How to Innovate Raman Spectroscopy for Textile Material Analysis

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Raman Spectroscopy Evolution and Textile Analysis Goals

Raman spectroscopy has evolved significantly since its discovery by C.V. Raman in 1928, transforming from a purely scientific tool into a versatile analytical technique with widespread industrial applications. The initial decades saw limited practical use due to technical constraints, but the introduction of laser technology in the 1960s marked a pivotal advancement. This innovation provided the intense, monochromatic light source necessary for efficient Raman scattering detection, dramatically improving signal quality and expanding potential applications.

The 1980s and 1990s witnessed further revolutionary developments with the integration of charge-coupled devices (CCDs) and Fourier-transform technology, which substantially enhanced detection sensitivity and spectral resolution. These improvements made Raman spectroscopy increasingly accessible for material analysis across various industries, including textiles. The miniaturization trend of the 2000s led to portable and handheld Raman devices, enabling on-site analysis capabilities previously confined to laboratory settings.

In the textile industry specifically, Raman spectroscopy has emerged as a powerful non-destructive analytical method. Traditional textile analysis relied heavily on chemical testing methods that often damaged samples and generated hazardous waste. The non-invasive nature of Raman spectroscopy represents a significant advancement, allowing for detailed material characterization without sample preparation or destruction.

Current technological objectives in this field focus on overcoming several persistent challenges. Enhancing sensitivity for detecting trace components in complex textile matrices remains a primary goal, particularly for identifying low-concentration additives, dyes, and finishing agents. Researchers are also working to minimize fluorescence interference, which frequently obscures Raman signals when analyzing colored or treated textiles.

Another critical objective involves developing specialized databases and algorithms for textile-specific applications. These resources would enable rapid identification of fiber types, blends, treatments, and contaminants, supporting quality control and authentication processes. The industry also seeks more robust calibration methods to ensure consistent results across different instruments and operating conditions.

The integration of artificial intelligence and machine learning represents perhaps the most transformative goal in modern Raman spectroscopy for textiles. These technologies promise to automate spectral interpretation, detect subtle pattern variations, and provide predictive insights about material performance and durability. This evolution aims to transition Raman technology from a purely analytical tool to a predictive one that can inform textile design and manufacturing processes.

Ultimately, the field is moving toward creating comprehensive, user-friendly Raman systems specifically optimized for textile applications, capable of providing real-time, in-line monitoring during production processes while maintaining the accuracy and reliability of laboratory-grade analysis.

The 1980s and 1990s witnessed further revolutionary developments with the integration of charge-coupled devices (CCDs) and Fourier-transform technology, which substantially enhanced detection sensitivity and spectral resolution. These improvements made Raman spectroscopy increasingly accessible for material analysis across various industries, including textiles. The miniaturization trend of the 2000s led to portable and handheld Raman devices, enabling on-site analysis capabilities previously confined to laboratory settings.

In the textile industry specifically, Raman spectroscopy has emerged as a powerful non-destructive analytical method. Traditional textile analysis relied heavily on chemical testing methods that often damaged samples and generated hazardous waste. The non-invasive nature of Raman spectroscopy represents a significant advancement, allowing for detailed material characterization without sample preparation or destruction.

Current technological objectives in this field focus on overcoming several persistent challenges. Enhancing sensitivity for detecting trace components in complex textile matrices remains a primary goal, particularly for identifying low-concentration additives, dyes, and finishing agents. Researchers are also working to minimize fluorescence interference, which frequently obscures Raman signals when analyzing colored or treated textiles.

Another critical objective involves developing specialized databases and algorithms for textile-specific applications. These resources would enable rapid identification of fiber types, blends, treatments, and contaminants, supporting quality control and authentication processes. The industry also seeks more robust calibration methods to ensure consistent results across different instruments and operating conditions.

The integration of artificial intelligence and machine learning represents perhaps the most transformative goal in modern Raman spectroscopy for textiles. These technologies promise to automate spectral interpretation, detect subtle pattern variations, and provide predictive insights about material performance and durability. This evolution aims to transition Raman technology from a purely analytical tool to a predictive one that can inform textile design and manufacturing processes.

Ultimately, the field is moving toward creating comprehensive, user-friendly Raman systems specifically optimized for textile applications, capable of providing real-time, in-line monitoring during production processes while maintaining the accuracy and reliability of laboratory-grade analysis.

