Perovskite Solar Module Encapsulation: Materials, Cost, and Performance Trade-Offs

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Encapsulation Evolution and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering the potential for high efficiency and low-cost manufacturing. The evolution of perovskite encapsulation techniques has been crucial in addressing the stability and durability challenges inherent to these devices. Initially, perovskite solar cells were highly susceptible to environmental factors such as moisture, oxygen, and heat, leading to rapid degradation and limited lifespans.

The primary objective of perovskite encapsulation research has been to develop materials and methods that effectively protect the sensitive perovskite layer from these degradation factors while maintaining high device performance. Early encapsulation efforts focused on adapting techniques from organic electronics, such as glass-glass sealing with epoxy resins. However, these methods proved insufficient for the unique requirements of perovskite solar cells.

As research progressed, more sophisticated encapsulation strategies emerged. These included the development of hydrophobic and oxygen-impermeable barrier materials, as well as the incorporation of getter materials to absorb moisture and oxygen that penetrate the encapsulation. The use of flexible polymeric materials also gained traction, offering the potential for lightweight and bendable solar modules.

A significant milestone in perovskite encapsulation was the introduction of multi-layer barrier films, which combine alternating organic and inorganic layers to create a tortuous path for moisture and oxygen diffusion. This approach has shown promising results in extending the operational lifetime of perovskite solar cells from hours to months and even years under certain conditions.

Recent advancements have focused on integrating encapsulation materials that not only protect the perovskite layer but also enhance device performance. For instance, luminescent downshifting materials have been incorporated into encapsulation layers to improve light harvesting efficiency. Additionally, self-healing encapsulants that can repair minor damage over time are being explored to further extend module lifetimes.

The current objectives in perovskite encapsulation research are multifaceted. Researchers aim to develop encapsulation solutions that can provide a minimum operational lifetime of 25 years, matching the industry standard for silicon-based photovoltaics. This goal necessitates materials that can withstand prolonged exposure to UV radiation, temperature cycling, and mechanical stress while maintaining their barrier properties.

Another key objective is to reduce the cost and complexity of encapsulation processes to enable large-scale manufacturing of perovskite solar modules. This includes the development of rapid curing techniques and materials compatible with roll-to-roll processing. Furthermore, there is a growing emphasis on environmentally friendly encapsulation materials to align with sustainability goals and reduce the overall carbon footprint of perovskite solar technology.

The primary objective of perovskite encapsulation research has been to develop materials and methods that effectively protect the sensitive perovskite layer from these degradation factors while maintaining high device performance. Early encapsulation efforts focused on adapting techniques from organic electronics, such as glass-glass sealing with epoxy resins. However, these methods proved insufficient for the unique requirements of perovskite solar cells.

As research progressed, more sophisticated encapsulation strategies emerged. These included the development of hydrophobic and oxygen-impermeable barrier materials, as well as the incorporation of getter materials to absorb moisture and oxygen that penetrate the encapsulation. The use of flexible polymeric materials also gained traction, offering the potential for lightweight and bendable solar modules.

A significant milestone in perovskite encapsulation was the introduction of multi-layer barrier films, which combine alternating organic and inorganic layers to create a tortuous path for moisture and oxygen diffusion. This approach has shown promising results in extending the operational lifetime of perovskite solar cells from hours to months and even years under certain conditions.

Recent advancements have focused on integrating encapsulation materials that not only protect the perovskite layer but also enhance device performance. For instance, luminescent downshifting materials have been incorporated into encapsulation layers to improve light harvesting efficiency. Additionally, self-healing encapsulants that can repair minor damage over time are being explored to further extend module lifetimes.

The current objectives in perovskite encapsulation research are multifaceted. Researchers aim to develop encapsulation solutions that can provide a minimum operational lifetime of 25 years, matching the industry standard for silicon-based photovoltaics. This goal necessitates materials that can withstand prolonged exposure to UV radiation, temperature cycling, and mechanical stress while maintaining their barrier properties.

Another key objective is to reduce the cost and complexity of encapsulation processes to enable large-scale manufacturing of perovskite solar modules. This includes the development of rapid curing techniques and materials compatible with roll-to-roll processing. Furthermore, there is a growing emphasis on environmentally friendly encapsulation materials to align with sustainability goals and reduce the overall carbon footprint of perovskite solar technology.

Market Analysis for Perovskite Solar Modules

The perovskite solar module market is experiencing rapid growth and attracting significant attention from both industry players and investors. As a promising alternative to traditional silicon-based solar cells, perovskite technology offers several advantages, including lower production costs, higher efficiency potential, and versatility in applications.

