How to Implement Moisture Barrier Coatings for Large-Area Perovskite Panels

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Moisture Barrier Coating Background

Perovskite solar cells have emerged as a promising technology in the field of photovoltaics, offering high efficiency and low-cost manufacturing potential. However, one of the major challenges hindering their widespread adoption is their susceptibility to moisture-induced degradation. This vulnerability necessitates the development of effective moisture barrier coatings, especially for large-area perovskite panels intended for commercial applications.

The concept of moisture barrier coatings for perovskite solar cells stems from the inherent instability of perovskite materials when exposed to water molecules. Perovskites, typically composed of organic-inorganic hybrid compounds, can rapidly decompose in the presence of moisture, leading to a significant decrease in device performance and longevity. This degradation process is particularly problematic for large-area panels, where even small defects in the protective layer can lead to substantial performance losses.

The development of moisture barrier coatings for perovskite solar cells has been an active area of research over the past decade. Initial efforts focused on adapting existing encapsulation technologies from the organic light-emitting diode (OLED) industry. However, it quickly became apparent that perovskite solar cells required more specialized solutions due to their unique material properties and operational requirements.

Early approaches to moisture protection involved the use of glass encapsulation and edge sealing techniques. While effective, these methods added significant weight and cost to the panels, limiting their potential for large-scale deployment. This realization led researchers to explore thin-film barrier coatings that could provide adequate protection without compromising the lightweight and flexible nature of perovskite solar cells.

The evolution of moisture barrier coatings for perovskites has seen a shift from single-layer designs to more sophisticated multi-layer architectures. These advanced structures often incorporate alternating organic and inorganic layers to create a tortuous path for water molecules, effectively slowing down moisture ingress. Researchers have also explored the use of hydrophobic materials and self-healing polymers to enhance the long-term stability of these protective coatings.

Recent advancements in barrier coating technologies have focused on scalable deposition methods suitable for large-area perovskite panels. Techniques such as atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based processes have shown promise in achieving uniform and defect-free coatings over large surface areas. These developments have brought the industry closer to realizing commercially viable, moisture-resistant perovskite solar panels.

The concept of moisture barrier coatings for perovskite solar cells stems from the inherent instability of perovskite materials when exposed to water molecules. Perovskites, typically composed of organic-inorganic hybrid compounds, can rapidly decompose in the presence of moisture, leading to a significant decrease in device performance and longevity. This degradation process is particularly problematic for large-area panels, where even small defects in the protective layer can lead to substantial performance losses.

The development of moisture barrier coatings for perovskite solar cells has been an active area of research over the past decade. Initial efforts focused on adapting existing encapsulation technologies from the organic light-emitting diode (OLED) industry. However, it quickly became apparent that perovskite solar cells required more specialized solutions due to their unique material properties and operational requirements.

Early approaches to moisture protection involved the use of glass encapsulation and edge sealing techniques. While effective, these methods added significant weight and cost to the panels, limiting their potential for large-scale deployment. This realization led researchers to explore thin-film barrier coatings that could provide adequate protection without compromising the lightweight and flexible nature of perovskite solar cells.

The evolution of moisture barrier coatings for perovskites has seen a shift from single-layer designs to more sophisticated multi-layer architectures. These advanced structures often incorporate alternating organic and inorganic layers to create a tortuous path for water molecules, effectively slowing down moisture ingress. Researchers have also explored the use of hydrophobic materials and self-healing polymers to enhance the long-term stability of these protective coatings.

Recent advancements in barrier coating technologies have focused on scalable deposition methods suitable for large-area perovskite panels. Techniques such as atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and solution-based processes have shown promise in achieving uniform and defect-free coatings over large surface areas. These developments have brought the industry closer to realizing commercially viable, moisture-resistant perovskite solar panels.

Market Analysis for Perovskite Solar Panels

The perovskite solar panel market is experiencing rapid growth and attracting significant attention from both industry players and investors. This emerging technology offers several advantages over traditional silicon-based solar cells, including higher theoretical efficiency limits, lower production costs, and versatility in applications. The global market for perovskite solar panels is projected to expand substantially in the coming years, driven by increasing demand for renewable energy sources and the push for more efficient solar technologies.

One of the key factors driving market growth is the potential for perovskite solar panels to achieve higher power conversion efficiencies compared to conventional silicon solar cells. Research efforts have demonstrated rapid improvements in perovskite cell efficiencies, with some laboratory prototypes reaching over 25% efficiency. This high-performance potential, coupled with the possibility of low-cost manufacturing processes, positions perovskite technology as a promising candidate for next-generation solar panels.