Market Demand for Advanced Textile Material Characterization

The global textile industry is experiencing a significant shift towards advanced material characterization techniques, creating a robust market demand for innovative analytical solutions. Traditional methods of textile analysis often lack precision, speed, and non-destructive capabilities required by modern manufacturing processes. This gap has created a substantial opportunity for Raman spectroscopy applications in textile material analysis, with the market expected to grow considerably over the next decade.

Manufacturing efficiency requirements are driving demand for real-time, in-line material characterization tools. Textile producers face increasing pressure to maintain quality while accelerating production cycles, necessitating analytical techniques that can be integrated directly into manufacturing lines. Raman spectroscopy's non-contact nature makes it particularly suitable for this application, allowing for continuous monitoring without disrupting production flows.

The growing complexity of textile materials is another significant market driver. With the rise of technical textiles, smart fabrics, and composite materials, manufacturers require more sophisticated analytical capabilities to verify composition, structural integrity, and functional properties. Traditional testing methods often fall short when analyzing these complex materials, creating demand for spectroscopic techniques that can provide molecular-level insights.

Sustainability concerns are reshaping market requirements for textile analysis tools. As brands commit to environmental goals, there is increasing need to verify recycled content, identify microplastic shedding potential, and ensure compliance with chemical regulations. Raman spectroscopy offers advantages in identifying polymer types and additives without sample preparation, supporting these sustainability initiatives.

Consumer safety regulations worldwide have become more stringent, particularly regarding restricted substances in textiles. This regulatory landscape has expanded the market for analytical techniques that can detect prohibited chemicals at increasingly lower concentrations. The specificity of Raman spectroscopy in identifying chemical compounds makes it valuable for compliance verification.

The counterfeit textile market continues to grow, creating demand for authentication technologies. Luxury brands and technical textile manufacturers seek reliable methods to verify material authenticity throughout the supply chain. Raman spectroscopy's ability to create unique "fingerprints" of materials offers promising applications in this area.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for advanced textile characterization technologies. As textile manufacturing continues to expand in these regions, investments in quality control infrastructure are following, creating new market opportunities for innovative analytical solutions like advanced Raman spectroscopy systems tailored to textile applications.

Manufacturing efficiency requirements are driving demand for real-time, in-line material characterization tools. Textile producers face increasing pressure to maintain quality while accelerating production cycles, necessitating analytical techniques that can be integrated directly into manufacturing lines. Raman spectroscopy's non-contact nature makes it particularly suitable for this application, allowing for continuous monitoring without disrupting production flows.

The growing complexity of textile materials is another significant market driver. With the rise of technical textiles, smart fabrics, and composite materials, manufacturers require more sophisticated analytical capabilities to verify composition, structural integrity, and functional properties. Traditional testing methods often fall short when analyzing these complex materials, creating demand for spectroscopic techniques that can provide molecular-level insights.

Sustainability concerns are reshaping market requirements for textile analysis tools. As brands commit to environmental goals, there is increasing need to verify recycled content, identify microplastic shedding potential, and ensure compliance with chemical regulations. Raman spectroscopy offers advantages in identifying polymer types and additives without sample preparation, supporting these sustainability initiatives.

Consumer safety regulations worldwide have become more stringent, particularly regarding restricted substances in textiles. This regulatory landscape has expanded the market for analytical techniques that can detect prohibited chemicals at increasingly lower concentrations. The specificity of Raman spectroscopy in identifying chemical compounds makes it valuable for compliance verification.

The counterfeit textile market continues to grow, creating demand for authentication technologies. Luxury brands and technical textile manufacturers seek reliable methods to verify material authenticity throughout the supply chain. Raman spectroscopy's ability to create unique "fingerprints" of materials offers promising applications in this area.

Emerging economies, particularly in Asia-Pacific, represent the fastest-growing market segment for advanced textile characterization technologies. As textile manufacturing continues to expand in these regions, investments in quality control infrastructure are following, creating new market opportunities for innovative analytical solutions like advanced Raman spectroscopy systems tailored to textile applications.

Current Limitations of Raman Technology in Textile Industry

Despite the significant potential of Raman spectroscopy in textile analysis, several technical limitations currently hinder its widespread adoption in the textile industry. The sensitivity of conventional Raman systems remains insufficient for detecting trace components in complex textile matrices, particularly when analyzing blended fabrics or materials with multiple chemical treatments. This sensitivity issue becomes more pronounced when attempting to identify low-concentration additives, dyes, or finishing agents that are critical for quality control and authentication purposes.

