Raman Spectroscopy vs XPS: Surface Chemistry Determination

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Analysis Technology Background and Objectives

Surface analysis techniques have evolved significantly over the past several decades, becoming essential tools for understanding material properties at the molecular and atomic levels. Among these techniques, Raman spectroscopy and X-ray Photoelectron Spectroscopy (XPS) represent two distinct yet complementary approaches to surface chemistry determination. The development of these technologies has been driven by increasing demands in materials science, semiconductor manufacturing, pharmaceutical research, and nanotechnology applications.

Raman spectroscopy, discovered by C.V. Raman in 1928, has transformed from a purely academic tool into a versatile analytical technique. Its evolution accelerated in the 1960s with the invention of lasers, which provided the intense monochromatic light sources necessary for efficient Raman scattering detection. Further advancements in detector technology, particularly charge-coupled devices (CCDs) in the 1980s, dramatically improved sensitivity and data acquisition speeds.

XPS, also known as Electron Spectroscopy for Chemical Analysis (ESCA), emerged in the 1960s through the pioneering work of Kai Siegbahn, who later received the Nobel Prize for his contributions. The technique has since become more sophisticated with improvements in vacuum technology, X-ray sources, and electron energy analyzers, enabling higher resolution and greater surface sensitivity.

The technological trajectory of both methods has been characterized by miniaturization, automation, and integration with complementary techniques. Modern systems now offer unprecedented spatial resolution, with some Raman systems achieving sub-micron resolution and XPS reaching the nanometer scale through synchrotron radiation sources and advanced focusing optics.

The primary objective in comparing these technologies is to establish their respective strengths, limitations, and optimal application scenarios for surface chemistry determination. Specifically, this analysis aims to evaluate their capabilities in terms of spatial resolution, chemical specificity, sampling depth, quantitative accuracy, and suitability for various material classes including metals, semiconductors, polymers, and biological samples.

Additionally, this technical assessment seeks to explore emerging hybrid approaches that combine aspects of both techniques, such as correlative Raman-XPS imaging, which promises more comprehensive surface characterization. The evaluation will also consider practical factors including sample preparation requirements, analysis time, cost considerations, and expertise needed for data interpretation.

Understanding the complementary nature of these techniques is crucial for developing effective analytical strategies in research and industrial applications, particularly as materials become more complex and the demands for precise surface characterization continue to increase in fields ranging from catalysis to biomedical implants.

Raman spectroscopy, discovered by C.V. Raman in 1928, has transformed from a purely academic tool into a versatile analytical technique. Its evolution accelerated in the 1960s with the invention of lasers, which provided the intense monochromatic light sources necessary for efficient Raman scattering detection. Further advancements in detector technology, particularly charge-coupled devices (CCDs) in the 1980s, dramatically improved sensitivity and data acquisition speeds.

XPS, also known as Electron Spectroscopy for Chemical Analysis (ESCA), emerged in the 1960s through the pioneering work of Kai Siegbahn, who later received the Nobel Prize for his contributions. The technique has since become more sophisticated with improvements in vacuum technology, X-ray sources, and electron energy analyzers, enabling higher resolution and greater surface sensitivity.

The technological trajectory of both methods has been characterized by miniaturization, automation, and integration with complementary techniques. Modern systems now offer unprecedented spatial resolution, with some Raman systems achieving sub-micron resolution and XPS reaching the nanometer scale through synchrotron radiation sources and advanced focusing optics.

The primary objective in comparing these technologies is to establish their respective strengths, limitations, and optimal application scenarios for surface chemistry determination. Specifically, this analysis aims to evaluate their capabilities in terms of spatial resolution, chemical specificity, sampling depth, quantitative accuracy, and suitability for various material classes including metals, semiconductors, polymers, and biological samples.

