How to Enhance Antifreeze Compatibility with Modern Engines?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Objectives

Antifreeze, also known as engine coolant, has undergone significant evolution since its inception in the early 20th century. Initially developed to prevent water from freezing in vehicle radiators, antifreeze has transformed into a sophisticated fluid crucial for modern engine performance and longevity. The primary objective of antifreeze has expanded beyond mere freeze protection to encompass a range of functions essential for today's advanced engines.

The evolution of antifreeze can be traced through several key stages. Early formulations primarily consisted of methanol or ethylene glycol mixed with water. These basic solutions effectively lowered the freezing point of the coolant but offered limited protection against corrosion and overheating. As automotive technology advanced, so did the demands placed on engine coolants.

In the mid-20th century, the introduction of inhibited ethylene glycol marked a significant milestone. This formulation not only provided freeze protection but also incorporated corrosion inhibitors to protect metal components within the cooling system. The addition of these inhibitors addressed the growing concern of engine damage caused by chemical reactions between the coolant and various metals used in engine construction.

The late 20th century saw the development of extended life coolants (ELCs) and organic acid technology (OAT) formulations. These advanced coolants offered improved protection against corrosion, cavitation, and scaling, while also extending service intervals. The shift towards more environmentally friendly options led to the introduction of propylene glycol-based coolants, which are less toxic than their ethylene glycol counterparts.

Current objectives for antifreeze technology focus on enhancing compatibility with modern engines, which are increasingly complex and operate under more demanding conditions. Key goals include improving heat transfer efficiency to support higher engine temperatures, reducing pump cavitation to enhance coolant flow, and providing better protection for aluminum components, which are now more prevalent in engine design.

Another critical objective is to develop universal coolant formulations that are compatible with a wide range of vehicle makes and models. This aim addresses the challenges posed by the proliferation of manufacturer-specific coolants, which can lead to confusion and potential engine damage if mixed incorrectly.

Furthermore, there is a growing emphasis on sustainability and environmental impact. Research is ongoing to develop bio-based coolants that offer comparable performance to traditional formulations while reducing the carbon footprint of automotive fluids. Additionally, efforts are being made to improve the recyclability of used coolants, aligning with broader automotive industry sustainability goals.

The evolution of antifreeze can be traced through several key stages. Early formulations primarily consisted of methanol or ethylene glycol mixed with water. These basic solutions effectively lowered the freezing point of the coolant but offered limited protection against corrosion and overheating. As automotive technology advanced, so did the demands placed on engine coolants.

In the mid-20th century, the introduction of inhibited ethylene glycol marked a significant milestone. This formulation not only provided freeze protection but also incorporated corrosion inhibitors to protect metal components within the cooling system. The addition of these inhibitors addressed the growing concern of engine damage caused by chemical reactions between the coolant and various metals used in engine construction.

The late 20th century saw the development of extended life coolants (ELCs) and organic acid technology (OAT) formulations. These advanced coolants offered improved protection against corrosion, cavitation, and scaling, while also extending service intervals. The shift towards more environmentally friendly options led to the introduction of propylene glycol-based coolants, which are less toxic than their ethylene glycol counterparts.

Current objectives for antifreeze technology focus on enhancing compatibility with modern engines, which are increasingly complex and operate under more demanding conditions. Key goals include improving heat transfer efficiency to support higher engine temperatures, reducing pump cavitation to enhance coolant flow, and providing better protection for aluminum components, which are now more prevalent in engine design.

Another critical objective is to develop universal coolant formulations that are compatible with a wide range of vehicle makes and models. This aim addresses the challenges posed by the proliferation of manufacturer-specific coolants, which can lead to confusion and potential engine damage if mixed incorrectly.

Furthermore, there is a growing emphasis on sustainability and environmental impact. Research is ongoing to develop bio-based coolants that offer comparable performance to traditional formulations while reducing the carbon footprint of automotive fluids. Additionally, efforts are being made to improve the recyclability of used coolants, aligning with broader automotive industry sustainability goals.

Market Analysis for Advanced Coolants

The advanced coolant market is experiencing significant growth driven by the increasing complexity of modern engine designs and the demand for more efficient thermal management systems. As automotive manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the need for advanced coolants that can effectively protect and enhance engine performance has become paramount.

