How to Use Raman Spectroscopy for Synthetic Fiber Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Raman Spectroscopy in Fiber Analysis: Background and Objectives

Raman spectroscopy has emerged as a powerful analytical technique in materials science since its discovery in 1928 by Sir C.V. Raman. The technology has evolved significantly over the past century, transitioning from basic laboratory applications to sophisticated industrial implementations. In the context of synthetic fiber analysis, Raman spectroscopy offers unique capabilities for non-destructive, rapid, and detailed characterization of polymeric materials that constitute modern synthetic fibers.

The evolution of Raman technology has been marked by several significant milestones, including the development of Fourier Transform Raman spectroscopy in the 1980s, the introduction of portable Raman devices in the 1990s, and the recent integration of artificial intelligence for spectral analysis in the 2010s. These advancements have progressively enhanced the applicability of Raman techniques in industrial settings, particularly in quality control and material verification processes within the textile industry.

Synthetic fibers, which account for approximately 65% of global fiber production, represent a diverse category of materials with varying chemical compositions, structures, and properties. The ability to accurately identify, characterize, and differentiate these fibers is crucial for numerous applications ranging from textile manufacturing to forensic analysis. Traditional analytical methods often require extensive sample preparation, destructive testing, or provide limited molecular information.

The primary technical objective of applying Raman spectroscopy to synthetic fiber analysis is to develop robust, efficient, and accurate methodologies for fiber identification, composition analysis, and quality assessment. This includes the characterization of fiber polymers, additives, dyes, and structural features at the molecular level, as well as the detection of contaminants or adulterants that may affect fiber performance or authenticity.

Secondary objectives include the development of standardized protocols for Raman analysis of different fiber types, the creation of comprehensive spectral libraries for automated identification systems, and the integration of Raman technology into existing quality control workflows in textile manufacturing. These objectives align with the broader industry trends toward digitalization, automation, and enhanced quality assurance in textile production.

The technological trajectory suggests that future developments will likely focus on miniaturization of Raman devices for in-field testing, enhanced spectral resolution for more detailed molecular analysis, and the integration of machine learning algorithms for more sophisticated pattern recognition and material characterization. These advancements are expected to further expand the utility of Raman spectroscopy in synthetic fiber analysis across various industrial applications.

The evolution of Raman technology has been marked by several significant milestones, including the development of Fourier Transform Raman spectroscopy in the 1980s, the introduction of portable Raman devices in the 1990s, and the recent integration of artificial intelligence for spectral analysis in the 2010s. These advancements have progressively enhanced the applicability of Raman techniques in industrial settings, particularly in quality control and material verification processes within the textile industry.

Synthetic fibers, which account for approximately 65% of global fiber production, represent a diverse category of materials with varying chemical compositions, structures, and properties. The ability to accurately identify, characterize, and differentiate these fibers is crucial for numerous applications ranging from textile manufacturing to forensic analysis. Traditional analytical methods often require extensive sample preparation, destructive testing, or provide limited molecular information.

The primary technical objective of applying Raman spectroscopy to synthetic fiber analysis is to develop robust, efficient, and accurate methodologies for fiber identification, composition analysis, and quality assessment. This includes the characterization of fiber polymers, additives, dyes, and structural features at the molecular level, as well as the detection of contaminants or adulterants that may affect fiber performance or authenticity.

Secondary objectives include the development of standardized protocols for Raman analysis of different fiber types, the creation of comprehensive spectral libraries for automated identification systems, and the integration of Raman technology into existing quality control workflows in textile manufacturing. These objectives align with the broader industry trends toward digitalization, automation, and enhanced quality assurance in textile production.

The technological trajectory suggests that future developments will likely focus on miniaturization of Raman devices for in-field testing, enhanced spectral resolution for more detailed molecular analysis, and the integration of machine learning algorithms for more sophisticated pattern recognition and material characterization. These advancements are expected to further expand the utility of Raman spectroscopy in synthetic fiber analysis across various industrial applications.

