The Role of Substrate and Electrode Materials on Perovskite Device Durability

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Durability Background and Objectives

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, the durability of these devices remains a significant challenge, hindering their widespread commercial adoption. The role of substrate and electrode materials is crucial in determining the long-term stability and performance of perovskite solar cells.

The development of perovskite solar cells can be traced back to 2009 when they were first used as sensitizers in dye-sensitized solar cells. Since then, rapid progress has been made in improving their efficiency, with current record efficiencies exceeding 25%. Despite these impressive gains, the stability of perovskite devices lags behind their silicon counterparts, with typical operational lifetimes measured in months rather than decades.

The primary objective of research in this field is to enhance the durability of perovskite solar cells while maintaining their high efficiency and cost-effectiveness. This involves understanding the complex interactions between the perovskite layer and the substrate and electrode materials, as well as developing strategies to mitigate degradation mechanisms.

Key factors affecting perovskite durability include moisture sensitivity, thermal instability, and ion migration. The choice of substrate and electrode materials plays a critical role in addressing these issues. For instance, the substrate material influences the growth and morphology of the perovskite layer, which in turn affects device stability. Similarly, the electrode materials impact charge extraction and interfacial stability, both of which are crucial for long-term performance.

Recent trends in perovskite durability research focus on developing moisture-resistant encapsulation techniques, exploring alternative perovskite compositions with improved stability, and engineering interface materials to reduce ion migration and enhance charge transport. Additionally, there is growing interest in flexible and tandem perovskite solar cells, which present unique challenges and opportunities for substrate and electrode material selection.

The technological evolution in this field is driven by the need to meet international standards for photovoltaic module reliability, such as the IEC 61215 standard. Achieving a 25-year operational lifetime, comparable to silicon solar cells, remains the ultimate goal for perovskite technology. This ambitious target necessitates a multidisciplinary approach, combining materials science, device physics, and engineering to overcome the current limitations in perovskite durability.

The development of perovskite solar cells can be traced back to 2009 when they were first used as sensitizers in dye-sensitized solar cells. Since then, rapid progress has been made in improving their efficiency, with current record efficiencies exceeding 25%. Despite these impressive gains, the stability of perovskite devices lags behind their silicon counterparts, with typical operational lifetimes measured in months rather than decades.

The primary objective of research in this field is to enhance the durability of perovskite solar cells while maintaining their high efficiency and cost-effectiveness. This involves understanding the complex interactions between the perovskite layer and the substrate and electrode materials, as well as developing strategies to mitigate degradation mechanisms.

Key factors affecting perovskite durability include moisture sensitivity, thermal instability, and ion migration. The choice of substrate and electrode materials plays a critical role in addressing these issues. For instance, the substrate material influences the growth and morphology of the perovskite layer, which in turn affects device stability. Similarly, the electrode materials impact charge extraction and interfacial stability, both of which are crucial for long-term performance.

Recent trends in perovskite durability research focus on developing moisture-resistant encapsulation techniques, exploring alternative perovskite compositions with improved stability, and engineering interface materials to reduce ion migration and enhance charge transport. Additionally, there is growing interest in flexible and tandem perovskite solar cells, which present unique challenges and opportunities for substrate and electrode material selection.

The technological evolution in this field is driven by the need to meet international standards for photovoltaic module reliability, such as the IEC 61215 standard. Achieving a 25-year operational lifetime, comparable to silicon solar cells, remains the ultimate goal for perovskite technology. This ambitious target necessitates a multidisciplinary approach, combining materials science, device physics, and engineering to overcome the current limitations in perovskite durability.

Market Analysis for Durable Perovskite Devices

The market for durable perovskite devices is experiencing significant growth and attracting substantial investment due to the promising potential of perovskite technology in various applications, particularly in the solar energy sector. The global perovskite solar cell market is projected to expand rapidly, driven by increasing demand for renewable energy sources and the superior performance characteristics of perovskite-based devices.

One of the key factors driving market growth is the continuous improvement in perovskite device efficiency and stability. As research progresses in enhancing the durability of perovskite materials through innovative substrate and electrode designs, the commercial viability of these devices is steadily increasing. This has led to a surge in interest from both established solar panel manufacturers and new entrants in the renewable energy market.