The global market for advanced coolants is projected to expand at a steady rate over the next five years, with a particular focus on products that offer improved compatibility with modern engine materials and components. This growth is fueled by the automotive industry's shift towards electric and hybrid vehicles, which require specialized cooling solutions to manage battery temperatures and optimize powertrain efficiency.

In terms of regional distribution, North America and Europe currently dominate the advanced coolant market, owing to their well-established automotive industries and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid expansion of the automotive sector in countries like China and India.

The market is characterized by intense competition among key players, including major chemical companies and specialized coolant manufacturers. These companies are investing heavily in research and development to create innovative formulations that address the specific needs of modern engines, such as improved heat transfer properties, extended service life, and enhanced protection against corrosion and cavitation.

One of the key trends shaping the market is the growing demand for environmentally friendly coolants. As sustainability becomes a central focus for both consumers and regulators, there is an increasing preference for biodegradable and non-toxic coolant formulations. This trend is driving the development of new, eco-friendly products that maintain high performance while reducing environmental impact.

Another significant factor influencing the market is the rise of electric vehicles (EVs). The unique cooling requirements of EV batteries and powertrains are creating new opportunities for advanced coolant manufacturers. These specialized coolants must not only manage temperature effectively but also provide excellent electrical insulation properties to ensure the safety and longevity of EV components.

The aftermarket segment for advanced coolants is also showing strong growth potential. As vehicle owners become more aware of the importance of proper engine maintenance, there is an increasing demand for high-quality coolants that can extend engine life and improve performance. This trend is particularly evident in emerging markets, where the average age of vehicles tends to be higher.

The global market for advanced coolants is projected to expand at a steady rate over the next five years, with a particular focus on products that offer improved compatibility with modern engine materials and components. This growth is fueled by the automotive industry's shift towards electric and hybrid vehicles, which require specialized cooling solutions to manage battery temperatures and optimize powertrain efficiency.

In terms of regional distribution, North America and Europe currently dominate the advanced coolant market, owing to their well-established automotive industries and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid expansion of the automotive sector in countries like China and India.

The market is characterized by intense competition among key players, including major chemical companies and specialized coolant manufacturers. These companies are investing heavily in research and development to create innovative formulations that address the specific needs of modern engines, such as improved heat transfer properties, extended service life, and enhanced protection against corrosion and cavitation.

One of the key trends shaping the market is the growing demand for environmentally friendly coolants. As sustainability becomes a central focus for both consumers and regulators, there is an increasing preference for biodegradable and non-toxic coolant formulations. This trend is driving the development of new, eco-friendly products that maintain high performance while reducing environmental impact.

Another significant factor influencing the market is the rise of electric vehicles (EVs). The unique cooling requirements of EV batteries and powertrains are creating new opportunities for advanced coolant manufacturers. These specialized coolants must not only manage temperature effectively but also provide excellent electrical insulation properties to ensure the safety and longevity of EV components.

The aftermarket segment for advanced coolants is also showing strong growth potential. As vehicle owners become more aware of the importance of proper engine maintenance, there is an increasing demand for high-quality coolants that can extend engine life and improve performance. This trend is particularly evident in emerging markets, where the average age of vehicles tends to be higher.

Current Challenges in Antifreeze Formulations

The current challenges in antifreeze formulations for modern engines are multifaceted and complex. One of the primary issues is the increasing demand for more efficient heat transfer capabilities. As engines become more compact and powerful, the need for superior thermal management grows, putting pressure on antifreeze manufacturers to develop formulations that can effectively dissipate heat under extreme conditions.

Another significant challenge is the compatibility with new materials used in modern engine designs. Advanced alloys and composites are being incorporated into engine components, requiring antifreeze formulations that do not react adversely with these materials. This necessitates extensive testing and reformulation to ensure long-term protection against corrosion and degradation of engine parts.

Environmental concerns also pose a substantial challenge to antifreeze manufacturers. There is a growing demand for more eco-friendly formulations that reduce the environmental impact of antifreeze disposal. This includes developing biodegradable alternatives and reducing the use of toxic additives, while still maintaining the required performance characteristics.

The longevity of antifreeze formulations is another area of concern. Modern engines are designed to operate for longer periods between maintenance intervals, requiring antifreeze that can maintain its effectiveness over extended periods. This challenge is compounded by the need to protect against a wider range of temperature extremes, as vehicles are expected to perform reliably in diverse climatic conditions.

