Raman Spectroscopy vs NIR: Material Characterization Effectiveness

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spectroscopic Analysis Background and Objectives

Spectroscopic analysis techniques have evolved significantly over the past century, with Raman spectroscopy and Near-Infrared (NIR) spectroscopy emerging as powerful tools for material characterization. Raman spectroscopy, discovered by C.V. Raman in 1928, utilizes the inelastic scattering of monochromatic light to provide information about molecular vibrations. NIR spectroscopy, developed in the 1950s, analyzes the absorption of electromagnetic radiation in the 780-2500 nm wavelength range. Both techniques have experienced remarkable technological advancement, particularly with the introduction of Fourier Transform methods, fiber optics, and miniaturized components in the 1980s and 1990s.

The evolution of these spectroscopic methods has been driven by increasing demands for non-destructive, rapid, and accurate material analysis across various industries. Recent developments include portable and handheld devices, enhanced computational capabilities for data processing, and integration with artificial intelligence for spectral interpretation. The convergence of these technologies has expanded the application scope of both Raman and NIR spectroscopy from traditional laboratory settings to field deployments and inline process monitoring.

Current technological trends indicate a growing interest in comparative effectiveness between these complementary techniques. While Raman spectroscopy excels in molecular fingerprinting and can detect subtle structural differences, NIR offers advantages in penetration depth and sample handling flexibility. Understanding their relative strengths and limitations has become crucial for optimizing analytical workflows and material characterization protocols.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Raman spectroscopy and NIR spectroscopy in terms of their effectiveness for material characterization across diverse applications. Specifically, we aim to evaluate their performance metrics including sensitivity, specificity, resolution, sample preparation requirements, and data interpretation complexity.

Secondary objectives include identifying optimal application scenarios for each technique, exploring potential synergistic implementations where both methods could be deployed complementarily, and forecasting technological advancements that might alter their comparative effectiveness in the next 3-5 years. This analysis will consider factors such as cost-effectiveness, operational complexity, and integration capabilities with existing industrial processes.

The findings from this research will serve as a foundation for strategic decision-making regarding technology investment, method development, and analytical protocol optimization. By thoroughly understanding the comparative advantages of these spectroscopic techniques, organizations can make informed choices about which technology best suits their specific material characterization needs, potentially leading to improved quality control, research capabilities, and process efficiency.

The evolution of these spectroscopic methods has been driven by increasing demands for non-destructive, rapid, and accurate material analysis across various industries. Recent developments include portable and handheld devices, enhanced computational capabilities for data processing, and integration with artificial intelligence for spectral interpretation. The convergence of these technologies has expanded the application scope of both Raman and NIR spectroscopy from traditional laboratory settings to field deployments and inline process monitoring.

Current technological trends indicate a growing interest in comparative effectiveness between these complementary techniques. While Raman spectroscopy excels in molecular fingerprinting and can detect subtle structural differences, NIR offers advantages in penetration depth and sample handling flexibility. Understanding their relative strengths and limitations has become crucial for optimizing analytical workflows and material characterization protocols.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Raman spectroscopy and NIR spectroscopy in terms of their effectiveness for material characterization across diverse applications. Specifically, we aim to evaluate their performance metrics including sensitivity, specificity, resolution, sample preparation requirements, and data interpretation complexity.

Secondary objectives include identifying optimal application scenarios for each technique, exploring potential synergistic implementations where both methods could be deployed complementarily, and forecasting technological advancements that might alter their comparative effectiveness in the next 3-5 years. This analysis will consider factors such as cost-effectiveness, operational complexity, and integration capabilities with existing industrial processes.

The findings from this research will serve as a foundation for strategic decision-making regarding technology investment, method development, and analytical protocol optimization. By thoroughly understanding the comparative advantages of these spectroscopic techniques, organizations can make informed choices about which technology best suits their specific material characterization needs, potentially leading to improved quality control, research capabilities, and process efficiency.