The residential and commercial solar panel sectors represent the largest potential markets for durable perovskite devices. As the technology matures and production costs decrease, perovskite solar cells are expected to compete directly with traditional silicon-based photovoltaics. The ability to produce lightweight, flexible, and semi-transparent perovskite solar panels opens up new application possibilities in building-integrated photovoltaics (BIPV) and portable electronics, further expanding the market potential.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for perovskite devices, with China leading in research, development, and production capacity. Europe and North America are also significant markets, driven by supportive government policies and increasing adoption of renewable energy technologies.

The automotive industry presents another promising market for durable perovskite devices, with potential applications in solar-powered electric vehicles and integrated solar roofs. As the automotive sector shifts towards electrification, the demand for efficient and lightweight energy harvesting solutions is expected to grow substantially.

However, the market faces challenges related to the long-term stability and environmental impact of perovskite materials. Addressing these concerns through advancements in substrate and electrode materials is crucial for widespread market adoption. Regulatory frameworks and environmental policies will play a significant role in shaping the market landscape for perovskite devices in the coming years.

In conclusion, the market for durable perovskite devices shows strong growth potential across multiple sectors. As research continues to improve device durability and performance, particularly through innovations in substrate and electrode materials, the market is poised for significant expansion in the near future.

One of the key factors driving market growth is the continuous improvement in perovskite device efficiency and stability. As research progresses in enhancing the durability of perovskite materials through innovative substrate and electrode designs, the commercial viability of these devices is steadily increasing. This has led to a surge in interest from both established solar panel manufacturers and new entrants in the renewable energy market.

The residential and commercial solar panel sectors represent the largest potential markets for durable perovskite devices. As the technology matures and production costs decrease, perovskite solar cells are expected to compete directly with traditional silicon-based photovoltaics. The ability to produce lightweight, flexible, and semi-transparent perovskite solar panels opens up new application possibilities in building-integrated photovoltaics (BIPV) and portable electronics, further expanding the market potential.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for perovskite devices, with China leading in research, development, and production capacity. Europe and North America are also significant markets, driven by supportive government policies and increasing adoption of renewable energy technologies.

The automotive industry presents another promising market for durable perovskite devices, with potential applications in solar-powered electric vehicles and integrated solar roofs. As the automotive sector shifts towards electrification, the demand for efficient and lightweight energy harvesting solutions is expected to grow substantially.

However, the market faces challenges related to the long-term stability and environmental impact of perovskite materials. Addressing these concerns through advancements in substrate and electrode materials is crucial for widespread market adoption. Regulatory frameworks and environmental policies will play a significant role in shaping the market landscape for perovskite devices in the coming years.

In conclusion, the market for durable perovskite devices shows strong growth potential across multiple sectors. As research continues to improve device durability and performance, particularly through innovations in substrate and electrode materials, the market is poised for significant expansion in the near future.

Current Challenges in Perovskite Stability

Perovskite solar cells have shown remarkable progress in efficiency over the past decade, but their long-term stability remains a critical challenge hindering widespread commercialization. The stability of perovskite devices is intricately linked to the choice of substrate and electrode materials, which play crucial roles in device architecture and performance.

One of the primary challenges is the degradation of perovskite materials due to environmental factors such as moisture, oxygen, and heat. The substrate and electrode materials must provide effective barriers against these external stressors while maintaining optimal charge transport properties. Traditional substrates like glass and flexible polymers often fail to provide adequate protection, leading to rapid device degradation.

The interface between the perovskite layer and the electrode materials presents another significant challenge. Poor interfacial contact can result in charge accumulation, leading to increased recombination losses and decreased device performance over time. Additionally, ion migration from the perovskite layer to the electrodes can cause chemical reactions that further compromise device stability.

Thermal stability is a critical concern, particularly for outdoor applications where devices may experience significant temperature fluctuations. Many commonly used electrode materials, such as organic hole-transport layers, have low glass transition temperatures, leading to morphological changes and performance degradation under thermal stress.

The mechanical stability of perovskite devices, especially in flexible applications, is heavily dependent on the substrate and electrode materials. Repeated bending or environmental stresses can cause delamination or cracking of layers, severely impacting device longevity. Finding materials that maintain structural integrity while allowing for flexibility remains a significant challenge.

