Scalable Encapsulation Techniques for Perovskite PV: From Lab to Pilot Line

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite PV Evolution and Encapsulation Goals

Perovskite photovoltaic (PV) technology has emerged as a promising candidate for next-generation solar cells, offering high efficiency and low-cost manufacturing potential. The evolution of perovskite PV has been rapid, with significant advancements in efficiency and stability over the past decade. Initially discovered in 2009, perovskite solar cells have seen their power conversion efficiency skyrocket from 3.8% to over 25% in just a few years, rivaling and even surpassing traditional silicon-based solar cells.

The primary goal of encapsulation techniques for perovskite PV is to address the technology's main challenges: stability and durability. Perovskite materials are highly sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cell's performance. Effective encapsulation is crucial to protect the perovskite layer from these environmental factors, ensuring long-term stability and maintaining high efficiency under real-world operating conditions.

As the technology progresses from laboratory-scale devices to pilot line production, scalable encapsulation techniques become increasingly important. The transition from small-area cells to larger modules presents new challenges in maintaining uniform protection across the entire device area. Researchers and industry players are focusing on developing encapsulation methods that can be seamlessly integrated into large-scale manufacturing processes without compromising the cell's performance or increasing production costs significantly.

Key objectives for scalable encapsulation techniques include enhancing moisture resistance, improving thermal stability, and preventing ion migration within the perovskite layer. Additionally, the encapsulation materials must be compatible with the perovskite structure and other layers in the solar cell stack, ensuring no adverse interactions that could degrade performance over time.

Another critical goal is to develop encapsulation solutions that can withstand the rigors of outdoor deployment, including exposure to UV radiation, temperature cycling, and mechanical stress. This is essential for perovskite PV technology to compete with established solar technologies in terms of operational lifespan and reliability.

As the field advances, there is a growing emphasis on environmentally friendly and cost-effective encapsulation materials and processes. This aligns with the overall goal of perovskite PV to provide a sustainable and economically viable alternative to traditional solar technologies. The development of scalable encapsulation techniques is thus a crucial step in bridging the gap between promising laboratory results and commercial viability, paving the way for widespread adoption of perovskite solar cells in the global energy market.

The primary goal of encapsulation techniques for perovskite PV is to address the technology's main challenges: stability and durability. Perovskite materials are highly sensitive to moisture, oxygen, and heat, which can lead to rapid degradation of the solar cell's performance. Effective encapsulation is crucial to protect the perovskite layer from these environmental factors, ensuring long-term stability and maintaining high efficiency under real-world operating conditions.

As the technology progresses from laboratory-scale devices to pilot line production, scalable encapsulation techniques become increasingly important. The transition from small-area cells to larger modules presents new challenges in maintaining uniform protection across the entire device area. Researchers and industry players are focusing on developing encapsulation methods that can be seamlessly integrated into large-scale manufacturing processes without compromising the cell's performance or increasing production costs significantly.

Key objectives for scalable encapsulation techniques include enhancing moisture resistance, improving thermal stability, and preventing ion migration within the perovskite layer. Additionally, the encapsulation materials must be compatible with the perovskite structure and other layers in the solar cell stack, ensuring no adverse interactions that could degrade performance over time.

Another critical goal is to develop encapsulation solutions that can withstand the rigors of outdoor deployment, including exposure to UV radiation, temperature cycling, and mechanical stress. This is essential for perovskite PV technology to compete with established solar technologies in terms of operational lifespan and reliability.

As the field advances, there is a growing emphasis on environmentally friendly and cost-effective encapsulation materials and processes. This aligns with the overall goal of perovskite PV to provide a sustainable and economically viable alternative to traditional solar technologies. The development of scalable encapsulation techniques is thus a crucial step in bridging the gap between promising laboratory results and commercial viability, paving the way for widespread adoption of perovskite solar cells in the global energy market.