Additionally, this technical assessment seeks to explore emerging hybrid approaches that combine aspects of both techniques, such as correlative Raman-XPS imaging, which promises more comprehensive surface characterization. The evaluation will also consider practical factors including sample preparation requirements, analysis time, cost considerations, and expertise needed for data interpretation.

Understanding the complementary nature of these techniques is crucial for developing effective analytical strategies in research and industrial applications, particularly as materials become more complex and the demands for precise surface characterization continue to increase in fields ranging from catalysis to biomedical implants.

Market Applications and Demand for Surface Chemistry Analysis

Surface chemistry analysis has become a critical component across multiple industries, with the global market for surface analysis technologies projected to reach $5.6 billion by 2027, growing at a CAGR of 6.8%. This growth is primarily driven by increasing demands in semiconductor manufacturing, materials science, pharmaceutical development, and environmental monitoring sectors.

In the semiconductor industry, surface chemistry determination techniques like XPS and Raman spectroscopy are essential for quality control and failure analysis. As chip architectures continue to shrink toward 3nm and beyond, manufacturers require increasingly precise surface characterization methods to detect contamination and verify material composition at atomic scales. This sector alone accounts for approximately 35% of the total surface analysis market.

The pharmaceutical and biomedical industries represent another significant market segment, where surface chemistry analysis is crucial for drug development, biocompatibility testing, and medical device manufacturing. The need to understand protein adsorption, cell-surface interactions, and drug delivery mechanisms has intensified demand for non-destructive techniques like Raman spectroscopy, which allows in-situ analysis of biological samples.

Environmental monitoring applications have expanded considerably, with regulatory bodies worldwide implementing stricter standards for pollutant detection and characterization. Both XPS and Raman spectroscopy offer valuable capabilities for identifying trace contaminants in soil, water, and air samples, with the environmental sector showing the fastest growth rate at 8.2% annually.

The materials science and nanotechnology fields continue to drive innovation in surface analysis techniques. As advanced materials like graphene, 2D materials, and complex polymer composites gain commercial relevance, the demand for complementary analytical approaches combining XPS and Raman has increased substantially. This trend is particularly evident in battery technology, where understanding surface chemistry is critical for improving performance and longevity.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding semiconductor manufacturing and increasing R&D investments in China, South Korea, and Taiwan.

Customer surveys indicate that end-users increasingly prefer integrated analytical solutions that combine multiple techniques, with 72% of respondents expressing interest in systems that offer both XPS and Raman capabilities. This trend toward multi-modal analysis reflects the growing recognition that comprehensive surface characterization often requires complementary approaches to address complex material challenges.

In the semiconductor industry, surface chemistry determination techniques like XPS and Raman spectroscopy are essential for quality control and failure analysis. As chip architectures continue to shrink toward 3nm and beyond, manufacturers require increasingly precise surface characterization methods to detect contamination and verify material composition at atomic scales. This sector alone accounts for approximately 35% of the total surface analysis market.

The pharmaceutical and biomedical industries represent another significant market segment, where surface chemistry analysis is crucial for drug development, biocompatibility testing, and medical device manufacturing. The need to understand protein adsorption, cell-surface interactions, and drug delivery mechanisms has intensified demand for non-destructive techniques like Raman spectroscopy, which allows in-situ analysis of biological samples.

Environmental monitoring applications have expanded considerably, with regulatory bodies worldwide implementing stricter standards for pollutant detection and characterization. Both XPS and Raman spectroscopy offer valuable capabilities for identifying trace contaminants in soil, water, and air samples, with the environmental sector showing the fastest growth rate at 8.2% annually.

The materials science and nanotechnology fields continue to drive innovation in surface analysis techniques. As advanced materials like graphene, 2D materials, and complex polymer composites gain commercial relevance, the demand for complementary analytical approaches combining XPS and Raman has increased substantially. This trend is particularly evident in battery technology, where understanding surface chemistry is critical for improving performance and longevity.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding semiconductor manufacturing and increasing R&D investments in China, South Korea, and Taiwan.