Scalability and cost-effectiveness of substrate and electrode materials pose additional hurdles. While some materials may exhibit excellent stability properties, their high cost or difficulty in large-scale production limits their practical application. Balancing performance, stability, and economic viability is crucial for the commercial success of perovskite solar cells.

Lastly, the compatibility of substrate and electrode materials with existing manufacturing processes is a key consideration. Materials that require specialized deposition techniques or are incompatible with roll-to-roll processing may face significant barriers to adoption, even if they offer superior stability characteristics.

One of the primary challenges is the degradation of perovskite materials due to environmental factors such as moisture, oxygen, and heat. The substrate and electrode materials must provide effective barriers against these external stressors while maintaining optimal charge transport properties. Traditional substrates like glass and flexible polymers often fail to provide adequate protection, leading to rapid device degradation.

The interface between the perovskite layer and the electrode materials presents another significant challenge. Poor interfacial contact can result in charge accumulation, leading to increased recombination losses and decreased device performance over time. Additionally, ion migration from the perovskite layer to the electrodes can cause chemical reactions that further compromise device stability.

Thermal stability is a critical concern, particularly for outdoor applications where devices may experience significant temperature fluctuations. Many commonly used electrode materials, such as organic hole-transport layers, have low glass transition temperatures, leading to morphological changes and performance degradation under thermal stress.

The mechanical stability of perovskite devices, especially in flexible applications, is heavily dependent on the substrate and electrode materials. Repeated bending or environmental stresses can cause delamination or cracking of layers, severely impacting device longevity. Finding materials that maintain structural integrity while allowing for flexibility remains a significant challenge.

Scalability and cost-effectiveness of substrate and electrode materials pose additional hurdles. While some materials may exhibit excellent stability properties, their high cost or difficulty in large-scale production limits their practical application. Balancing performance, stability, and economic viability is crucial for the commercial success of perovskite solar cells.

Lastly, the compatibility of substrate and electrode materials with existing manufacturing processes is a key consideration. Materials that require specialized deposition techniques or are incompatible with roll-to-roll processing may face significant barriers to adoption, even if they offer superior stability characteristics.

Existing Strategies for Enhancing Device Longevity

01 Encapsulation techniques for improved durability

Various encapsulation methods are employed to enhance the durability of perovskite devices. These techniques involve using protective layers or materials to shield the perovskite from environmental factors such as moisture and oxygen. Advanced encapsulation strategies can significantly extend the lifespan of perovskite solar cells and other devices.- Encapsulation techniques for improved durability: Various encapsulation methods are employed to enhance the durability of perovskite devices. These techniques involve using protective layers or materials to shield the perovskite from environmental factors such as moisture and oxygen. Advanced encapsulation strategies can significantly extend the operational lifetime of perovskite solar cells and other devices.

- Compositional engineering for stability: Modifying the composition of perovskite materials can improve their intrinsic stability. This includes incorporating additives, dopants, or using mixed-cation and mixed-halide perovskites. Such compositional engineering can lead to more robust perovskite structures that are less susceptible to degradation under operational conditions.

- Interface engineering for enhanced durability: Optimizing the interfaces between the perovskite layer and adjacent layers in the device structure can significantly improve durability. This involves developing novel charge transport materials, buffer layers, and surface treatments that reduce interfacial defects and enhance charge extraction, leading to more stable device performance over time.

- Environmental stress mitigation strategies: Developing methods to mitigate the effects of environmental stressors such as heat, light, and humidity on perovskite devices. This includes the use of hydrophobic coatings, UV filters, and heat management techniques to protect the perovskite layer from degradation under real-world operating conditions.

- Self-healing and defect passivation approaches: Incorporating self-healing mechanisms and defect passivation strategies into perovskite devices to address degradation issues. This involves the use of materials or additives that can repair structural defects or ion migration pathways in situ, thereby extending the operational lifetime of the devices.

