How to Achieve Robust Structural Solutions with Accura 25?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 is a stereolithography (SLA) resin developed by 3D Systems, renowned for its exceptional strength, stiffness, and durability. This material has gained significant attention in the field of additive manufacturing due to its ability to produce robust structural solutions for various applications. The evolution of Accura 25 can be traced back to the early 2000s when the demand for high-performance materials in 3D printing began to surge.

The primary objective of Accura 25 is to provide a versatile solution for creating strong, functional parts that can withstand demanding environments. This material aims to bridge the gap between prototype and end-use parts, offering properties comparable to those of engineering plastics produced through traditional manufacturing methods.

Over the years, Accura 25 has undergone several iterations to improve its performance characteristics. The material's development has been driven by the increasing need for 3D printed parts that can endure high stress, temperature variations, and chemical exposure. These advancements have positioned Accura 25 as a go-to material for industries such as aerospace, automotive, and consumer goods manufacturing.

One of the key technological trends in the development of Accura 25 has been the focus on enhancing its mechanical properties while maintaining excellent surface finish and dimensional accuracy. This has been achieved through careful formulation of the resin composition and optimization of the curing process.

The pursuit of robust structural solutions with Accura 25 aligns with the broader industry trend of moving 3D printing from rapid prototyping to production of end-use parts. This shift has necessitated continuous improvement in material properties, print quality, and post-processing techniques to meet the stringent requirements of various industrial applications.

Looking ahead, the technological goals for Accura 25 and similar materials include further improvements in impact resistance, heat deflection temperature, and long-term stability. There is also a growing emphasis on developing sustainable formulations that reduce environmental impact without compromising performance.

As we explore how to achieve robust structural solutions with Accura 25, it is essential to consider the material's unique properties, its processing requirements, and the design considerations that can maximize its potential. This investigation will involve examining the latest advancements in SLA technology, post-curing techniques, and innovative design approaches that leverage the strengths of Accura 25 to create high-performance structural components.

The primary objective of Accura 25 is to provide a versatile solution for creating strong, functional parts that can withstand demanding environments. This material aims to bridge the gap between prototype and end-use parts, offering properties comparable to those of engineering plastics produced through traditional manufacturing methods.

Over the years, Accura 25 has undergone several iterations to improve its performance characteristics. The material's development has been driven by the increasing need for 3D printed parts that can endure high stress, temperature variations, and chemical exposure. These advancements have positioned Accura 25 as a go-to material for industries such as aerospace, automotive, and consumer goods manufacturing.

One of the key technological trends in the development of Accura 25 has been the focus on enhancing its mechanical properties while maintaining excellent surface finish and dimensional accuracy. This has been achieved through careful formulation of the resin composition and optimization of the curing process.

The pursuit of robust structural solutions with Accura 25 aligns with the broader industry trend of moving 3D printing from rapid prototyping to production of end-use parts. This shift has necessitated continuous improvement in material properties, print quality, and post-processing techniques to meet the stringent requirements of various industrial applications.

Looking ahead, the technological goals for Accura 25 and similar materials include further improvements in impact resistance, heat deflection temperature, and long-term stability. There is also a growing emphasis on developing sustainable formulations that reduce environmental impact without compromising performance.

As we explore how to achieve robust structural solutions with Accura 25, it is essential to consider the material's unique properties, its processing requirements, and the design considerations that can maximize its potential. This investigation will involve examining the latest advancements in SLA technology, post-curing techniques, and innovative design approaches that leverage the strengths of Accura 25 to create high-performance structural components.

Market Demand Analysis for Robust Structural Solutions

The market demand for robust structural solutions using Accura 25 has been steadily increasing across various industries. This growth is primarily driven by the need for high-performance, durable materials in aerospace, automotive, and industrial manufacturing sectors. Accura 25 offers exceptional strength, thermal stability, and dimensional accuracy, making it an attractive option for producing complex parts and prototypes.

In the aerospace industry, there is a growing demand for lightweight yet strong components that can withstand extreme conditions. Accura 25's ability to produce parts with high heat deflection temperatures and excellent mechanical properties aligns well with these requirements. The material's resistance to chemicals and moisture also makes it suitable for producing functional prototypes and end-use parts in aircraft and spacecraft applications.

