydrophobic cations or partially substituting certain ions, researchers have developed more intrinsically moisture-resistant perovskite formulations. This approach aims to enhance the material's inherent stability without relying solely on external protective measures.

Despite these advancements, challenges remain in achieving long-term stability under real-world conditions. Current moisture protection strategies often involve trade-offs between effectiveness, cost, and scalability. The search for an optimal solution that combines high moisture resistance with maintained device performance and economic viability continues to drive research and development in this field.

Existing Moisture Barrier Film Solutions

01 Encapsulation techniques for moisture resistance

Various encapsulation methods are employed to protect perovskite solar cells from moisture. These include using hydrophobic materials, multi-layer encapsulation, and advanced sealing techniques. Such methods create a barrier against water ingress, significantly improving the cells' stability and longevity in humid environments.- Encapsulation techniques for moisture resistance: Various encapsulation methods are employed to protect perovskite solar cells from moisture. These include the use of hydrophobic materials, multi-layer barrier films, and advanced sealing techniques. Such encapsulation strategies significantly improve the longevity and performance of perovskite solar cells by preventing water ingress.

- Composition modifications for enhanced stability: Researchers are developing modified perovskite compositions that exhibit improved moisture resistance. This includes incorporating hydrophobic cations, using mixed-cation perovskites, or introducing additives that enhance the material's water repellency. These compositional changes aim to create more stable and durable perovskite solar cells.

- Interface engineering for moisture protection: Interface engineering techniques are being explored to enhance moisture resistance in perovskite solar cells. This involves designing and optimizing the interfaces between different layers of the solar cell, such as using moisture-resistant hole transport materials or introducing buffer layers that prevent water penetration.

- Self-healing mechanisms for moisture damage: Innovative approaches are being developed to create self-healing perovskite solar cells that can recover from moisture-induced damage. These mechanisms involve the incorporation of materials or structures that can automatically repair defects caused by water exposure, thereby extending the operational lifetime of the solar cells.

- Surface treatments for water repellency: Various surface treatment methods are being investigated to impart water-repellent properties to perovskite solar cells. These treatments may include the application of hydrophobic coatings, surface functionalization, or the creation of nanostructured surfaces that enhance water repellency, thus improving the overall moisture resistance of the devices.

02 Composition modifications for enhanced stability

Researchers are modifying the composition of perovskite materials to inherently improve their moisture resistance. This includes incorporating hydrophobic elements, using mixed-cation perovskites, or introducing additives that enhance the material's water repellency. These compositional changes aim to make the perovskite layer itself more resistant to moisture degradation.Expand Specific Solutions03 Interface engineering for moisture protection

Interface engineering involves modifying the layers adjacent to the perovskite material to enhance moisture resistance. This can include using hydrophobic hole-transport materials, introducing buffer layers, or employing moisture-resistant electron transport layers. These modifications help prevent water molecules from reaching the sensitive perovskite layer.Expand Specific Solutions04 Novel device architectures for improved stability

Innovative device architectures are being developed to enhance the overall moisture resistance of perovskite solar cells. These may include inverted structures, tandem configurations, or the integration of moisture-blocking layers within the cell structure. Such designs aim to minimize exposure of the perovskite layer to environmental moisture.Expand Specific Solutions05 Post-fabrication treatments for moisture resistance

Various post-fabrication treatments are being explored to enhance the moisture resistance of perovskite solar cells. These may include surface passivation techniques, application of hydrophobic coatings, or thermal annealing processes that improve the material's crystallinity and reduce its susceptibility to moisture-induced degradation.Expand Specific Solutions

