Protective Coatings for Perovskite Modules: Best Materials and Application Methods

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Module Protection Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the long-term stability of perovskite modules remains a significant challenge, hindering their widespread commercial adoption. The primary objective of this research is to explore and develop effective protective coatings for perovskite modules, focusing on identifying the best materials and application methods to enhance their durability and performance.

The evolution of perovskite solar technology has been rapid since its introduction in 2009. Initial efficiencies of around 3.8% have skyrocketed to over 25% in just over a decade, surpassing many traditional photovoltaic technologies. This remarkable progress has attracted substantial attention from both academia and industry, driving intensive research efforts worldwide. However, the inherent instability of perovskite materials when exposed to moisture, oxygen, heat, and light has become a critical bottleneck for their practical application.

Protective coatings play a crucial role in addressing these stability issues by creating a barrier between the sensitive perovskite layer and external environmental factors. The development of effective coating materials and application techniques is essential for extending the operational lifetime of perovskite modules from months to the years required for commercial viability. This research aims to systematically investigate various coating materials, including organic and inorganic compounds, as well as hybrid systems, to determine their efficacy in protecting perovskite modules.

The technical goals of this study encompass several key aspects. Firstly, we seek to identify coating materials that offer superior protection against moisture ingress and oxygen permeation while maintaining high optical transparency to ensure minimal impact on module efficiency. Secondly, we aim to develop application methods that enable uniform and defect-free coating deposition, crucial for ensuring comprehensive protection across the entire module surface. Additionally, we will explore the compatibility of these coatings with different perovskite compositions and module architectures to ensure broad applicability.

Furthermore, this research will investigate the long-term stability of coated perovskite modules under various environmental conditions, including temperature cycling, humidity exposure, and prolonged light soaking. By conducting accelerated aging tests and outdoor field trials, we aim to quantify the effectiveness of different coating strategies in real-world scenarios. The ultimate goal is to establish a set of best practices and materials recommendations that can significantly enhance the operational lifetime of perovskite solar modules, potentially bringing this promising technology closer to commercial reality.

The evolution of perovskite solar technology has been rapid since its introduction in 2009. Initial efficiencies of around 3.8% have skyrocketed to over 25% in just over a decade, surpassing many traditional photovoltaic technologies. This remarkable progress has attracted substantial attention from both academia and industry, driving intensive research efforts worldwide. However, the inherent instability of perovskite materials when exposed to moisture, oxygen, heat, and light has become a critical bottleneck for their practical application.

Protective coatings play a crucial role in addressing these stability issues by creating a barrier between the sensitive perovskite layer and external environmental factors. The development of effective coating materials and application techniques is essential for extending the operational lifetime of perovskite modules from months to the years required for commercial viability. This research aims to systematically investigate various coating materials, including organic and inorganic compounds, as well as hybrid systems, to determine their efficacy in protecting perovskite modules.

The technical goals of this study encompass several key aspects. Firstly, we seek to identify coating materials that offer superior protection against moisture ingress and oxygen permeation while maintaining high optical transparency to ensure minimal impact on module efficiency. Secondly, we aim to develop application methods that enable uniform and defect-free coating deposition, crucial for ensuring comprehensive protection across the entire module surface. Additionally, we will explore the compatibility of these coatings with different perovskite compositions and module architectures to ensure broad applicability.

Furthermore, this research will investigate the long-term stability of coated perovskite modules under various environmental conditions, including temperature cycling, humidity exposure, and prolonged light soaking. By conducting accelerated aging tests and outdoor field trials, we aim to quantify the effectiveness of different coating strategies in real-world scenarios. The ultimate goal is to establish a set of best practices and materials recommendations that can significantly enhance the operational lifetime of perovskite solar modules, potentially bringing this promising technology closer to commercial reality.

Market Analysis for Perovskite Solar Modules

The global market for perovskite solar modules is experiencing rapid growth and attracting significant attention from investors, researchers, and industry players. This emerging technology offers several advantages over traditional silicon-based solar cells, including lower production costs, higher efficiency potential, and versatility in applications.

Market projections indicate substantial growth for perovskite solar modules in the coming years. The market size is expected to expand as the technology matures and becomes more commercially viable. Key drivers for this growth include increasing demand for renewable energy sources, government initiatives promoting clean energy adoption, and the need for more efficient and cost-effective solar solutions.