Signal-to-noise ratio (SNR) presents another substantial challenge, especially when examining colored or fluorescent textiles. Many textile dyes and optical brighteners exhibit strong fluorescence that can overwhelm the relatively weak Raman signals, making meaningful spectral acquisition difficult without specialized techniques. Current instrumentation often requires extended acquisition times or high laser powers to compensate, which can lead to sample degradation or altered material properties.

Spatial resolution limitations restrict the ability to characterize heterogeneous textile structures at the fiber or microfiber level. Most commercial Raman systems operate at resolutions insufficient for distinguishing between individual fibers in tightly woven fabrics or for mapping chemical distributions across complex textile interfaces. This hampers detailed analysis of fiber blends, coatings, and surface treatments that are increasingly common in modern technical textiles.

Data interpretation challenges persist due to the complexity of textile Raman spectra. Overlapping bands, matrix effects, and spectral variations due to physical properties (crystallinity, orientation, etc.) complicate automated analysis. Current spectral libraries and reference databases for textile materials remain incomplete, particularly for novel synthetic fibers, sustainable alternatives, and proprietary formulations used in high-performance textiles.

Instrumentation constraints further limit field applications. Most high-performance Raman systems remain laboratory-bound, bulky, and expensive, preventing in-line quality control or on-site authentication. Portable systems exist but typically sacrifice performance parameters critical for textile analysis. The lack of standardized methods and protocols specifically designed for textile applications also impedes consistent results across different instruments and laboratories.

Cost-effectiveness remains a significant barrier, as the expense of high-quality Raman instrumentation often outweighs the perceived benefits for many textile manufacturers. The specialized expertise required to operate systems and interpret results further increases the total cost of implementation, particularly for small and medium-sized enterprises that dominate certain segments of the textile industry.

Signal-to-noise ratio (SNR) presents another substantial challenge, especially when examining colored or fluorescent textiles. Many textile dyes and optical brighteners exhibit strong fluorescence that can overwhelm the relatively weak Raman signals, making meaningful spectral acquisition difficult without specialized techniques. Current instrumentation often requires extended acquisition times or high laser powers to compensate, which can lead to sample degradation or altered material properties.

Spatial resolution limitations restrict the ability to characterize heterogeneous textile structures at the fiber or microfiber level. Most commercial Raman systems operate at resolutions insufficient for distinguishing between individual fibers in tightly woven fabrics or for mapping chemical distributions across complex textile interfaces. This hampers detailed analysis of fiber blends, coatings, and surface treatments that are increasingly common in modern technical textiles.

Data interpretation challenges persist due to the complexity of textile Raman spectra. Overlapping bands, matrix effects, and spectral variations due to physical properties (crystallinity, orientation, etc.) complicate automated analysis. Current spectral libraries and reference databases for textile materials remain incomplete, particularly for novel synthetic fibers, sustainable alternatives, and proprietary formulations used in high-performance textiles.

Instrumentation constraints further limit field applications. Most high-performance Raman systems remain laboratory-bound, bulky, and expensive, preventing in-line quality control or on-site authentication. Portable systems exist but typically sacrifice performance parameters critical for textile analysis. The lack of standardized methods and protocols specifically designed for textile applications also impedes consistent results across different instruments and laboratories.

Cost-effectiveness remains a significant barrier, as the expense of high-quality Raman instrumentation often outweighs the perceived benefits for many textile manufacturers. The specialized expertise required to operate systems and interpret results further increases the total cost of implementation, particularly for small and medium-sized enterprises that dominate certain segments of the textile industry.

Existing Raman Solutions for Textile Material Analysis

01 Raman spectroscopy instrumentation and apparatus design

Various designs and configurations of Raman spectroscopy instruments are disclosed, including improvements in optical components, detection systems, and overall apparatus architecture. These innovations focus on enhancing sensitivity, resolution, and reliability of Raman measurements while reducing interference from background signals. Advanced designs incorporate specialized light sources, filters, and detectors to optimize spectral acquisition and analysis capabilities.- Raman spectroscopy instrumentation and systems: Various innovations in Raman spectroscopy instrumentation focus on improving measurement accuracy, sensitivity, and portability. These systems include specialized components such as lasers, detectors, and optical arrangements designed to enhance signal collection and reduce noise. Advanced systems may incorporate automated calibration, multiple excitation wavelengths, or miniaturized components for field deployment.