Market Applications and Industry Demand

The market for material characterization technologies, particularly Raman spectroscopy and Near-Infrared (NIR) spectroscopy, has witnessed substantial growth across multiple industries. The global spectroscopy market was valued at approximately $14.2 billion in 2021 and is projected to reach $20.5 billion by 2027, with molecular spectroscopy techniques like Raman and NIR representing significant segments of this market.

Pharmaceutical and biotechnology sectors remain the largest consumers of these technologies, utilizing both Raman and NIR for raw material identification, verification, and quality control throughout the manufacturing process. The implementation of Process Analytical Technology (PAT) initiatives has further accelerated adoption in these industries, with companies increasingly integrating spectroscopic methods into continuous manufacturing processes.

Food and agriculture industries have embraced NIR technology more extensively due to its effectiveness in analyzing moisture content, protein levels, and other nutritional parameters. The global food safety testing market, where spectroscopic techniques play a crucial role, is expanding at a CAGR of 7.3%, driven by stringent regulatory requirements and consumer demand for quality assurance.

The chemical industry utilizes both technologies for process monitoring and quality control, with Raman spectroscopy gaining traction for its ability to analyze aqueous solutions and identify specific chemical compounds without sample preparation. Meanwhile, the polymers and materials science sector leverages both techniques for composition analysis and structural characterization.

Environmental monitoring represents an emerging application area, particularly for portable Raman devices that enable field detection of contaminants and hazardous substances. This segment is experiencing rapid growth as regulatory bodies worldwide implement stricter environmental protection measures.

Geographically, North America and Europe currently dominate the market for advanced spectroscopic technologies, accounting for approximately 60% of global demand. However, Asia-Pacific regions, particularly China and India, are witnessing the fastest growth rates due to expanding pharmaceutical manufacturing, chemical production, and increasing quality control requirements.

The demand for miniaturized, portable spectroscopic devices has surged across all industries, with the handheld spectroscopy market growing at nearly twice the rate of benchtop instruments. This trend reflects the increasing need for on-site, real-time analysis capabilities in various industrial settings and field applications.

Pharmaceutical and biotechnology sectors remain the largest consumers of these technologies, utilizing both Raman and NIR for raw material identification, verification, and quality control throughout the manufacturing process. The implementation of Process Analytical Technology (PAT) initiatives has further accelerated adoption in these industries, with companies increasingly integrating spectroscopic methods into continuous manufacturing processes.

Food and agriculture industries have embraced NIR technology more extensively due to its effectiveness in analyzing moisture content, protein levels, and other nutritional parameters. The global food safety testing market, where spectroscopic techniques play a crucial role, is expanding at a CAGR of 7.3%, driven by stringent regulatory requirements and consumer demand for quality assurance.

The chemical industry utilizes both technologies for process monitoring and quality control, with Raman spectroscopy gaining traction for its ability to analyze aqueous solutions and identify specific chemical compounds without sample preparation. Meanwhile, the polymers and materials science sector leverages both techniques for composition analysis and structural characterization.

Environmental monitoring represents an emerging application area, particularly for portable Raman devices that enable field detection of contaminants and hazardous substances. This segment is experiencing rapid growth as regulatory bodies worldwide implement stricter environmental protection measures.

Geographically, North America and Europe currently dominate the market for advanced spectroscopic technologies, accounting for approximately 60% of global demand. However, Asia-Pacific regions, particularly China and India, are witnessing the fastest growth rates due to expanding pharmaceutical manufacturing, chemical production, and increasing quality control requirements.

The demand for miniaturized, portable spectroscopic devices has surged across all industries, with the handheld spectroscopy market growing at nearly twice the rate of benchtop instruments. This trend reflects the increasing need for on-site, real-time analysis capabilities in various industrial settings and field applications.

Current Capabilities and Technical Limitations

Raman spectroscopy and Near-Infrared (NIR) spectroscopy represent two powerful analytical techniques widely employed for material characterization across various industries. Currently, Raman spectroscopy demonstrates exceptional capabilities in molecular fingerprinting with high specificity, allowing for precise identification of chemical compounds and their structural arrangements. Its ability to detect subtle changes in molecular vibrations enables differentiation between similar materials and polymorphs that other techniques might miss.