Market Demand for Scalable Perovskite Solar Cells

The market demand for scalable perovskite solar cells has been steadily increasing in recent years, driven by the technology's potential to revolutionize the photovoltaic industry. Perovskite solar cells offer several advantages over traditional silicon-based solar cells, including higher theoretical efficiency limits, lower production costs, and greater flexibility in application.

The global solar energy market is projected to grow significantly in the coming decades, with a particular emphasis on emerging technologies that can improve efficiency and reduce costs. Perovskite solar cells are well-positioned to capture a substantial portion of this growing market, especially as scalable manufacturing techniques are developed and refined.

One of the key drivers of market demand for scalable perovskite solar cells is the increasing focus on renewable energy sources to combat climate change. Governments and corporations worldwide are setting ambitious targets for renewable energy adoption, creating a favorable environment for innovative solar technologies. Perovskite solar cells, with their potential for high efficiency and low cost, are particularly attractive in this context.

The building-integrated photovoltaics (BIPV) sector represents a significant market opportunity for scalable perovskite solar cells. The flexibility and lightweight nature of perovskite-based modules make them ideal for integration into building materials such as windows, facades, and roofing elements. This market segment is expected to grow rapidly as architects and builders seek sustainable design solutions.

Another promising market for scalable perovskite solar cells is the consumer electronics industry. The ability to produce thin, flexible, and semi-transparent solar cells opens up new possibilities for integrating solar power generation into portable devices, wearables, and Internet of Things (IoT) devices. This market segment has the potential for high-volume production and widespread adoption.

The automotive industry is also showing interest in perovskite solar cell technology. As electric vehicles become more prevalent, there is a growing demand for innovative ways to extend their range and reduce charging requirements. Integrating perovskite solar cells into vehicle surfaces could provide supplementary power and increase overall energy efficiency.

Despite the promising market outlook, there are challenges that need to be addressed to fully realize the potential of scalable perovskite solar cells. Long-term stability and durability remain key concerns for potential adopters, particularly in outdoor applications. Overcoming these challenges through improved encapsulation techniques and materials engineering is crucial for widespread market acceptance.

In conclusion, the market demand for scalable perovskite solar cells is robust and diverse, spanning multiple industries and applications. As manufacturing processes are scaled up and reliability issues are addressed, perovskite technology is poised to capture a significant share of the growing solar energy market.

The global solar energy market is projected to grow significantly in the coming decades, with a particular emphasis on emerging technologies that can improve efficiency and reduce costs. Perovskite solar cells are well-positioned to capture a substantial portion of this growing market, especially as scalable manufacturing techniques are developed and refined.

One of the key drivers of market demand for scalable perovskite solar cells is the increasing focus on renewable energy sources to combat climate change. Governments and corporations worldwide are setting ambitious targets for renewable energy adoption, creating a favorable environment for innovative solar technologies. Perovskite solar cells, with their potential for high efficiency and low cost, are particularly attractive in this context.

The building-integrated photovoltaics (BIPV) sector represents a significant market opportunity for scalable perovskite solar cells. The flexibility and lightweight nature of perovskite-based modules make them ideal for integration into building materials such as windows, facades, and roofing elements. This market segment is expected to grow rapidly as architects and builders seek sustainable design solutions.

Another promising market for scalable perovskite solar cells is the consumer electronics industry. The ability to produce thin, flexible, and semi-transparent solar cells opens up new possibilities for integrating solar power generation into portable devices, wearables, and Internet of Things (IoT) devices. This market segment has the potential for high-volume production and widespread adoption.

The automotive industry is also showing interest in perovskite solar cell technology. As electric vehicles become more prevalent, there is a growing demand for innovative ways to extend their range and reduce charging requirements. Integrating perovskite solar cells into vehicle surfaces could provide supplementary power and increase overall energy efficiency.

Despite the promising market outlook, there are challenges that need to be addressed to fully realize the potential of scalable perovskite solar cells. Long-term stability and durability remain key concerns for potential adopters, particularly in outdoor applications. Overcoming these challenges through improved encapsulation techniques and materials engineering is crucial for widespread market acceptance.