- Biomedical applications of Raman spectroscopy: Raman spectroscopy is increasingly applied in biomedical fields for non-invasive diagnostics and analysis. These applications include tissue characterization, disease detection, blood analysis, and monitoring of biological processes. The technology enables molecular-level identification of biomarkers without requiring sample preparation, making it valuable for clinical diagnostics and medical research.

- Enhanced Raman techniques and signal processing: Advanced Raman techniques such as Surface-Enhanced Raman Spectroscopy (SERS), Resonance Raman, and Spatially Offset Raman Spectroscopy (SORS) significantly improve detection sensitivity and specificity. These methods are complemented by sophisticated signal processing algorithms that extract meaningful data from complex spectra, reduce background interference, and enable automated analysis for rapid identification of chemical compounds.

- Industrial and environmental monitoring applications: Raman spectroscopy provides real-time monitoring capabilities for industrial processes and environmental analysis. Applications include quality control in pharmaceutical manufacturing, detection of contaminants in water and soil, monitoring of chemical reactions, and identification of hazardous materials. These systems often feature ruggedized designs for harsh environments and can be integrated with automated sampling systems.

- Portable and handheld Raman devices: Miniaturized Raman spectroscopy devices enable field-based analysis across multiple industries. These portable systems incorporate compact lasers, detectors, and processors while maintaining sufficient sensitivity for practical applications. Handheld devices feature user-friendly interfaces, onboard spectral libraries, and wireless connectivity for remote data analysis, making sophisticated chemical identification accessible outside laboratory environments.

02 Biomedical and clinical applications of Raman spectroscopy

Raman spectroscopy techniques applied to medical diagnostics, clinical analysis, and biological sample characterization. These applications include non-invasive disease detection, tissue analysis, blood component measurement, and in vivo monitoring of physiological parameters. The technology enables rapid, label-free identification of biomarkers and molecular changes associated with various medical conditions, providing valuable diagnostic information without extensive sample preparation.Expand Specific Solutions03 Enhanced Raman techniques and signal processing methods

Advanced methodologies for improving Raman signal quality and data analysis, including surface-enhanced Raman spectroscopy (SERS), resonance Raman, and specialized computational algorithms. These techniques address challenges such as weak Raman scattering, fluorescence interference, and complex spectral interpretation. Signal processing innovations include machine learning approaches, multivariate analysis, and automated spectral feature extraction to enhance detection sensitivity and specificity.Expand Specific Solutions04 Portable and miniaturized Raman systems

Development of compact, field-deployable Raman spectroscopy devices for on-site analysis and point-of-care applications. These innovations focus on miniaturization of optical components, integration with microfluidics, and development of handheld or wearable devices. Portable systems enable real-time analysis in diverse environments including industrial settings, environmental monitoring, and remote healthcare applications, while maintaining measurement accuracy comparable to laboratory instruments.Expand Specific Solutions05 Industrial and material analysis applications

Implementation of Raman spectroscopy for quality control, process monitoring, and material characterization in industrial settings. Applications include pharmaceutical manufacturing, polymer analysis, semiconductor processing, and detection of contaminants or adulterants in various products. These techniques provide non-destructive, rapid assessment of chemical composition, crystallinity, and molecular structure, enabling real-time process control and quality assurance across multiple industries.Expand Specific Solutions

Leading Companies and Research Institutions in Raman Technology

Raman spectroscopy for textile material analysis is currently in a growth phase, with the market expanding as industries seek more precise, non-destructive analytical methods. The global market for this technology in textile applications is estimated to reach $350-400 million by 2025, driven by increasing demand for quality control and counterfeit detection. Technologically, the field is advancing rapidly with key players at different maturity levels. ChemImage Corp. and Bruker Optics lead with commercial solutions specifically for textiles, while academic institutions like Zhejiang Sci-Tech University and China National Silk Museum contribute fundamental research. Companies including HP Development, IBM, and Excelitas Technologies are developing complementary technologies to enhance spectral resolution and portability. Research institutions such as UK Research & Innovation and King's College London are bridging the gap between laboratory techniques and industrial applications, focusing on AI integration and miniaturization to make Raman spectroscopy more accessible for routine textile analysis.