The spatial resolution of modern Raman systems has reached submicron levels, particularly with confocal Raman microscopy, permitting detailed mapping of heterogeneous samples at microscopic scales. Recent advancements in Surface-Enhanced Raman Spectroscopy (SERS) have dramatically improved sensitivity, enabling detection limits approaching single-molecule levels in optimized conditions.

NIR spectroscopy, conversely, excels in rapid, non-destructive analysis of bulk materials with minimal sample preparation. Current NIR systems can analyze multiple components simultaneously, making them ideal for process monitoring applications. The technology has evolved to incorporate portable and handheld devices, facilitating in-field testing across pharmaceutical, agricultural, and food industries.

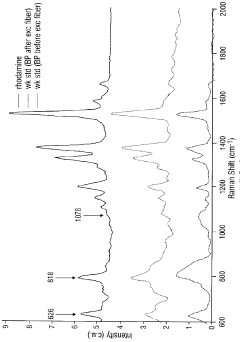

Despite these impressive capabilities, both technologies face significant limitations. Raman spectroscopy suffers from inherently weak signal intensity, with typically only one in 10^6-10^8 photons undergoing Raman scattering. This necessitates longer acquisition times or higher laser powers, potentially damaging sensitive samples. Fluorescence interference remains a persistent challenge, often overwhelming the Raman signal, particularly with biological samples or materials containing fluorophores.

NIR spectroscopy confronts its own set of limitations, primarily related to spectral interpretation complexity. NIR bands are typically broad, overlapping, and less specific than Raman peaks, requiring sophisticated chemometric methods for meaningful analysis. Water absorption significantly impacts NIR spectra, complicating analysis of aqueous samples or materials with varying moisture content.

The depth penetration capabilities differ markedly between the techniques. While NIR can penetrate several millimeters into samples, allowing bulk analysis, Raman typically provides surface or near-surface information unless specialized techniques are employed. Temperature sensitivity affects both methods, with NIR particularly susceptible to thermal variations that can shift spectral features.

Current technical development focuses on overcoming these limitations through hardware innovations and advanced data processing. Time-resolved Raman systems are being developed to mitigate fluorescence interference, while multivariate calibration methods are enhancing NIR's specificity. Hybrid systems combining both techniques are emerging as promising solutions to leverage the complementary strengths of each approach while minimizing their individual limitations.

The spatial resolution of modern Raman systems has reached submicron levels, particularly with confocal Raman microscopy, permitting detailed mapping of heterogeneous samples at microscopic scales. Recent advancements in Surface-Enhanced Raman Spectroscopy (SERS) have dramatically improved sensitivity, enabling detection limits approaching single-molecule levels in optimized conditions.

NIR spectroscopy, conversely, excels in rapid, non-destructive analysis of bulk materials with minimal sample preparation. Current NIR systems can analyze multiple components simultaneously, making them ideal for process monitoring applications. The technology has evolved to incorporate portable and handheld devices, facilitating in-field testing across pharmaceutical, agricultural, and food industries.

Despite these impressive capabilities, both technologies face significant limitations. Raman spectroscopy suffers from inherently weak signal intensity, with typically only one in 10^6-10^8 photons undergoing Raman scattering. This necessitates longer acquisition times or higher laser powers, potentially damaging sensitive samples. Fluorescence interference remains a persistent challenge, often overwhelming the Raman signal, particularly with biological samples or materials containing fluorophores.

NIR spectroscopy confronts its own set of limitations, primarily related to spectral interpretation complexity. NIR bands are typically broad, overlapping, and less specific than Raman peaks, requiring sophisticated chemometric methods for meaningful analysis. Water absorption significantly impacts NIR spectra, complicating analysis of aqueous samples or materials with varying moisture content.

The depth penetration capabilities differ markedly between the techniques. While NIR can penetrate several millimeters into samples, allowing bulk analysis, Raman typically provides surface or near-surface information unless specialized techniques are employed. Temperature sensitivity affects both methods, with NIR particularly susceptible to thermal variations that can shift spectral features.