The global market for perovskite solar modules is projected to expand substantially in the coming years, driven by increasing demand for renewable energy sources and the need for more efficient solar technologies. Key market segments include residential and commercial rooftop installations, building-integrated photovoltaics (BIPV), and portable solar devices.

One of the primary factors fueling market growth is the potential for perovskite solar modules to achieve higher power conversion efficiencies compared to conventional silicon-based solar cells. This efficiency advantage, coupled with lower manufacturing costs, positions perovskite technology as a compelling option for both large-scale solar farms and distributed energy generation.

The market is also benefiting from ongoing research and development efforts aimed at improving the stability and durability of perovskite solar modules. As these challenges are addressed, the technology is expected to gain wider acceptance and adoption across various applications.

Geographically, Asia-Pacific is emerging as a key market for perovskite solar modules, with China and Japan leading in research and development activities. Europe and North America are also significant markets, driven by supportive government policies and increasing investments in renewable energy infrastructure.

However, the market faces some challenges, including concerns about the long-term stability of perovskite materials and the need for scalable manufacturing processes. Addressing these issues will be crucial for widespread commercialization and market penetration.

Competition in the perovskite solar module market is intensifying, with both established solar companies and startups vying for market share. Strategic partnerships and collaborations between research institutions and industry players are becoming increasingly common, accelerating the pace of innovation and commercialization.

The market is also influenced by broader trends in the renewable energy sector, such as the growing focus on sustainability and the transition towards decentralized energy systems. These factors are expected to create new opportunities for perovskite solar module applications in areas such as smart cities, electric vehicle charging infrastructure, and off-grid power solutions.

The global market for perovskite solar modules is projected to expand substantially in the coming years, driven by increasing demand for renewable energy sources and the need for more efficient solar technologies. Key market segments include residential and commercial rooftop installations, building-integrated photovoltaics (BIPV), and portable solar devices.

One of the primary factors fueling market growth is the potential for perovskite solar modules to achieve higher power conversion efficiencies compared to conventional silicon-based solar cells. This efficiency advantage, coupled with lower manufacturing costs, positions perovskite technology as a compelling option for both large-scale solar farms and distributed energy generation.

The market is also benefiting from ongoing research and development efforts aimed at improving the stability and durability of perovskite solar modules. As these challenges are addressed, the technology is expected to gain wider acceptance and adoption across various applications.

Geographically, Asia-Pacific is emerging as a key market for perovskite solar modules, with China and Japan leading in research and development activities. Europe and North America are also significant markets, driven by supportive government policies and increasing investments in renewable energy infrastructure.

However, the market faces some challenges, including concerns about the long-term stability of perovskite materials and the need for scalable manufacturing processes. Addressing these issues will be crucial for widespread commercialization and market penetration.

Competition in the perovskite solar module market is intensifying, with both established solar companies and startups vying for market share. Strategic partnerships and collaborations between research institutions and industry players are becoming increasingly common, accelerating the pace of innovation and commercialization.

The market is also influenced by broader trends in the renewable energy sector, such as the growing focus on sustainability and the transition towards decentralized energy systems. These factors are expected to create new opportunities for perovskite solar module applications in areas such as smart cities, electric vehicle charging infrastructure, and off-grid power solutions.

Current Encapsulation Challenges and Limitations

Perovskite solar modules face several critical encapsulation challenges that hinder their widespread commercialization and long-term stability. One of the primary issues is the inherent moisture sensitivity of perovskite materials. When exposed to humidity, perovskites tend to degrade rapidly, leading to a significant decrease in module efficiency and overall performance. This necessitates the development of highly effective moisture barriers, which adds complexity and cost to the encapsulation process.

Thermal stability is another major concern for perovskite solar modules. The perovskite layer can undergo phase transitions or decomposition at elevated temperatures, which are often encountered during normal operating conditions or accelerated aging tests. Current encapsulation materials struggle to provide adequate thermal management while maintaining flexibility and optical transparency.

Oxygen permeation presents an additional challenge, as it can lead to oxidation of the perovskite layer and charge transport materials. Existing encapsulation techniques often fall short in completely preventing oxygen ingress over extended periods, compromising the long-term stability of the modules.

The mechanical fragility of perovskite layers poses difficulties in designing encapsulation systems that can protect against physical stresses without impacting the device's performance. Balancing the need for robust protection with the requirement for flexibility in certain applications remains a significant challenge.