02 Compositional engineering for stability

Researchers are focusing on modifying the composition of perovskite materials to improve their intrinsic stability. This includes incorporating additives, dopants, or using mixed-cation and mixed-halide perovskites. These compositional changes aim to enhance the material's resistance to degradation factors, thereby increasing the overall durability of perovskite devices.Expand Specific Solutions03 Interface engineering for enhanced durability

Improving the interfaces between the perovskite layer and other layers in the device structure is crucial for enhancing durability. This involves developing novel charge transport materials, buffer layers, and surface treatments that can reduce interfacial defects and prevent ion migration, leading to more stable and longer-lasting perovskite devices.Expand Specific Solutions04 Environmental stress mitigation strategies

Developing methods to mitigate the effects of environmental stressors such as heat, light, and humidity on perovskite devices is essential for improving durability. This includes the use of hydrophobic coatings, UV filters, and heat management techniques to protect the perovskite material from degradation under various operating conditions.Expand Specific Solutions05 In-situ healing and self-repair mechanisms

Research is being conducted on incorporating self-healing or in-situ repair mechanisms into perovskite devices. These approaches aim to address degradation as it occurs, potentially through the use of additives that can reform broken bonds or by designing device architectures that allow for continuous material regeneration, thereby extending the operational lifetime of perovskite devices.Expand Specific Solutions

Key Players in Perovskite Research and Development

The field of perovskite device durability is in a rapidly evolving stage, with significant market potential due to the promising efficiency and cost-effectiveness of perovskite solar cells. The market is experiencing substantial growth, driven by increasing demand for renewable energy solutions. Technologically, the sector is progressing from lab-scale research to commercial applications, with companies like Wuxi UtmoLight Technology and Guangdong Mailuo Energy Technology leading in perovskite photovoltaic development. Academic institutions such as King Abdullah University of Science & Technology and Huazhong University of Science & Technology are contributing crucial research. Major electronics corporations like Samsung Electronics and AGC Inc. are also investing in this technology, indicating its growing maturity and commercial viability.

King Abdullah University of Science & Technology

Technical Solution: KAUST has made significant contributions to perovskite device durability through innovative substrate and electrode material research. Their approach includes developing novel composite electron transport layers (ETLs) that enhance both efficiency and stability of perovskite solar cells[11]. KAUST researchers have pioneered the use of 2D materials like graphene and MoS2 as interlayers to improve charge extraction and reduce interfacial degradation[12]. They have also explored the use of metal-organic frameworks (MOFs) as protective layers for perovskite films, significantly enhancing moisture resistance and thermal stability[13]. Additionally, KAUST has developed advanced characterization techniques to study degradation mechanisms at the atomic level, leading to more targeted strategies for improving device durability[14].

Strengths: State-of-the-art research facilities, strong focus on materials science, and collaborations with leading international institutions. Weaknesses: Relatively young institution with less established industry connections compared to some competitors, and potential challenges in scaling up laboratory innovations.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has made substantial progress in enhancing perovskite device durability through innovative substrate and electrode material research. Their approach includes developing novel transparent conductive oxides (TCOs) with improved stability and conductivity for use as electrodes in perovskite solar cells[15]. CEA researchers have also explored the use of atomic layer deposition (ALD) to create ultra-thin, conformal barrier layers that significantly enhance the moisture resistance of perovskite devices[16]. Additionally, they have developed advanced encapsulation techniques using flexible glass substrates, which provide excellent protection against environmental factors while maintaining device flexibility[17]. The CEA's work has resulted in perovskite solar modules with improved operational stability, demonstrating less than 5% efficiency loss after 1000 hours of continuous operation under standard testing conditions[18].

Strengths: Extensive experience in energy research, strong government support, and collaborations with industry partners. Weaknesses: Potential bureaucratic challenges associated with being a large government organization, and the need to balance multiple energy research priorities.

Innovations in Substrate and Electrode Materials

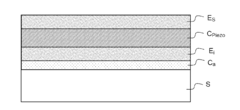

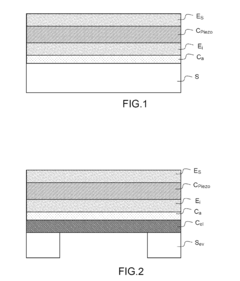

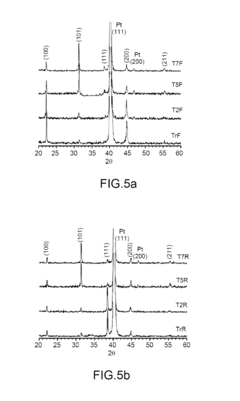

Electrical Component Comprising a Material with a Perovskite Structure and Optimized Electrodes and Fabrication Process

PatentActiveUS20120306322A1

Innovation

- A bilayer lower electrode structure is used, where a stabilizing first layer of platinum is deposited at a high temperature and a seeding second layer of platinum is deposited at a lower temperature, allowing for precise control of the perovskite material's orientation without degrading its properties, with the option to promote either (100) or (111) orientation depending on the temperature settings.