ChemImage Corp.

Technical Solution: ChemImage has developed advanced Raman spectroscopy solutions specifically for textile analysis through their Molecular Chemical Imaging (MCI) technology. Their approach combines Raman spectroscopy with digital imaging to create chemical maps of textile materials at the molecular level. The company's proprietary FALCON II Raman chemical imaging microscope system enables rapid, non-destructive analysis of textile fibers, dyes, and finishes with high spatial resolution. ChemImage's technology employs multivariate statistical analysis algorithms to differentiate between similar textile materials and identify contaminants or adulterants that might be invisible to conventional analysis methods. Their systems can detect subtle variations in polymer structures, crystallinity, and orientation in synthetic fibers, providing crucial information for quality control and material development[1][3]. The company has also pioneered portable Raman devices that allow for in-field textile authentication, particularly valuable for identifying counterfeit textiles in supply chain verification.

Strengths: Superior chemical specificity allowing identification of complex fiber blends and treatments; non-destructive analysis preserving sample integrity; high spatial resolution capable of detecting microscopic variations in fiber composition. Weaknesses: Higher equipment costs compared to conventional spectroscopy; requires specialized training for data interpretation; some fluorescent dyes in textiles may interfere with Raman signals requiring additional data processing.

Bruker Optics, Inc.

Technical Solution: Bruker has developed the SENTERRA II Raman microscope system specifically optimized for textile material analysis. Their technology integrates high-resolution confocal Raman spectroscopy with automated multi-point sampling to characterize heterogeneous textile materials with unprecedented precision. Bruker's innovation includes their proprietary OPUS software with specialized textile analysis modules that can identify fiber types, blends, dyes, and finishing agents through comprehensive spectral libraries containing over 25,000 reference materials[1]. The company has pioneered non-contact, non-destructive analysis methods that preserve delicate historical textiles while providing molecular-level information about their composition and degradation. Their MultiRAM FT-Raman spectrometer employs near-infrared excitation (1064 nm) to minimize fluorescence interference common in dyed textiles, enabling clear spectral acquisition from previously challenging colored samples[3]. Bruker has also developed portable Raman systems (BRAVO) with proprietary SSE™ (Sequentially Shifted Excitation) technology that automatically mitigates fluorescence effects, making field analysis of textiles practical for authentication and quality control applications.

Strengths: Superior fluorescence suppression capabilities critical for analyzing dyed textiles; comprehensive spectral libraries specifically for textile materials; intuitive software designed for non-specialists in spectroscopy. Weaknesses: Higher initial investment compared to basic spectroscopic tools; some portable systems sacrifice spectral resolution for mobility; requires periodic software updates to maintain current material databases.

Key Innovations in Raman Spectroscopy for Fiber Identification

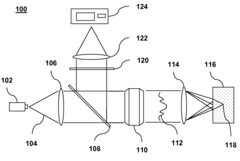

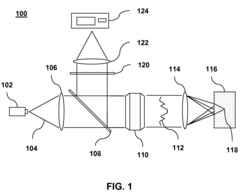

Apparatus and methods for performing Raman spectroscopy in scattering medium

PatentActiveUS8749793B2

Innovation

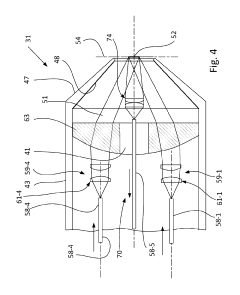

- The use of a spatial light modulator, such as a tunable acoustic gradient-index (TAG) lens or a liquid crystal/MEMS based spatial light modulator, to shape the wavefront of the laser beam, converting it into a Bessel beam that can self-heal and maintain focus within the scattering medium, compensating for phase modulation induced by scattering and allowing deeper penetration and analysis.