Current technical development focuses on overcoming these limitations through hardware innovations and advanced data processing. Time-resolved Raman systems are being developed to mitigate fluorescence interference, while multivariate calibration methods are enhancing NIR's specificity. Hybrid systems combining both techniques are emerging as promising solutions to leverage the complementary strengths of each approach while minimizing their individual limitations.

Comparative Analysis of Raman and NIR Technologies

01 Comparative effectiveness of Raman and NIR spectroscopy for material characterization

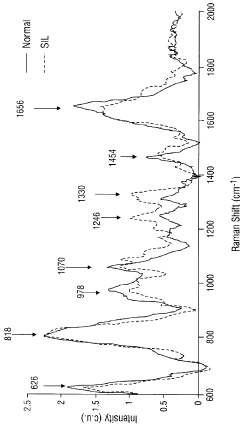

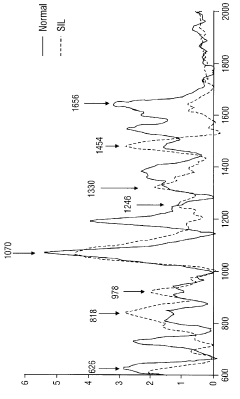

Raman spectroscopy and Near-Infrared (NIR) spectroscopy offer complementary approaches for material characterization with distinct advantages. Raman spectroscopy provides detailed molecular fingerprinting through inelastic light scattering, enabling identification of specific chemical bonds and structures with high specificity. NIR spectroscopy, operating in the 780-2500nm wavelength range, excels at analyzing organic compounds through absorption measurements of molecular overtones and combinations. The comparative effectiveness depends on the material being analyzed, with Raman being superior for crystalline structures and inorganic compounds, while NIR performs better for bulk organic materials and moisture content analysis.- Comparative advantages of Raman and NIR spectroscopy in material characterization: Raman spectroscopy and Near-Infrared (NIR) spectroscopy offer complementary approaches to material characterization with distinct advantages. Raman spectroscopy provides detailed molecular fingerprinting through inelastic light scattering, enabling identification of specific chemical bonds and crystalline structures with high spatial resolution. NIR spectroscopy excels at penetrating deeper into samples, allowing for bulk analysis and quantitative measurements of chemical composition, particularly for organic materials containing C-H, O-H, and N-H bonds. The combination of both techniques provides comprehensive material characterization by capturing both surface molecular structure and bulk composition information.

- Medical and biological applications of combined spectroscopic techniques: Raman and NIR spectroscopy are increasingly utilized in medical diagnostics and biological sample analysis. These techniques enable non-invasive tissue characterization, blood component analysis, and disease detection through identification of biomarkers and metabolic changes. The spectroscopic methods can differentiate between healthy and pathological tissues based on their unique spectral signatures, allowing for early disease detection. Advanced algorithms process the spectral data to identify subtle changes indicative of disease states, while portable devices facilitate point-of-care diagnostics. These technologies support real-time monitoring during surgical procedures and can analyze biological samples with minimal preparation.

- Industrial quality control and process monitoring applications: Spectroscopic techniques provide powerful tools for industrial quality control and process monitoring across various sectors. In manufacturing, these methods enable real-time analysis of raw materials, intermediates, and finished products without destructive testing. The techniques can verify material composition, detect contaminants, and ensure batch-to-batch consistency in pharmaceutical, food, chemical, and polymer industries. Process analytical technology (PAT) implementations incorporate these spectroscopic methods for continuous monitoring of production processes, allowing for immediate adjustments to maintain product quality. The non-contact nature of these techniques makes them suitable for monitoring hazardous materials or sterile environments.

- Advanced data processing and machine learning integration: The effectiveness of spectroscopic material characterization is significantly enhanced through advanced data processing techniques and machine learning algorithms. Multivariate analysis methods such as principal component analysis (PCA) and partial least squares (PLS) regression extract meaningful information from complex spectral datasets. Machine learning algorithms improve the accuracy of material identification and quantification by recognizing patterns in spectral data that might be imperceptible to traditional analysis methods. Deep learning approaches can automatically identify spectral features associated with specific material properties or compositions. These computational methods enable the development of robust calibration models that can account for environmental variations and sample heterogeneity, improving the reliability of spectroscopic analysis in real-world applications.