The market for perovskite solar panels is still in its early stages, with most applications currently focused on research and development. However, several companies and research institutions are working towards commercialization, with pilot production lines and small-scale deployments already underway. The market is expected to see significant growth in the coming years as the technology matures and production scales up.

In terms of applications, perovskite solar panels are being explored for various use cases. These include building-integrated photovoltaics (BIPV), where the panels can be incorporated into windows, facades, and roofing materials. The lightweight and flexible nature of perovskite cells also makes them suitable for portable and wearable electronics, as well as for use in space applications.

The market landscape is characterized by a mix of established solar companies investing in perovskite research and development, as well as startups focused specifically on perovskite technology. Collaborations between academic institutions, research organizations, and industry players are common, driving innovation and accelerating the path to commercialization.

However, the market faces several challenges that need to be addressed for widespread adoption. These include improving the long-term stability and durability of perovskite solar cells, particularly in relation to moisture sensitivity. The development of effective moisture barrier coatings for large-area perovskite panels is crucial for overcoming this challenge and enabling the technology to compete with established solar technologies in outdoor applications.

One of the key factors driving market growth is the potential for perovskite solar panels to achieve higher power conversion efficiencies compared to conventional silicon solar cells. Research efforts have demonstrated rapid improvements in perovskite cell efficiencies, with some laboratory prototypes reaching over 25% efficiency. This high-performance potential, coupled with the possibility of low-cost manufacturing processes, positions perovskite technology as a promising candidate for next-generation solar panels.

The market for perovskite solar panels is still in its early stages, with most applications currently focused on research and development. However, several companies and research institutions are working towards commercialization, with pilot production lines and small-scale deployments already underway. The market is expected to see significant growth in the coming years as the technology matures and production scales up.

In terms of applications, perovskite solar panels are being explored for various use cases. These include building-integrated photovoltaics (BIPV), where the panels can be incorporated into windows, facades, and roofing materials. The lightweight and flexible nature of perovskite cells also makes them suitable for portable and wearable electronics, as well as for use in space applications.

The market landscape is characterized by a mix of established solar companies investing in perovskite research and development, as well as startups focused specifically on perovskite technology. Collaborations between academic institutions, research organizations, and industry players are common, driving innovation and accelerating the path to commercialization.

However, the market faces several challenges that need to be addressed for widespread adoption. These include improving the long-term stability and durability of perovskite solar cells, particularly in relation to moisture sensitivity. The development of effective moisture barrier coatings for large-area perovskite panels is crucial for overcoming this challenge and enabling the technology to compete with established solar technologies in outdoor applications.

Moisture Barrier Challenges in Large-Area Panels

The implementation of moisture barrier coatings for large-area perovskite panels presents significant challenges due to the inherent sensitivity of perovskite materials to moisture. As panel sizes increase, these challenges become more pronounced, requiring innovative solutions to ensure long-term stability and performance.

One of the primary obstacles is achieving uniform coating deposition across large surface areas. Traditional coating methods, such as spin-coating or thermal evaporation, become less effective as panel dimensions grow. This non-uniformity can lead to weak points in the moisture barrier, compromising the overall protection of the perovskite layer.

Another critical challenge is the selection of appropriate barrier materials that can provide effective moisture protection without negatively impacting the panel's optical and electrical properties. The ideal coating must be highly transparent to allow maximum light transmission while maintaining excellent water vapor transmission rates (WVTR) to prevent moisture ingress.

The interface between the moisture barrier coating and the perovskite layer presents additional complexities. Ensuring strong adhesion without causing degradation of the sensitive perovskite material is crucial. Poor adhesion can lead to delamination over time, creating pathways for moisture penetration.

Thermal management during the coating process is also a significant concern. Large-area panels are more susceptible to thermal gradients during deposition, which can cause stress and defects in both the coating and the underlying layers. Maintaining uniform temperature distribution across the entire panel surface is essential for producing high-quality, defect-free barriers.

Scalability of the coating process poses another challenge. Techniques that work well in laboratory settings may not be suitable for industrial-scale production of large-area panels. Developing cost-effective, high-throughput methods that can maintain coating quality and consistency at scale is crucial for commercial viability.