Compatibility with other fluids in the engine system is an ongoing challenge. As engine designs evolve, the interaction between antifreeze and other fluids such as motor oil, transmission fluid, and brake fluid becomes more complex. Ensuring that antifreeze formulations do not compromise the integrity or performance of these other fluids is crucial.

The increasing use of hybrid and electric vehicles presents unique challenges for antifreeze formulations. These vehicles often have different cooling requirements and may use the antifreeze for battery thermal management as well. Developing formulations that can effectively serve these dual purposes while maintaining compatibility with the electrical systems is a significant hurdle.

Lastly, the cost-effectiveness of new antifreeze formulations remains a challenge. As the complexity of formulations increases to meet the demands of modern engines, manufacturers must balance performance improvements with production costs to maintain market competitiveness. This often requires innovative approaches to sourcing ingredients and optimizing production processes.

Another significant challenge is the compatibility with new materials used in modern engine designs. Advanced alloys and composites are being incorporated into engine components, requiring antifreeze formulations that do not react adversely with these materials. This necessitates extensive testing and reformulation to ensure long-term protection against corrosion and degradation of engine parts.

Environmental concerns also pose a substantial challenge to antifreeze manufacturers. There is a growing demand for more eco-friendly formulations that reduce the environmental impact of antifreeze disposal. This includes developing biodegradable alternatives and reducing the use of toxic additives, while still maintaining the required performance characteristics.

The longevity of antifreeze formulations is another area of concern. Modern engines are designed to operate for longer periods between maintenance intervals, requiring antifreeze that can maintain its effectiveness over extended periods. This challenge is compounded by the need to protect against a wider range of temperature extremes, as vehicles are expected to perform reliably in diverse climatic conditions.

Compatibility with other fluids in the engine system is an ongoing challenge. As engine designs evolve, the interaction between antifreeze and other fluids such as motor oil, transmission fluid, and brake fluid becomes more complex. Ensuring that antifreeze formulations do not compromise the integrity or performance of these other fluids is crucial.

The increasing use of hybrid and electric vehicles presents unique challenges for antifreeze formulations. These vehicles often have different cooling requirements and may use the antifreeze for battery thermal management as well. Developing formulations that can effectively serve these dual purposes while maintaining compatibility with the electrical systems is a significant hurdle.

Lastly, the cost-effectiveness of new antifreeze formulations remains a challenge. As the complexity of formulations increases to meet the demands of modern engines, manufacturers must balance performance improvements with production costs to maintain market competitiveness. This often requires innovative approaches to sourcing ingredients and optimizing production processes.

Modern Antifreeze Solution Analysis

01 Antifreeze composition compatibility

Developing antifreeze compositions that are compatible with various cooling system materials and other fluids. This involves formulating mixtures that prevent corrosion, maintain stability, and ensure proper heat transfer across different automotive applications.- Antifreeze composition compatibility with engine materials: Antifreeze formulations are designed to be compatible with various engine materials, including metals, plastics, and rubber components. This compatibility ensures that the antifreeze does not cause corrosion, degradation, or other adverse effects on engine parts. The composition may include corrosion inhibitors and additives that protect different materials while maintaining the antifreeze's cooling properties.

- Mixing different types of antifreeze: Compatibility between different types of antifreeze is crucial when mixing or replacing coolants in a vehicle. Some antifreeze formulations are designed to be compatible with others, allowing for easier transitions or top-ups. However, mixing incompatible types can lead to reduced performance, gel formation, or precipitation of additives. It's important to consider the chemical composition and intended use when combining different antifreeze products.

- Environmental and biodegradability considerations: Antifreeze compatibility extends to environmental concerns, with some formulations designed to be more biodegradable or less toxic. These environmentally friendly options aim to reduce the impact on ecosystems in case of spills or improper disposal. The challenge lies in maintaining effective antifreeze properties while improving environmental compatibility.

- Compatibility with specific cooling system components: Certain antifreeze formulations are developed to be compatible with specific cooling system components, such as radiators, water pumps, or heat exchangers. This targeted compatibility ensures optimal performance and longevity of these components. The antifreeze may contain additives that prevent scale formation, reduce cavitation, or enhance heat transfer efficiency in specific parts of the cooling system.