Market Demand for Advanced Synthetic Fiber Characterization

The global synthetic fiber market has witnessed substantial growth, reaching approximately $64 billion in 2022, with projections indicating continued expansion at a CAGR of 5.8% through 2030. This growth trajectory underscores the increasing demand for advanced characterization techniques like Raman spectroscopy across various industrial sectors.

Textile manufacturers face mounting pressure to verify fiber composition and quality as regulatory requirements become more stringent worldwide. The European Union's textile labeling regulations and similar frameworks in North America and Asia have created a compliance-driven demand for precise analytical methods. Raman spectroscopy offers manufacturers the ability to meet these requirements while maintaining production efficiency.

Quality control represents another significant market driver, particularly in high-performance technical textiles used in automotive, aerospace, and medical applications. These sectors demand materials with specific mechanical, thermal, and chemical properties that can only be guaranteed through advanced characterization techniques. The market for quality assurance systems in synthetic fiber production was valued at $3.2 billion in 2022, with Raman-based solutions capturing an increasing share.

Consumer preferences are shifting toward sustainable and recycled synthetic fibers, creating new market opportunities. Brands must verify recycled content claims and ensure consistent performance of these materials. Raman spectroscopy enables rapid identification of recycled versus virgin polymers and detection of contaminants in recycled feedstock, addressing a market segment growing at 12% annually.

The forensic textile analysis market, though smaller in absolute terms, shows significant growth potential. Law enforcement agencies, insurance companies, and authentication services increasingly rely on spectroscopic techniques to verify textile composition in counterfeit investigations and legal proceedings.

Research institutions and R&D departments within fiber manufacturing companies represent another key market segment. The development of novel synthetic fibers with enhanced properties requires sophisticated analytical capabilities, driving investment in advanced characterization equipment.

Geographically, the Asia-Pacific region dominates demand for synthetic fiber characterization technologies, accounting for 45% of the global market. This concentration aligns with the region's manufacturing footprint. However, North America and Europe lead in the adoption of cutting-edge analytical techniques, particularly in specialized applications requiring higher precision and reliability.

Textile manufacturers face mounting pressure to verify fiber composition and quality as regulatory requirements become more stringent worldwide. The European Union's textile labeling regulations and similar frameworks in North America and Asia have created a compliance-driven demand for precise analytical methods. Raman spectroscopy offers manufacturers the ability to meet these requirements while maintaining production efficiency.

Quality control represents another significant market driver, particularly in high-performance technical textiles used in automotive, aerospace, and medical applications. These sectors demand materials with specific mechanical, thermal, and chemical properties that can only be guaranteed through advanced characterization techniques. The market for quality assurance systems in synthetic fiber production was valued at $3.2 billion in 2022, with Raman-based solutions capturing an increasing share.

Consumer preferences are shifting toward sustainable and recycled synthetic fibers, creating new market opportunities. Brands must verify recycled content claims and ensure consistent performance of these materials. Raman spectroscopy enables rapid identification of recycled versus virgin polymers and detection of contaminants in recycled feedstock, addressing a market segment growing at 12% annually.

The forensic textile analysis market, though smaller in absolute terms, shows significant growth potential. Law enforcement agencies, insurance companies, and authentication services increasingly rely on spectroscopic techniques to verify textile composition in counterfeit investigations and legal proceedings.

Research institutions and R&D departments within fiber manufacturing companies represent another key market segment. The development of novel synthetic fibers with enhanced properties requires sophisticated analytical capabilities, driving investment in advanced characterization equipment.

Geographically, the Asia-Pacific region dominates demand for synthetic fiber characterization technologies, accounting for 45% of the global market. This concentration aligns with the region's manufacturing footprint. However, North America and Europe lead in the adoption of cutting-edge analytical techniques, particularly in specialized applications requiring higher precision and reliability.