Long-term stability and durability of the moisture barrier coating under various environmental conditions is a critical factor. The coating must withstand temperature fluctuations, UV exposure, and mechanical stresses without degrading or losing its protective properties over the expected lifetime of the perovskite panel.

Lastly, the environmental impact and regulatory compliance of moisture barrier materials and deposition processes must be considered. As the industry moves towards larger-scale production, the use of environmentally friendly materials and sustainable manufacturing practices becomes increasingly important.

One of the primary obstacles is achieving uniform coating deposition across large surface areas. Traditional coating methods, such as spin-coating or thermal evaporation, become less effective as panel dimensions grow. This non-uniformity can lead to weak points in the moisture barrier, compromising the overall protection of the perovskite layer.

Another critical challenge is the selection of appropriate barrier materials that can provide effective moisture protection without negatively impacting the panel's optical and electrical properties. The ideal coating must be highly transparent to allow maximum light transmission while maintaining excellent water vapor transmission rates (WVTR) to prevent moisture ingress.

The interface between the moisture barrier coating and the perovskite layer presents additional complexities. Ensuring strong adhesion without causing degradation of the sensitive perovskite material is crucial. Poor adhesion can lead to delamination over time, creating pathways for moisture penetration.

Thermal management during the coating process is also a significant concern. Large-area panels are more susceptible to thermal gradients during deposition, which can cause stress and defects in both the coating and the underlying layers. Maintaining uniform temperature distribution across the entire panel surface is essential for producing high-quality, defect-free barriers.

Scalability of the coating process poses another challenge. Techniques that work well in laboratory settings may not be suitable for industrial-scale production of large-area panels. Developing cost-effective, high-throughput methods that can maintain coating quality and consistency at scale is crucial for commercial viability.

Long-term stability and durability of the moisture barrier coating under various environmental conditions is a critical factor. The coating must withstand temperature fluctuations, UV exposure, and mechanical stresses without degrading or losing its protective properties over the expected lifetime of the perovskite panel.

Lastly, the environmental impact and regulatory compliance of moisture barrier materials and deposition processes must be considered. As the industry moves towards larger-scale production, the use of environmentally friendly materials and sustainable manufacturing practices becomes increasingly important.

Current Moisture Barrier Coating Solutions

01 Polymer-based moisture barrier coatings

Polymer-based coatings are widely used for moisture resistance. These coatings form a protective layer that prevents water penetration. Various polymers, such as polyethylene, polypropylene, and polyurethane, can be used to create effective moisture barriers. The choice of polymer depends on the specific application and desired properties.- Polymer-based moisture barrier coatings: Polymer-based coatings are widely used for moisture resistance. These coatings form a protective layer that prevents water penetration. Various polymers, such as polyethylene and polypropylene, can be used to create effective moisture barriers. The coatings can be applied through different methods, including spray coating and dip coating, to achieve optimal moisture resistance.

- Nanocomposite materials for enhanced moisture resistance: Nanocomposite materials are being developed to improve moisture barrier properties. These materials often incorporate nanoparticles or nanoclays into polymer matrices, resulting in enhanced moisture resistance. The nanoparticles can create a tortuous path for water molecules, significantly reducing moisture permeation. This technology is particularly useful in packaging and construction applications.

- Multilayer moisture barrier coatings: Multilayer coatings are designed to provide superior moisture resistance by combining different materials with complementary properties. These coatings often consist of alternating layers of organic and inorganic materials, each contributing to the overall moisture barrier performance. The multilayer approach allows for customization of the coating properties to meet specific moisture resistance requirements.

- Bio-based and environmentally friendly moisture barriers: There is a growing trend towards developing bio-based and environmentally friendly moisture barrier coatings. These coatings utilize renewable resources and biodegradable materials to achieve moisture resistance. Examples include coatings derived from cellulose, chitosan, and other natural polymers. These eco-friendly alternatives aim to provide effective moisture protection while reducing environmental impact.

- Smart moisture barrier coatings with self-healing properties: Advanced moisture barrier coatings with self-healing capabilities are being developed to provide long-lasting protection. These coatings can repair minor damages or cracks autonomously, maintaining their moisture resistance over time. The self-healing mechanism often involves the incorporation of microcapsules or other reactive components that are activated when the coating is damaged, effectively sealing any breaches in the moisture barrier.