- Long-life antifreeze formulations: Long-life antifreeze formulations are designed to remain compatible with engine materials and maintain their effectiveness over extended periods. These formulations often use organic acid technology (OAT) or hybrid organic acid technology (HOAT) to provide prolonged protection against corrosion and degradation. The challenge is to ensure that these long-life formulations remain compatible with a wide range of vehicle makes and models over their extended service life.

02 Compatibility testing methods

Implementing testing procedures to evaluate the compatibility of antifreeze solutions with different materials and systems. These methods assess factors such as corrosion resistance, thermal stability, and long-term performance to ensure safe and effective use in various environments.Expand Specific Solutions03 Additives for enhancing compatibility

Incorporating specific additives into antifreeze formulations to improve their compatibility with a wide range of materials and fluids. These additives can include corrosion inhibitors, stabilizers, and surfactants that enhance the overall performance and versatility of the antifreeze solution.Expand Specific Solutions04 Material selection for antifreeze systems

Choosing appropriate materials for antifreeze systems and components that are compatible with various antifreeze formulations. This involves selecting metals, plastics, and other materials that can withstand prolonged exposure to antifreeze solutions without degradation or adverse reactions.Expand Specific Solutions05 Antifreeze recycling and reuse compatibility

Developing methods for recycling and reusing antifreeze solutions while maintaining their compatibility with various systems. This includes purification techniques, additive replenishment, and testing procedures to ensure that recycled antifreeze meets performance and compatibility standards.Expand Specific Solutions

Key Antifreeze Manufacturers and Engine Makers

The antifreeze compatibility market for modern engines is in a mature stage, with a global market size estimated in billions of dollars. Technological advancements are driven by the need for more efficient and environmentally friendly solutions. Key players like BASF Corp., Adeka Corp., and Clariant Produkte (Deutschland) GmbH are at the forefront of innovation, developing advanced formulations to meet stringent engine requirements. Automotive manufacturers such as Honda Motor Co., Ltd. and Hyundai Motor Co., Ltd. are collaborating with chemical companies to ensure optimal compatibility. The market is characterized by ongoing research and development efforts to improve antifreeze performance, longevity, and environmental impact, with a focus on meeting evolving emission standards and engine technologies.

BASF Corp.

Technical Solution: BASF has developed advanced antifreeze formulations that enhance compatibility with modern engines. Their Glysantin® G40® technology utilizes organic acid technology (OAT) with silicate additives, providing superior corrosion protection for aluminum and ferrous metals[1]. This formulation is specifically designed to meet the demands of high-performance engines, offering extended service life up to 250,000 km or 5 years[2]. BASF's antifreeze solutions also incorporate special additives that prevent cavitation and reduce deposit formation in cooling systems, ensuring optimal heat transfer and engine efficiency[3].

Strengths: Excellent corrosion protection, long service life, and improved heat transfer. Weaknesses: Potentially higher cost compared to conventional antifreeze formulations.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a proprietary antifreeze formulation tailored for their modern engine designs. Their Type 2 Blue antifreeze utilizes a hybrid organic acid technology (HOAT) that combines the benefits of OAT and traditional inhibitors[4]. This formulation provides enhanced protection against corrosion, particularly for aluminum components, which are increasingly common in modern engines. Honda's antifreeze also incorporates special additives that prevent electrolysis and reduce the formation of scale deposits in the cooling system[5]. The company has conducted extensive compatibility testing to ensure their antifreeze performs optimally across their entire range of vehicles, from compact cars to high-performance models.

Strengths: Specifically designed for Honda engines, excellent aluminum protection. Weaknesses: May not be universally compatible with other manufacturers' engines.

Innovative Antifreeze Additives Research

Glycerin-containing antifreezing agent concentrates with corrosion protection

PatentWO2006092376A1

Innovation

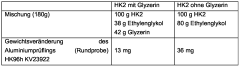

- An antifreeze/corrosion protection concentrate containing 10 to 50% glycerol by weight, with a preferred range of 15 to 35%, along with additional alcohols like ethylene glycol, and specific corrosion inhibitors such as aliphatic and aromatic acids, amines, and silicates, which are mixed with a superconcentrate to create a balanced composition for enhanced performance.

Antifreeze concentrates comprising glycerine with corrosion protection

PatentInactiveEP1859002A1

Innovation

- An antifreeze/corrosion protection concentrate containing 10 to 50% glycerol by weight, with a preferred range of 15 to 35%, along with ethylene glycol and other alcohols, and specific corrosion inhibitors to enhance both corrosion protection and frost resistance.