The automotive sector is another key driver of market demand for robust structural solutions using Accura 25. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing need for advanced materials that can replace traditional metal components. Accura 25's high strength-to-weight ratio and ability to produce complex geometries make it an ideal choice for creating lightweight structural parts, such as brackets, housings, and interior components.

In the industrial manufacturing sector, the demand for Accura 25 is fueled by the need for rapid prototyping and small-batch production of functional parts. The material's ability to withstand high temperatures and maintain dimensional stability under load makes it suitable for creating tooling, jigs, and fixtures used in manufacturing processes. This capability allows companies to reduce lead times and costs associated with traditional tooling methods.

The medical device industry is also showing increased interest in Accura 25 for producing robust structural solutions. The material's biocompatibility and ability to be sterilized make it suitable for creating surgical guides, medical device prototypes, and custom implants. As personalized medicine continues to advance, the demand for materials that can produce patient-specific solutions is expected to grow.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is projected to experience significant growth in the coming years. This growth is attributed to the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new materials with enhanced properties.

However, challenges such as high material costs and the need for specialized equipment may limit market penetration in some sectors. Despite these challenges, the overall market demand for robust structural solutions using Accura 25 remains strong, driven by its unique combination of properties and the growing need for advanced materials in high-performance applications.

In the aerospace industry, there is a growing demand for lightweight yet strong components that can withstand extreme conditions. Accura 25's ability to produce parts with high heat deflection temperatures and excellent mechanical properties aligns well with these requirements. The material's resistance to chemicals and moisture also makes it suitable for producing functional prototypes and end-use parts in aircraft and spacecraft applications.

The automotive sector is another key driver of market demand for robust structural solutions using Accura 25. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing need for advanced materials that can replace traditional metal components. Accura 25's high strength-to-weight ratio and ability to produce complex geometries make it an ideal choice for creating lightweight structural parts, such as brackets, housings, and interior components.

In the industrial manufacturing sector, the demand for Accura 25 is fueled by the need for rapid prototyping and small-batch production of functional parts. The material's ability to withstand high temperatures and maintain dimensional stability under load makes it suitable for creating tooling, jigs, and fixtures used in manufacturing processes. This capability allows companies to reduce lead times and costs associated with traditional tooling methods.

The medical device industry is also showing increased interest in Accura 25 for producing robust structural solutions. The material's biocompatibility and ability to be sterilized make it suitable for creating surgical guides, medical device prototypes, and custom implants. As personalized medicine continues to advance, the demand for materials that can produce patient-specific solutions is expected to grow.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is projected to experience significant growth in the coming years. This growth is attributed to the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new materials with enhanced properties.

However, challenges such as high material costs and the need for specialized equipment may limit market penetration in some sectors. Despite these challenges, the overall market demand for robust structural solutions using Accura 25 remains strong, driven by its unique combination of properties and the growing need for advanced materials in high-performance applications.

Current Challenges in Accura 25 Applications

Accura 25, a widely used stereolithography resin in additive manufacturing, faces several challenges in achieving robust structural solutions. One of the primary issues is the material's inherent brittleness, which limits its application in high-stress environments. This characteristic makes Accura 25 parts susceptible to fracture under sudden impacts or prolonged cyclic loading, potentially compromising the integrity of the final product.

Another significant challenge lies in the dimensional accuracy and stability of Accura 25 parts. The material exhibits a tendency to warp or distort during the post-curing process, particularly for large or complex geometries. This warpage can lead to deviations from the intended design specifications, affecting both form and function of the printed components. Additionally, the material's sensitivity to environmental factors such as humidity and temperature fluctuations can cause dimensional changes over time, further complicating long-term structural reliability.

The surface finish of Accura 25 parts also presents challenges in certain applications. While the material can achieve relatively smooth surfaces compared to some other 3D printing technologies, it may still require post-processing to meet high-end finish requirements. This additional step adds time and cost to the manufacturing process and may introduce variability in the final product quality.

Achieving consistent mechanical properties across different build orientations remains a hurdle for Accura 25 applications. The anisotropic nature of the stereolithography process can result in varying strength and stiffness characteristics depending on the part's orientation during printing. This anisotropy complicates design considerations and may necessitate compromises in part orientation or overengineering to ensure structural integrity in all directions.