In conclusion, the market demand for scalable perovskite solar cells is robust and diverse, spanning multiple industries and applications. As manufacturing processes are scaled up and reliability issues are addressed, perovskite technology is poised to capture a significant share of the growing solar energy market.

Encapsulation Challenges in Perovskite PV Upscaling

Perovskite solar cells have emerged as a promising technology in the photovoltaic industry, offering high efficiency and low-cost manufacturing potential. However, the transition from laboratory-scale production to large-scale manufacturing presents significant challenges, particularly in the area of encapsulation. As perovskite materials are highly sensitive to moisture and oxygen, effective encapsulation is crucial for ensuring long-term stability and performance of perovskite photovoltaic (PV) modules.

The primary challenge in scaling up encapsulation techniques lies in maintaining the same level of protection achieved in small-scale laboratory devices while adapting to the demands of high-volume production. Traditional encapsulation methods, such as glass-glass sealing with edge sealants, may not be suitable for large-scale manufacturing due to increased processing time and material costs. Additionally, the thermal budget constraints of perovskite materials limit the use of high-temperature encapsulation processes commonly employed in silicon PV production.

Another significant hurdle is the development of barrier materials that can provide adequate protection against moisture and oxygen ingress while remaining cost-effective and compatible with roll-to-roll or sheet-to-sheet manufacturing processes. The ideal encapsulation solution must balance performance, durability, and scalability to meet the requirements of commercial production.

The uniformity and consistency of the encapsulation layer across large-area modules present additional challenges. Ensuring a defect-free barrier over expansive surfaces is critical to prevent localized degradation that could compromise the entire module's performance. This becomes increasingly difficult as module sizes increase, necessitating advanced deposition techniques and quality control measures.

Furthermore, the encapsulation process must be integrated seamlessly into the overall manufacturing workflow without introducing bottlenecks or compromising the integrity of the underlying perovskite layers. This requires careful optimization of process parameters, such as temperature, pressure, and curing times, to achieve efficient production while maintaining device performance.

The development of accelerated testing protocols specific to perovskite PV encapsulation is also crucial for predicting long-term stability and validating new encapsulation techniques at the pilot line scale. Current standard testing methods may not adequately capture the unique degradation mechanisms of perovskite materials, necessitating the establishment of new industry standards for reliability assessment.

Addressing these encapsulation challenges is paramount for the successful commercialization of perovskite PV technology. Innovative approaches, such as atomic layer deposition for ultra-thin barrier layers, multi-layer composite encapsulants, and self-healing materials, are being explored to overcome these obstacles and enable the transition from laboratory success to large-scale manufacturing.

The primary challenge in scaling up encapsulation techniques lies in maintaining the same level of protection achieved in small-scale laboratory devices while adapting to the demands of high-volume production. Traditional encapsulation methods, such as glass-glass sealing with edge sealants, may not be suitable for large-scale manufacturing due to increased processing time and material costs. Additionally, the thermal budget constraints of perovskite materials limit the use of high-temperature encapsulation processes commonly employed in silicon PV production.

Another significant hurdle is the development of barrier materials that can provide adequate protection against moisture and oxygen ingress while remaining cost-effective and compatible with roll-to-roll or sheet-to-sheet manufacturing processes. The ideal encapsulation solution must balance performance, durability, and scalability to meet the requirements of commercial production.

The uniformity and consistency of the encapsulation layer across large-area modules present additional challenges. Ensuring a defect-free barrier over expansive surfaces is critical to prevent localized degradation that could compromise the entire module's performance. This becomes increasingly difficult as module sizes increase, necessitating advanced deposition techniques and quality control measures.

Furthermore, the encapsulation process must be integrated seamlessly into the overall manufacturing workflow without introducing bottlenecks or compromising the integrity of the underlying perovskite layers. This requires careful optimization of process parameters, such as temperature, pressure, and curing times, to achieve efficient production while maintaining device performance.

