How to Implement Antifreeze in Biotechnology Applications?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze in Biotech: Background and Objectives

Antifreeze proteins (AFPs) and antifreeze glycoproteins (AFGPs) are remarkable biomolecules found in various organisms, including fish, insects, and plants, that have evolved to survive in sub-zero temperatures. These proteins have the unique ability to inhibit ice crystal growth and recrystallization, making them invaluable in biotechnology applications. The discovery of antifreeze proteins dates back to the 1950s when scientists observed that certain fish species could survive in freezing Arctic waters without their blood freezing.

The primary objective of implementing antifreeze in biotechnology applications is to harness the ice-binding and recrystallization inhibition properties of these proteins to enhance the preservation of biological materials and improve the quality of frozen products. This technology has far-reaching implications across various sectors, including medicine, food science, and agriculture.

In the medical field, antifreeze proteins hold promise for improving the cryopreservation of organs, tissues, and cells for transplantation and research purposes. By preventing ice crystal formation during freezing and thawing processes, these proteins can significantly reduce cellular damage and maintain the viability of biological samples. This could potentially revolutionize organ transplantation by extending the preservation time of donor organs and increasing their availability.

The food industry stands to benefit greatly from antifreeze technology, particularly in the production of frozen foods and ice cream. By incorporating antifreeze proteins into food products, manufacturers can improve texture, prevent ice crystal growth during storage, and enhance the overall quality and shelf life of frozen goods. This not only leads to better consumer experiences but also reduces food waste and extends distribution capabilities.

In agriculture, antifreeze proteins offer potential solutions for crop protection against frost damage. By developing transgenic plants that express antifreeze proteins, researchers aim to enhance the cold tolerance of economically important crops, potentially expanding cultivation zones and improving food security in regions prone to frost.

The evolution of antifreeze technology in biotechnology applications has been driven by advancements in protein engineering, recombinant DNA technology, and our understanding of protein-ice interactions. As research progresses, scientists are exploring synthetic antifreeze compounds and novel applications in materials science, such as de-icing solutions for aircraft and wind turbines.

The implementation of antifreeze in biotechnology faces several challenges, including the need for cost-effective production methods, regulatory approval for various applications, and addressing potential allergenicity concerns. However, the potential benefits and wide-ranging applications continue to drive research and development in this field, promising innovative solutions to longstanding problems in cryopreservation and cold tolerance across multiple industries.

The primary objective of implementing antifreeze in biotechnology applications is to harness the ice-binding and recrystallization inhibition properties of these proteins to enhance the preservation of biological materials and improve the quality of frozen products. This technology has far-reaching implications across various sectors, including medicine, food science, and agriculture.

In the medical field, antifreeze proteins hold promise for improving the cryopreservation of organs, tissues, and cells for transplantation and research purposes. By preventing ice crystal formation during freezing and thawing processes, these proteins can significantly reduce cellular damage and maintain the viability of biological samples. This could potentially revolutionize organ transplantation by extending the preservation time of donor organs and increasing their availability.

The food industry stands to benefit greatly from antifreeze technology, particularly in the production of frozen foods and ice cream. By incorporating antifreeze proteins into food products, manufacturers can improve texture, prevent ice crystal growth during storage, and enhance the overall quality and shelf life of frozen goods. This not only leads to better consumer experiences but also reduces food waste and extends distribution capabilities.

In agriculture, antifreeze proteins offer potential solutions for crop protection against frost damage. By developing transgenic plants that express antifreeze proteins, researchers aim to enhance the cold tolerance of economically important crops, potentially expanding cultivation zones and improving food security in regions prone to frost.

The evolution of antifreeze technology in biotechnology applications has been driven by advancements in protein engineering, recombinant DNA technology, and our understanding of protein-ice interactions. As research progresses, scientists are exploring synthetic antifreeze compounds and novel applications in materials science, such as de-icing solutions for aircraft and wind turbines.

The implementation of antifreeze in biotechnology faces several challenges, including the need for cost-effective production methods, regulatory approval for various applications, and addressing potential allergenicity concerns. However, the potential benefits and wide-ranging applications continue to drive research and development in this field, promising innovative solutions to longstanding problems in cryopreservation and cold tolerance across multiple industries.

Market Analysis for Cryopreservation Solutions

The cryopreservation solutions market has experienced significant growth in recent years, driven by advancements in biotechnology and increasing demand for long-term preservation of biological materials. This market encompasses a wide range of products, including antifreeze proteins, cryoprotectants, and specialized media designed to protect cells, tissues, and organs during freezing and thawing processes.