Current Capabilities and Challenges in Raman Fiber Analysis

Raman spectroscopy has emerged as a powerful analytical tool for synthetic fiber characterization, offering non-destructive, rapid, and highly specific molecular information. Current capabilities in this field have advanced significantly over the past decade, with modern Raman systems providing enhanced sensitivity and resolution that enable detailed analysis of fiber composition, structure, and properties.

Commercial Raman instruments now routinely achieve spatial resolution below 1 μm, allowing for precise analysis of individual fibers and even specific regions within a single fiber. This capability has proven invaluable for identifying contaminants, analyzing fiber blends, and characterizing fiber surface treatments. Additionally, portable and handheld Raman devices have democratized access to this technology, enabling in-field analysis without sample preparation.

Chemometric approaches have substantially improved data processing capabilities, with multivariate analysis techniques such as Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression enabling automated fiber identification and quantitative analysis of fiber blends. These methods have been successfully implemented in quality control processes across the textile industry.

Despite these advancements, significant challenges persist in Raman analysis of synthetic fibers. Fluorescence interference remains a major obstacle, particularly with colored or dyed fibers, often overwhelming the weaker Raman signals. While techniques such as shifted-excitation Raman difference spectroscopy (SERDS) and time-gated Raman spectroscopy have shown promise in mitigating fluorescence, they add complexity and cost to the analytical process.

Sample heating during analysis presents another challenge, especially for thermally sensitive synthetic fibers like polyamides and polyesters. Excessive laser power can induce structural changes or even degradation, compromising the integrity of the analysis. This necessitates careful optimization of measurement parameters, often at the expense of signal quality.

Quantitative analysis remains difficult due to variations in sample presentation, fiber orientation effects, and the complex relationship between Raman signal intensity and concentration. Reference standards for different fiber types and compositions are often lacking, limiting the accuracy of quantitative determinations.

The heterogeneity of synthetic fibers presents additional complications, as variations in crystallinity, orientation, and additives can significantly affect Raman spectra. This makes it challenging to develop comprehensive spectral libraries and automated identification algorithms that account for all possible variations within a fiber type.

Surface-enhanced Raman spectroscopy (SERS) offers promising solutions to sensitivity limitations but faces challenges in reproducibility and standardization when applied to fiber analysis. The development of reliable SERS substrates specifically designed for fiber applications remains an active area of research with significant potential for breakthrough advancements.

Commercial Raman instruments now routinely achieve spatial resolution below 1 μm, allowing for precise analysis of individual fibers and even specific regions within a single fiber. This capability has proven invaluable for identifying contaminants, analyzing fiber blends, and characterizing fiber surface treatments. Additionally, portable and handheld Raman devices have democratized access to this technology, enabling in-field analysis without sample preparation.

Chemometric approaches have substantially improved data processing capabilities, with multivariate analysis techniques such as Principal Component Analysis (PCA) and Partial Least Squares (PLS) regression enabling automated fiber identification and quantitative analysis of fiber blends. These methods have been successfully implemented in quality control processes across the textile industry.

Despite these advancements, significant challenges persist in Raman analysis of synthetic fibers. Fluorescence interference remains a major obstacle, particularly with colored or dyed fibers, often overwhelming the weaker Raman signals. While techniques such as shifted-excitation Raman difference spectroscopy (SERDS) and time-gated Raman spectroscopy have shown promise in mitigating fluorescence, they add complexity and cost to the analytical process.

Sample heating during analysis presents another challenge, especially for thermally sensitive synthetic fibers like polyamides and polyesters. Excessive laser power can induce structural changes or even degradation, compromising the integrity of the analysis. This necessitates careful optimization of measurement parameters, often at the expense of signal quality.

Quantitative analysis remains difficult due to variations in sample presentation, fiber orientation effects, and the complex relationship between Raman signal intensity and concentration. Reference standards for different fiber types and compositions are often lacking, limiting the accuracy of quantitative determinations.