Customer surveys indicate that end-users increasingly prefer integrated analytical solutions that combine multiple techniques, with 72% of respondents expressing interest in systems that offer both XPS and Raman capabilities. This trend toward multi-modal analysis reflects the growing recognition that comprehensive surface characterization often requires complementary approaches to address complex material challenges.

Current Capabilities and Limitations of Raman and XPS Technologies

Raman spectroscopy and X-ray Photoelectron Spectroscopy (XPS) represent two powerful analytical techniques for surface chemistry determination, each with distinct capabilities and limitations. Raman spectroscopy excels in providing molecular fingerprinting through the detection of vibrational modes, offering non-destructive analysis with minimal sample preparation requirements. Modern Raman systems can achieve spatial resolution down to sub-micron levels, enabling detailed mapping of heterogeneous surfaces.

However, Raman spectroscopy faces significant limitations in surface sensitivity, typically probing depths of several hundred nanometers to micrometers, which often exceeds the true surface layer of interest. The technique also struggles with fluorescence interference, which can overwhelm the relatively weak Raman signals, particularly in organic and biological samples. Additionally, certain materials exhibit poor Raman scattering efficiency, resulting in weak signal intensity that challenges accurate analysis.

XPS, conversely, demonstrates exceptional surface sensitivity, analyzing only the top 1-10 nm of a sample's surface, making it ideal for true surface chemistry determination. The technique provides quantitative elemental composition data and critical information about chemical states and bonding environments through chemical shift analysis. Modern XPS systems achieve energy resolutions below 0.5 eV, enabling precise differentiation between subtle chemical states.

Despite these advantages, XPS operates under ultra-high vacuum conditions, imposing significant constraints on sample compatibility and preventing in-situ or ambient pressure analysis without specialized equipment. The spatial resolution of conventional XPS systems (typically 10-150 μm) remains inferior to Raman capabilities, though recent advances in synchrotron-based and imaging XPS have improved this limitation. XPS also faces challenges in detecting hydrogen and helium, and sample damage from X-ray exposure can alter surface chemistry during measurement.

From a practical perspective, Raman spectroscopy offers advantages in speed, with acquisition times typically ranging from seconds to minutes, compared to XPS's longer acquisition times (often 30+ minutes for detailed spectra). Raman systems also tend to be more portable and less expensive than XPS instruments, which require complex vacuum systems and X-ray sources.

The complementary nature of these techniques has driven recent technological developments focused on overcoming their respective limitations. Surface-enhanced Raman spectroscopy (SERS) has dramatically improved surface sensitivity, while ambient-pressure XPS systems now enable analysis under near-atmospheric conditions. Multimodal approaches combining both techniques are increasingly employed to provide comprehensive surface characterization across different depth scales and chemical sensitivities.

However, Raman spectroscopy faces significant limitations in surface sensitivity, typically probing depths of several hundred nanometers to micrometers, which often exceeds the true surface layer of interest. The technique also struggles with fluorescence interference, which can overwhelm the relatively weak Raman signals, particularly in organic and biological samples. Additionally, certain materials exhibit poor Raman scattering efficiency, resulting in weak signal intensity that challenges accurate analysis.

XPS, conversely, demonstrates exceptional surface sensitivity, analyzing only the top 1-10 nm of a sample's surface, making it ideal for true surface chemistry determination. The technique provides quantitative elemental composition data and critical information about chemical states and bonding environments through chemical shift analysis. Modern XPS systems achieve energy resolutions below 0.5 eV, enabling precise differentiation between subtle chemical states.

Despite these advantages, XPS operates under ultra-high vacuum conditions, imposing significant constraints on sample compatibility and preventing in-situ or ambient pressure analysis without specialized equipment. The spatial resolution of conventional XPS systems (typically 10-150 μm) remains inferior to Raman capabilities, though recent advances in synchrotron-based and imaging XPS have improved this limitation. XPS also faces challenges in detecting hydrogen and helium, and sample damage from X-ray exposure can alter surface chemistry during measurement.

