Raman Spectroscopy vs TGA: Application in Thermal Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Raman and TGA Thermal Analysis Background and Objectives

Thermal analysis techniques have evolved significantly over the past decades, with various methodologies developed to understand material behavior under temperature variations. Among these techniques, Raman spectroscopy and Thermogravimetric Analysis (TGA) represent two distinct yet complementary approaches that have gained prominence in materials science, chemistry, and engineering applications. Historically, thermal analysis began with simple observation of physical changes during heating, but has now advanced to sophisticated instrumental methods providing quantitative data on thermal properties and chemical transformations.

Raman spectroscopy, discovered by C.V. Raman in 1928, utilizes the inelastic scattering of light to provide information about molecular vibrations. Its application in thermal analysis emerged in the 1970s but has seen exponential growth with the advent of advanced lasers and detectors in the past two decades. Meanwhile, TGA, which measures mass changes as a function of temperature, has been a staple technique since the 1950s, with continuous refinements in sensitivity and automation.

The convergence of these technologies represents a significant trend in analytical instrumentation, where complementary data streams provide more comprehensive material characterization. This evolution reflects the growing demand for multi-parameter analysis in complex material systems, particularly in emerging fields like nanomaterials, pharmaceuticals, and advanced polymers.

The primary objective of this technical research is to evaluate the comparative strengths, limitations, and synergistic potential of Raman spectroscopy and TGA in thermal analysis applications. Specifically, we aim to assess how Raman's molecular-level structural insights can complement TGA's bulk compositional data to provide enhanced understanding of thermal degradation mechanisms, phase transitions, and reaction kinetics.

Additionally, this research seeks to identify emerging technological innovations in both fields, particularly focusing on in-situ Raman spectroscopy during thermal events and high-resolution TGA techniques. The integration of these methodologies with other analytical techniques, such as mass spectrometry and infrared spectroscopy, represents another important trajectory to explore.

Furthermore, we intend to establish clear guidelines for selecting the appropriate technique based on specific application requirements, material characteristics, and desired outcomes. This includes considerations of sample preparation, data interpretation challenges, and practical implementation in both research and industrial settings.

Ultimately, this technical assessment aims to provide a roadmap for future development and application of these complementary techniques, highlighting opportunities for technological advancement and addressing current limitations in thermal analysis methodologies.

Raman spectroscopy, discovered by C.V. Raman in 1928, utilizes the inelastic scattering of light to provide information about molecular vibrations. Its application in thermal analysis emerged in the 1970s but has seen exponential growth with the advent of advanced lasers and detectors in the past two decades. Meanwhile, TGA, which measures mass changes as a function of temperature, has been a staple technique since the 1950s, with continuous refinements in sensitivity and automation.

The convergence of these technologies represents a significant trend in analytical instrumentation, where complementary data streams provide more comprehensive material characterization. This evolution reflects the growing demand for multi-parameter analysis in complex material systems, particularly in emerging fields like nanomaterials, pharmaceuticals, and advanced polymers.

The primary objective of this technical research is to evaluate the comparative strengths, limitations, and synergistic potential of Raman spectroscopy and TGA in thermal analysis applications. Specifically, we aim to assess how Raman's molecular-level structural insights can complement TGA's bulk compositional data to provide enhanced understanding of thermal degradation mechanisms, phase transitions, and reaction kinetics.

Additionally, this research seeks to identify emerging technological innovations in both fields, particularly focusing on in-situ Raman spectroscopy during thermal events and high-resolution TGA techniques. The integration of these methodologies with other analytical techniques, such as mass spectrometry and infrared spectroscopy, represents another important trajectory to explore.

Furthermore, we intend to establish clear guidelines for selecting the appropriate technique based on specific application requirements, material characteristics, and desired outcomes. This includes considerations of sample preparation, data interpretation challenges, and practical implementation in both research and industrial settings.

Ultimately, this technical assessment aims to provide a roadmap for future development and application of these complementary techniques, highlighting opportunities for technological advancement and addressing current limitations in thermal analysis methodologies.