The heterogeneity of synthetic fibers presents additional complications, as variations in crystallinity, orientation, and additives can significantly affect Raman spectra. This makes it challenging to develop comprehensive spectral libraries and automated identification algorithms that account for all possible variations within a fiber type.

Surface-enhanced Raman spectroscopy (SERS) offers promising solutions to sensitivity limitations but faces challenges in reproducibility and standardization when applied to fiber analysis. The development of reliable SERS substrates specifically designed for fiber applications remains an active area of research with significant potential for breakthrough advancements.

Established Methodologies for Synthetic Fiber Identification

01 Raman spectroscopy instrumentation and apparatus design

Various designs and configurations of Raman spectroscopy instruments are disclosed, including improvements in optical components, detection systems, and overall apparatus architecture. These innovations focus on enhancing sensitivity, resolution, and reliability of Raman measurements while reducing interference from background signals. The designs incorporate specialized light sources, filters, detectors, and optical arrangements to optimize the collection of Raman scattered light from samples.- Raman spectroscopy instrumentation and apparatus design: Various designs and configurations of Raman spectroscopy instruments are disclosed, including improvements in optical components, detection systems, and overall apparatus architecture. These innovations focus on enhancing sensitivity, resolution, and reliability of Raman measurements while reducing interference from background signals. The designs incorporate specialized light sources, filters, and detectors to optimize the collection of Raman scattered light from samples.

- Biomedical applications of Raman spectroscopy: Raman spectroscopy techniques applied to medical diagnostics and biological sample analysis, enabling non-invasive or minimally invasive detection of diseases, tissue characterization, and molecular identification in biological specimens. These methods utilize the unique vibrational fingerprints of biomolecules to identify pathological conditions, monitor therapeutic responses, and analyze cellular components without requiring extensive sample preparation or destructive testing procedures.

- Enhanced Raman techniques and signal processing: Advanced Raman spectroscopy techniques including surface-enhanced Raman spectroscopy (SERS), tip-enhanced Raman spectroscopy (TERS), and specialized signal processing methods to improve detection limits and spectral quality. These approaches utilize nanomaterials, plasmonic structures, or computational algorithms to amplify weak Raman signals, reduce noise, and extract meaningful information from complex spectral data, enabling detection of trace amounts of substances and improved molecular characterization.

- Industrial and environmental monitoring applications: Implementation of Raman spectroscopy for real-time monitoring and analysis in industrial processes, environmental testing, and quality control applications. These systems provide rapid, non-destructive analysis of chemical compositions, contaminants, and material properties in various settings including manufacturing facilities, field environments, and quality assurance laboratories, allowing for immediate feedback and process optimization without extensive sample preparation.

- Portable and miniaturized Raman systems: Development of compact, portable, and field-deployable Raman spectroscopy systems that maintain high performance while reducing size, weight, and power requirements. These innovations include miniaturized optical components, integrated photonics, and specialized designs that enable Raman analysis outside of laboratory settings. The portable systems facilitate on-site testing for applications in security screening, forensic investigation, pharmaceutical verification, and geological exploration.

02 Raman spectroscopy for biomedical applications

Raman spectroscopy techniques applied to biomedical diagnostics and analysis, including non-invasive monitoring of biological samples, disease detection, and tissue characterization. These applications leverage the ability of Raman spectroscopy to provide molecular-level information without sample destruction. The technologies enable real-time analysis of biological tissues, bodily fluids, and cellular components for medical diagnostics, treatment monitoring, and research purposes.Expand Specific Solutions03 Enhanced Raman techniques and signal processing

Advanced Raman spectroscopy techniques including surface-enhanced Raman spectroscopy (SERS), resonance Raman, and specialized signal processing methods to improve detection sensitivity and specificity. These enhancements allow for detection of trace amounts of substances and improved discrimination between similar compounds. The technologies incorporate novel substrate materials, data analysis algorithms, and measurement protocols to overcome traditional limitations of conventional Raman spectroscopy.Expand Specific Solutions04 Portable and miniaturized Raman systems