- Portable and miniaturized spectroscopic systems: Advancements in miniaturization have led to the development of portable Raman and NIR spectroscopic systems that maintain high analytical performance while enabling field deployment. These compact instruments utilize microelectromechanical systems (MEMS), integrated photonics, and specialized optical components to reduce size without sacrificing sensitivity. Handheld devices allow for on-site material identification and quality verification in applications ranging from pharmaceutical authentication to geological exploration. Miniaturized spectroscopic systems can be integrated into smartphones or dedicated portable devices, democratizing access to advanced analytical capabilities. These systems often incorporate wireless connectivity for data transmission and cloud-based analysis, enabling remote expert consultation and centralized data management.

02 Medical and biological applications of spectroscopic techniques

Both Raman and NIR spectroscopy have proven highly effective for medical and biological material characterization. These techniques enable non-invasive analysis of tissues, bodily fluids, and pharmaceutical compounds. In medical diagnostics, they can detect biomarkers, analyze blood components, and identify pathological changes in tissues without requiring sample preparation or causing damage. The spectroscopic methods allow for real-time monitoring of biological processes and can differentiate between healthy and diseased tissues based on their molecular composition. These technologies have been integrated into medical devices for point-of-care diagnostics and surgical guidance systems.Expand Specific Solutions03 Advanced data processing and analysis methods for spectroscopic data

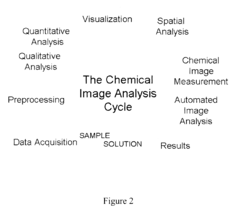

The effectiveness of both spectroscopic techniques is significantly enhanced through advanced data processing methods. Machine learning algorithms, multivariate analysis, and chemometric approaches are employed to extract meaningful information from complex spectral data. These computational methods enable pattern recognition, classification of materials, quantitative analysis, and can compensate for instrumental variations and environmental interferences. Principal component analysis, partial least squares regression, and neural networks are commonly used to process spectral data, improving the accuracy and reliability of material characterization. Real-time data processing capabilities have expanded the application range of these spectroscopic techniques in industrial settings.Expand Specific Solutions04 Industrial applications and quality control using spectroscopic techniques

Raman and NIR spectroscopy have become essential tools for industrial quality control and process monitoring. These techniques enable rapid, non-destructive analysis of raw materials, intermediates, and finished products across various industries including pharmaceuticals, food, agriculture, and petrochemicals. The spectroscopic methods can verify material identity, quantify components, detect contaminants, and ensure batch-to-batch consistency. In-line and at-line implementations allow for real-time process monitoring and control, reducing production costs and improving product quality. The techniques are particularly valuable for analyzing multiple components simultaneously without sample preparation.Expand Specific Solutions05 Technological advancements in spectroscopic instrumentation

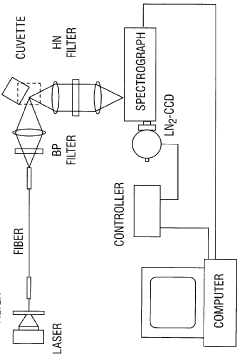

Recent technological innovations have significantly improved the effectiveness of Raman and NIR spectroscopic techniques for material characterization. Miniaturization of components has led to portable and handheld devices that enable field analysis without sacrificing performance. Advanced detector technologies have improved sensitivity and signal-to-noise ratios, allowing for faster acquisition times and detection of trace components. Fiber optic probes enable remote sensing and in-situ measurements in challenging environments. Hybrid systems combining multiple spectroscopic techniques provide more comprehensive material characterization by leveraging the strengths of each method. These advancements have expanded the application range and accessibility of spectroscopic analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Raman Spectroscopy vs NIR material characterization market is in a growth phase, with increasing adoption across pharmaceutical, chemical, and materials science industries. The global spectroscopy market is projected to reach approximately $20 billion by 2025, with Raman and NIR segments showing robust growth rates. Technologically, both methods are mature but continuously evolving, with companies developing more sophisticated applications. Leading players include established instrumentation providers like Hitachi and Excelitas Technologies, alongside specialized firms such as SciAps. Academic institutions (National University of Singapore, Zhejiang University) are driving fundamental research, while industrial players (ExxonMobil, HP) focus on application-specific developments. The competitive landscape features a mix of large corporations providing comprehensive solutions and niche players offering specialized expertise in targeted applications.