Furthermore, the long-term durability of Accura 25 parts under various environmental conditions is a concern. The material's susceptibility to degradation when exposed to UV light or certain chemicals limits its use in outdoor or harsh industrial environments without additional protective measures. This degradation can lead to a reduction in mechanical properties over time, potentially compromising the structural integrity of the component.

Lastly, the challenge of optimizing build parameters for Accura 25 to achieve the best balance between print speed, resolution, and structural properties remains an ongoing issue. The interdependence of these factors often requires careful tuning and experimentation to find the optimal settings for each specific application, which can be time-consuming and resource-intensive.

Another significant challenge lies in the dimensional accuracy and stability of Accura 25 parts. The material exhibits a tendency to warp or distort during the post-curing process, particularly for large or complex geometries. This warpage can lead to deviations from the intended design specifications, affecting both form and function of the printed components. Additionally, the material's sensitivity to environmental factors such as humidity and temperature fluctuations can cause dimensional changes over time, further complicating long-term structural reliability.

The surface finish of Accura 25 parts also presents challenges in certain applications. While the material can achieve relatively smooth surfaces compared to some other 3D printing technologies, it may still require post-processing to meet high-end finish requirements. This additional step adds time and cost to the manufacturing process and may introduce variability in the final product quality.

Achieving consistent mechanical properties across different build orientations remains a hurdle for Accura 25 applications. The anisotropic nature of the stereolithography process can result in varying strength and stiffness characteristics depending on the part's orientation during printing. This anisotropy complicates design considerations and may necessitate compromises in part orientation or overengineering to ensure structural integrity in all directions.

Furthermore, the long-term durability of Accura 25 parts under various environmental conditions is a concern. The material's susceptibility to degradation when exposed to UV light or certain chemicals limits its use in outdoor or harsh industrial environments without additional protective measures. This degradation can lead to a reduction in mechanical properties over time, potentially compromising the structural integrity of the component.

Lastly, the challenge of optimizing build parameters for Accura 25 to achieve the best balance between print speed, resolution, and structural properties remains an ongoing issue. The interdependence of these factors often requires careful tuning and experimentation to find the optimal settings for each specific application, which can be time-consuming and resource-intensive.

Existing Structural Solutions with Accura 25

01 Structural analysis and optimization

Techniques for analyzing and optimizing the structural robustness of Accura 25, including finite element analysis, stress testing, and iterative design improvements to enhance overall structural integrity and performance under various conditions.- Structural analysis and optimization: Advanced techniques for analyzing and optimizing the structural robustness of Accura 25 components. This includes methods for assessing structural integrity, identifying weak points, and implementing design improvements to enhance overall robustness.

- Material properties and testing: Evaluation of Accura 25 material properties and development of testing protocols to ensure structural robustness. This involves characterizing mechanical properties, conducting stress tests, and analyzing material behavior under various conditions to improve product reliability.

- Simulation and modeling techniques: Utilization of advanced simulation and modeling techniques to predict and enhance the structural robustness of Accura 25 components. This includes finite element analysis, computational fluid dynamics, and other virtual testing methods to optimize designs before physical prototyping.

- Manufacturing process optimization: Refinement of manufacturing processes to improve the structural robustness of Accura 25 products. This involves optimizing parameters such as curing time, temperature control, and post-processing techniques to enhance the final product's structural integrity.

- Quality control and monitoring systems: Implementation of advanced quality control and monitoring systems to ensure consistent structural robustness in Accura 25 components. This includes the development of real-time monitoring tools, non-destructive testing methods, and data-driven quality assurance processes.

02 Material composition and properties

Investigation of the material composition of Accura 25, focusing on its mechanical properties, thermal stability, and resistance to environmental factors. This includes studies on improving the material's strength, durability, and longevity through additives or processing techniques.Expand Specific Solutions03 Manufacturing processes for enhanced robustness

Development of advanced manufacturing processes and techniques specifically tailored to improve the structural robustness of Accura 25 components. This includes optimizing 3D printing parameters, post-processing methods, and quality control measures.Expand Specific Solutions04 Testing and validation methodologies

Implementation of comprehensive testing and validation methodologies to assess and ensure the structural robustness of Accura 25 parts. This involves developing standardized test procedures, simulating real-world conditions, and utilizing advanced measurement techniques.Expand Specific Solutions05 Application-specific robustness enhancements