From a practical perspective, Raman spectroscopy offers advantages in speed, with acquisition times typically ranging from seconds to minutes, compared to XPS's longer acquisition times (often 30+ minutes for detailed spectra). Raman systems also tend to be more portable and less expensive than XPS instruments, which require complex vacuum systems and X-ray sources.

The complementary nature of these techniques has driven recent technological developments focused on overcoming their respective limitations. Surface-enhanced Raman spectroscopy (SERS) has dramatically improved surface sensitivity, while ambient-pressure XPS systems now enable analysis under near-atmospheric conditions. Multimodal approaches combining both techniques are increasingly employed to provide comprehensive surface characterization across different depth scales and chemical sensitivities.

Comparative Analysis of Raman Spectroscopy and XPS Methodologies

01 Combined use of Raman spectroscopy and XPS for surface analysis

The integration of Raman spectroscopy and X-ray Photoelectron Spectroscopy (XPS) provides complementary information for comprehensive surface chemistry determination. Raman spectroscopy offers molecular structural information while XPS provides elemental composition and chemical state analysis of surfaces. This combination enables more accurate characterization of surface properties, chemical bonding, and material interfaces than either technique alone.- Combined use of Raman spectroscopy and XPS for surface analysis: The integration of Raman spectroscopy and X-ray Photoelectron Spectroscopy (XPS) provides complementary surface chemistry information. While Raman spectroscopy offers insights into molecular vibrations and chemical bonds, XPS reveals elemental composition and chemical states of surface atoms. This combined approach enables comprehensive characterization of surface properties, including chemical composition, bonding states, and structural features, allowing for more accurate determination of surface chemistry than either technique alone.

- In-situ and real-time surface chemistry monitoring systems: Advanced systems have been developed for in-situ and real-time monitoring of surface chemistry using Raman spectroscopy and XPS. These systems allow for the observation of dynamic surface processes, chemical reactions, and transformations as they occur. The integration of these spectroscopic techniques with environmental control chambers enables the study of surfaces under various conditions, such as different temperatures, pressures, or gas environments, providing valuable insights into surface behavior in realistic operating conditions.

- Surface characterization of nanomaterials and thin films: Raman spectroscopy and XPS are particularly valuable for characterizing nanomaterials and thin films, where surface properties dominate material behavior. These techniques can determine the chemical composition, crystallinity, defects, and electronic structure of nanomaterials and thin film surfaces with high sensitivity. The non-destructive nature of Raman spectroscopy, combined with the surface sensitivity of XPS, makes this combination ideal for analyzing delicate nanoscale structures and interfaces in advanced materials and devices.

- Data processing and analysis methods for spectroscopic surface data: Advanced data processing and analysis methods have been developed to extract meaningful information from Raman and XPS spectroscopic data. These include multivariate analysis, machine learning algorithms, and computational modeling approaches that can identify patterns, correlations, and chemical signatures in complex spectral datasets. Such methods enhance the ability to interpret surface chemistry information, enabling more accurate identification of chemical species, quantification of surface components, and detection of subtle chemical changes on material surfaces.

- Biomedical and pharmaceutical applications of surface chemistry determination: Raman spectroscopy and XPS are increasingly applied in biomedical and pharmaceutical fields for surface chemistry determination. These techniques can characterize biomaterial surfaces, drug delivery systems, and biointerfaces to understand interactions with biological environments. The ability to analyze surface chemistry without extensive sample preparation makes these methods valuable for studying biological samples, implant materials, and pharmaceutical formulations, providing insights into biocompatibility, drug release mechanisms, and surface modifications for enhanced performance.