The perovskite solar module market is segmented based on application areas, including building-integrated photovoltaics (BIPV), portable electronics, automotive, and utility-scale solar farms. Each segment presents unique opportunities and challenges for market penetration. BIPV applications are particularly promising due to the lightweight and flexible nature of perovskite modules, allowing for seamless integration into building materials.

Geographically, Asia-Pacific is anticipated to be the fastest-growing region for perovskite solar modules, driven by countries like China, Japan, and South Korea investing heavily in research and development. Europe and North America are also expected to witness significant market growth, supported by favorable government policies and increasing adoption of renewable energy technologies.

However, the market faces several challenges that need to be addressed for widespread commercialization. These include improving the long-term stability of perovskite modules, scaling up production processes, and addressing environmental concerns related to lead content in some perovskite formulations. Overcoming these hurdles is crucial for realizing the full market potential of perovskite solar technology.

The competitive landscape of the perovskite solar module market is characterized by a mix of established solar companies and innovative startups. Many firms are focusing on developing proprietary technologies and manufacturing processes to gain a competitive edge. Collaborations between research institutions and industry players are also driving innovation and accelerating market development.

Investors are showing increasing interest in perovskite solar technology, with significant funding being directed towards research and development efforts. This influx of capital is expected to fuel further advancements in materials, manufacturing techniques, and overall module performance, potentially leading to breakthroughs that could reshape the solar energy landscape.

Market projections indicate substantial growth for perovskite solar modules in the coming years. The market size is expected to expand as the technology matures and becomes more commercially viable. Key drivers for this growth include increasing demand for renewable energy sources, government initiatives promoting clean energy adoption, and the need for more efficient and cost-effective solar solutions.

The perovskite solar module market is segmented based on application areas, including building-integrated photovoltaics (BIPV), portable electronics, automotive, and utility-scale solar farms. Each segment presents unique opportunities and challenges for market penetration. BIPV applications are particularly promising due to the lightweight and flexible nature of perovskite modules, allowing for seamless integration into building materials.

Geographically, Asia-Pacific is anticipated to be the fastest-growing region for perovskite solar modules, driven by countries like China, Japan, and South Korea investing heavily in research and development. Europe and North America are also expected to witness significant market growth, supported by favorable government policies and increasing adoption of renewable energy technologies.

However, the market faces several challenges that need to be addressed for widespread commercialization. These include improving the long-term stability of perovskite modules, scaling up production processes, and addressing environmental concerns related to lead content in some perovskite formulations. Overcoming these hurdles is crucial for realizing the full market potential of perovskite solar technology.

The competitive landscape of the perovskite solar module market is characterized by a mix of established solar companies and innovative startups. Many firms are focusing on developing proprietary technologies and manufacturing processes to gain a competitive edge. Collaborations between research institutions and industry players are also driving innovation and accelerating market development.

Investors are showing increasing interest in perovskite solar technology, with significant funding being directed towards research and development efforts. This influx of capital is expected to fuel further advancements in materials, manufacturing techniques, and overall module performance, potentially leading to breakthroughs that could reshape the solar energy landscape.

Current Challenges in Perovskite Module Stability

Perovskite solar cells have shown remarkable potential in the field of photovoltaics, but their widespread adoption is hindered by significant stability issues. The primary challenge lies in the inherent instability of perovskite materials when exposed to environmental factors such as moisture, oxygen, heat, and light. These factors can lead to rapid degradation of the perovskite layer, resulting in a substantial decrease in device performance and longevity.

Moisture-induced degradation is particularly problematic, as perovskite materials are highly sensitive to water. Even trace amounts of moisture can trigger the decomposition of the perovskite crystal structure, leading to the formation of hydrated phases and ultimately, complete material breakdown. This sensitivity necessitates robust encapsulation techniques to protect the perovskite layer from ambient humidity.

Oxygen exposure presents another critical challenge, as it can induce oxidation of the perovskite material and charge transport layers. This oxidation process not only affects the perovskite itself but can also lead to the degradation of interfacial layers, compromising the overall device architecture and efficiency.

Thermal instability is a significant concern, especially for outdoor applications where solar modules are exposed to varying temperatures. Perovskite materials can undergo phase transitions or decomposition at elevated temperatures, leading to irreversible damage to the device structure. Developing thermally stable perovskite compositions and protective layers that can withstand operational temperatures is crucial for long-term module stability.

Light-induced degradation, or photodegradation, is another major challenge. Prolonged exposure to intense light can cause ion migration within the perovskite layer, leading to defect formation and accelerated degradation. This is particularly problematic for solar applications, where constant light exposure is inevitable.