Tailoring the structural robustness of Accura 25 for specific applications, such as aerospace, automotive, or medical devices. This includes developing specialized formulations or treatments to meet the unique requirements and environmental challenges of different industries.Expand Specific Solutions

Key Players in Accura 25 Industry

The competitive landscape for achieving robust structural solutions with Accura 25 is characterized by a mature market with significant players across automotive, aerospace, and manufacturing sectors. Companies like Toyota, Hitachi, and Boeing are leveraging advanced materials and technologies to enhance structural integrity. The market size is substantial, driven by demand for lightweight, durable components in various industries. Technologically, the field is well-developed, with ongoing research at institutions like Zhejiang University and Northwestern Polytechnical University pushing boundaries. Companies such as JTEKT and Denso are at the forefront, integrating Accura 25 into their product lines, indicating a high level of technical maturity and market readiness.

Nikon Corp.

Technical Solution: Nikon has leveraged its expertise in optics and precision manufacturing to develop a unique approach for achieving robust structural solutions with Accura 25. Their method involves using high-precision stereolithography systems to create Accura 25 parts with exceptional surface finish and dimensional accuracy. Nikon's process incorporates advanced laser control algorithms that optimize the curing process, resulting in improved mechanical properties and reduced internal stresses in the final parts[10]. The company has also developed a proprietary post-processing technique that combines thermal treatment with UV exposure to enhance the long-term stability of Accura 25 structures. Additionally, Nikon employs advanced optical metrology systems to ensure the quality and consistency of produced parts, enabling the creation of high-performance structural components for industries such as aerospace and medical devices[11].

Strengths: Produces parts with exceptional surface finish and dimensional accuracy, improves long-term stability of Accura 25 structures, and ensures high quality through advanced metrology. Weaknesses: May be limited to smaller, precision parts due to the focus on high-resolution stereolithography, and potentially higher equipment costs.

Airbus Operations GmbH

Technical Solution: Airbus has implemented Accura 25 in their structural solutions through an innovative approach combining additive manufacturing and advanced material science. Their method involves using Accura 25 for creating precise, high-resolution prototypes and functional parts for aircraft interiors and non-critical structural components. Airbus has developed a proprietary post-processing technique that enhances the mechanical properties of Accura 25 parts, improving their durability and resistance to environmental factors[4]. The company also employs a digital twin approach, creating virtual models of Accura 25 components to simulate their performance throughout the aircraft's lifecycle, ensuring long-term structural integrity[5]. This strategy allows Airbus to rapidly iterate designs and reduce time-to-market for new aircraft components.

Strengths: Enables quick design iterations, reduces manufacturing lead times, and allows for complex geometries in aircraft components. Weaknesses: Limited to non-critical structural parts due to certification requirements, and potential long-term durability concerns in harsh aerospace environments.

Core Innovations in Accura 25 Structural Design

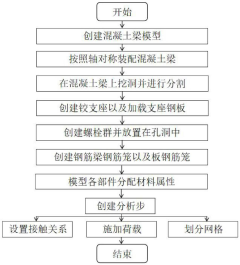

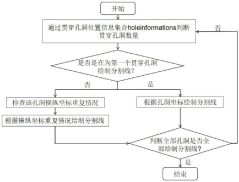

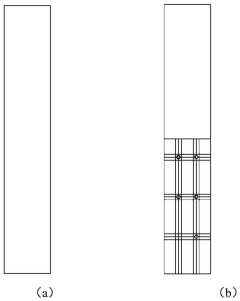

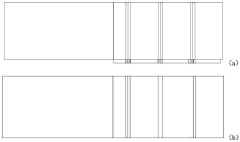

Python language-based bolt connection ECC-RC beam Abaqus model parametric modeling method

PatentActiveCN118228548A

Innovation

- The parametric modeling method of the Abaqus model of bolted ECC-RC beams based on the Python language is used to create models of concrete beams, bolts, steel cages, etc. through a series of steps, and the intelligent parametric modeling of the model is realized using the development functions that come with Python. , including operations such as setting the sketch state, dividing the model, merging parts, applying loads, etc.