Excelitas Technologies Corp.

Technical Solution: Excelitas Technologies has developed specialized photonic components and subsystems that enhance the performance of both Raman and NIR spectroscopy systems. Their ProPhotonix laser modules deliver precisely controlled excitation wavelengths with exceptional stability (±0.01nm) critical for accurate Raman measurements. The company's avalanche photodiode (APD) detectors achieve quantum efficiencies exceeding 85% in the near-infrared region, significantly improving signal-to-noise ratios in spectroscopic applications. Excelitas has pioneered miniaturized optical bench designs that reduce the footprint of spectroscopic systems by up to 70% while maintaining performance specifications. Their patented MEMS-based optical filter technology enables rapid wavelength scanning without moving parts, increasing reliability in field-deployed systems. The company's integrated Raman probe assemblies incorporate specialized optical coatings that minimize autofluorescence, addressing one of the key limitations in conventional Raman spectroscopy implementations.

Strengths: Industry-leading detector sensitivity enhances performance in low-concentration applications; Miniaturized designs enable integration into portable and handheld devices; Specialized optical coatings significantly reduce fluorescence interference; Vertically integrated manufacturing ensures component compatibility. Weaknesses: Components require integration with broader systems rather than providing complete solutions; Higher cost compared to generic optical components; Customization requirements can extend implementation timelines.

SciAps, Inc.

Technical Solution: SciAps has developed advanced handheld Raman and LIBS (Laser Induced Breakdown Spectroscopy) analyzers for material characterization. Their Z-series Raman analyzers utilize 1030nm excitation lasers to minimize fluorescence interference, a common limitation in traditional Raman systems. The company's proprietary algorithms enable rapid material identification within seconds, with their database containing over 10,000 compounds for reference matching. SciAps has integrated their Raman technology with cloud-based data management systems allowing for real-time analysis updates and remote expert consultation. Their dual-technology approach combines Raman with LIBS in some models to provide complementary analytical capabilities, addressing limitations of each individual technique when used alone. This integration allows for both molecular structure identification (Raman) and elemental composition analysis (LIBS) in a single portable device.

Strengths: Superior fluorescence rejection through optimized laser wavelength selection; Extensive compound library for accurate identification; Ruggedized portable design for field applications; Integration with cloud platforms for continuous improvement. Weaknesses: Higher cost compared to single-technology solutions; Limited penetration depth compared to NIR for certain materials; Requires more user training than some competing technologies.

Key Patents and Scientific Breakthroughs

Near-infrared raman spectroscopy for in vitro and in vivo detection of cervical precancers

PatentInactiveUS5991653A

Innovation

- The application of Raman spectroscopy using near-infrared radiation to differentiate normal and abnormal cervical tissues by analyzing specific emission frequencies and developing multivariate statistical models for accurate diagnosis, potentially combined with fluorescence spectroscopy for enhanced accuracy.

Near infrared chemical imaging microscope

PatentInactiveUS6734962B2

Innovation

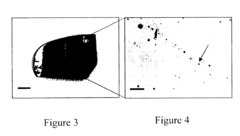

- The development of a NIR chemical imaging microscope utilizing liquid crystal (LC) imaging spectrometer technology for wavelength selection, integrated with a refractive optical microscope and infinity-corrected objectives, allowing for real-time sample positioning and focusing, and enabling high-resolution (spatial and spectral) imaging in two and three spatial dimensions without moving parts, using a Chemical Imaging Addition Method for qualitative and quantitative analysis.

Cost-Benefit Analysis and ROI Considerations

When evaluating the implementation of Raman spectroscopy versus Near-Infrared (NIR) spectroscopy for material characterization, a comprehensive cost-benefit analysis is essential for making informed investment decisions. The initial capital expenditure for Raman systems typically ranges from $30,000 to $150,000, significantly higher than NIR systems which generally cost between $20,000 and $80,000. This substantial difference in upfront investment necessitates careful consideration of long-term returns.