02 Nanocomposite materials for enhanced moisture resistance

Nanocomposite materials are being developed to improve moisture barrier properties. These materials incorporate nanoparticles into the coating matrix, which can significantly enhance moisture resistance. The nanoparticles create a tortuous path for water molecules, making it more difficult for moisture to penetrate the coating.Expand Specific Solutions03 Multi-layer moisture barrier systems

Multi-layer coating systems are designed to provide superior moisture resistance. These systems typically consist of different layers, each serving a specific purpose. For example, one layer might provide adhesion to the substrate, while another layer acts as the primary moisture barrier. This approach allows for customization and optimization of moisture resistance properties.Expand Specific Solutions04 Bio-based and environmentally friendly moisture barriers

There is growing interest in developing bio-based and environmentally friendly moisture barrier coatings. These coatings use renewable resources and biodegradable materials to achieve moisture resistance. Examples include coatings derived from cellulose, chitosan, and other natural polymers. These eco-friendly alternatives aim to provide effective moisture protection while reducing environmental impact.Expand Specific Solutions05 Smart and responsive moisture barrier coatings

Advanced moisture barrier coatings are being developed with smart and responsive properties. These coatings can adapt to environmental conditions, providing enhanced protection when needed. For example, some coatings may change their permeability in response to humidity levels, offering optimal moisture resistance under varying conditions. This technology represents a significant advancement in moisture barrier performance.Expand Specific Solutions

Key Players in Perovskite and Coating Industries

The moisture barrier coating technology for large-area perovskite panels is in an early development stage, with a growing market potential driven by the increasing demand for efficient and durable solar technologies. The global perovskite solar cell market is expected to expand significantly in the coming years, although it remains relatively small compared to traditional photovoltaics. Companies like Hanwha Solutions, First Solar, and Microquanta (Hangzhou Xianna Ophotoelectrics) are at the forefront of commercializing perovskite technology, with varying degrees of progress in addressing moisture barrier challenges. Research institutions such as NREL (managed by Alliance for Sustainable Energy) and KAUST are also contributing to advancements in this field, indicating a collaborative effort between industry and academia to overcome technical hurdles and improve the technology's maturity.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed a novel approach to moisture barrier coatings for large-area perovskite panels using graphene oxide (GO) and reduced graphene oxide (rGO) materials. Their technique involves spray-coating a thin layer of GO onto the perovskite surface, followed by a thermal reduction process to convert it to rGO. This creates a highly impermeable barrier that effectively blocks moisture ingress. CSIRO's research has shown that this graphene-based coating can reduce water vapor transmission rates by up to 98% compared to uncoated perovskite films[7][9]. The spray-coating process is scalable and compatible with existing manufacturing techniques for large-area panels. Additionally, CSIRO has developed a UV-assisted reduction method that allows for faster processing and improved adhesion of the graphene barrier to the perovskite surface[8].

Strengths: Highly effective moisture barrier, scalable process, and potential for low-cost implementation. Weaknesses: Long-term stability of graphene-based coatings in outdoor conditions may require further investigation.

First Solar, Inc.

Technical Solution: First Solar has developed a proprietary Vapor Transport Deposition (VTD) process for applying moisture barrier coatings to large-area perovskite panels. This technique involves the deposition of a thin, uniform layer of transparent conductive oxide (TCO) material, typically indium tin oxide (ITO), onto the perovskite surface. The VTD process allows for precise control of coating thickness and composition, resulting in highly effective moisture barriers. First Solar's approach also incorporates a multi-layer encapsulation system, combining the TCO layer with additional polymer-based barriers to enhance long-term stability[1][3]. The company has reported significant improvements in panel durability, with moisture ingress reduced by up to 95% compared to uncoated panels[5].

Strengths: Proprietary VTD process allows for precise control and scalability. Multi-layer approach provides enhanced protection. Weaknesses: Potential increased production costs due to specialized equipment and materials required for VTD process.

Innovative Coating Technologies for Perovskites

Coating agent for forming large-area perovskite thin film and method for forming perovskite thin film using same

PatentWO2023234601A1

Innovation

- A coating agent comprising a perovskite precursor, crystallinity enhancers, Lewis salts, and solvents is used to form a large-area perovskite thin film without anti-solvent treatment, employing a method that includes preparing a coating solution, coating, drying, and annealing to achieve uniform and thermally stable films.