Finite element simulation method for progressive damage analysis of composite material bolted connection

PatentPendingCN117828936A

Innovation

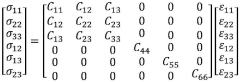

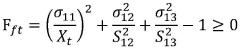

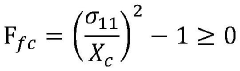

- Hashin failure criterion and VUMAT subroutine are used, combined with Abaqus finite element software, to establish a three-dimensional progressive damage analysis model of composite bolt connections, simulating the nonlinear stress distribution and initial assembly damage during the bolt tightening process. Through Hashin failure criterion and cohesive contact method Characterize intra- and inter-layer damage.

Material Properties and Characterization of Accura 25

Accura 25 is a widely used stereolithography (SLA) resin known for its versatility and performance in various applications. To achieve robust structural solutions with this material, a comprehensive understanding of its properties and characteristics is essential. Accura 25 exhibits a unique combination of strength, durability, and dimensional stability, making it suitable for producing functional prototypes and end-use parts.

The mechanical properties of Accura 25 are characterized by its high tensile strength, typically ranging from 55 to 65 MPa, and a modulus of elasticity between 2,600 and 3,000 MPa. These values indicate good load-bearing capabilities and resistance to deformation under stress. The material also demonstrates excellent elongation at break, usually between 6% and 8%, providing a balance between rigidity and flexibility that is crucial for many structural applications.

Thermal properties play a significant role in the performance of Accura 25 parts. The material has a glass transition temperature (Tg) of approximately 62°C, which defines the upper limit of its thermal stability for structural applications. Understanding this limitation is crucial when designing parts that may be exposed to elevated temperatures during operation.

Dimensional accuracy is another key characteristic of Accura 25. The material exhibits low shrinkage rates during curing, typically less than 0.2%, which contributes to its ability to produce parts with high precision and repeatability. This property is particularly valuable in applications requiring tight tolerances and consistent performance across multiple production runs.

The surface finish of parts produced with Accura 25 is generally smooth, with the potential for further improvement through post-processing techniques such as sanding or polishing. This characteristic enhances both the aesthetic appeal and functional performance of the final parts, particularly in applications where surface quality affects fluid dynamics or tribological properties.

Accura 25 also demonstrates good chemical resistance to a range of substances, including many oils, greases, and mild acids. However, it is important to note that prolonged exposure to certain solvents or strong chemicals can affect the material's integrity and performance. Proper consideration of the intended operating environment is crucial when selecting Accura 25 for specific applications.

The material's optical properties, including its translucency and ability to be tinted, offer additional design flexibility. This characteristic allows for the creation of parts that can incorporate visual indicators or light-transmitting features, expanding the range of potential applications in fields such as medical devices or consumer products.

Understanding these material properties and characteristics is fundamental to leveraging the full potential of Accura 25 in structural solutions. By carefully considering these factors in the design and manufacturing process, engineers can optimize part performance, durability, and reliability across a wide spectrum of applications.

The mechanical properties of Accura 25 are characterized by its high tensile strength, typically ranging from 55 to 65 MPa, and a modulus of elasticity between 2,600 and 3,000 MPa. These values indicate good load-bearing capabilities and resistance to deformation under stress. The material also demonstrates excellent elongation at break, usually between 6% and 8%, providing a balance between rigidity and flexibility that is crucial for many structural applications.

Thermal properties play a significant role in the performance of Accura 25 parts. The material has a glass transition temperature (Tg) of approximately 62°C, which defines the upper limit of its thermal stability for structural applications. Understanding this limitation is crucial when designing parts that may be exposed to elevated temperatures during operation.

Dimensional accuracy is another key characteristic of Accura 25. The material exhibits low shrinkage rates during curing, typically less than 0.2%, which contributes to its ability to produce parts with high precision and repeatability. This property is particularly valuable in applications requiring tight tolerances and consistent performance across multiple production runs.

The surface finish of parts produced with Accura 25 is generally smooth, with the potential for further improvement through post-processing techniques such as sanding or polishing. This characteristic enhances both the aesthetic appeal and functional performance of the final parts, particularly in applications where surface quality affects fluid dynamics or tribological properties.

Accura 25 also demonstrates good chemical resistance to a range of substances, including many oils, greases, and mild acids. However, it is important to note that prolonged exposure to certain solvents or strong chemicals can affect the material's integrity and performance. Proper consideration of the intended operating environment is crucial when selecting Accura 25 for specific applications.