The global cryopreservation solutions market was valued at approximately $1.7 billion in 2020 and is projected to reach $3.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 10.5% during the forecast period. This growth is primarily attributed to the expanding applications of cryopreservation in various sectors, including healthcare, pharmaceuticals, and biotechnology research.

One of the key drivers of market growth is the increasing demand for stem cell banking and regenerative medicine. As stem cell therapies gain traction in treating various diseases, the need for effective cryopreservation solutions to maintain the viability and functionality of these cells has surged. The cord blood banking segment, in particular, has shown substantial growth, with a market size of $1.1 billion in 2020 and expected to reach $2.4 billion by 2026.

The pharmaceutical and biotechnology industries are also significant contributors to the cryopreservation solutions market. These sectors rely heavily on cryopreservation for the storage and transport of biological samples, drug compounds, and cell lines used in research and development. The market for cryopreservation solutions in drug discovery and development is expected to grow at a CAGR of 12.3% from 2021 to 2026.

Geographically, North America dominates the cryopreservation solutions market, accounting for approximately 40% of the global market share. This dominance is attributed to the presence of major biotechnology and pharmaceutical companies, advanced healthcare infrastructure, and significant investments in research and development. Europe follows closely, with a market share of around 30%, driven by increasing government funding for biomedical research and a growing focus on personalized medicine.

The Asia-Pacific region is emerging as the fastest-growing market for cryopreservation solutions, with a projected CAGR of 13.2% from 2021 to 2026. This growth is fueled by rapid advancements in healthcare infrastructure, increasing research activities, and rising investments in biotechnology across countries like China, Japan, and India.

Key players in the cryopreservation solutions market include Thermo Fisher Scientific, Merck KGaA, BioLife Solutions, and Cytiva. These companies are focusing on developing innovative antifreeze solutions and cryoprotectants to enhance the efficiency and reliability of cryopreservation processes. The market is characterized by intense competition and a trend towards strategic collaborations and partnerships to expand product portfolios and geographical presence.

The global cryopreservation solutions market was valued at approximately $1.7 billion in 2020 and is projected to reach $3.2 billion by 2026, growing at a compound annual growth rate (CAGR) of 10.5% during the forecast period. This growth is primarily attributed to the expanding applications of cryopreservation in various sectors, including healthcare, pharmaceuticals, and biotechnology research.

One of the key drivers of market growth is the increasing demand for stem cell banking and regenerative medicine. As stem cell therapies gain traction in treating various diseases, the need for effective cryopreservation solutions to maintain the viability and functionality of these cells has surged. The cord blood banking segment, in particular, has shown substantial growth, with a market size of $1.1 billion in 2020 and expected to reach $2.4 billion by 2026.

The pharmaceutical and biotechnology industries are also significant contributors to the cryopreservation solutions market. These sectors rely heavily on cryopreservation for the storage and transport of biological samples, drug compounds, and cell lines used in research and development. The market for cryopreservation solutions in drug discovery and development is expected to grow at a CAGR of 12.3% from 2021 to 2026.

Geographically, North America dominates the cryopreservation solutions market, accounting for approximately 40% of the global market share. This dominance is attributed to the presence of major biotechnology and pharmaceutical companies, advanced healthcare infrastructure, and significant investments in research and development. Europe follows closely, with a market share of around 30%, driven by increasing government funding for biomedical research and a growing focus on personalized medicine.

The Asia-Pacific region is emerging as the fastest-growing market for cryopreservation solutions, with a projected CAGR of 13.2% from 2021 to 2026. This growth is fueled by rapid advancements in healthcare infrastructure, increasing research activities, and rising investments in biotechnology across countries like China, Japan, and India.

Key players in the cryopreservation solutions market include Thermo Fisher Scientific, Merck KGaA, BioLife Solutions, and Cytiva. These companies are focusing on developing innovative antifreeze solutions and cryoprotectants to enhance the efficiency and reliability of cryopreservation processes. The market is characterized by intense competition and a trend towards strategic collaborations and partnerships to expand product portfolios and geographical presence.

Current Challenges in Biotech Antifreeze Technology

The implementation of antifreeze technologies in biotechnology applications faces several significant challenges. One of the primary obstacles is the potential toxicity of traditional antifreeze compounds to biological systems. Many conventional antifreeze agents, such as ethylene glycol or propylene glycol, can be harmful to cells and organisms, limiting their use in biotech applications.