Operational costs present another critical dimension for comparison. Raman systems often require more sophisticated maintenance protocols and specialized technical expertise, resulting in higher annual maintenance costs averaging 8-12% of the initial investment. In contrast, NIR systems generally demand 5-8% of the initial cost for maintenance. However, the consumables for Raman spectroscopy are minimal, while NIR may require regular replacement of certain components, particularly light sources and optical filters.

The return on investment timeline differs significantly between these technologies. NIR systems typically achieve ROI within 1-3 years in industrial applications due to lower initial costs and operational expenses. Raman systems, despite higher initial investments, may offer superior ROI in specific applications where their unique capabilities justify the premium, with typical ROI periods of 2-5 years depending on application intensity.

Productivity gains represent a substantial factor in the cost-benefit equation. Raman spectroscopy's superior specificity and minimal sample preparation requirements can reduce analysis time by 30-50% compared to traditional methods, potentially saving 15-25 labor hours weekly in high-throughput environments. NIR offers comparable time savings but may require more extensive calibration efforts initially.

Risk mitigation value must also be quantified. Raman's ability to detect subtle material differences can prevent costly manufacturing errors, with potential savings of $50,000-$250,000 annually in quality control applications. NIR systems provide similar benefits but may be less effective for certain material distinctions, particularly in complex mixtures or when analyzing materials with similar chemical structures.

Scalability considerations reveal that NIR systems generally offer more cost-effective scaling across multiple production lines, with incremental units costing 60-70% of the initial system. Raman technology typically maintains higher costs for additional units, with economies of scale providing only modest 10-20% reductions for subsequent installations.

AI and automation integration capabilities increasingly influence ROI calculations. Both technologies support automation, but Raman's more distinctive spectral features often enable more robust algorithm development, potentially reducing false positives by 15-25% compared to NIR in certain applications, translating to significant operational savings over time.

Operational costs present another critical dimension for comparison. Raman systems often require more sophisticated maintenance protocols and specialized technical expertise, resulting in higher annual maintenance costs averaging 8-12% of the initial investment. In contrast, NIR systems generally demand 5-8% of the initial cost for maintenance. However, the consumables for Raman spectroscopy are minimal, while NIR may require regular replacement of certain components, particularly light sources and optical filters.

The return on investment timeline differs significantly between these technologies. NIR systems typically achieve ROI within 1-3 years in industrial applications due to lower initial costs and operational expenses. Raman systems, despite higher initial investments, may offer superior ROI in specific applications where their unique capabilities justify the premium, with typical ROI periods of 2-5 years depending on application intensity.

Productivity gains represent a substantial factor in the cost-benefit equation. Raman spectroscopy's superior specificity and minimal sample preparation requirements can reduce analysis time by 30-50% compared to traditional methods, potentially saving 15-25 labor hours weekly in high-throughput environments. NIR offers comparable time savings but may require more extensive calibration efforts initially.

Risk mitigation value must also be quantified. Raman's ability to detect subtle material differences can prevent costly manufacturing errors, with potential savings of $50,000-$250,000 annually in quality control applications. NIR systems provide similar benefits but may be less effective for certain material distinctions, particularly in complex mixtures or when analyzing materials with similar chemical structures.

Scalability considerations reveal that NIR systems generally offer more cost-effective scaling across multiple production lines, with incremental units costing 60-70% of the initial system. Raman technology typically maintains higher costs for additional units, with economies of scale providing only modest 10-20% reductions for subsequent installations.

AI and automation integration capabilities increasingly influence ROI calculations. Both technologies support automation, but Raman's more distinctive spectral features often enable more robust algorithm development, potentially reducing false positives by 15-25% compared to NIR in certain applications, translating to significant operational savings over time.

Miniaturization and Portability Advancements

The miniaturization and portability of spectroscopic technologies have revolutionized material characterization capabilities across various industries. Both Raman spectroscopy and Near-Infrared (NIR) systems have undergone significant transformations from bulky laboratory equipment to compact, field-deployable devices, though with different engineering challenges and outcomes.