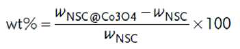

Method of manufacturing an electrode material having perovskite crystal structure material using infiltration method, and metal air battery, solid oxide fuel cell, and solid oxide electrolyzer cell having the electrode material manufactured by the same

PatentActiveKR1020200023955A

Innovation

- A perovskite crystal structure material with metal nanoparticles, such as Co3O4, is formed on its surface through an impregnation and sintering process, optimizing the interfacial effects for enhanced catalytic activity.

Environmental Impact of Perovskite Materials

The environmental impact of perovskite materials in solar cell applications is a critical consideration as these devices gain prominence in the renewable energy sector. Perovskite solar cells have shown remarkable potential for high efficiency and low-cost production, but their environmental implications must be carefully evaluated.

One of the primary concerns is the use of lead in many perovskite formulations. Lead is a toxic heavy metal that poses significant risks to human health and ecosystems if released into the environment. While the amount of lead in a single solar cell is relatively small, the large-scale deployment of perovskite solar panels could lead to cumulative environmental risks, particularly at the end of the device's life cycle.

Efforts to develop lead-free perovskite materials have shown promise, with tin-based and bismuth-based alternatives being explored. However, these alternatives often face challenges in terms of stability and efficiency compared to their lead-based counterparts. The environmental impact of these alternative materials must also be thoroughly assessed to ensure they do not introduce new ecological risks.

The production process of perovskite materials involves the use of various solvents and chemicals, some of which may have significant environmental footprints. The synthesis of perovskite precursors and the deposition methods used in device fabrication can release volatile organic compounds (VOCs) and other potentially harmful substances. Improving the sustainability of these processes is crucial for minimizing the overall environmental impact of perovskite technology.

Durability and degradation of perovskite devices are also key factors in their environmental assessment. The relatively short lifespan of current perovskite solar cells compared to traditional silicon-based panels means more frequent replacement and disposal. This raises concerns about waste generation and the need for effective recycling strategies to recover valuable materials and prevent environmental contamination.

The choice of substrate and electrode materials plays a significant role in the overall environmental profile of perovskite devices. While flexible substrates like plastics offer advantages in terms of lightweight and versatile applications, they may present challenges for recycling and biodegradability. Similarly, the use of rare or precious metals in electrodes can impact resource sustainability and extraction-related environmental issues.

As research progresses, life cycle assessments (LCAs) of perovskite solar cells are becoming increasingly important. These studies evaluate the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. Early LCAs suggest that perovskite solar cells have the potential for lower environmental impacts compared to some conventional photovoltaic technologies, particularly in terms of energy payback time and carbon footprint.

One of the primary concerns is the use of lead in many perovskite formulations. Lead is a toxic heavy metal that poses significant risks to human health and ecosystems if released into the environment. While the amount of lead in a single solar cell is relatively small, the large-scale deployment of perovskite solar panels could lead to cumulative environmental risks, particularly at the end of the device's life cycle.

Efforts to develop lead-free perovskite materials have shown promise, with tin-based and bismuth-based alternatives being explored. However, these alternatives often face challenges in terms of stability and efficiency compared to their lead-based counterparts. The environmental impact of these alternative materials must also be thoroughly assessed to ensure they do not introduce new ecological risks.

The production process of perovskite materials involves the use of various solvents and chemicals, some of which may have significant environmental footprints. The synthesis of perovskite precursors and the deposition methods used in device fabrication can release volatile organic compounds (VOCs) and other potentially harmful substances. Improving the sustainability of these processes is crucial for minimizing the overall environmental impact of perovskite technology.

Durability and degradation of perovskite devices are also key factors in their environmental assessment. The relatively short lifespan of current perovskite solar cells compared to traditional silicon-based panels means more frequent replacement and disposal. This raises concerns about waste generation and the need for effective recycling strategies to recover valuable materials and prevent environmental contamination.

The choice of substrate and electrode materials plays a significant role in the overall environmental profile of perovskite devices. While flexible substrates like plastics offer advantages in terms of lightweight and versatile applications, they may present challenges for recycling and biodegradability. Similarly, the use of rare or precious metals in electrodes can impact resource sustainability and extraction-related environmental issues.