Another major challenge is maintaining the functionality and stability of biomolecules in the presence of antifreeze agents. Proteins, enzymes, and other biological components often exhibit altered activity or undergo denaturation when exposed to antifreeze compounds, compromising their intended functions in biotechnological processes.

The scalability of antifreeze solutions for large-scale biotech applications presents additional difficulties. Developing cost-effective and efficient methods for producing and incorporating antifreeze agents into biological systems at industrial scales remains a significant hurdle.

Furthermore, the complexity of biological systems makes it challenging to predict and control the interactions between antifreeze compounds and various cellular components. This unpredictability can lead to unintended consequences and affect the overall performance of biotech processes.

Regulatory compliance and safety considerations also pose challenges in implementing antifreeze technologies in biotechnology. Stringent regulations govern the use of additives in biotech products, particularly those intended for medical or food-related applications, necessitating extensive testing and validation processes.

The development of bio-compatible and biodegradable antifreeze agents is another area of concern. Creating compounds that can effectively prevent freezing while remaining environmentally friendly and easily metabolized by biological systems is a complex task that requires innovative approaches.

Additionally, the diverse range of biotechnology applications, each with unique requirements, complicates the development of universal antifreeze solutions. Tailoring antifreeze technologies to specific biotech processes, such as cryopreservation, biofuel production, or enzyme stabilization, demands specialized research and development efforts.

Lastly, the integration of antifreeze technologies with existing biotech infrastructure and processes presents technical and logistical challenges. Modifying established protocols and equipment to accommodate new antifreeze methods often requires significant investments in time, resources, and expertise.

Another major challenge is maintaining the functionality and stability of biomolecules in the presence of antifreeze agents. Proteins, enzymes, and other biological components often exhibit altered activity or undergo denaturation when exposed to antifreeze compounds, compromising their intended functions in biotechnological processes.

The scalability of antifreeze solutions for large-scale biotech applications presents additional difficulties. Developing cost-effective and efficient methods for producing and incorporating antifreeze agents into biological systems at industrial scales remains a significant hurdle.

Furthermore, the complexity of biological systems makes it challenging to predict and control the interactions between antifreeze compounds and various cellular components. This unpredictability can lead to unintended consequences and affect the overall performance of biotech processes.

Regulatory compliance and safety considerations also pose challenges in implementing antifreeze technologies in biotechnology. Stringent regulations govern the use of additives in biotech products, particularly those intended for medical or food-related applications, necessitating extensive testing and validation processes.

The development of bio-compatible and biodegradable antifreeze agents is another area of concern. Creating compounds that can effectively prevent freezing while remaining environmentally friendly and easily metabolized by biological systems is a complex task that requires innovative approaches.

Additionally, the diverse range of biotechnology applications, each with unique requirements, complicates the development of universal antifreeze solutions. Tailoring antifreeze technologies to specific biotech processes, such as cryopreservation, biofuel production, or enzyme stabilization, demands specialized research and development efforts.

Lastly, the integration of antifreeze technologies with existing biotech infrastructure and processes presents technical and logistical challenges. Modifying established protocols and equipment to accommodate new antifreeze methods often requires significant investments in time, resources, and expertise.

Existing Antifreeze Protocols in Biotechnology

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and one or more freezing point depressants. Common depressants include glycols (such as ethylene glycol or propylene glycol), alcohols, and salts. These components work together to lower the freezing point of the solution, making it effective in preventing freezing in various applications.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and one or more freezing point depressants. Common depressants include glycols (such as ethylene glycol or propylene glycol), alcohols, and salts. These components work together to lower the freezing point of the solution, making it effective in preventing freezing in various applications.

- Additives for enhanced performance: Various additives can be incorporated into antifreeze formulations to improve their performance. These may include corrosion inhibitors, anti-foaming agents, pH buffers, and dyes. Such additives help protect metal components, prevent foam formation, maintain optimal pH levels, and allow for easy identification of the antifreeze solution.

- Environmental and safety considerations: There is a growing focus on developing environmentally friendly and less toxic antifreeze formulations. This includes the use of biodegradable components, such as propylene glycol, and the exploration of natural or plant-based freezing point depressants. These alternatives aim to reduce environmental impact and improve safety for humans and animals.