UV stability is a critical factor that current encapsulation methods struggle to address effectively. Prolonged exposure to UV radiation can cause degradation of both the perovskite material and the encapsulation layers, leading to reduced module lifetime and efficiency.

Cost considerations further complicate the encapsulation challenge. Many high-performance barrier materials and advanced encapsulation techniques come with substantial cost implications, potentially offsetting the inherent cost advantages of perovskite technology. Striking a balance between performance and economic viability is crucial for commercial success.

Scalability of encapsulation processes presents another limitation. Techniques that work well for small-scale laboratory devices often face significant hurdles when scaled up to commercial module sizes. Ensuring uniform and defect-free encapsulation over large areas remains a technical challenge.

Thermal stability is another major concern for perovskite solar modules. The perovskite layer can undergo phase transitions or decomposition at elevated temperatures, which are often encountered during normal operating conditions or accelerated aging tests. Current encapsulation materials struggle to provide adequate thermal management while maintaining flexibility and optical transparency.

Oxygen permeation presents an additional challenge, as it can lead to oxidation of the perovskite layer and charge transport materials. Existing encapsulation techniques often fall short in completely preventing oxygen ingress over extended periods, compromising the long-term stability of the modules.

The mechanical fragility of perovskite layers poses difficulties in designing encapsulation systems that can protect against physical stresses without impacting the device's performance. Balancing the need for robust protection with the requirement for flexibility in certain applications remains a significant challenge.

UV stability is a critical factor that current encapsulation methods struggle to address effectively. Prolonged exposure to UV radiation can cause degradation of both the perovskite material and the encapsulation layers, leading to reduced module lifetime and efficiency.

Cost considerations further complicate the encapsulation challenge. Many high-performance barrier materials and advanced encapsulation techniques come with substantial cost implications, potentially offsetting the inherent cost advantages of perovskite technology. Striking a balance between performance and economic viability is crucial for commercial success.

Scalability of encapsulation processes presents another limitation. Techniques that work well for small-scale laboratory devices often face significant hurdles when scaled up to commercial module sizes. Ensuring uniform and defect-free encapsulation over large areas remains a technical challenge.

Existing Encapsulation Material Solutions

01 Encapsulation materials for perovskite solar modules

Various encapsulation materials are being developed to improve the performance and cost-effectiveness of perovskite solar modules. These materials aim to enhance moisture resistance, thermal stability, and overall durability of the modules. Advanced polymers, glass-based composites, and hybrid organic-inorganic materials are being explored to provide better protection for the sensitive perovskite layers.- Encapsulation materials for perovskite solar modules: Various encapsulation materials are being developed to improve the performance and cost-effectiveness of perovskite solar modules. These materials aim to protect the sensitive perovskite layer from environmental factors while maintaining high efficiency. Advanced polymers, glass-based composites, and hybrid organic-inorganic materials are being explored to enhance durability and reduce production costs.

- Cost-effective manufacturing processes: Researchers are developing innovative manufacturing techniques to reduce the overall cost of perovskite solar module production. These processes focus on scalable methods for depositing perovskite layers, implementing efficient encapsulation techniques, and optimizing material usage. Advancements in roll-to-roll processing and automated assembly lines are being explored to decrease production expenses while maintaining high-quality outputs.

- Performance enhancement through interface engineering: Interface engineering plays a crucial role in improving the performance of perovskite solar modules. By optimizing the interfaces between different layers, researchers aim to reduce charge recombination, enhance charge extraction, and improve overall device stability. Novel interface materials and treatments are being developed to boost efficiency and longevity of encapsulated perovskite modules.

- Moisture and oxygen barrier technologies: Effective moisture and oxygen barrier technologies are essential for enhancing the long-term stability of perovskite solar modules. Advanced encapsulation techniques are being developed to protect the sensitive perovskite layer from environmental degradation. These include multi-layer barrier films, edge sealants, and self-healing materials that can significantly extend the operational lifetime of the modules while maintaining their high performance.

- Integration of perovskite modules in building-integrated photovoltaics: Researchers are exploring ways to integrate perovskite solar modules into building-integrated photovoltaics (BIPV) systems. This approach aims to reduce overall installation costs and improve aesthetic appeal. Innovative encapsulation designs are being developed to allow for flexible, semi-transparent, and customizable perovskite modules that can be seamlessly incorporated into building facades, windows, and roofing materials.