Development of compact, portable, and field-deployable Raman spectroscopy systems for on-site analysis and real-time monitoring applications. These innovations focus on miniaturization of components, power efficiency, and ruggedization for field use while maintaining analytical performance. The systems enable Raman analysis outside of laboratory environments for applications in environmental monitoring, security screening, quality control, and point-of-care diagnostics.Expand Specific Solutions05 Raman spectroscopy for material identification and analysis

Application of Raman spectroscopy for identification, characterization, and quality control of various materials including pharmaceuticals, chemicals, polymers, and nanomaterials. These technologies utilize the unique vibrational fingerprints provided by Raman scattering to identify substances, detect contaminants, and analyze material properties. The methods include specialized sampling techniques, reference libraries, and analytical protocols for rapid and accurate material analysis in industrial and research settings.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Spectroscopic Analysis

The Raman spectroscopy market for synthetic fiber analysis is in a growth phase, with increasing adoption across textile manufacturing and quality control sectors. The market size is expanding steadily, driven by demand for non-destructive analytical techniques in industrial applications. Technologically, the field shows moderate maturity with established players like Shimadzu Corp. and Bruker Optics offering commercial solutions, while research institutions including Zhejiang Sci-Tech University and Donghua University advance fiber-specific applications. ChemImage Corp. and Innovative Photonic Solutions are developing specialized instrumentation, while academic players like University of California and Purdue Research Foundation contribute fundamental research. The ecosystem demonstrates a balanced mix of established analytical instrument manufacturers and specialized technology developers working to enhance sensitivity, portability, and application-specific capabilities.

ChemImage Corp.

Technical Solution: ChemImage has developed advanced Raman spectroscopy systems specifically optimized for synthetic fiber analysis. Their technology combines Raman chemical imaging with multivariate analysis to provide comprehensive characterization of fiber composition, structure, and properties. The company's Falcon II Raman chemical imaging microscope enables rapid identification of polymer types, additives, and contaminants in synthetic fibers with high spatial resolution. Their proprietary algorithms can distinguish between similar polymer structures (such as different polyester variants) and detect subtle differences in crystallinity and orientation that affect fiber performance. ChemImage's systems incorporate reference libraries containing spectral signatures of common synthetic fibers including polyester, nylon, acrylic, and specialty fibers, allowing for automated identification and quality control. The technology also enables depth profiling to analyze fiber cross-sections and core-sheath structures without physical sectioning.

Strengths: Superior chemical imaging capabilities allowing spatial mapping of fiber components; high sensitivity for detecting trace additives and contaminants; non-destructive analysis preserving sample integrity. Weaknesses: Higher cost compared to conventional Raman systems; requires specialized training for optimal operation; data interpretation can be complex for highly heterogeneous fiber samples.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has developed comprehensive Raman spectroscopy solutions specifically optimized for synthetic fiber analysis across the entire production chain. Their LabRAM series incorporates dual-wavelength excitation (532nm and 785nm) allowing optimal analysis of different fiber types while minimizing fluorescence interference. Shimadzu's systems feature automated polarization control that enables detailed analysis of molecular orientation within fibers—a critical parameter affecting mechanical properties. Their proprietary fiber-mounting accessories maintain consistent tension during analysis, ensuring reproducible results for elastic materials. Shimadzu has developed specialized calibration standards specifically for synthetic fiber applications, ensuring measurement accuracy across different instrument configurations. Their LabSolutions software includes dedicated modules for fiber identification, crystallinity determination, and blend ratio analysis with capabilities for batch processing large sample sets. The company has also pioneered the integration of Raman with complementary techniques like FTIR and thermal analysis in unified workflows specifically designed for comprehensive fiber characterization.