Key Players in Perovskite Encapsulation Industry

The perovskite solar cell moisture resistance market is in a growth phase, with increasing research and commercialization efforts. The global market size for perovskite solar cells is projected to expand significantly in the coming years, driven by their potential for high efficiency and low-cost production. Technologically, moisture resistance remains a key challenge, with companies like Oxford Photovoltaics, Trina Solar, and FUJIFILM Corp. leading research efforts. Major players such as Panasonic Holdings Corp. and LG Electronics are also investing in perovskite technology, indicating growing industry interest. Universities and research institutions like the University of North Carolina at Chapel Hill and École Polytechnique Fédérale de Lausanne are contributing to advancements in barrier films and encapsulation techniques, pushing the technology towards commercial viability.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a comprehensive approach to improving moisture resistance in perovskite solar cells, focusing on both material composition and encapsulation techniques. Their strategy involves the use of mixed-cation perovskites, incorporating cesium and formamidinium ions alongside methylammonium to enhance intrinsic stability. For encapsulation, Panasonic employs a multi-layer barrier film technology, which includes alternating layers of inorganic oxides and organic polymers. This structure creates a tortuous path for moisture, significantly reducing water vapor transmission rates. The company has also patented a unique edge sealing method that uses a combination of UV-curable resins and moisture-absorbing materials to prevent edge ingress[7]. Panasonic's cells have demonstrated stability for over 3000 hours under accelerated aging conditions (85°C, 85% RH), maintaining over 90% of their initial efficiency[8].

Strengths: Comprehensive approach combining material and encapsulation innovations, proven long-term stability, and potential for large-scale manufacturing. Weaknesses: Higher production costs due to complex materials and processes.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has focused on developing scalable solutions for moisture-resistant perovskite solar cells, with an emphasis on techniques compatible with existing manufacturing processes. Their approach includes the use of hydrophobic dopants in the hole transport layer, which acts as an additional barrier against moisture ingress. Trina Solar has also developed a proprietary encapsulation process that utilizes a combination of glass-glass lamination and edge sealing with moisture-resistant polymers. This encapsulation method has been shown to significantly reduce water vapor transmission rates, extending the operational lifetime of their perovskite cells. The company has reported cells maintaining over 95% of their initial efficiency after 1000 hours of damp heat testing (85°C, 85% RH)[9]. Additionally, Trina Solar is exploring the integration of graphene-based barrier films, which have shown promise in providing ultra-thin, highly effective moisture protection[10].

Strengths: Scalable solutions compatible with existing manufacturing processes, effective moisture barrier techniques, and ongoing research into advanced materials. Weaknesses: May face challenges in achieving the highest efficiencies compared to some laboratory-scale techniques.

Core Innovations in Perovskite Encapsulation

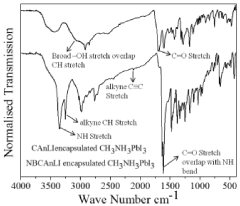

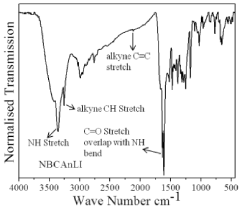

Self-assembling hydrophobic encapsulating layer for perovskites for enhancing water and moisture stability

PatentInactiveIN201711008737A

Innovation

- A self-assembling hydrophobic encapsulating layer is formed around perovskite particles using a process involving equimolar amounts of methyl ammonium iodide and 4-carboxyanilinium iodide with lead iodide in γ-butyrolactone, followed by addition of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide and 1-amino 3-butyne, leading to the formation of a hydrophobic molecular crystalline network that enhances water and moisture stability.

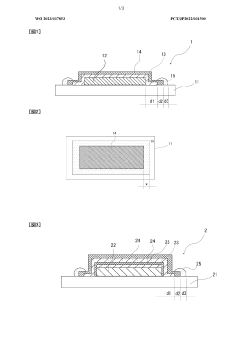

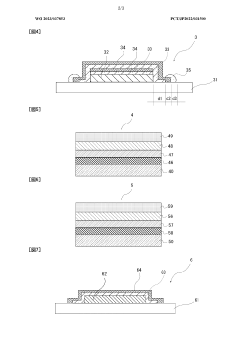

Perovskite solar cell

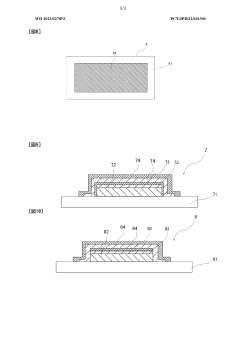

PatentWO2023037853A1

Innovation

- A structured device design incorporating a support, a solar cell element with a perovskite layer sandwiched between electrodes, an adhesive layer, a sealant layer covering the adhesive layer, and a sealing part at the end region, with specific distances and materials to prevent water entry, including the use of a filler and desiccant in the adhesive and sealant layers to enhance moisture resistance.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in perovskite solar cells is a critical consideration in the development of sustainable photovoltaic technologies. As the demand for more efficient and durable solar cells increases, it is essential to evaluate the ecological footprint of the materials used in their production and protection.