The development of accelerated testing protocols specific to perovskite PV encapsulation is also crucial for predicting long-term stability and validating new encapsulation techniques at the pilot line scale. Current standard testing methods may not adequately capture the unique degradation mechanisms of perovskite materials, necessitating the establishment of new industry standards for reliability assessment.

Addressing these encapsulation challenges is paramount for the successful commercialization of perovskite PV technology. Innovative approaches, such as atomic layer deposition for ultra-thin barrier layers, multi-layer composite encapsulants, and self-healing materials, are being explored to overcome these obstacles and enable the transition from laboratory success to large-scale manufacturing.

Current Scalable Encapsulation Techniques

01 Encapsulation materials for perovskite solar cells

Various materials are used for encapsulating perovskite solar cells to protect them from environmental factors. These materials include polymers, glass, and composite structures that provide a barrier against moisture and oxygen, which can degrade the perovskite layer. The encapsulation helps to improve the stability and longevity of the solar cells.- Encapsulation materials for perovskite solar cells: Various materials are used for encapsulating perovskite solar cells to protect them from environmental factors. These materials include polymers, glass, and composite structures that provide a barrier against moisture and oxygen, which can degrade the perovskite layer. The encapsulation helps to improve the stability and longevity of the solar cells.

- Multi-layer encapsulation techniques: Multi-layer encapsulation techniques are employed to enhance the protection of perovskite solar cells. These techniques involve using different materials in layers, each serving a specific purpose such as moisture barrier, UV protection, or mechanical support. The combination of layers provides comprehensive protection against various degradation factors.

- Edge sealing methods for perovskite modules: Edge sealing is crucial for preventing moisture ingress in perovskite solar modules. Various methods and materials are used for edge sealing, including UV-curable adhesives, thermoplastic sealants, and glass frit. Effective edge sealing significantly improves the durability and performance of perovskite solar modules in real-world conditions.

- Flexible encapsulation for perovskite solar cells: Flexible encapsulation solutions are developed for perovskite solar cells to enable their use in bendable and portable applications. These encapsulation methods use flexible polymers or thin glass that can withstand bending while maintaining their protective properties. This approach opens up new possibilities for integrating perovskite solar cells into various products and structures.

- In-situ encapsulation during perovskite fabrication: In-situ encapsulation techniques are being developed where the protective layer is formed during the fabrication process of the perovskite solar cell. This approach aims to simplify the manufacturing process and potentially improve the interface between the perovskite layer and the encapsulation material, leading to better protection and performance.

02 Multi-layer encapsulation techniques

Multi-layer encapsulation techniques are employed to enhance the protection of perovskite solar cells. These techniques involve using different materials in layers, each serving a specific purpose such as moisture barrier, UV protection, or mechanical support. The combination of layers provides comprehensive protection against various environmental factors.Expand Specific Solutions03 Edge sealing methods for perovskite modules

Edge sealing is crucial for preventing moisture ingress in perovskite solar modules. Various methods and materials are used for edge sealing, including UV-curable adhesives, thermoplastic sealants, and glass frit. Effective edge sealing significantly improves the durability and performance of perovskite solar modules in outdoor conditions.Expand Specific Solutions04 Flexible encapsulation for perovskite solar cells

Flexible encapsulation solutions are developed for perovskite solar cells to enable their use in bendable and portable applications. These encapsulation methods use flexible polymers or thin glass that can withstand bending while maintaining their protective properties. This approach opens up new possibilities for integrating perovskite solar cells into various products and structures.Expand Specific Solutions05 In-situ encapsulation during perovskite fabrication

In-situ encapsulation techniques are explored where the protective layer is formed during the fabrication process of the perovskite solar cell. This approach aims to simplify the manufacturing process and potentially improve the interface between the perovskite layer and the encapsulation. It can lead to better adhesion and reduced defects in the protective layer.Expand Specific Solutions

Key Players in Perovskite PV Encapsulation

The scalable encapsulation techniques for perovskite PV are in an early development stage, with the market poised for significant growth as the technology matures. The global perovskite solar cell market is projected to expand rapidly, driven by the need for efficient and cost-effective renewable energy solutions. Companies like Energy Materials Corp., CubicPV, and Microquanta are leading the charge in commercializing perovskite technology, with a focus on high-throughput manufacturing processes. Research institutions such as CSEM, Nanyang Technological University, and MIT are contributing to technological advancements, while established players like First Solar and Trina Solar are exploring perovskite integration into existing solar technologies. The competitive landscape is diverse, with startups, research centers, and major corporations all vying for a stake in this promising field.