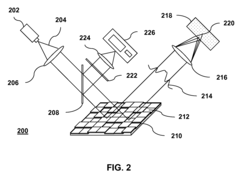

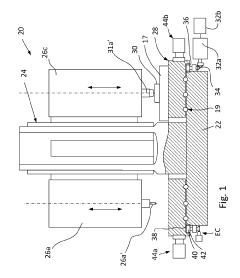

Method for in-line testing and surface analysis of test material with participation of raman spectroscopy

PatentActiveUS10258239B2

Innovation

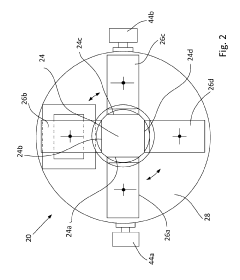

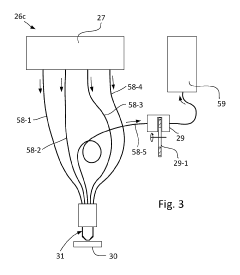

- A rotary arrangement of test and measurement units installed on a vertical column with a rotary platform allows for precise repositioning of the sample under the Raman spectrometer, enabling repeated measurements at the same point of interest, and a multi-wavelength Raman spectroscopy probe with tilted laser beams minimizes interference from luminescence, ensuring accurate signal separation and optimal signal/noise ratio.

Sustainability Impact of Advanced Textile Analysis Methods

The integration of advanced textile analysis methods like Raman spectroscopy represents a significant opportunity to enhance sustainability across the textile industry value chain. By enabling precise material identification and quality control without destructive testing, these technologies substantially reduce material waste during manufacturing processes. Traditional testing methods often require cutting samples from fabric rolls, resulting in considerable waste, especially in high-volume production environments. Raman spectroscopy's non-destructive nature preserves material integrity while providing accurate compositional data.

Energy consumption represents another critical sustainability dimension where advanced spectroscopic methods demonstrate advantages. Conventional textile analysis frequently involves chemical processing and laboratory procedures with significant energy requirements. In contrast, modern Raman systems can operate with relatively low power consumption, particularly when utilizing newer laser technologies and efficient optical components. Portable Raman devices further reduce the carbon footprint associated with sample transportation to centralized testing facilities.

Chemical usage reduction constitutes perhaps the most substantial environmental benefit of spectroscopic analysis methods. Traditional textile testing often employs various solvents, reagents, and chemical treatments that generate hazardous waste requiring specialized disposal. Raman spectroscopy eliminates these chemical inputs while simultaneously enabling better detection of harmful substances in textiles, supporting compliance with regulations like REACH and facilitating the production of safer consumer products.

Water conservation emerges as another significant sustainability advantage. Conventional textile testing frequently requires water-intensive processes for sample preparation and analysis. Spectroscopic methods operate without water consumption, aligning with industry initiatives to reduce water usage throughout the textile production lifecycle. This aspect becomes increasingly important as water scarcity affects more manufacturing regions globally.

The lifecycle extension potential of textiles analyzed with advanced methods also contributes to sustainability goals. By accurately identifying material composition and structural characteristics, manufacturers can optimize products for durability and recyclability. This supports circular economy principles by facilitating better end-of-life material recovery and reducing the environmental impact of textile disposal.

Finally, these technologies enable better traceability and authentication of sustainable materials. As consumers and regulators demand greater transparency regarding material sourcing and environmental claims, Raman spectroscopy provides objective verification of fiber content, helping prevent "greenwashing" and supporting legitimate sustainability initiatives in the textile industry.

Energy consumption represents another critical sustainability dimension where advanced spectroscopic methods demonstrate advantages. Conventional textile analysis frequently involves chemical processing and laboratory procedures with significant energy requirements. In contrast, modern Raman systems can operate with relatively low power consumption, particularly when utilizing newer laser technologies and efficient optical components. Portable Raman devices further reduce the carbon footprint associated with sample transportation to centralized testing facilities.

Chemical usage reduction constitutes perhaps the most substantial environmental benefit of spectroscopic analysis methods. Traditional textile testing often employs various solvents, reagents, and chemical treatments that generate hazardous waste requiring specialized disposal. Raman spectroscopy eliminates these chemical inputs while simultaneously enabling better detection of harmful substances in textiles, supporting compliance with regulations like REACH and facilitating the production of safer consumer products.

Water conservation emerges as another significant sustainability advantage. Conventional textile testing frequently requires water-intensive processes for sample preparation and analysis. Spectroscopic methods operate without water consumption, aligning with industry initiatives to reduce water usage throughout the textile production lifecycle. This aspect becomes increasingly important as water scarcity affects more manufacturing regions globally.

The lifecycle extension potential of textiles analyzed with advanced methods also contributes to sustainability goals. By accurately identifying material composition and structural characteristics, manufacturers can optimize products for durability and recyclability. This supports circular economy principles by facilitating better end-of-life material recovery and reducing the environmental impact of textile disposal.