Environmental Impact of Antifreeze

The environmental impact of antifreeze is a critical consideration in the automotive industry, particularly as efforts to enhance antifreeze compatibility with modern engines continue. Traditional antifreeze formulations, primarily based on ethylene glycol, have long been a source of environmental concern due to their toxicity and persistence in ecosystems.

When antifreeze leaks or is improperly disposed of, it can contaminate soil and water sources, posing significant risks to wildlife and aquatic organisms. Ethylene glycol, the main component in many antifreeze products, is particularly harmful to animals, as its sweet taste attracts them, leading to ingestion and potential fatal poisoning. This has prompted the development of less toxic alternatives, such as propylene glycol-based antifreeze, which offers reduced environmental risks while maintaining similar performance characteristics.

Modern engine designs have necessitated the evolution of antifreeze formulations to meet more stringent environmental standards. The push for longer-lasting coolants has led to the introduction of organic acid technology (OAT) and hybrid organic acid technology (HOAT) antifreezes. These formulations not only provide better protection for modern engines but also have a lower environmental footprint due to their extended service life and reduced need for frequent replacement.

The disposal of antifreeze remains a significant environmental challenge. Improper disposal can lead to groundwater contamination and harm to wastewater treatment systems. To address this, many regions have implemented recycling programs for used antifreeze, which help to reduce the volume of waste and minimize environmental impact. These recycling processes typically involve removing contaminants and rejuvenating the antifreeze for reuse, significantly reducing the demand for new production and associated environmental costs.

As the automotive industry moves towards more environmentally friendly practices, there is an increasing focus on developing biodegradable antifreeze solutions. These products aim to break down more readily in the environment, reducing long-term ecological impacts. Research is ongoing to find plant-based alternatives that can match the performance of traditional antifreeze while offering improved environmental credentials.

The environmental impact of antifreeze also extends to its production process. Manufacturers are increasingly adopting greener production methods, including the use of renewable energy sources and more efficient manufacturing techniques to reduce the carbon footprint associated with antifreeze production. Additionally, there is a growing trend towards using recycled materials in antifreeze packaging, further contributing to overall sustainability efforts in the industry.

When antifreeze leaks or is improperly disposed of, it can contaminate soil and water sources, posing significant risks to wildlife and aquatic organisms. Ethylene glycol, the main component in many antifreeze products, is particularly harmful to animals, as its sweet taste attracts them, leading to ingestion and potential fatal poisoning. This has prompted the development of less toxic alternatives, such as propylene glycol-based antifreeze, which offers reduced environmental risks while maintaining similar performance characteristics.

Modern engine designs have necessitated the evolution of antifreeze formulations to meet more stringent environmental standards. The push for longer-lasting coolants has led to the introduction of organic acid technology (OAT) and hybrid organic acid technology (HOAT) antifreezes. These formulations not only provide better protection for modern engines but also have a lower environmental footprint due to their extended service life and reduced need for frequent replacement.

The disposal of antifreeze remains a significant environmental challenge. Improper disposal can lead to groundwater contamination and harm to wastewater treatment systems. To address this, many regions have implemented recycling programs for used antifreeze, which help to reduce the volume of waste and minimize environmental impact. These recycling processes typically involve removing contaminants and rejuvenating the antifreeze for reuse, significantly reducing the demand for new production and associated environmental costs.

As the automotive industry moves towards more environmentally friendly practices, there is an increasing focus on developing biodegradable antifreeze solutions. These products aim to break down more readily in the environment, reducing long-term ecological impacts. Research is ongoing to find plant-based alternatives that can match the performance of traditional antifreeze while offering improved environmental credentials.

The environmental impact of antifreeze also extends to its production process. Manufacturers are increasingly adopting greener production methods, including the use of renewable energy sources and more efficient manufacturing techniques to reduce the carbon footprint associated with antifreeze production. Additionally, there is a growing trend towards using recycled materials in antifreeze packaging, further contributing to overall sustainability efforts in the industry.

Antifreeze Testing and Standards

Antifreeze testing and standards play a crucial role in ensuring the compatibility and effectiveness of antifreeze solutions with modern engines. As engine technologies continue to evolve, the requirements for antifreeze formulations have become increasingly stringent, necessitating more comprehensive and rigorous testing procedures.