Raman spectroscopy has experienced remarkable advancements in miniaturization over the past decade. Early portable Raman devices weighed several kilograms and required external power sources, limiting their field applications. Recent innovations have produced handheld Raman spectrometers weighing less than 1 kg, incorporating high-performance lasers, sophisticated optical filtering systems, and sensitive detectors. Companies like Thermo Fisher Scientific and Metrohm have developed palm-sized devices that maintain spectral resolution comparable to benchtop systems while operating on battery power for 4-8 hours.

NIR technology has traditionally held an advantage in miniaturization due to its simpler optical requirements and less stringent detector specifications. Current portable NIR devices are generally lighter (some under 500g) and more energy-efficient than their Raman counterparts. The absence of laser excitation sources reduces power consumption significantly, with some NIR devices operating continuously for up to 12 hours on a single charge. Manufacturers like JDSU and Ocean Insight have developed smartphone-compatible NIR modules, further expanding accessibility.

The miniaturization trajectories of these technologies reveal interesting trade-offs. Raman systems have faced greater challenges in reducing size while maintaining performance due to their need for precise laser sources, sophisticated filtering, and cooling systems. However, recent developments in photonic integrated circuits and MEMS (Micro-Electro-Mechanical Systems) technology have enabled significant breakthroughs, particularly in maintaining spectral resolution in compact formats.

NIR systems have benefited from advances in InGaAs detector arrays and LED light sources, allowing for dramatic size reductions without significant performance compromises. The integration of machine learning algorithms has further enhanced the capabilities of miniaturized NIR systems, compensating for some hardware limitations through sophisticated data processing.

Looking forward, both technologies are converging toward true pocket-sized instruments with wireless connectivity and cloud-based data processing capabilities. Emerging developments in silicon photonics and quantum dot sensors promise further size reductions while enhancing sensitivity for both technologies. The ultimate goal of "spectroscopy-on-a-chip" appears increasingly achievable, with potential integration into everyday consumer devices within the next 5-10 years.

Raman spectroscopy has experienced remarkable advancements in miniaturization over the past decade. Early portable Raman devices weighed several kilograms and required external power sources, limiting their field applications. Recent innovations have produced handheld Raman spectrometers weighing less than 1 kg, incorporating high-performance lasers, sophisticated optical filtering systems, and sensitive detectors. Companies like Thermo Fisher Scientific and Metrohm have developed palm-sized devices that maintain spectral resolution comparable to benchtop systems while operating on battery power for 4-8 hours.

NIR technology has traditionally held an advantage in miniaturization due to its simpler optical requirements and less stringent detector specifications. Current portable NIR devices are generally lighter (some under 500g) and more energy-efficient than their Raman counterparts. The absence of laser excitation sources reduces power consumption significantly, with some NIR devices operating continuously for up to 12 hours on a single charge. Manufacturers like JDSU and Ocean Insight have developed smartphone-compatible NIR modules, further expanding accessibility.

The miniaturization trajectories of these technologies reveal interesting trade-offs. Raman systems have faced greater challenges in reducing size while maintaining performance due to their need for precise laser sources, sophisticated filtering, and cooling systems. However, recent developments in photonic integrated circuits and MEMS (Micro-Electro-Mechanical Systems) technology have enabled significant breakthroughs, particularly in maintaining spectral resolution in compact formats.

NIR systems have benefited from advances in InGaAs detector arrays and LED light sources, allowing for dramatic size reductions without significant performance compromises. The integration of machine learning algorithms has further enhanced the capabilities of miniaturized NIR systems, compensating for some hardware limitations through sophisticated data processing.

Looking forward, both technologies are converging toward true pocket-sized instruments with wireless connectivity and cloud-based data processing capabilities. Emerging developments in silicon photonics and quantum dot sensors promise further size reductions while enhancing sensitivity for both technologies. The ultimate goal of "spectroscopy-on-a-chip" appears increasingly achievable, with potential integration into everyday consumer devices within the next 5-10 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!