02 In-situ and real-time surface chemistry monitoring systems

Advanced systems have been developed that allow for in-situ and real-time monitoring of surface chemistry using Raman spectroscopy and XPS. These systems enable the observation of dynamic surface processes, chemical reactions, and transformations as they occur. The integration of these spectroscopic techniques with environmental control chambers permits analysis under various conditions, including different temperatures, pressures, and gas environments.Expand Specific Solutions03 Surface chemistry determination for semiconductor and electronic materials

Raman spectroscopy and XPS are extensively used for surface chemistry determination in semiconductor processing and electronic materials. These techniques help characterize thin films, interfaces, defects, and contaminants critical for device performance. The combined approach allows for analysis of chemical composition, bonding states, and structural properties of surfaces and interfaces in microelectronic components and devices.Expand Specific Solutions04 Nanomaterial and thin film surface characterization

For nanomaterials and thin films, Raman spectroscopy and XPS provide crucial information about surface chemistry, structure, and properties. These techniques help determine the composition, thickness, uniformity, and chemical states of nanoscale materials. The combination enables detailed analysis of surface functionalization, defects, and interactions between nanomaterials and their environment, which is essential for applications in catalysis, sensors, and advanced materials.Expand Specific Solutions05 Biomedical and pharmaceutical surface analysis applications

Raman spectroscopy and XPS are valuable tools for surface chemistry determination in biomedical and pharmaceutical applications. These techniques help analyze biomaterial surfaces, drug delivery systems, implant materials, and biological interfaces. The combined approach provides insights into surface modifications, protein adsorption, biocompatibility, and interactions between biological systems and material surfaces, supporting the development of improved medical devices and therapeutic systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Surface Analysis

Raman Spectroscopy vs XPS for surface chemistry determination represents a competitive landscape in an established yet evolving analytical instrumentation market. The field is currently in a mature growth phase with an estimated global market size of $5-7 billion, growing at 5-7% annually. Leading companies like Thermo Electron Scientific Instruments, VG Systems, and Hitachi High-Tech America dominate the commercial space, while research institutions such as CNRS, Swiss Federal Institute of Technology, and Huazhong University of Science & Technology drive innovation. The technology has reached high maturity for standard applications, with companies like Intel, Samsung, and BASF utilizing both techniques for advanced materials development. Recent advancements by Haydale Graphene Industries and Torr Scientific demonstrate ongoing refinement in specialized applications, particularly for nanomaterials and semiconductor surfaces.

VG Systems Ltd.

Technical Solution: VG Systems has developed specialized surface analysis instrumentation focusing on complementary XPS and Raman capabilities. Their SIGMA Probe XPS system features a microfocused monochromatic X-ray source that enables chemical state imaging with spatial resolution down to 15μm, while their integrated Raman module provides molecular information with comparable spatial resolution. The company's unique approach includes a patented sample transfer system that maintains ultra-high vacuum conditions between analysis chambers, preventing surface contamination during multimodal analysis. Their systems incorporate angle-resolved XPS capabilities that enable non-destructive depth profiling of the top 10nm of surfaces, complementing the deeper penetration of Raman analysis (typically 1-5μm). VG's data integration platform automatically correlates spectral features from both techniques, helping researchers distinguish between surface and bulk phenomena. This technology has proven particularly valuable for analyzing heterogeneous catalysts, where surface active sites often differ chemically from bulk material composition.

Strengths: Superior vacuum integrity during sample transfer; excellent depth profiling capabilities; specialized software for correlative analysis. Weaknesses: More limited global service network compared to larger competitors; systems optimized for research rather than high-throughput industrial applications; higher learning curve for new users.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron Scientific Instruments has developed comprehensive surface analysis solutions combining both Raman spectroscopy and XPS technologies. Their ESCALAB Xi+ XPS system provides high-sensitivity surface chemical analysis with detection limits below 0.1 atomic percent and depth profiling capabilities down to nanometer scale. This system is complemented by their DXR3 Raman microscope platform that offers spatial resolution down to 1μm with minimal sample preparation. Their integrated workflow allows researchers to first use Raman for rapid, non-destructive bulk and surface characterization, followed by XPS for precise elemental composition and chemical state analysis of the uppermost surface layers (1-10nm). This complementary approach enables complete characterization of complex materials where surface chemistry differs significantly from bulk properties. Their Avantage data system provides multivariate analysis tools that can correlate data from both techniques to generate comprehensive surface chemistry profiles.