- Application-specific antifreeze solutions: Different applications require tailored antifreeze formulations. For example, automotive antifreeze may have different requirements compared to those used in industrial cooling systems or wind turbines. Factors such as operating temperature range, material compatibility, and specific performance needs are considered when developing application-specific solutions.

- Testing and quality control methods: Various testing methods are employed to ensure the effectiveness and quality of antifreeze solutions. These may include freezing point depression tests, boiling point elevation tests, corrosion tests, and stability tests. Quality control measures are crucial to guarantee consistent performance and reliability of antifreeze products across different batches and applications.

02 Additives for enhanced performance

Various additives are incorporated into antifreeze formulations to improve their performance. These may include corrosion inhibitors, anti-foaming agents, pH stabilizers, and lubricants. Such additives help protect engine components, maintain the solution's effectiveness, and extend its lifespan.Expand Specific Solutions03 Environmental and safety considerations

There is a growing focus on developing environmentally friendly and less toxic antifreeze solutions. This includes the use of biodegradable components, such as propylene glycol-based formulations, and the exploration of natural or plant-derived ingredients to replace traditional, more harmful chemicals.Expand Specific Solutions04 Application-specific formulations

Antifreeze solutions are tailored for specific applications, such as automotive cooling systems, industrial processes, or renewable energy systems. Each application may require different freezing point depression levels, heat transfer properties, and compatibility with materials used in the system.Expand Specific Solutions05 Testing and quality control methods

Various methods are employed to test and ensure the quality of antifreeze solutions. These include measuring freezing point depression, boiling point elevation, pH levels, and corrosion protection capabilities. Advanced techniques may be used to analyze the composition and effectiveness of the solutions under different conditions.Expand Specific Solutions

Key Players in Biotech Antifreeze Industry

The implementation of antifreeze in biotechnology applications is in a rapidly evolving phase, with a growing market driven by increasing demand in cryopreservation and cold chain logistics. The technology's maturity varies across different applications, ranging from established methods to emerging innovations. Companies like Advanced Industrial Science & Technology and Kaneka Corp. are at the forefront of research and development, while institutions such as the University of Shanghai for Science & Technology and Northwest A&F University contribute to academic advancements. Sanofi Pasteur SA and Air Liquide SA are leveraging antifreeze technologies in pharmaceutical and industrial applications, respectively. The competitive landscape is diverse, with both specialized biotech firms and large multinational corporations actively participating in this field.

Protokinetix, Inc.

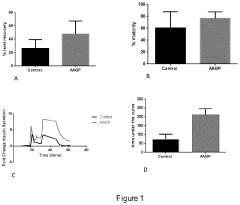

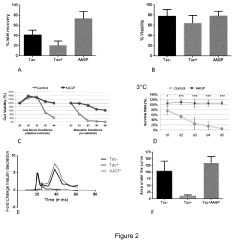

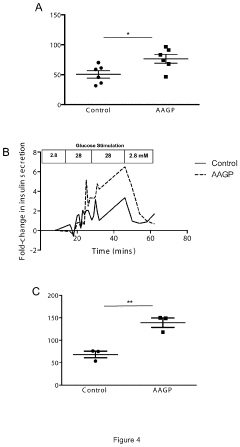

Technical Solution: Protokinetix has developed AAGP® (Anti-Aging Glycopeptide), a synthetic molecule that mimics antifreeze proteins found in cold-adapted organisms. AAGP® acts as a cell preservation agent, protecting cells from damage during freezing and thawing processes. The company has demonstrated AAGP®'s effectiveness in preserving various cell types, including stem cells, islet cells, and corneal tissues[1][2]. Their technology involves incorporating AAGP® into cryopreservation solutions, allowing for improved cell viability and functionality post-thaw. Protokinetix has conducted extensive research on optimizing AAGP® concentrations and application methods for different cell types and tissues, aiming to enhance the efficiency of cell and organ transplantation procedures.

Strengths: Highly effective in preserving cell viability during freeze-thaw cycles; versatile application across various cell types and tissues. Weaknesses: May require optimization for each specific cell type or tissue; potential regulatory hurdles for widespread clinical adoption.

Air Liquide SA

Technical Solution: Air Liquide has developed cryogenic solutions for biopreservation, leveraging their expertise in industrial gases and cryogenics. Their approach involves using liquid nitrogen-based systems for controlled rate freezing and storage of biological samples. Air Liquide's technology includes advanced cryogenic freezers and storage tanks equipped with precise temperature control and monitoring systems[3]. They have also developed specialized cryopreservation media formulations that incorporate cryoprotectants to minimize ice crystal formation during freezing. Air Liquide's solutions are designed to maintain sample integrity over long periods, with applications in biobanking, cell therapy, and regenerative medicine[4].