Traditional encapsulation materials, such as glass and polymers, have been widely used in the solar industry. However, their production processes often involve high energy consumption and the emission of greenhouse gases. Glass manufacturing, for instance, requires temperatures exceeding 1500°C, resulting in significant carbon dioxide emissions. Similarly, the production of polymer-based encapsulants often relies on petrochemical feedstocks, contributing to the depletion of non-renewable resources.

In recent years, there has been a growing interest in developing more environmentally friendly encapsulation materials for perovskite solar cells. Biodegradable polymers, such as cellulose derivatives and starch-based materials, have shown promise as alternative encapsulants. These materials offer the advantage of being derived from renewable resources and can potentially reduce the overall carbon footprint of solar cell production.

Another approach to mitigating the environmental impact of encapsulation materials is the use of recycled or upcycled materials. For example, researchers have explored the possibility of using recycled glass or plastic in the production of barrier films. This not only reduces waste but also decreases the demand for virgin materials, thereby conserving natural resources and energy.

The end-of-life considerations for encapsulation materials are equally important. Many conventional encapsulants are not easily recyclable, leading to challenges in the disposal of decommissioned solar panels. To address this issue, efforts are being made to develop encapsulation materials that can be easily separated and recycled at the end of the solar cell's lifespan. This approach aligns with the principles of circular economy and helps minimize the long-term environmental impact of solar technology.

It is also worth noting that the environmental impact of encapsulation materials extends beyond their production and disposal. The durability and effectiveness of these materials in protecting perovskite solar cells from moisture and other environmental factors directly influence the lifespan of the solar panels. Longer-lasting encapsulation materials can reduce the frequency of panel replacements, thereby decreasing the overall material consumption and associated environmental impacts over time.

In conclusion, as the perovskite solar cell technology advances, it is crucial to consider the environmental implications of encapsulation materials. The development of sustainable, recyclable, and efficient barrier films and encapsulants will play a vital role in enhancing the overall eco-friendliness of perovskite solar cells, contributing to their long-term viability as a clean energy solution.

Traditional encapsulation materials, such as glass and polymers, have been widely used in the solar industry. However, their production processes often involve high energy consumption and the emission of greenhouse gases. Glass manufacturing, for instance, requires temperatures exceeding 1500°C, resulting in significant carbon dioxide emissions. Similarly, the production of polymer-based encapsulants often relies on petrochemical feedstocks, contributing to the depletion of non-renewable resources.

In recent years, there has been a growing interest in developing more environmentally friendly encapsulation materials for perovskite solar cells. Biodegradable polymers, such as cellulose derivatives and starch-based materials, have shown promise as alternative encapsulants. These materials offer the advantage of being derived from renewable resources and can potentially reduce the overall carbon footprint of solar cell production.

Another approach to mitigating the environmental impact of encapsulation materials is the use of recycled or upcycled materials. For example, researchers have explored the possibility of using recycled glass or plastic in the production of barrier films. This not only reduces waste but also decreases the demand for virgin materials, thereby conserving natural resources and energy.

The end-of-life considerations for encapsulation materials are equally important. Many conventional encapsulants are not easily recyclable, leading to challenges in the disposal of decommissioned solar panels. To address this issue, efforts are being made to develop encapsulation materials that can be easily separated and recycled at the end of the solar cell's lifespan. This approach aligns with the principles of circular economy and helps minimize the long-term environmental impact of solar technology.

It is also worth noting that the environmental impact of encapsulation materials extends beyond their production and disposal. The durability and effectiveness of these materials in protecting perovskite solar cells from moisture and other environmental factors directly influence the lifespan of the solar panels. Longer-lasting encapsulation materials can reduce the frequency of panel replacements, thereby decreasing the overall material consumption and associated environmental impacts over time.