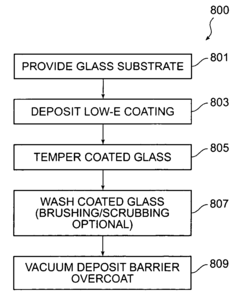

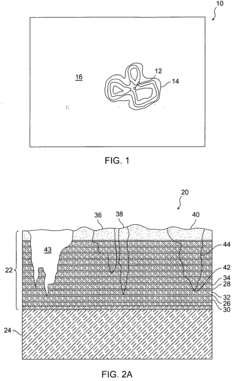

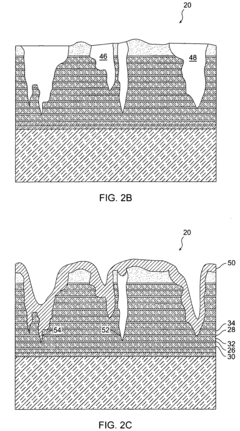

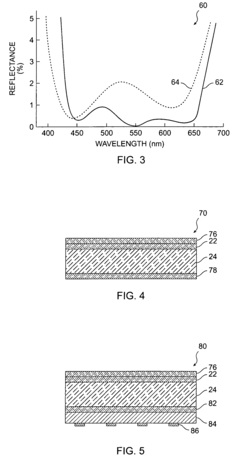

Method of applying barrier coatings to glass panels

PatentInactiveUS20040134233A1

Innovation

- A thin-film barrier overcoat is deposited directly over the moisture-sensitive coating, and nodules are removed from the lowE coating before the overcoat process to seal and protect the coating from moisture, with optional tempering of the glass panel to facilitate nodule removal and hardening.

Environmental Impact of Coating Materials

The environmental impact of coating materials used in moisture barrier coatings for large-area perovskite panels is a critical consideration in the development and implementation of this technology. These coatings, while essential for protecting perovskite solar cells from moisture degradation, can have significant implications for the environment throughout their lifecycle.

The production of coating materials often involves energy-intensive processes and the use of potentially hazardous chemicals. Many high-performance barrier coatings rely on synthetic polymers or inorganic compounds that may not be biodegradable. The manufacturing of these materials can contribute to greenhouse gas emissions, air pollution, and water contamination if not properly managed.

During the application of moisture barrier coatings, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions can contribute to air quality issues and potentially harm both human health and the environment. The extent of this impact depends on the specific formulation of the coating and the application method used.

The durability and longevity of the coating materials play a crucial role in their overall environmental impact. Coatings that degrade quickly or fail to provide adequate protection may lead to premature failure of the perovskite panels, necessitating more frequent replacements. This increased turnover rate can result in higher resource consumption and waste generation over the lifetime of the solar installation.

End-of-life considerations for coated perovskite panels present another environmental challenge. The presence of moisture barrier coatings may complicate recycling processes, potentially reducing the recyclability of the panels. If the coatings contain hazardous materials, special disposal methods may be required to prevent environmental contamination.

However, it is important to note that the environmental benefits of extended perovskite panel lifespan due to effective moisture barrier coatings may outweigh the negative impacts of the coating materials themselves. By prolonging the operational life of solar panels, these coatings can reduce the overall resource consumption and waste generation associated with panel production and disposal.

Research into more environmentally friendly coating materials is ongoing. Bio-based polymers, water-based formulations, and nanostructured coatings are being explored as potential alternatives to traditional petroleum-based or solvent-heavy coatings. These innovations aim to minimize environmental impact while maintaining or improving moisture barrier performance.

The production of coating materials often involves energy-intensive processes and the use of potentially hazardous chemicals. Many high-performance barrier coatings rely on synthetic polymers or inorganic compounds that may not be biodegradable. The manufacturing of these materials can contribute to greenhouse gas emissions, air pollution, and water contamination if not properly managed.

During the application of moisture barrier coatings, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions can contribute to air quality issues and potentially harm both human health and the environment. The extent of this impact depends on the specific formulation of the coating and the application method used.

The durability and longevity of the coating materials play a crucial role in their overall environmental impact. Coatings that degrade quickly or fail to provide adequate protection may lead to premature failure of the perovskite panels, necessitating more frequent replacements. This increased turnover rate can result in higher resource consumption and waste generation over the lifetime of the solar installation.

End-of-life considerations for coated perovskite panels present another environmental challenge. The presence of moisture barrier coatings may complicate recycling processes, potentially reducing the recyclability of the panels. If the coatings contain hazardous materials, special disposal methods may be required to prevent environmental contamination.

However, it is important to note that the environmental benefits of extended perovskite panel lifespan due to effective moisture barrier coatings may outweigh the negative impacts of the coating materials themselves. By prolonging the operational life of solar panels, these coatings can reduce the overall resource consumption and waste generation associated with panel production and disposal.