Strengths: Industry-leading sensitivity and resolution in both techniques; seamless integration of complementary data; advanced software for multivariate analysis. Weaknesses: High capital equipment costs; requires significant technical expertise to operate both systems effectively; XPS analysis requires vacuum conditions which can alter some sample properties.

Key Technical Innovations in Surface Chemistry Determination

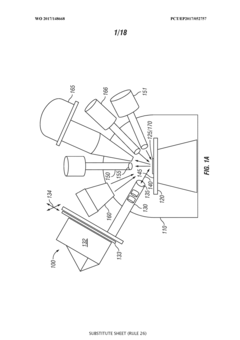

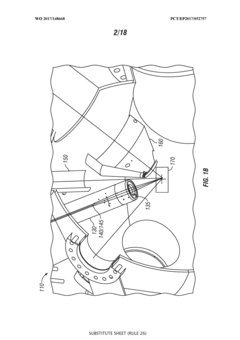

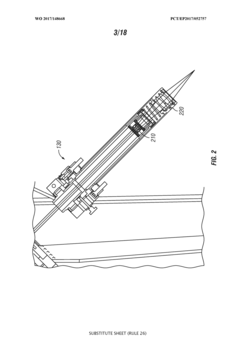

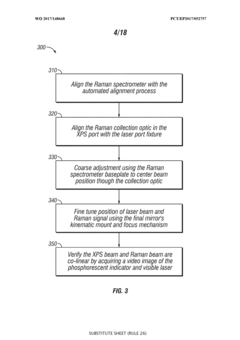

XPS and raman sample analysis system and method

PatentWO2017148668A2

Innovation

- A combined process that performs Raman spectroscopic analysis and XPS analysis within a vacuum chamber, where the duration of XPS analysis can be longer than Raman spectroscopic analysis, with co-alignment of laser and X-ray beam spots for improved resolution and image registration, and includes ion bombardment to remove surface layers or protective layers for detailed chemical and structural characterization.

Method of characterising surface chemistry

PatentInactiveGB2530827A

Innovation

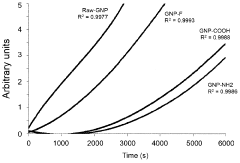

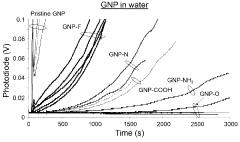

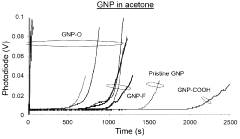

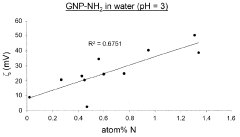

- A method involving the dispersion of particulate materials in a liquid, monitoring changes over time, and comparing sample data to reference data to determine surface chemistry, including functionalization, type, and degree of functionalization, using simple and non-destructive spectroscopic measurements like light transmission.

Sample Preparation Requirements and Considerations

Sample preparation represents a critical factor in determining the quality and reliability of both Raman spectroscopy and X-ray Photoelectron Spectroscopy (XPS) analyses for surface chemistry determination. The two techniques impose different requirements that must be carefully considered to ensure optimal results.

For Raman spectroscopy, samples generally require minimal preparation, which constitutes one of its key advantages. Solid samples can often be analyzed directly without modification, though polishing may improve signal quality by reducing surface roughness effects. Liquid samples typically need containment in appropriate vessels that minimize background interference, such as quartz cuvettes. Powdered samples may be compressed into pellets to enhance signal collection efficiency and reproducibility.