Strengths: Extensive experience in cryogenics; comprehensive solutions from freezing to long-term storage. Weaknesses: May be more focused on equipment and infrastructure rather than novel antifreeze compounds; potential high costs for smaller research facilities.

Innovative Antifreeze Protein Research

Process for freezing tissues of living organism

PatentWO1989009548A1

Innovation

- A method involving immersion in an antifreeze solution, adjusted to match the pH and osmotic pressure of the biological tissue, which is cooled to a temperature range that allows rapid passage through the ice crystal formation zone without forming needle-like crystals, using solutions like ethylene glycol or glycerin derivatives.

Use of Anti-aging glycopeptides to enhance pancreatic cell health, survival and improve transplant outcome

PatentPendingUS20230414675A1

Innovation

- An in vitro method involving the use of gem-difluorinated C-glycopeptide compounds to enhance engraftment, improve insulin secretory function, protect cells from immunosuppressant toxicity, and decrease inflammatory responses of isolated pancreatic cells before transplantation.

Regulatory Framework for Biopreservation Products

The regulatory framework for biopreservation products is a critical aspect of implementing antifreeze technologies in biotechnology applications. This framework encompasses a complex set of guidelines, standards, and regulations that govern the development, production, and use of biopreservation products, including antifreeze agents.

At the international level, organizations such as the World Health Organization (WHO) and the International Conference on Harmonisation (ICH) provide overarching guidelines for the quality, safety, and efficacy of biological products. These guidelines often serve as a foundation for national regulatory bodies to develop their specific requirements for biopreservation products.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating biopreservation products. The FDA's Center for Biologics Evaluation and Research (CBER) oversees the approval process for biological products, including those used in cryopreservation and antifreeze applications. Manufacturers must comply with Good Manufacturing Practices (GMP) and demonstrate the safety and efficacy of their products through rigorous clinical trials and laboratory testing.

The European Medicines Agency (EMA) provides a similar regulatory framework for the European Union. The EMA's Committee for Advanced Therapies (CAT) is responsible for assessing the quality, safety, and efficacy of advanced therapy medicinal products, which may include certain biopreservation technologies.

Regulatory bodies also focus on the environmental impact of biopreservation products. The Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the EU regulate the use and disposal of chemicals used in antifreeze formulations to ensure environmental safety.

Specific regulations for biopreservation products often address issues such as product stability, sterility, and biocompatibility. Manufacturers must provide detailed documentation on the composition, manufacturing process, and quality control measures for their products. Additionally, they must demonstrate that their antifreeze agents do not adversely affect the viability or functionality of the preserved biological materials.

As the field of biotechnology continues to advance, regulatory frameworks are evolving to keep pace with new technologies. This includes the development of guidelines for novel antifreeze compounds, such as antifreeze proteins derived from organisms like fish or insects. Regulatory bodies are increasingly focusing on the long-term effects of these compounds on preserved biological materials and their potential impact on recipients of preserved tissues or organs.

At the international level, organizations such as the World Health Organization (WHO) and the International Conference on Harmonisation (ICH) provide overarching guidelines for the quality, safety, and efficacy of biological products. These guidelines often serve as a foundation for national regulatory bodies to develop their specific requirements for biopreservation products.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating biopreservation products. The FDA's Center for Biologics Evaluation and Research (CBER) oversees the approval process for biological products, including those used in cryopreservation and antifreeze applications. Manufacturers must comply with Good Manufacturing Practices (GMP) and demonstrate the safety and efficacy of their products through rigorous clinical trials and laboratory testing.

The European Medicines Agency (EMA) provides a similar regulatory framework for the European Union. The EMA's Committee for Advanced Therapies (CAT) is responsible for assessing the quality, safety, and efficacy of advanced therapy medicinal products, which may include certain biopreservation technologies.

Regulatory bodies also focus on the environmental impact of biopreservation products. The Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in the EU regulate the use and disposal of chemicals used in antifreeze formulations to ensure environmental safety.

Specific regulations for biopreservation products often address issues such as product stability, sterility, and biocompatibility. Manufacturers must provide detailed documentation on the composition, manufacturing process, and quality control measures for their products. Additionally, they must demonstrate that their antifreeze agents do not adversely affect the viability or functionality of the preserved biological materials.