02 Cost-effective manufacturing processes

Researchers are developing innovative manufacturing processes to reduce the production costs of perovskite solar modules. These include roll-to-roll printing, spray coating, and other scalable deposition techniques. The focus is on improving throughput, reducing material waste, and minimizing energy consumption during the encapsulation process, thereby lowering overall manufacturing costs.Expand Specific Solutions03 Performance enhancement through encapsulation design

Novel encapsulation designs are being implemented to enhance the performance of perovskite solar modules. These designs focus on optimizing light management, reducing interfacial losses, and improving charge extraction. Multilayer encapsulation structures, textured surfaces, and integrated optical elements are some of the approaches being explored to boost module efficiency.Expand Specific Solutions04 Long-term stability and degradation prevention

Addressing the long-term stability of perovskite solar modules is crucial for their commercial viability. Encapsulation strategies are being developed to prevent degradation caused by moisture, oxygen, and UV radiation. These include the use of barrier films, getter materials, and UV-blocking layers. The goal is to extend the operational lifetime of the modules while maintaining their high performance.Expand Specific Solutions05 Integration of perovskite modules with existing technologies

Research is ongoing to develop encapsulation methods that enable the integration of perovskite solar modules with existing photovoltaic technologies. This includes tandem solar cell configurations, where perovskite layers are combined with silicon or other established solar cell materials. The encapsulation must be compatible with both perovskite and conventional solar cell architectures to maximize overall system performance and cost-effectiveness.Expand Specific Solutions

Key Players in Perovskite Encapsulation Industry

The perovskite solar module encapsulation market is in its early growth stage, characterized by rapid technological advancements and increasing commercial interest. The global market size is projected to expand significantly in the coming years, driven by the growing demand for efficient and cost-effective solar energy solutions. While the technology is promising, it is still evolving in terms of stability and durability. Key players like Trina Solar, CSEM, and LG Electronics are investing heavily in R&D to overcome these challenges. Emerging companies such as Microquanta and Caelux are also making significant strides in perovskite technology development. The competitive landscape is dynamic, with both established solar manufacturers and innovative startups vying for market share in this potentially disruptive technology sector.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has developed advanced encapsulation techniques for perovskite solar modules, focusing on improving stability and longevity. Their approach involves a multi-layer encapsulation strategy, utilizing moisture-resistant polymers and glass-glass configurations. They have implemented a proprietary edge sealing technology that significantly reduces water ingress, a critical factor in perovskite degradation[1]. Trina's encapsulation process also incorporates UV-blocking layers to protect the perovskite material from photodegradation. The company has reported achieving module lifetimes of over 25 years in accelerated aging tests, comparable to traditional silicon modules[2]. Additionally, Trina Solar has been working on scalable manufacturing processes for these encapsulation techniques, aiming to reduce production costs while maintaining high performance[3].

Strengths: Industry-leading stability and longevity, scalable manufacturing processes. Weaknesses: Potentially higher initial costs due to advanced materials, complexity in mass production.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has pioneered innovative encapsulation materials for perovskite solar modules, focusing on inorganic-organic hybrid compositions. Their research has led to the development of a novel glass-ceramic composite encapsulant that offers superior moisture resistance and thermal stability[4]. This material combines the transparency of glass with the flexibility and low-temperature processability of ceramics. The institute has also explored the use of atomic layer deposition (ALD) for ultra-thin, conformal barrier layers that protect perovskite films without compromising light transmission[5]. Their encapsulation strategy includes the integration of self-healing polymers that can repair minor damage over time, potentially extending module lifespan[6].

Strengths: Cutting-edge materials science, potential for breakthrough performance. Weaknesses: Early stage of development, may face challenges in scaling up for commercial production.

Innovative Encapsulation Techniques Analysis

Encapsulating material for perovskite -based solar cells

PatentWO2025052310A1

Innovation

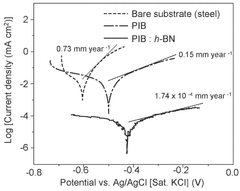

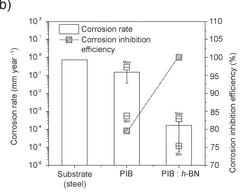

- An encapsulating material comprising a polymer matrix of polyisobutylene (PIB) with a molecular weight between 30,000 and 800,000 Da, combined with two-dimensional (2D) flakes such as hexagonal boron nitride (h-BN), which provides a solvent-free, deformation-free, and industrially usable encapsulation strategy. This material exhibits viscoelastic properties, maintaining effectiveness from -40°C to 85°C, and improves adhesion, barrier, and thermal management properties.