Research into more environmentally friendly coating materials is ongoing. Bio-based polymers, water-based formulations, and nanostructured coatings are being explored as potential alternatives to traditional petroleum-based or solvent-heavy coatings. These innovations aim to minimize environmental impact while maintaining or improving moisture barrier performance.

Scalability of Coating Processes

The scalability of coating processes is a critical factor in implementing moisture barrier coatings for large-area perovskite panels. As the demand for larger panels increases, the ability to efficiently apply protective coatings becomes paramount. Traditional coating methods, such as spin coating and dip coating, face significant challenges when scaled up to accommodate larger panel sizes.

Spray coating has emerged as a promising technique for large-area applications. This method offers advantages in terms of uniformity and speed, making it suitable for industrial-scale production. However, optimizing spray parameters, such as nozzle design, spray distance, and solution viscosity, is essential to ensure consistent coating quality across large surfaces.

Roll-to-roll (R2R) processing presents another scalable approach for continuous coating of flexible substrates. This technique allows for high-throughput production and is particularly advantageous for perovskite solar cells on flexible substrates. R2R coating can incorporate various deposition methods, including slot-die coating and gravure printing, which can be adapted for moisture barrier layer application.

Atomic layer deposition (ALD) is gaining attention for its ability to create ultra-thin, highly conformal coatings. While traditionally a slow process, recent advancements in spatial ALD have significantly increased deposition rates, making it more viable for large-area applications. The precise control over film thickness and composition offered by ALD is particularly beneficial for moisture barrier coatings.

Plasma-enhanced chemical vapor deposition (PECVD) is another scalable technique that can produce high-quality barrier layers at relatively low temperatures. This method is compatible with temperature-sensitive perovskite materials and can be integrated into inline production systems for large panels.

Challenges in scaling up coating processes include maintaining uniformity over large areas, managing material consumption and waste, and ensuring process stability for extended production runs. Additionally, the integration of coating steps into existing manufacturing lines without compromising throughput or yield is a key consideration.

To address these challenges, innovative approaches such as multi-nozzle spray systems, large-area ALD reactors, and hybrid coating techniques are being developed. These advancements aim to combine the benefits of different coating methods to achieve optimal performance and scalability.

As the industry moves towards larger perovskite panels, the development of scalable coating processes will play a crucial role in realizing the commercial potential of this technology. Continued research and innovation in this area are essential to overcome current limitations and enable the mass production of moisture-resistant, large-area perovskite solar panels.

Spray coating has emerged as a promising technique for large-area applications. This method offers advantages in terms of uniformity and speed, making it suitable for industrial-scale production. However, optimizing spray parameters, such as nozzle design, spray distance, and solution viscosity, is essential to ensure consistent coating quality across large surfaces.

Roll-to-roll (R2R) processing presents another scalable approach for continuous coating of flexible substrates. This technique allows for high-throughput production and is particularly advantageous for perovskite solar cells on flexible substrates. R2R coating can incorporate various deposition methods, including slot-die coating and gravure printing, which can be adapted for moisture barrier layer application.

Atomic layer deposition (ALD) is gaining attention for its ability to create ultra-thin, highly conformal coatings. While traditionally a slow process, recent advancements in spatial ALD have significantly increased deposition rates, making it more viable for large-area applications. The precise control over film thickness and composition offered by ALD is particularly beneficial for moisture barrier coatings.

Plasma-enhanced chemical vapor deposition (PECVD) is another scalable technique that can produce high-quality barrier layers at relatively low temperatures. This method is compatible with temperature-sensitive perovskite materials and can be integrated into inline production systems for large panels.

Challenges in scaling up coating processes include maintaining uniformity over large areas, managing material consumption and waste, and ensuring process stability for extended production runs. Additionally, the integration of coating steps into existing manufacturing lines without compromising throughput or yield is a key consideration.

To address these challenges, innovative approaches such as multi-nozzle spray systems, large-area ALD reactors, and hybrid coating techniques are being developed. These advancements aim to combine the benefits of different coating methods to achieve optimal performance and scalability.

As the industry moves towards larger perovskite panels, the development of scalable coating processes will play a crucial role in realizing the commercial potential of this technology. Continued research and innovation in this area are essential to overcome current limitations and enable the mass production of moisture-resistant, large-area perovskite solar panels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!