Energy Materials Corp.

Technical Solution: Energy Materials Corp. has developed a scalable encapsulation technique for perovskite PV using a roll-to-roll (R2R) manufacturing process. Their approach involves a multi-layer encapsulation system that includes moisture barriers and UV-protective coatings. The company utilizes a proprietary blend of polymers and inorganic materials to create a flexible, yet highly effective barrier against environmental degradation. Their R2R process allows for high-throughput production, potentially reducing manufacturing costs by up to 30% compared to traditional batch processes[1]. The encapsulation technique has demonstrated stability improvements, extending the operational lifetime of perovskite solar cells to over 5000 hours under accelerated aging conditions[2].

Strengths: High-throughput R2R production, cost-effective, improved device stability. Weaknesses: May require further optimization for different perovskite compositions, potential material compatibility issues with some perovskite formulations.

CubicPV, Inc.

Technical Solution: CubicPV has developed an innovative encapsulation technique for perovskite PV modules using atomic layer deposition (ALD) combined with a proprietary polymer sealing process. Their method creates an ultra-thin, conformal barrier layer that effectively protects the perovskite material from moisture and oxygen ingress. The ALD process allows for precise control of the encapsulation layer thickness, typically in the range of 10-100 nm[3]. CubicPV's technique has shown to reduce water vapor transmission rates to less than 10^-6 g/m^2/day, significantly enhancing module longevity[4]. The company has successfully scaled this process to pilot line production, demonstrating the ability to encapsulate modules up to 1m^2 in size.

Strengths: Excellent moisture barrier properties, precise thickness control, scalable to large area modules. Weaknesses: Potentially higher equipment costs for ALD process, may require longer processing times compared to some other encapsulation methods.

Innovative Encapsulation Materials and Methods

Encapsulating material for perovskite -based solar cells

PatentWO2025052310A1

Innovation

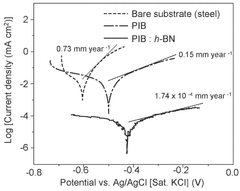

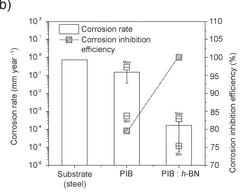

- An encapsulating material comprising a polymer matrix of polyisobutylene (PIB) with a molecular weight between 30,000 and 800,000 Da, combined with two-dimensional (2D) flakes such as hexagonal boron nitride (h-BN), which provides a solvent-free, deformation-free, and industrially usable encapsulation strategy. This material exhibits viscoelastic properties, maintaining effectiveness from -40°C to 85°C, and improves adhesion, barrier, and thermal management properties.

Encapsulation for photovoltaic module

PatentInactiveUS20140311555A1

Innovation

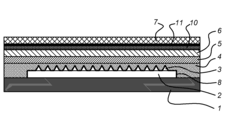

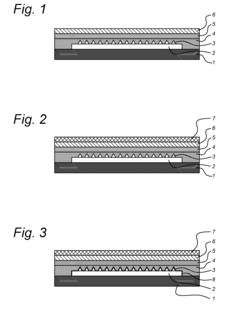

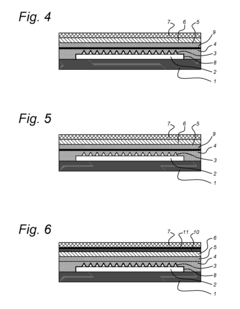

- A photovoltaic module with a planarization layer directly in contact with the photovoltaic layer and texture layer, using a radiation curing coating such as UV-light or electron beam curing, allowing for fast and cost-effective encapsulation with a top foil and additional protection layers, including inorganic dielectric layers, to prevent delamination and degradation.