The American Society for Testing and Materials (ASTM) has developed a series of standardized tests to evaluate the performance of antifreeze solutions. These tests assess various properties, including corrosion protection, heat transfer efficiency, and chemical stability. The ASTM D3306 standard, for instance, specifies the requirements for glycol-based engine coolants used in automotive applications.

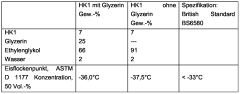

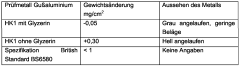

One of the key tests in the ASTM battery is the ASTM D1384, which evaluates the corrosion protection provided by antifreeze solutions. This test simulates the conditions inside an engine cooling system, exposing metal specimens to the antifreeze solution for extended periods. The results are used to determine the solution's ability to prevent corrosion of various engine materials, including cast iron, steel, aluminum, copper, brass, and solder.

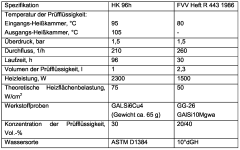

In addition to corrosion protection, antifreeze solutions must also demonstrate compatibility with modern engine materials and components. The ASTM D4340 test assesses the effects of antifreeze on aluminum heat rejection surfaces, which are increasingly common in modern engines due to their lightweight properties and excellent heat dissipation characteristics.

To address the specific needs of heavy-duty diesel engines, the ASTM D6210 standard has been developed. This standard includes more rigorous testing procedures, such as the cavitation-erosion test (ASTM D7583), which evaluates the antifreeze's ability to protect cylinder liners from cavitation damage.

As environmental concerns grow, new standards are emerging to assess the biodegradability and environmental impact of antifreeze solutions. The ASTM D5864 test method, for example, determines the aerobic aquatic biodegradation of lubricants or their components, which can be applied to antifreeze formulations.

In Europe, the British Standards Institution (BSI) has developed its own set of standards for antifreeze testing, including BS 6580:2010. This standard specifies the requirements for ethylene glycol-based engine coolants and includes tests for compatibility with non-metallic materials commonly found in modern cooling systems.

To enhance antifreeze compatibility with modern engines, manufacturers must not only meet these established standards but also anticipate future requirements. This involves continuous research and development to improve formulations, focusing on aspects such as extended service life, improved heat transfer properties, and compatibility with advanced materials used in electric and hybrid vehicle cooling systems.

The American Society for Testing and Materials (ASTM) has developed a series of standardized tests to evaluate the performance of antifreeze solutions. These tests assess various properties, including corrosion protection, heat transfer efficiency, and chemical stability. The ASTM D3306 standard, for instance, specifies the requirements for glycol-based engine coolants used in automotive applications.

One of the key tests in the ASTM battery is the ASTM D1384, which evaluates the corrosion protection provided by antifreeze solutions. This test simulates the conditions inside an engine cooling system, exposing metal specimens to the antifreeze solution for extended periods. The results are used to determine the solution's ability to prevent corrosion of various engine materials, including cast iron, steel, aluminum, copper, brass, and solder.

In addition to corrosion protection, antifreeze solutions must also demonstrate compatibility with modern engine materials and components. The ASTM D4340 test assesses the effects of antifreeze on aluminum heat rejection surfaces, which are increasingly common in modern engines due to their lightweight properties and excellent heat dissipation characteristics.

To address the specific needs of heavy-duty diesel engines, the ASTM D6210 standard has been developed. This standard includes more rigorous testing procedures, such as the cavitation-erosion test (ASTM D7583), which evaluates the antifreeze's ability to protect cylinder liners from cavitation damage.

As environmental concerns grow, new standards are emerging to assess the biodegradability and environmental impact of antifreeze solutions. The ASTM D5864 test method, for example, determines the aerobic aquatic biodegradation of lubricants or their components, which can be applied to antifreeze formulations.

In Europe, the British Standards Institution (BSI) has developed its own set of standards for antifreeze testing, including BS 6580:2010. This standard specifies the requirements for ethylene glycol-based engine coolants and includes tests for compatibility with non-metallic materials commonly found in modern cooling systems.

To enhance antifreeze compatibility with modern engines, manufacturers must not only meet these established standards but also anticipate future requirements. This involves continuous research and development to improve formulations, focusing on aspects such as extended service life, improved heat transfer properties, and compatibility with advanced materials used in electric and hybrid vehicle cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!