Strengths: Comprehensive solution covering the entire workflow from sampling to analysis; excellent reproducibility through specialized fiber-handling accessories; versatile excitation options suitable for diverse fiber types; strong integration with complementary analytical techniques. Weaknesses: Systems typically require dedicated laboratory space and controlled environments; higher initial investment compared to single-purpose analyzers; some advanced features require specialized training to utilize effectively.

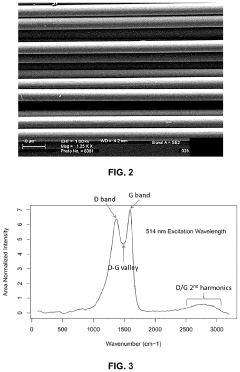

Key Spectral Signatures and Interpretation Protocols

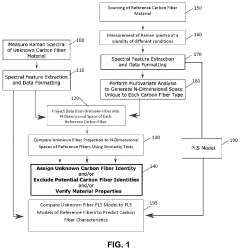

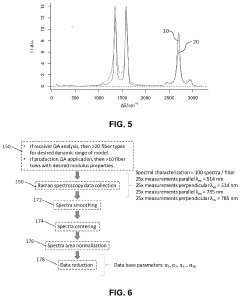

Carbon fiber classification using raman spectroscopy

PatentActiveUS11982624B2

Innovation

- The use of multi-condition Raman spectroscopy combined with multivariate data analyses, such as principal component analysis (PCA) and partial least squares (PLS) models, to identify carbon fibers and estimate their physical characteristics by projecting Raman spectral data into predefined spaces and comparing with reference data.

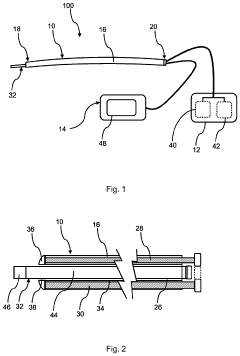

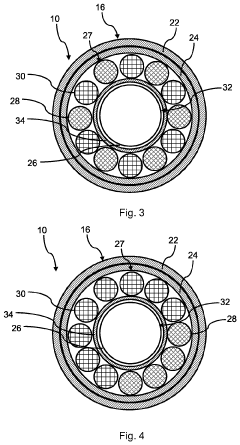

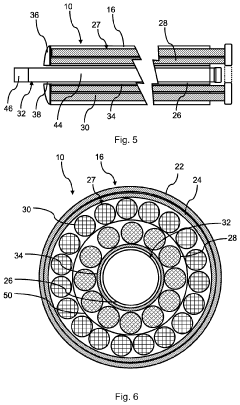

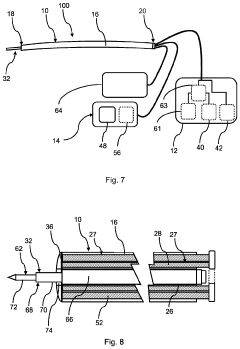

Raman spectroscopy probe, raman spectroscopy apparatus including the raman spectroscopy probe and elongate assembly

PatentPendingUS20240032797A1

Innovation

- The Raman spectroscopy probe design features Raman fibers arranged outside the instrument lumen, allowing for a larger cross-sectional area and increased number of fibers, which enhances light collection and signal strength by positioning them radially around the perimeter of the probe, while maintaining the instrument lumen's diameter.

Quality Control Standards and Industry Benchmarks

In the synthetic fiber industry, quality control standards and industry benchmarks play a crucial role in ensuring product consistency, reliability, and compliance with regulatory requirements. Raman spectroscopy has emerged as a powerful analytical tool that aligns with these standards while offering enhanced capabilities for fiber characterization and quality assurance.

The International Organization for Standardization (ISO) has established several standards relevant to synthetic fiber analysis, including ISO 1833 for quantitative chemical analysis of textile fibers and ISO 2076 for generic names of man-made fibers. When implementing Raman spectroscopy in quality control processes, manufacturers must ensure compliance with these standards while leveraging the technique's unique advantages in molecular fingerprinting.