XPS, conversely, demands more stringent preparation protocols due to its extreme surface sensitivity. Samples must be thoroughly cleaned to remove surface contaminants, particularly adventitious carbon and oxygen species that can significantly skew results. Common cleaning methods include solvent washing, plasma treatment, ion sputtering, or heat treatment under vacuum, though each may potentially alter the surface chemistry being investigated.

Sample size and geometry considerations differ markedly between the techniques. Raman accommodates various sample dimensions and geometries with minimal constraints, allowing for in-situ and non-destructive analysis of components. XPS typically requires samples that fit within specific chamber dimensions, usually not exceeding a few centimeters, and must be compatible with ultra-high vacuum conditions.

Environmental stability presents another critical consideration. Raman samples can generally be analyzed under ambient conditions, though certain materials may be sensitive to laser-induced heating or photodegradation, necessitating reduced laser power or sample cooling. XPS samples must withstand ultra-high vacuum environments (10^-9 to 10^-10 torr), making the analysis of volatile compounds challenging without specialized preparation techniques.

Conductivity requirements also differ significantly. While Raman spectroscopy works equally well with conductive and non-conductive materials, XPS analysis of insulators often requires charge compensation techniques to prevent surface charging artifacts. This may involve low-energy electron flooding or conductive coatings on non-analysis areas.

Sample homogeneity affects both techniques but in different ways. Raman's spatial resolution (typically 1-2 μm) means heterogeneous samples can be mapped with high precision. XPS offers lower spatial resolution (typically 10-200 μm) but provides more comprehensive surface chemical state information, making sample homogeneity more critical for representative analysis.

For Raman spectroscopy, samples generally require minimal preparation, which constitutes one of its key advantages. Solid samples can often be analyzed directly without modification, though polishing may improve signal quality by reducing surface roughness effects. Liquid samples typically need containment in appropriate vessels that minimize background interference, such as quartz cuvettes. Powdered samples may be compressed into pellets to enhance signal collection efficiency and reproducibility.

XPS, conversely, demands more stringent preparation protocols due to its extreme surface sensitivity. Samples must be thoroughly cleaned to remove surface contaminants, particularly adventitious carbon and oxygen species that can significantly skew results. Common cleaning methods include solvent washing, plasma treatment, ion sputtering, or heat treatment under vacuum, though each may potentially alter the surface chemistry being investigated.

Sample size and geometry considerations differ markedly between the techniques. Raman accommodates various sample dimensions and geometries with minimal constraints, allowing for in-situ and non-destructive analysis of components. XPS typically requires samples that fit within specific chamber dimensions, usually not exceeding a few centimeters, and must be compatible with ultra-high vacuum conditions.

Environmental stability presents another critical consideration. Raman samples can generally be analyzed under ambient conditions, though certain materials may be sensitive to laser-induced heating or photodegradation, necessitating reduced laser power or sample cooling. XPS samples must withstand ultra-high vacuum environments (10^-9 to 10^-10 torr), making the analysis of volatile compounds challenging without specialized preparation techniques.

Conductivity requirements also differ significantly. While Raman spectroscopy works equally well with conductive and non-conductive materials, XPS analysis of insulators often requires charge compensation techniques to prevent surface charging artifacts. This may involve low-energy electron flooding or conductive coatings on non-analysis areas.

Sample homogeneity affects both techniques but in different ways. Raman's spatial resolution (typically 1-2 μm) means heterogeneous samples can be mapped with high precision. XPS offers lower spatial resolution (typically 10-200 μm) but provides more comprehensive surface chemical state information, making sample homogeneity more critical for representative analysis.

Cost-Benefit Analysis of Raman vs XPS Implementation

When evaluating the implementation of Raman spectroscopy versus X-ray Photoelectron Spectroscopy (XPS) for surface chemistry determination, a comprehensive cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value.

The initial capital expenditure for XPS systems typically ranges from $500,000 to $2 million, depending on capabilities and specifications. This represents a substantial financial commitment compared to Raman spectroscopy systems, which generally cost between $50,000 and $300,000. This price differential of approximately one order of magnitude makes Raman systems significantly more accessible for organizations with limited capital budgets.