As the field of biotechnology continues to advance, regulatory frameworks are evolving to keep pace with new technologies. This includes the development of guidelines for novel antifreeze compounds, such as antifreeze proteins derived from organisms like fish or insects. Regulatory bodies are increasingly focusing on the long-term effects of these compounds on preserved biological materials and their potential impact on recipients of preserved tissues or organs.

Environmental Impact of Antifreeze Compounds

The implementation of antifreeze compounds in biotechnology applications has raised significant environmental concerns due to their potential impact on ecosystems. Traditional antifreeze agents, such as ethylene glycol and propylene glycol, have been widely used in various industries, including biotechnology. However, their release into the environment can lead to adverse effects on aquatic and terrestrial ecosystems.

One of the primary environmental concerns associated with antifreeze compounds is their toxicity to wildlife. When these substances enter water bodies, they can be ingested by aquatic organisms, leading to acute or chronic toxicity. Fish, amphibians, and other aquatic species are particularly vulnerable to the harmful effects of antifreeze compounds. Moreover, birds and mammals that consume contaminated water or prey on affected aquatic organisms may also suffer from secondary poisoning.

Soil contamination is another significant environmental issue related to antifreeze compounds. When these substances leach into the soil, they can alter soil chemistry and negatively impact plant growth. This can lead to reduced biodiversity and ecosystem disruption in affected areas. Additionally, antifreeze compounds may persist in the environment for extended periods, potentially accumulating in soil and sediments over time.

The biodegradation of antifreeze compounds is a crucial factor in assessing their environmental impact. While some antifreeze agents are biodegradable, others may persist in the environment for longer periods, leading to prolonged ecological effects. The rate of biodegradation can vary depending on environmental conditions, such as temperature, pH, and the presence of specific microorganisms capable of breaking down these compounds.

Water pollution is a significant concern associated with antifreeze compounds. When these substances enter water systems, they can alter water quality, potentially affecting drinking water sources and aquatic ecosystems. The contamination of groundwater and surface water bodies can have far-reaching consequences for both human health and environmental integrity.

To mitigate the environmental impact of antifreeze compounds in biotechnology applications, researchers are exploring alternative, eco-friendly solutions. These include the development of bio-based antifreeze agents derived from natural sources, such as plant extracts or microbial products. These alternatives aim to provide effective antifreeze properties while minimizing environmental risks.

Furthermore, improved waste management practices and containment strategies are being implemented to prevent the release of antifreeze compounds into the environment. This includes proper disposal methods, recycling initiatives, and the use of closed-loop systems in biotechnology processes to minimize environmental exposure.

One of the primary environmental concerns associated with antifreeze compounds is their toxicity to wildlife. When these substances enter water bodies, they can be ingested by aquatic organisms, leading to acute or chronic toxicity. Fish, amphibians, and other aquatic species are particularly vulnerable to the harmful effects of antifreeze compounds. Moreover, birds and mammals that consume contaminated water or prey on affected aquatic organisms may also suffer from secondary poisoning.

Soil contamination is another significant environmental issue related to antifreeze compounds. When these substances leach into the soil, they can alter soil chemistry and negatively impact plant growth. This can lead to reduced biodiversity and ecosystem disruption in affected areas. Additionally, antifreeze compounds may persist in the environment for extended periods, potentially accumulating in soil and sediments over time.

The biodegradation of antifreeze compounds is a crucial factor in assessing their environmental impact. While some antifreeze agents are biodegradable, others may persist in the environment for longer periods, leading to prolonged ecological effects. The rate of biodegradation can vary depending on environmental conditions, such as temperature, pH, and the presence of specific microorganisms capable of breaking down these compounds.

Water pollution is a significant concern associated with antifreeze compounds. When these substances enter water systems, they can alter water quality, potentially affecting drinking water sources and aquatic ecosystems. The contamination of groundwater and surface water bodies can have far-reaching consequences for both human health and environmental integrity.

To mitigate the environmental impact of antifreeze compounds in biotechnology applications, researchers are exploring alternative, eco-friendly solutions. These include the development of bio-based antifreeze agents derived from natural sources, such as plant extracts or microbial products. These alternatives aim to provide effective antifreeze properties while minimizing environmental risks.

Furthermore, improved waste management practices and containment strategies are being implemented to prevent the release of antifreeze compounds into the environment. This includes proper disposal methods, recycling initiatives, and the use of closed-loop systems in biotechnology processes to minimize environmental exposure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!