ASTM International provides complementary standards, particularly ASTM D276 for identification of fibers in textiles and ASTM D6789 for test methods using infrared spectroscopy. Although these standards don't specifically address Raman spectroscopy, they establish the framework within which Raman techniques must operate to gain industry acceptance. The American Association of Textile Chemists and Colorists (AATCC) has also developed test methods that complement spectroscopic analysis in fiber identification and quality assessment.

Industry benchmarks for Raman spectroscopic analysis of synthetic fibers typically include spectral resolution requirements of 4-8 cm⁻¹, signal-to-noise ratios exceeding 1000:1 for routine analysis, and measurement reproducibility within ±2% for quantitative applications. These parameters ensure that the spectroscopic data obtained is sufficiently reliable for quality control decisions and product certification.

For polyester fibers, industry standards typically require detection of crystallinity variations within ±1%, while for nylon fibers, the ability to distinguish between different polymorphs (such as α and γ forms) is considered essential. Polypropylene fiber analysis demands accurate determination of tacticity ratios, with benchmarks typically set at detection limits of 2-3% for isotactic/syndiotactic variations.

The textile and apparel industry has established additional benchmarks specific to consumer-facing products, including OEKO-TEX® Standard 100 for harmful substances testing and the Global Recycled Standard (GRS) for recycled content verification. Raman spectroscopy supports compliance with these standards by enabling non-destructive verification of fiber composition and detecting contaminants at concentrations below regulatory thresholds.

As sustainability concerns drive industry evolution, new benchmarks are emerging around recycled content verification and biodegradability assessment. Raman spectroscopy's ability to distinguish between virgin and recycled polymers, as well as identify biodegradable additives in synthetic fibers, positions it as an essential tool for meeting these evolving quality standards in the increasingly sustainability-focused textile industry.

The International Organization for Standardization (ISO) has established several standards relevant to synthetic fiber analysis, including ISO 1833 for quantitative chemical analysis of textile fibers and ISO 2076 for generic names of man-made fibers. When implementing Raman spectroscopy in quality control processes, manufacturers must ensure compliance with these standards while leveraging the technique's unique advantages in molecular fingerprinting.

ASTM International provides complementary standards, particularly ASTM D276 for identification of fibers in textiles and ASTM D6789 for test methods using infrared spectroscopy. Although these standards don't specifically address Raman spectroscopy, they establish the framework within which Raman techniques must operate to gain industry acceptance. The American Association of Textile Chemists and Colorists (AATCC) has also developed test methods that complement spectroscopic analysis in fiber identification and quality assessment.

Industry benchmarks for Raman spectroscopic analysis of synthetic fibers typically include spectral resolution requirements of 4-8 cm⁻¹, signal-to-noise ratios exceeding 1000:1 for routine analysis, and measurement reproducibility within ±2% for quantitative applications. These parameters ensure that the spectroscopic data obtained is sufficiently reliable for quality control decisions and product certification.

For polyester fibers, industry standards typically require detection of crystallinity variations within ±1%, while for nylon fibers, the ability to distinguish between different polymorphs (such as α and γ forms) is considered essential. Polypropylene fiber analysis demands accurate determination of tacticity ratios, with benchmarks typically set at detection limits of 2-3% for isotactic/syndiotactic variations.

The textile and apparel industry has established additional benchmarks specific to consumer-facing products, including OEKO-TEX® Standard 100 for harmful substances testing and the Global Recycled Standard (GRS) for recycled content verification. Raman spectroscopy supports compliance with these standards by enabling non-destructive verification of fiber composition and detecting contaminants at concentrations below regulatory thresholds.