The interface between the perovskite layer and charge transport layers presents additional stability challenges. Chemical reactions or ion migration at these interfaces can lead to the formation of insulating barriers or recombination centers, negatively impacting device performance over time.

Scaling up perovskite solar cells from small laboratory devices to large-area modules introduces new stability issues. Uniformity in deposition and encapsulation becomes more challenging at larger scales, potentially leading to localized degradation and overall reduced module stability.

Addressing these multifaceted stability challenges requires a comprehensive approach, combining innovative materials engineering, advanced encapsulation techniques, and optimized device architectures. The development of effective protective coatings that can simultaneously address moisture ingress, oxygen permeation, thermal management, and UV protection is critical for enhancing the long-term stability of perovskite solar modules and realizing their commercial potential.

Moisture-induced degradation is particularly problematic, as perovskite materials are highly sensitive to water. Even trace amounts of moisture can trigger the decomposition of the perovskite crystal structure, leading to the formation of hydrated phases and ultimately, complete material breakdown. This sensitivity necessitates robust encapsulation techniques to protect the perovskite layer from ambient humidity.

Oxygen exposure presents another critical challenge, as it can induce oxidation of the perovskite material and charge transport layers. This oxidation process not only affects the perovskite itself but can also lead to the degradation of interfacial layers, compromising the overall device architecture and efficiency.

Thermal instability is a significant concern, especially for outdoor applications where solar modules are exposed to varying temperatures. Perovskite materials can undergo phase transitions or decomposition at elevated temperatures, leading to irreversible damage to the device structure. Developing thermally stable perovskite compositions and protective layers that can withstand operational temperatures is crucial for long-term module stability.

Light-induced degradation, or photodegradation, is another major challenge. Prolonged exposure to intense light can cause ion migration within the perovskite layer, leading to defect formation and accelerated degradation. This is particularly problematic for solar applications, where constant light exposure is inevitable.

The interface between the perovskite layer and charge transport layers presents additional stability challenges. Chemical reactions or ion migration at these interfaces can lead to the formation of insulating barriers or recombination centers, negatively impacting device performance over time.

Scaling up perovskite solar cells from small laboratory devices to large-area modules introduces new stability issues. Uniformity in deposition and encapsulation becomes more challenging at larger scales, potentially leading to localized degradation and overall reduced module stability.

Addressing these multifaceted stability challenges requires a comprehensive approach, combining innovative materials engineering, advanced encapsulation techniques, and optimized device architectures. The development of effective protective coatings that can simultaneously address moisture ingress, oxygen permeation, thermal management, and UV protection is critical for enhancing the long-term stability of perovskite solar modules and realizing their commercial potential.

Existing Protective Coating Solutions

01 Encapsulation materials for perovskite solar cells

Various encapsulation materials are used to protect perovskite solar cells from environmental factors. These materials include polymers, glass, and composite structures that provide a barrier against moisture and oxygen, which can degrade the perovskite layer. The encapsulation helps to extend the lifespan and maintain the efficiency of the solar modules.- Encapsulation materials for perovskite solar cells: Various encapsulation materials are used to protect perovskite solar cells from environmental factors. These materials include polymers, glass, and composite structures that provide a barrier against moisture and oxygen, which can degrade the perovskite layer. The encapsulation helps to extend the lifespan and maintain the efficiency of the solar modules.

- Protective coatings with self-healing properties: Self-healing protective coatings are being developed for perovskite solar modules. These coatings can repair minor damage automatically, reducing the need for maintenance and extending the module's lifespan. The self-healing properties are achieved through the incorporation of specific polymers or nanoparticles that respond to environmental stimuli.

- Transparent conductive oxide (TCO) layers as protective coatings: Transparent conductive oxide layers serve a dual purpose in perovskite solar modules. They act as both a protective coating and an electrode, allowing light to pass through while shielding the perovskite layer from environmental factors. Common TCO materials include indium tin oxide (ITO) and fluorine-doped tin oxide (FTO).

- Hydrophobic and oleophobic coatings for enhanced protection: Hydrophobic and oleophobic coatings are applied to perovskite solar modules to repel water and oils, providing additional protection against environmental contaminants. These coatings can be based on fluoropolymers or silicone materials and help to maintain the module's performance by preventing the accumulation of dirt and moisture on the surface.