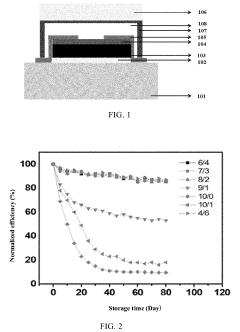

Perovskite solar cell, encapsulation method thereof, and photovoltaic assembly containing same

PatentActiveUS20230329015A1

Innovation

- A perovskite solar cell structure is developed with a transparent conductive glass substrate, transport layers, a perovskite layer, a conductive electrode, and a back plate glass encapsulated with an adhesive, forming an enclosed space filled with a mixture of inert gas and methylamine gas at a specific volume ratio, which inhibits water and oxygen contact and methylamine gas escape, enhancing stability and safety.

Cost-Performance Trade-off Assessment

The cost-performance trade-off assessment for perovskite solar module encapsulation is a critical aspect of advancing this promising technology towards commercial viability. The primary challenge lies in balancing the need for high-performance encapsulation materials with the economic constraints of large-scale production.

Current encapsulation materials, such as glass and ethylene-vinyl acetate (EVA), offer excellent protection but contribute significantly to the overall module cost. Glass, while providing superior barrier properties, adds substantial weight and rigidity to the modules. EVA, on the other hand, is more cost-effective but may not provide sufficient protection against moisture ingress, a key concern for perovskite stability.

Emerging alternatives, such as flexible polymer-based encapsulants, present an opportunity to reduce costs while maintaining adequate performance. These materials offer the potential for roll-to-roll processing, which could dramatically decrease manufacturing expenses. However, their long-term stability and barrier properties are still under investigation, necessitating careful evaluation of their cost-benefit ratio.

The trade-off between material cost and module lifespan is particularly pronounced in perovskite solar technology. Higher-quality encapsulation materials may increase initial production costs but could extend the operational life of the modules, potentially offering a better return on investment over time. Conversely, less expensive materials might reduce upfront costs but could lead to shorter module lifespans and higher replacement rates.

Performance metrics such as power conversion efficiency and degradation rates must be weighed against the cost of encapsulation materials. Advanced multi-layer encapsulation systems, incorporating moisture barriers and UV-protective coatings, may enhance module performance and longevity but at a higher material cost. The challenge lies in identifying the optimal combination of materials that maximizes performance while minimizing cost.

Manufacturing scalability is another crucial factor in the cost-performance equation. Materials that are amenable to high-throughput production processes may offer significant cost advantages, even if their individual performance characteristics are slightly inferior to more expensive alternatives. This scalability factor must be carefully considered when assessing the overall economic viability of different encapsulation strategies.

In conclusion, the cost-performance trade-off assessment for perovskite solar module encapsulation requires a holistic approach, considering not only the immediate material costs but also long-term performance, manufacturing scalability, and potential market competitiveness. Ongoing research and development efforts are focused on striking the optimal balance to propel perovskite solar technology towards widespread commercial adoption.

Current encapsulation materials, such as glass and ethylene-vinyl acetate (EVA), offer excellent protection but contribute significantly to the overall module cost. Glass, while providing superior barrier properties, adds substantial weight and rigidity to the modules. EVA, on the other hand, is more cost-effective but may not provide sufficient protection against moisture ingress, a key concern for perovskite stability.

Emerging alternatives, such as flexible polymer-based encapsulants, present an opportunity to reduce costs while maintaining adequate performance. These materials offer the potential for roll-to-roll processing, which could dramatically decrease manufacturing expenses. However, their long-term stability and barrier properties are still under investigation, necessitating careful evaluation of their cost-benefit ratio.

The trade-off between material cost and module lifespan is particularly pronounced in perovskite solar technology. Higher-quality encapsulation materials may increase initial production costs but could extend the operational life of the modules, potentially offering a better return on investment over time. Conversely, less expensive materials might reduce upfront costs but could lead to shorter module lifespans and higher replacement rates.

Performance metrics such as power conversion efficiency and degradation rates must be weighed against the cost of encapsulation materials. Advanced multi-layer encapsulation systems, incorporating moisture barriers and UV-protective coatings, may enhance module performance and longevity but at a higher material cost. The challenge lies in identifying the optimal combination of materials that maximizes performance while minimizing cost.