In conclusion, as the perovskite solar cell technology advances, it is crucial to consider the environmental implications of encapsulation materials. The development of sustainable, recyclable, and efficient barrier films and encapsulants will play a vital role in enhancing the overall eco-friendliness of perovskite solar cells, contributing to their long-term viability as a clean energy solution.

Scalability of Moisture Protection Techniques

The scalability of moisture protection techniques for perovskite solar cells is a critical factor in their commercial viability and widespread adoption. Current laboratory-scale methods for enhancing moisture resistance, such as barrier films and encapsulation, face significant challenges when transitioning to large-scale production.

One of the primary scalability issues lies in the deposition of barrier films. While atomic layer deposition (ALD) and chemical vapor deposition (CVD) techniques offer excellent moisture protection at the lab scale, they are often slow and expensive processes that may not be suitable for high-throughput manufacturing. Roll-to-roll processing has shown promise for scaling up barrier film deposition, but maintaining uniform film quality over large areas remains a challenge.

Encapsulation techniques also face scalability hurdles. Glass-to-glass sealing, commonly used in small-scale devices, becomes increasingly difficult and costly for larger modules. Alternative encapsulation materials, such as flexible polymers, offer better scalability but may compromise long-term moisture protection.

The development of scalable moisture protection techniques requires a multifaceted approach. Researchers are exploring hybrid barrier systems that combine different materials and deposition methods to balance performance and manufacturability. For instance, combining solution-processed organic layers with inorganic barrier films deposited by plasma-enhanced CVD shows potential for large-scale production.

Another avenue for improving scalability is the development of self-healing materials that can autonomously repair moisture-induced damage. These materials could potentially extend the lifetime of perovskite solar cells without requiring complex manufacturing processes.

Standardization of testing protocols for moisture resistance is crucial for scaling up protection techniques. Currently, there is a lack of industry-wide standards for evaluating the long-term effectiveness of moisture barriers in real-world conditions. Establishing such standards would facilitate the comparison and optimization of different protection strategies at industrial scales.

Collaboration between academic researchers and industrial partners is essential for addressing scalability challenges. Joint efforts can help bridge the gap between laboratory innovations and practical manufacturing solutions, accelerating the development of commercially viable moisture protection techniques for perovskite solar cells.

One of the primary scalability issues lies in the deposition of barrier films. While atomic layer deposition (ALD) and chemical vapor deposition (CVD) techniques offer excellent moisture protection at the lab scale, they are often slow and expensive processes that may not be suitable for high-throughput manufacturing. Roll-to-roll processing has shown promise for scaling up barrier film deposition, but maintaining uniform film quality over large areas remains a challenge.

Encapsulation techniques also face scalability hurdles. Glass-to-glass sealing, commonly used in small-scale devices, becomes increasingly difficult and costly for larger modules. Alternative encapsulation materials, such as flexible polymers, offer better scalability but may compromise long-term moisture protection.

The development of scalable moisture protection techniques requires a multifaceted approach. Researchers are exploring hybrid barrier systems that combine different materials and deposition methods to balance performance and manufacturability. For instance, combining solution-processed organic layers with inorganic barrier films deposited by plasma-enhanced CVD shows potential for large-scale production.

Another avenue for improving scalability is the development of self-healing materials that can autonomously repair moisture-induced damage. These materials could potentially extend the lifetime of perovskite solar cells without requiring complex manufacturing processes.

Standardization of testing protocols for moisture resistance is crucial for scaling up protection techniques. Currently, there is a lack of industry-wide standards for evaluating the long-term effectiveness of moisture barriers in real-world conditions. Establishing such standards would facilitate the comparison and optimization of different protection strategies at industrial scales.

Collaboration between academic researchers and industrial partners is essential for addressing scalability challenges. Joint efforts can help bridge the gap between laboratory innovations and practical manufacturing solutions, accelerating the development of commercially viable moisture protection techniques for perovskite solar cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!