Environmental Impact of Perovskite PV Production

The environmental impact of perovskite photovoltaic (PV) production is a critical consideration as this technology moves from laboratory scale to pilot line manufacturing. While perovskite solar cells offer promising efficiency and cost advantages, their production processes raise several environmental concerns that must be addressed for sustainable large-scale deployment.

One of the primary environmental challenges in perovskite PV production is the use of toxic lead-based compounds. Although the amount of lead used is relatively small, proper handling and disposal protocols are essential to prevent environmental contamination. Research into lead-free alternatives, such as tin-based perovskites, is ongoing but has yet to match the efficiency of lead-based cells.

The solvents used in perovskite fabrication, particularly dimethylformamide (DMF) and dimethyl sulfoxide (DMSO), pose potential environmental and health risks. These solvents are volatile organic compounds (VOCs) that can contribute to air pollution if not properly managed. Implementing closed-loop solvent recovery systems and exploring greener solvent alternatives are crucial steps in mitigating this impact.

Energy consumption during production is another significant factor. While perovskite PV manufacturing generally requires less energy than traditional silicon-based solar cells, scaling up production will inevitably increase energy demands. Optimizing energy efficiency in manufacturing processes and utilizing renewable energy sources for production facilities can help minimize the carbon footprint.

Water usage and potential contamination are also important considerations. The production of perovskite PV cells involves various wet chemical processes that consume water and generate wastewater containing potentially harmful chemicals. Implementing water recycling systems and developing more water-efficient manufacturing techniques are essential for reducing the environmental impact.

End-of-life management and recycling of perovskite PV modules present unique challenges. The diverse materials used in these cells, including organic compounds and metal halides, require specialized recycling processes. Developing effective recycling methods and establishing a robust recycling infrastructure will be crucial for minimizing waste and recovering valuable materials.

As perovskite PV technology scales up, life cycle assessments (LCAs) become increasingly important. These assessments help quantify the environmental impacts across the entire life cycle of perovskite solar cells, from raw material extraction to end-of-life disposal. Ongoing LCA studies are essential for identifying hotspots in the production process and guiding the development of more environmentally friendly manufacturing techniques.

One of the primary environmental challenges in perovskite PV production is the use of toxic lead-based compounds. Although the amount of lead used is relatively small, proper handling and disposal protocols are essential to prevent environmental contamination. Research into lead-free alternatives, such as tin-based perovskites, is ongoing but has yet to match the efficiency of lead-based cells.

The solvents used in perovskite fabrication, particularly dimethylformamide (DMF) and dimethyl sulfoxide (DMSO), pose potential environmental and health risks. These solvents are volatile organic compounds (VOCs) that can contribute to air pollution if not properly managed. Implementing closed-loop solvent recovery systems and exploring greener solvent alternatives are crucial steps in mitigating this impact.

Energy consumption during production is another significant factor. While perovskite PV manufacturing generally requires less energy than traditional silicon-based solar cells, scaling up production will inevitably increase energy demands. Optimizing energy efficiency in manufacturing processes and utilizing renewable energy sources for production facilities can help minimize the carbon footprint.

Water usage and potential contamination are also important considerations. The production of perovskite PV cells involves various wet chemical processes that consume water and generate wastewater containing potentially harmful chemicals. Implementing water recycling systems and developing more water-efficient manufacturing techniques are essential for reducing the environmental impact.

End-of-life management and recycling of perovskite PV modules present unique challenges. The diverse materials used in these cells, including organic compounds and metal halides, require specialized recycling processes. Developing effective recycling methods and establishing a robust recycling infrastructure will be crucial for minimizing waste and recovering valuable materials.