Manufacturing scalability is another crucial factor in the cost-performance equation. Materials that are amenable to high-throughput production processes may offer significant cost advantages, even if their individual performance characteristics are slightly inferior to more expensive alternatives. This scalability factor must be carefully considered when assessing the overall economic viability of different encapsulation strategies.

In conclusion, the cost-performance trade-off assessment for perovskite solar module encapsulation requires a holistic approach, considering not only the immediate material costs but also long-term performance, manufacturing scalability, and potential market competitiveness. Ongoing research and development efforts are focused on striking the optimal balance to propel perovskite solar technology towards widespread commercial adoption.

Environmental Impact of Encapsulation Materials

The environmental impact of encapsulation materials used in perovskite solar modules is a critical consideration in the development and deployment of this emerging photovoltaic technology. Traditional encapsulation materials, such as ethylene-vinyl acetate (EVA) and polyolefin elastomers (POE), have been widely used in silicon-based solar panels. However, the unique characteristics of perovskite solar cells necessitate a reevaluation of encapsulation strategies and their environmental implications.

One of the primary environmental concerns associated with encapsulation materials is their end-of-life disposal. Many conventional encapsulants are not biodegradable and can contribute to plastic waste accumulation. As the perovskite solar industry scales up, the potential volume of non-recyclable encapsulation materials could become a significant environmental issue. This has led to increased research into biodegradable and recyclable alternatives, such as cellulose-based materials and thermoplastic polyurethanes.

The production process of encapsulation materials also has environmental ramifications. Traditional materials often require energy-intensive manufacturing processes and may involve the use of toxic solvents or additives. In contrast, some newer encapsulation materials being developed for perovskite solar cells aim to reduce the environmental footprint of production. For instance, water-based and solvent-free encapsulation methods are being explored to minimize harmful emissions and reduce energy consumption during manufacturing.

Another important aspect is the carbon footprint associated with the transportation and installation of encapsulated perovskite modules. The weight and bulk of encapsulation materials can significantly impact shipping costs and emissions. Lightweight and thin-film encapsulation technologies are being developed to address this issue, potentially reducing the overall environmental impact of module deployment.

The longevity and durability of encapsulation materials also play a crucial role in their environmental impact. Materials that extend the operational lifetime of perovskite solar modules can reduce the frequency of replacements and, consequently, the overall waste generated. However, this must be balanced against the potential for more environmentally harmful materials that offer superior protection but are less eco-friendly in their composition or disposal.

Lastly, the interaction between encapsulation materials and perovskite compounds raises concerns about potential environmental contamination. Some perovskite formulations contain lead, and while encapsulation is designed to prevent leakage, the long-term stability and potential for environmental release must be carefully assessed. Research into lead-free perovskites and advanced encapsulation techniques that can effectively contain any hazardous materials is ongoing, aiming to mitigate these environmental risks.

One of the primary environmental concerns associated with encapsulation materials is their end-of-life disposal. Many conventional encapsulants are not biodegradable and can contribute to plastic waste accumulation. As the perovskite solar industry scales up, the potential volume of non-recyclable encapsulation materials could become a significant environmental issue. This has led to increased research into biodegradable and recyclable alternatives, such as cellulose-based materials and thermoplastic polyurethanes.

The production process of encapsulation materials also has environmental ramifications. Traditional materials often require energy-intensive manufacturing processes and may involve the use of toxic solvents or additives. In contrast, some newer encapsulation materials being developed for perovskite solar cells aim to reduce the environmental footprint of production. For instance, water-based and solvent-free encapsulation methods are being explored to minimize harmful emissions and reduce energy consumption during manufacturing.

Another important aspect is the carbon footprint associated with the transportation and installation of encapsulated perovskite modules. The weight and bulk of encapsulation materials can significantly impact shipping costs and emissions. Lightweight and thin-film encapsulation technologies are being developed to address this issue, potentially reducing the overall environmental impact of module deployment.

The longevity and durability of encapsulation materials also play a crucial role in their environmental impact. Materials that extend the operational lifetime of perovskite solar modules can reduce the frequency of replacements and, consequently, the overall waste generated. However, this must be balanced against the potential for more environmentally harmful materials that offer superior protection but are less eco-friendly in their composition or disposal.

Lastly, the interaction between encapsulation materials and perovskite compounds raises concerns about potential environmental contamination. Some perovskite formulations contain lead, and while encapsulation is designed to prevent leakage, the long-term stability and potential for environmental release must be carefully assessed. Research into lead-free perovskites and advanced encapsulation techniques that can effectively contain any hazardous materials is ongoing, aiming to mitigate these environmental risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!