- Multi-layer protective structures for perovskite modules: Multi-layer protective structures are designed to provide comprehensive protection for perovskite solar modules. These structures typically consist of different materials with complementary properties, such as moisture barriers, UV-blocking layers, and scratch-resistant coatings. The combination of layers offers enhanced durability and longevity for the perovskite modules.

02 Protective coatings with self-healing properties

Self-healing protective coatings are being developed for perovskite solar modules. These coatings can repair minor damage automatically, preventing the ingress of harmful substances. The self-healing mechanism is often based on reversible chemical bonds or the incorporation of microcapsules containing healing agents.Expand Specific Solutions03 Multilayer protective structures

Multilayer protective structures are designed to provide comprehensive protection for perovskite modules. These structures typically consist of different materials with complementary properties, such as moisture barriers, UV blockers, and scratch-resistant layers. The combination of layers offers enhanced protection against various environmental stressors.Expand Specific Solutions04 Transparent conductive coatings

Transparent conductive coatings serve a dual purpose in perovskite solar modules. They act as a protective layer while also functioning as an electrode. These coatings are typically made of materials like indium tin oxide (ITO) or fluorine-doped tin oxide (FTO), which offer both optical transparency and electrical conductivity.Expand Specific Solutions05 Edge sealants for module protection

Edge sealants are crucial for protecting perovskite modules from lateral moisture ingress. These sealants are applied around the edges of the module to create a hermetic seal. Advanced edge sealant materials and application techniques are being developed to improve the long-term stability of perovskite solar cells.Expand Specific Solutions

Key Players in Perovskite Module Coating Industry

The research on protective coatings for perovskite modules is in a rapidly evolving phase, with significant market potential due to the growing demand for efficient and durable solar technologies. The industry is transitioning from early-stage research to commercialization, with a market size expected to expand substantially in the coming years. Companies like Wuxi UtmoLight Technology, Microquanta, and Oxford Photovoltaics are at the forefront, demonstrating varying levels of technological maturity. While some firms have achieved mass production capabilities, others are still in the research and development stage, indicating a diverse competitive landscape with opportunities for innovation and market entry.

Oxford Photovoltaics Ltd.

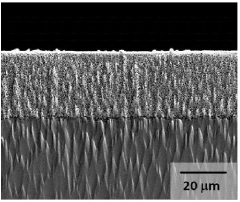

Technical Solution: Oxford PV has developed a perovskite-on-silicon tandem solar cell technology, which includes innovative protective coating methods. Their approach involves depositing a thin layer of perovskite material onto conventional silicon solar cells, creating a tandem structure. For protection, they utilize a multi-layer encapsulation system, incorporating both organic and inorganic materials. This system includes a moisture barrier layer, typically made of metal oxides like Al2O3 or SnO2, applied using atomic layer deposition (ALD) for precise thickness control[1]. Additionally, they employ a polymer-based sealant layer to further enhance moisture resistance and mechanical stability[2]. The company has achieved a record 29.52% conversion efficiency for perovskite-silicon tandem cells in 2022, demonstrating the effectiveness of their protective measures[3].

Strengths: High efficiency, scalable manufacturing process, and proven durability. Weaknesses: Potentially higher production costs due to complex multi-layer protection system and the need for specialized deposition equipment.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has pioneered several protective coating strategies for perovskite solar cells. One notable approach is the use of two-dimensional (2D) perovskite materials as a protective layer. This method involves depositing a thin layer of 2D perovskite on top of the 3D perovskite active layer, creating a more stable interface[4]. The 2D perovskite acts as a barrier against moisture and oxygen ingress while allowing efficient charge transport. EPFL researchers have also explored the use of hydrophobic fluorinated compounds as additives in the perovskite layer, enhancing its moisture resistance[5]. Additionally, they have developed a low-temperature solution-processed SnO2 electron transport layer, which serves as both a functional component and a protective barrier[6]. Their cells have demonstrated impressive stability, retaining over 95% of initial efficiency after 1000 hours of operation under standard testing conditions.

Strengths: Innovative use of 2D materials, solution-processable methods suitable for large-scale production. Weaknesses: Potential challenges in optimizing the interface between 2D and 3D perovskites, and ensuring long-term stability under real-world conditions.