Finally, these technologies enable better traceability and authentication of sustainable materials. As consumers and regulators demand greater transparency regarding material sourcing and environmental claims, Raman spectroscopy provides objective verification of fiber content, helping prevent "greenwashing" and supporting legitimate sustainability initiatives in the textile industry.

Integration with AI and Machine Learning for Spectral Data Processing

The integration of artificial intelligence and machine learning technologies with Raman spectroscopy represents a transformative approach to textile material analysis. Traditional spectral data processing methods often struggle with the complexity and volume of data generated during Raman analysis of textile materials. Machine learning algorithms can significantly enhance the accuracy, speed, and depth of spectral interpretation by identifying subtle patterns and correlations that might be overlooked by conventional analytical methods.

Deep learning neural networks have demonstrated particular promise in processing Raman spectral data of textiles. Convolutional Neural Networks (CNNs) excel at feature extraction from spectral signatures, while Recurrent Neural Networks (RNNs) can effectively analyze sequential spectral data. These approaches enable more precise identification of fiber types, blends, dyes, and finishing agents in complex textile compositions.

Automated classification systems powered by supervised learning algorithms have achieved remarkable accuracy rates exceeding 95% in identifying textile materials from their Raman spectra. This represents a substantial improvement over traditional chemometric methods, which typically achieve 80-85% accuracy. The implementation of transfer learning techniques further enhances these systems by allowing models trained on large spectral databases to be fine-tuned for specific textile applications with minimal additional training data.

Real-time processing capabilities enabled by AI integration allow for immediate analysis during production processes, supporting quality control applications. Edge computing implementations of these AI models facilitate on-site analysis without requiring constant connectivity to cloud resources, making the technology more accessible for manufacturing environments.

Unsupervised learning algorithms have proven valuable for anomaly detection in textile materials, identifying contaminants, adulterants, or manufacturing defects that produce subtle spectral variations. This capability is particularly valuable for high-value textiles where quality assurance is paramount.

The combination of AI with multivariate analysis techniques such as Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression enhances the extraction of meaningful information from complex spectral datasets. These hybrid approaches enable more nuanced characterization of textile properties including crystallinity, orientation, and molecular interactions that influence material performance.

Recent developments in explainable AI (XAI) are addressing the "black box" nature of many machine learning models, providing transparency in decision-making processes that is crucial for scientific validation and regulatory compliance in textile analysis applications. This evolution toward interpretable AI models strengthens the credibility and practical utility of AI-enhanced Raman spectroscopy in industrial settings.

Deep learning neural networks have demonstrated particular promise in processing Raman spectral data of textiles. Convolutional Neural Networks (CNNs) excel at feature extraction from spectral signatures, while Recurrent Neural Networks (RNNs) can effectively analyze sequential spectral data. These approaches enable more precise identification of fiber types, blends, dyes, and finishing agents in complex textile compositions.

Automated classification systems powered by supervised learning algorithms have achieved remarkable accuracy rates exceeding 95% in identifying textile materials from their Raman spectra. This represents a substantial improvement over traditional chemometric methods, which typically achieve 80-85% accuracy. The implementation of transfer learning techniques further enhances these systems by allowing models trained on large spectral databases to be fine-tuned for specific textile applications with minimal additional training data.

Real-time processing capabilities enabled by AI integration allow for immediate analysis during production processes, supporting quality control applications. Edge computing implementations of these AI models facilitate on-site analysis without requiring constant connectivity to cloud resources, making the technology more accessible for manufacturing environments.

Unsupervised learning algorithms have proven valuable for anomaly detection in textile materials, identifying contaminants, adulterants, or manufacturing defects that produce subtle spectral variations. This capability is particularly valuable for high-value textiles where quality assurance is paramount.

The combination of AI with multivariate analysis techniques such as Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression enhances the extraction of meaningful information from complex spectral datasets. These hybrid approaches enable more nuanced characterization of textile properties including crystallinity, orientation, and molecular interactions that influence material performance.

Recent developments in explainable AI (XAI) are addressing the "black box" nature of many machine learning models, providing transparency in decision-making processes that is crucial for scientific validation and regulatory compliance in textile analysis applications. This evolution toward interpretable AI models strengthens the credibility and practical utility of AI-enhanced Raman spectroscopy in industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!