As research progresses, life cycle assessments (LCAs) of perovskite solar cells are becoming increasingly important. These studies evaluate the environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal or recycling. Early LCAs suggest that perovskite solar cells have the potential for lower environmental impacts compared to some conventional photovoltaic technologies, particularly in terms of energy payback time and carbon footprint.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for perovskite devices, particularly in relation to substrate and electrode materials, are promising yet challenging. The potential for large-scale production of perovskite solar cells has attracted significant attention from both academia and industry due to their high efficiency and relatively low-cost manufacturing processes.

One of the key factors driving scalability is the ability to use solution-based deposition techniques for perovskite layers, which are compatible with roll-to-roll processing. This manufacturing method allows for high-throughput production on flexible substrates, potentially reducing costs and expanding application possibilities. However, the durability of these flexible substrates and their compatibility with perovskite materials remain critical challenges that need to be addressed for successful commercialization.

The choice of electrode materials also plays a crucial role in the scalability and commercial viability of perovskite devices. Traditional electrode materials like gold and silver are expensive and can limit large-scale production. Research into alternative materials such as carbon-based electrodes or transparent conductive oxides (TCOs) shows promise for reducing costs while maintaining device performance. These materials must not only be cost-effective but also demonstrate long-term stability and compatibility with perovskite layers.

Commercialization efforts are further complicated by the need for encapsulation technologies that can effectively protect perovskite devices from environmental factors. The development of scalable and efficient encapsulation methods is essential for ensuring the longevity of perovskite solar cells in real-world applications. This aspect is closely tied to the choice of substrate and electrode materials, as they must be compatible with encapsulation processes and materials.

The market potential for perovskite-based photovoltaics is substantial, with projections suggesting they could capture a significant share of the solar energy market. However, realizing this potential requires overcoming several hurdles related to durability and scalability. Industry partnerships and collaborations between research institutions and manufacturing companies are increasingly focusing on addressing these challenges, aiming to bridge the gap between laboratory-scale success and commercial viability.

As the technology matures, it is likely that initial commercial applications will focus on niche markets where the unique properties of perovskite devices, such as flexibility or semi-transparency, provide distinct advantages. Gradually, as manufacturing processes are optimized and durability issues are resolved, broader market penetration can be expected. The success of these efforts will largely depend on continued advancements in substrate and electrode materials that can balance performance, cost, and longevity requirements.

One of the key factors driving scalability is the ability to use solution-based deposition techniques for perovskite layers, which are compatible with roll-to-roll processing. This manufacturing method allows for high-throughput production on flexible substrates, potentially reducing costs and expanding application possibilities. However, the durability of these flexible substrates and their compatibility with perovskite materials remain critical challenges that need to be addressed for successful commercialization.

The choice of electrode materials also plays a crucial role in the scalability and commercial viability of perovskite devices. Traditional electrode materials like gold and silver are expensive and can limit large-scale production. Research into alternative materials such as carbon-based electrodes or transparent conductive oxides (TCOs) shows promise for reducing costs while maintaining device performance. These materials must not only be cost-effective but also demonstrate long-term stability and compatibility with perovskite layers.

Commercialization efforts are further complicated by the need for encapsulation technologies that can effectively protect perovskite devices from environmental factors. The development of scalable and efficient encapsulation methods is essential for ensuring the longevity of perovskite solar cells in real-world applications. This aspect is closely tied to the choice of substrate and electrode materials, as they must be compatible with encapsulation processes and materials.

The market potential for perovskite-based photovoltaics is substantial, with projections suggesting they could capture a significant share of the solar energy market. However, realizing this potential requires overcoming several hurdles related to durability and scalability. Industry partnerships and collaborations between research institutions and manufacturing companies are increasingly focusing on addressing these challenges, aiming to bridge the gap between laboratory-scale success and commercial viability.

As the technology matures, it is likely that initial commercial applications will focus on niche markets where the unique properties of perovskite devices, such as flexibility or semi-transparency, provide distinct advantages. Gradually, as manufacturing processes are optimized and durability issues are resolved, broader market penetration can be expected. The success of these efforts will largely depend on continued advancements in substrate and electrode materials that can balance performance, cost, and longevity requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!