Operational costs further differentiate these technologies. XPS requires ultra-high vacuum conditions, necessitating expensive vacuum pumps and maintenance. The systems also demand specialized facilities with controlled environments, adding to infrastructure costs. Conversely, Raman spectroscopy operates under ambient conditions without vacuum requirements, substantially reducing both facility demands and operational expenses.

Consumable costs present another distinction. XPS systems require regular replacement of X-ray sources and electron detectors, with annual maintenance costs typically reaching 5-10% of the initial investment. Raman systems primarily require occasional laser source replacement and have lower maintenance costs, generally 3-7% of the initial investment annually.

Personnel requirements also impact the cost structure. XPS operation demands specialized training and often dedicated technicians due to its complexity. Raman spectroscopy, while still requiring expertise, has a shorter learning curve and can often be operated by researchers after brief training periods, reducing dedicated personnel costs.

Time efficiency considerations reveal that XPS analysis is time-intensive, requiring sample preparation, system pump-down (often 8-24 hours), and sequential analysis of different elements. Raman spectroscopy offers rapid analysis with minimal sample preparation and real-time results, enabling higher throughput and faster decision-making in research and production environments.

The return on investment calculation must account for the specific information needs of the application. XPS provides quantitative elemental composition and chemical state information with superior surface sensitivity (top 1-10 nm), while Raman offers molecular structure information with varying penetration depths. For applications requiring precise surface elemental analysis, the higher cost of XPS may be justified despite the significant price premium.

Scalability considerations favor Raman spectroscopy, which can be more easily adapted to in-line monitoring and quality control applications due to its non-destructive nature and minimal sample preparation requirements. This adaptability can provide substantial long-term value in production environments where real-time analysis is beneficial.

The initial capital expenditure for XPS systems typically ranges from $500,000 to $2 million, depending on capabilities and specifications. This represents a substantial financial commitment compared to Raman spectroscopy systems, which generally cost between $50,000 and $300,000. This price differential of approximately one order of magnitude makes Raman systems significantly more accessible for organizations with limited capital budgets.

Operational costs further differentiate these technologies. XPS requires ultra-high vacuum conditions, necessitating expensive vacuum pumps and maintenance. The systems also demand specialized facilities with controlled environments, adding to infrastructure costs. Conversely, Raman spectroscopy operates under ambient conditions without vacuum requirements, substantially reducing both facility demands and operational expenses.

Consumable costs present another distinction. XPS systems require regular replacement of X-ray sources and electron detectors, with annual maintenance costs typically reaching 5-10% of the initial investment. Raman systems primarily require occasional laser source replacement and have lower maintenance costs, generally 3-7% of the initial investment annually.

Personnel requirements also impact the cost structure. XPS operation demands specialized training and often dedicated technicians due to its complexity. Raman spectroscopy, while still requiring expertise, has a shorter learning curve and can often be operated by researchers after brief training periods, reducing dedicated personnel costs.

Time efficiency considerations reveal that XPS analysis is time-intensive, requiring sample preparation, system pump-down (often 8-24 hours), and sequential analysis of different elements. Raman spectroscopy offers rapid analysis with minimal sample preparation and real-time results, enabling higher throughput and faster decision-making in research and production environments.

The return on investment calculation must account for the specific information needs of the application. XPS provides quantitative elemental composition and chemical state information with superior surface sensitivity (top 1-10 nm), while Raman offers molecular structure information with varying penetration depths. For applications requiring precise surface elemental analysis, the higher cost of XPS may be justified despite the significant price premium.

Scalability considerations favor Raman spectroscopy, which can be more easily adapted to in-line monitoring and quality control applications due to its non-destructive nature and minimal sample preparation requirements. This adaptability can provide substantial long-term value in production environments where real-time analysis is beneficial.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!