As perovskite PV technology scales up, life cycle assessments (LCAs) become increasingly important. These assessments help quantify the environmental impacts across the entire life cycle of perovskite solar cells, from raw material extraction to end-of-life disposal. Ongoing LCA studies are essential for identifying hotspots in the production process and guiding the development of more environmentally friendly manufacturing techniques.

Stability and Lifetime Enhancement Strategies

Perovskite solar cells have shown remarkable potential in photovoltaic technology, but their long-term stability remains a critical challenge for commercial viability. To address this issue, researchers and industry players are focusing on developing effective stability and lifetime enhancement strategies.

One of the primary approaches is the optimization of the perovskite material composition. By incorporating mixed cations and halides, researchers have achieved more stable perovskite structures that are less susceptible to degradation under environmental stresses. For instance, the addition of cesium or rubidium to the traditional methylammonium lead iodide perovskite has shown improved thermal and moisture stability.

Encapsulation techniques play a crucial role in protecting perovskite solar cells from external factors. Advanced encapsulation methods, such as atomic layer deposition (ALD) and chemical vapor deposition (CVD), are being explored to create ultra-thin, conformal barrier layers that effectively prevent moisture ingress and ion migration. These techniques are particularly promising for scaling up to pilot line production.

Interface engineering is another key strategy for enhancing stability. By carefully selecting and optimizing charge transport layers, researchers can mitigate interfacial degradation and improve charge extraction efficiency. Materials such as doped spiro-OMeTAD for hole transport and SnO2 for electron transport have shown promising results in enhancing device stability.

Additives and passivation agents are being investigated to reduce defects and trap states within the perovskite layer. Compounds like phenethylammonium iodide (PEAI) and potassium iodide have demonstrated the ability to passivate grain boundaries and surface defects, leading to improved operational stability and reduced hysteresis.

Light and heat management strategies are also being developed to mitigate photo-induced and thermal degradation. This includes the incorporation of UV filters and the development of thermally conductive substrates to dissipate heat more effectively. These approaches are particularly important for maintaining long-term stability under real-world operating conditions.

As the field progresses towards commercialization, accelerated aging tests and standardized stability protocols are being established to accurately predict and compare the lifetime of different perovskite solar cell architectures. This is crucial for translating lab-scale successes to pilot line production and eventual large-scale manufacturing.

One of the primary approaches is the optimization of the perovskite material composition. By incorporating mixed cations and halides, researchers have achieved more stable perovskite structures that are less susceptible to degradation under environmental stresses. For instance, the addition of cesium or rubidium to the traditional methylammonium lead iodide perovskite has shown improved thermal and moisture stability.

Encapsulation techniques play a crucial role in protecting perovskite solar cells from external factors. Advanced encapsulation methods, such as atomic layer deposition (ALD) and chemical vapor deposition (CVD), are being explored to create ultra-thin, conformal barrier layers that effectively prevent moisture ingress and ion migration. These techniques are particularly promising for scaling up to pilot line production.

Interface engineering is another key strategy for enhancing stability. By carefully selecting and optimizing charge transport layers, researchers can mitigate interfacial degradation and improve charge extraction efficiency. Materials such as doped spiro-OMeTAD for hole transport and SnO2 for electron transport have shown promising results in enhancing device stability.

Additives and passivation agents are being investigated to reduce defects and trap states within the perovskite layer. Compounds like phenethylammonium iodide (PEAI) and potassium iodide have demonstrated the ability to passivate grain boundaries and surface defects, leading to improved operational stability and reduced hysteresis.

Light and heat management strategies are also being developed to mitigate photo-induced and thermal degradation. This includes the incorporation of UV filters and the development of thermally conductive substrates to dissipate heat more effectively. These approaches are particularly important for maintaining long-term stability under real-world operating conditions.

As the field progresses towards commercialization, accelerated aging tests and standardized stability protocols are being established to accurately predict and compare the lifetime of different perovskite solar cell architectures. This is crucial for translating lab-scale successes to pilot line production and eventual large-scale manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!