As sustainability concerns drive industry evolution, new benchmarks are emerging around recycled content verification and biodegradability assessment. Raman spectroscopy's ability to distinguish between virgin and recycled polymers, as well as identify biodegradable additives in synthetic fibers, positions it as an essential tool for meeting these evolving quality standards in the increasingly sustainability-focused textile industry.

Environmental Impact of Raman-Based Fiber Analysis Methods

The implementation of Raman spectroscopy for synthetic fiber analysis presents significant environmental advantages compared to traditional analytical methods. Conventional fiber analysis techniques often rely on chemical processes that utilize hazardous solvents and reagents, generating substantial waste that requires specialized disposal procedures. In contrast, Raman spectroscopy offers a non-destructive analytical approach that dramatically reduces chemical consumption and waste generation, aligning with green chemistry principles.

Energy efficiency represents another critical environmental benefit of Raman-based methods. While initial equipment investment may be substantial, the operational energy requirements are relatively modest compared to techniques such as thermal analysis or chromatographic methods. Modern portable Raman devices have further improved energy efficiency, with some systems operating on rechargeable batteries for extended periods, reducing the carbon footprint associated with laboratory analyses.

The non-destructive nature of Raman spectroscopy contributes substantially to resource conservation. Traditional fiber analysis often requires sample preparation that renders materials unusable for further testing or applications. Raman analysis preserves sample integrity, allowing for multiple analyses on the same specimen and reducing the overall material consumption in quality control and research applications within the textile industry.

From a lifecycle perspective, Raman-based fiber analysis supports sustainable manufacturing practices. The technique enables more precise identification of fiber compositions, facilitating better recycling stream segregation and improving the quality of recycled textile materials. This capability becomes increasingly valuable as circular economy principles gain traction in the textile sector, where fiber identification accuracy directly impacts recycling efficiency.

Water conservation represents another significant environmental advantage. Unlike wet chemical methods that may consume substantial volumes of water for sample preparation and analysis, Raman spectroscopy requires virtually no water resources. This aspect is particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory and social scrutiny.

The environmental benefits extend to workplace safety considerations as well. By reducing exposure to potentially harmful chemicals used in conventional analysis methods, Raman spectroscopy creates safer working environments with lower requirements for ventilation systems and protective equipment, indirectly reducing the environmental footprint of laboratory operations through decreased energy consumption and material usage.

Energy efficiency represents another critical environmental benefit of Raman-based methods. While initial equipment investment may be substantial, the operational energy requirements are relatively modest compared to techniques such as thermal analysis or chromatographic methods. Modern portable Raman devices have further improved energy efficiency, with some systems operating on rechargeable batteries for extended periods, reducing the carbon footprint associated with laboratory analyses.

The non-destructive nature of Raman spectroscopy contributes substantially to resource conservation. Traditional fiber analysis often requires sample preparation that renders materials unusable for further testing or applications. Raman analysis preserves sample integrity, allowing for multiple analyses on the same specimen and reducing the overall material consumption in quality control and research applications within the textile industry.

From a lifecycle perspective, Raman-based fiber analysis supports sustainable manufacturing practices. The technique enables more precise identification of fiber compositions, facilitating better recycling stream segregation and improving the quality of recycled textile materials. This capability becomes increasingly valuable as circular economy principles gain traction in the textile sector, where fiber identification accuracy directly impacts recycling efficiency.

Water conservation represents another significant environmental advantage. Unlike wet chemical methods that may consume substantial volumes of water for sample preparation and analysis, Raman spectroscopy requires virtually no water resources. This aspect is particularly relevant in regions facing water scarcity challenges, where industrial water consumption faces increasing regulatory and social scrutiny.

The environmental benefits extend to workplace safety considerations as well. By reducing exposure to potentially harmful chemicals used in conventional analysis methods, Raman spectroscopy creates safer working environments with lower requirements for ventilation systems and protective equipment, indirectly reducing the environmental footprint of laboratory operations through decreased energy consumption and material usage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!