Innovative Materials for Perovskite Protection

Perovskites compositions, methods of producing, methods of use, and materials thereof

PatentPendingUS20240336798A1

Innovation

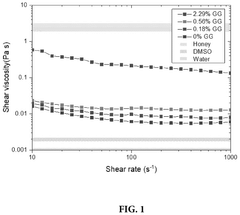

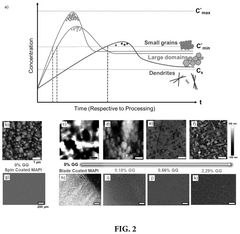

- A method involving the mixing of a perovskite precursor with an organic solvent and a polymer additive, such as gellan gum, to create a perovskite-polymer ink that is then deposited and flame-annealed on a substrate, eliminating the need for a quenching step and allowing for the production of high-quality perovskite materials in ambient conditions.

Method Of Perovskite Ceramics Protective layer Of Metal Interconnect Of Solid Oxide Fuel Cell, And Protective Layer Manufactured Using The Same

PatentActiveKR1020170026904A

Innovation

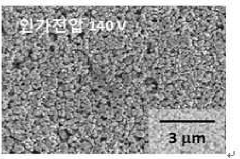

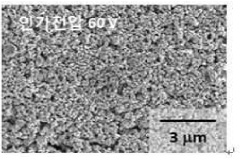

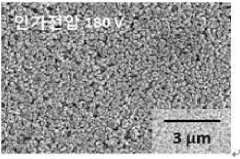

- A perovskite ceramic protective film is applied using electrophoresis on a conductive substrate, followed by drying and heat-treating, utilizing a ceramic powder dispersed in a solvent, with specific conditions for ultrasonic application, electrode distance, voltage, and heat treatment to ensure a uniform coating on complex-shaped metal separators.

Environmental Impact of Coating Materials

The environmental impact of coating materials used in perovskite solar modules is a critical consideration in the development and deployment of this emerging technology. As the industry moves towards large-scale production and implementation of perovskite solar cells, it is essential to evaluate the potential ecological consequences of the protective coatings employed.

One of the primary concerns is the use of organic solvents in the application of many coating materials. These solvents, often volatile organic compounds (VOCs), can contribute to air pollution and pose health risks to workers involved in the manufacturing process. Additionally, some coating materials may contain heavy metals or other toxic substances that could leach into the environment if not properly managed during the module's lifecycle.

The production of certain coating materials may also have significant energy requirements, contributing to indirect environmental impacts through increased carbon emissions. For instance, the synthesis of some inorganic materials used in protective coatings can be energy-intensive, potentially offsetting some of the environmental benefits gained from the use of perovskite solar technology.

Disposal and recycling of perovskite modules at the end of their operational life present another environmental challenge. The presence of protective coatings may complicate the recycling process, potentially leading to increased waste if effective recycling methods are not developed. This is particularly important given the relatively short lifespan of current perovskite solar cells compared to traditional silicon-based modules.

On the positive side, some coating materials being researched for perovskite modules are derived from abundant, naturally occurring substances. These bio-based or eco-friendly coatings could potentially reduce the environmental footprint of perovskite solar technology. For example, cellulose-based coatings or those derived from waste biomass show promise in terms of sustainability and biodegradability.

The application method of coating materials also plays a role in their environmental impact. Spray coating techniques, while efficient, may result in material waste and increased VOC emissions. In contrast, solution-based deposition methods might offer better material utilization but may require more energy-intensive drying processes.

As research in this field progresses, there is a growing focus on developing coating materials and application methods that minimize environmental impact without compromising the performance and durability of perovskite modules. This includes exploring water-based coating systems, investigating low-temperature processing techniques, and designing coatings that facilitate easier module recycling at end-of-life.

One of the primary concerns is the use of organic solvents in the application of many coating materials. These solvents, often volatile organic compounds (VOCs), can contribute to air pollution and pose health risks to workers involved in the manufacturing process. Additionally, some coating materials may contain heavy metals or other toxic substances that could leach into the environment if not properly managed during the module's lifecycle.

The production of certain coating materials may also have significant energy requirements, contributing to indirect environmental impacts through increased carbon emissions. For instance, the synthesis of some inorganic materials used in protective coatings can be energy-intensive, potentially offsetting some of the environmental benefits gained from the use of perovskite solar technology.

Disposal and recycling of perovskite modules at the end of their operational life present another environmental challenge. The presence of protective coatings may complicate the recycling process, potentially leading to increased waste if effective recycling methods are not developed. This is particularly important given the relatively short lifespan of current perovskite solar cells compared to traditional silicon-based modules.

On the positive side, some coating materials being researched for perovskite modules are derived from abundant, naturally occurring substances. These bio-based or eco-friendly coatings could potentially reduce the environmental footprint of perovskite solar technology. For example, cellulose-based coatings or those derived from waste biomass show promise in terms of sustainability and biodegradability.