The material's optical properties, including its translucency and ability to be tinted, offer additional design flexibility. This characteristic allows for the creation of parts that can incorporate visual indicators or light-transmitting features, expanding the range of potential applications in fields such as medical devices or consumer products.

Understanding these material properties and characteristics is fundamental to leveraging the full potential of Accura 25 in structural solutions. By carefully considering these factors in the design and manufacturing process, engineers can optimize part performance, durability, and reliability across a wide spectrum of applications.

Environmental Impact and Sustainability Considerations

In the pursuit of robust structural solutions using Accura 25, it is crucial to consider the environmental impact and sustainability aspects of this material and its applications. Accura 25 is a photopolymer resin widely used in stereolithography (SLA) 3D printing, known for its strength and durability. However, its environmental footprint and long-term sustainability must be carefully evaluated.

The production process of Accura 25 involves energy-intensive manufacturing and the use of petrochemical-based raw materials. This raises concerns about resource depletion and greenhouse gas emissions associated with its production. Furthermore, the curing process of the resin requires UV light, which consumes additional energy. To mitigate these impacts, manufacturers should explore renewable energy sources for production and optimize the curing process for energy efficiency.

The durability of Accura 25 structures contributes positively to sustainability by reducing the need for frequent replacements. However, the end-of-life disposal of Accura 25 products presents challenges. The material is not biodegradable and can persist in the environment for extended periods. Recycling options for Accura 25 are currently limited, as the cross-linked polymer structure makes it difficult to break down and reprocess.

To address these issues, research efforts should focus on developing bio-based alternatives to Accura 25 that maintain its robust structural properties while reducing environmental impact. Additionally, investigating methods for efficient recycling or upcycling of Accura 25 products could significantly improve its sustainability profile.

The use of Accura 25 in lightweight structural solutions can indirectly contribute to sustainability in certain applications. For instance, in aerospace or automotive industries, lighter components made with Accura 25 can lead to improved fuel efficiency and reduced emissions over the lifecycle of the vehicle or aircraft.

Water consumption and potential contamination during the manufacturing and cleaning processes of Accura 25 parts should also be considered. Implementing closed-loop water systems and efficient filtration methods can help minimize water usage and prevent the release of harmful chemicals into the environment.

As regulations around environmental protection and sustainability become more stringent, it is essential for manufacturers and users of Accura 25 to proactively address these concerns. This may involve life cycle assessments, exploring eco-friendly packaging options, and investing in research for more sustainable alternatives or improved end-of-life management strategies.

The production process of Accura 25 involves energy-intensive manufacturing and the use of petrochemical-based raw materials. This raises concerns about resource depletion and greenhouse gas emissions associated with its production. Furthermore, the curing process of the resin requires UV light, which consumes additional energy. To mitigate these impacts, manufacturers should explore renewable energy sources for production and optimize the curing process for energy efficiency.

The durability of Accura 25 structures contributes positively to sustainability by reducing the need for frequent replacements. However, the end-of-life disposal of Accura 25 products presents challenges. The material is not biodegradable and can persist in the environment for extended periods. Recycling options for Accura 25 are currently limited, as the cross-linked polymer structure makes it difficult to break down and reprocess.

To address these issues, research efforts should focus on developing bio-based alternatives to Accura 25 that maintain its robust structural properties while reducing environmental impact. Additionally, investigating methods for efficient recycling or upcycling of Accura 25 products could significantly improve its sustainability profile.

The use of Accura 25 in lightweight structural solutions can indirectly contribute to sustainability in certain applications. For instance, in aerospace or automotive industries, lighter components made with Accura 25 can lead to improved fuel efficiency and reduced emissions over the lifecycle of the vehicle or aircraft.

Water consumption and potential contamination during the manufacturing and cleaning processes of Accura 25 parts should also be considered. Implementing closed-loop water systems and efficient filtration methods can help minimize water usage and prevent the release of harmful chemicals into the environment.

As regulations around environmental protection and sustainability become more stringent, it is essential for manufacturers and users of Accura 25 to proactively address these concerns. This may involve life cycle assessments, exploring eco-friendly packaging options, and investing in research for more sustainable alternatives or improved end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!