The application method of coating materials also plays a role in their environmental impact. Spray coating techniques, while efficient, may result in material waste and increased VOC emissions. In contrast, solution-based deposition methods might offer better material utilization but may require more energy-intensive drying processes.

As research in this field progresses, there is a growing focus on developing coating materials and application methods that minimize environmental impact without compromising the performance and durability of perovskite modules. This includes exploring water-based coating systems, investigating low-temperature processing techniques, and designing coatings that facilitate easier module recycling at end-of-life.

Scalability of Coating Application Methods

The scalability of coating application methods is a critical factor in the commercial viability of perovskite solar modules. As the industry moves towards large-scale production, it is essential to evaluate and optimize coating techniques that can be efficiently implemented in high-volume manufacturing processes.

Spin coating, a widely used method in laboratory settings, faces significant challenges in scaling up for industrial production. While it offers precise control over film thickness and uniformity, its batch nature and material wastage limit its applicability for large-area modules. However, recent advancements in multi-head spin coating systems have shown promise in improving throughput and reducing material consumption.

Spray coating has emerged as a more scalable alternative, offering high-speed deposition and compatibility with roll-to-roll processing. Ultrasonic spray coating, in particular, has demonstrated excellent film uniformity and thickness control across large areas. The ability to adjust spray parameters such as nozzle distance, solution concentration, and substrate temperature allows for fine-tuning of the coating process to meet specific requirements.

Blade coating and slot-die coating are two other methods that have gained traction for their scalability and precise control over film thickness. These techniques are well-suited for continuous roll-to-roll production, enabling high-throughput manufacturing of perovskite modules. Recent studies have shown that blade coating can achieve uniform films over areas exceeding 100 cm², with the potential for further scaling.

Inkjet printing offers another promising avenue for scalable deposition of protective coatings. Its digital nature allows for precise patterning and minimal material waste, making it an attractive option for customized module designs. However, challenges remain in formulating stable inks with appropriate viscosity and surface tension for optimal printing performance.

As the industry progresses, hybrid approaches combining multiple coating techniques are being explored to leverage the strengths of each method. For instance, a combination of spray coating for bulk deposition and inkjet printing for localized repairs or enhancements could offer a versatile and scalable solution for protective coating application.

The development of in-line quality control and real-time process monitoring systems is crucial for ensuring consistent coating quality in large-scale production. Advanced imaging techniques and machine learning algorithms are being integrated into coating lines to detect and correct defects during the manufacturing process, further enhancing the scalability and reliability of protective coating applications for perovskite modules.

Spin coating, a widely used method in laboratory settings, faces significant challenges in scaling up for industrial production. While it offers precise control over film thickness and uniformity, its batch nature and material wastage limit its applicability for large-area modules. However, recent advancements in multi-head spin coating systems have shown promise in improving throughput and reducing material consumption.

Spray coating has emerged as a more scalable alternative, offering high-speed deposition and compatibility with roll-to-roll processing. Ultrasonic spray coating, in particular, has demonstrated excellent film uniformity and thickness control across large areas. The ability to adjust spray parameters such as nozzle distance, solution concentration, and substrate temperature allows for fine-tuning of the coating process to meet specific requirements.

Blade coating and slot-die coating are two other methods that have gained traction for their scalability and precise control over film thickness. These techniques are well-suited for continuous roll-to-roll production, enabling high-throughput manufacturing of perovskite modules. Recent studies have shown that blade coating can achieve uniform films over areas exceeding 100 cm², with the potential for further scaling.

Inkjet printing offers another promising avenue for scalable deposition of protective coatings. Its digital nature allows for precise patterning and minimal material waste, making it an attractive option for customized module designs. However, challenges remain in formulating stable inks with appropriate viscosity and surface tension for optimal printing performance.

As the industry progresses, hybrid approaches combining multiple coating techniques are being explored to leverage the strengths of each method. For instance, a combination of spray coating for bulk deposition and inkjet printing for localized repairs or enhancements could offer a versatile and scalable solution for protective coating application.

The development of in-line quality control and real-time process monitoring systems is crucial for ensuring consistent coating quality in large-scale production. Advanced imaging techniques and machine learning algorithms are being integrated into coating lines to detect and correct defects during the manufacturing process, further enhancing the scalability and reliability of protective coating applications for perovskite modules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!