Market Demand for Advanced Thermal Characterization Techniques

The thermal analysis market has witnessed substantial growth in recent years, driven by increasing demand for advanced material characterization techniques across various industries. The global thermal analysis market was valued at approximately $613 million in 2020 and is projected to reach $806 million by 2025, growing at a CAGR of 5.6%. This growth trajectory underscores the expanding need for sophisticated thermal characterization methodologies like Raman spectroscopy and Thermogravimetric Analysis (TGA).

Pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 35% of the total demand. These industries require precise thermal analysis for drug development, stability testing, and quality control processes. The ability to detect polymorphism, crystallinity changes, and degradation pathways is critical for ensuring drug efficacy and safety, driving the adoption of advanced thermal characterization techniques.

Materials science and polymer industries follow closely, contributing approximately 28% to market demand. As manufacturers develop increasingly complex composite materials, alloys, and polymers, the need for comprehensive thermal property analysis becomes paramount. These sectors particularly value techniques that can provide multi-parameter characterization without sample destruction.

Geographically, North America leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, primarily due to expanding manufacturing bases in China, India, and South Korea, coupled with increasing R&D investments.

A significant market trend is the growing preference for multi-functional analytical instruments that combine different measurement capabilities. End-users increasingly seek integrated solutions that provide complementary data sets, explaining the rising interest in combining Raman spectroscopy with traditional thermal analysis techniques like TGA.

Customer surveys indicate that key purchasing factors include measurement accuracy (cited by 87% of respondents), analytical versatility (76%), and automation capabilities (65%). There is also increasing demand for techniques that can perform in-situ measurements under varying environmental conditions, allowing real-time monitoring of thermal events and structural changes.

Regulatory requirements across industries are becoming more stringent, particularly in pharmaceutical and aerospace sectors, necessitating more comprehensive material characterization. This regulatory landscape is pushing organizations to invest in advanced thermal analysis technologies that offer higher precision, reproducibility, and documentation capabilities to ensure compliance.

Pharmaceutical and biotechnology sectors represent the largest market segments, accounting for nearly 35% of the total demand. These industries require precise thermal analysis for drug development, stability testing, and quality control processes. The ability to detect polymorphism, crystallinity changes, and degradation pathways is critical for ensuring drug efficacy and safety, driving the adoption of advanced thermal characterization techniques.

Materials science and polymer industries follow closely, contributing approximately 28% to market demand. As manufacturers develop increasingly complex composite materials, alloys, and polymers, the need for comprehensive thermal property analysis becomes paramount. These sectors particularly value techniques that can provide multi-parameter characterization without sample destruction.

Geographically, North America leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, primarily due to expanding manufacturing bases in China, India, and South Korea, coupled with increasing R&D investments.

A significant market trend is the growing preference for multi-functional analytical instruments that combine different measurement capabilities. End-users increasingly seek integrated solutions that provide complementary data sets, explaining the rising interest in combining Raman spectroscopy with traditional thermal analysis techniques like TGA.

Customer surveys indicate that key purchasing factors include measurement accuracy (cited by 87% of respondents), analytical versatility (76%), and automation capabilities (65%). There is also increasing demand for techniques that can perform in-situ measurements under varying environmental conditions, allowing real-time monitoring of thermal events and structural changes.

Regulatory requirements across industries are becoming more stringent, particularly in pharmaceutical and aerospace sectors, necessitating more comprehensive material characterization. This regulatory landscape is pushing organizations to invest in advanced thermal analysis technologies that offer higher precision, reproducibility, and documentation capabilities to ensure compliance.

Current Capabilities and Limitations of Raman and TGA Technologies

Raman spectroscopy and Thermogravimetric Analysis (TGA) represent two distinct yet complementary analytical techniques in thermal analysis applications. Raman spectroscopy excels in providing molecular-level structural information through the analysis of inelastic light scattering, offering non-destructive characterization of materials without sample preparation. Its capability to detect subtle changes in molecular vibrations makes it particularly valuable for identifying phase transitions, crystallinity changes, and chemical reactions during thermal processes.

The spatial resolution of modern Raman systems has reached sub-micron levels, enabling the analysis of heterogeneous samples with high precision. Additionally, temperature-controlled stages allow in-situ measurements at temperatures ranging from -196°C to over 1500°C, providing real-time monitoring of thermal events. Recent advancements in laser technology and detector sensitivity have significantly reduced acquisition times from minutes to seconds, making kinetic studies increasingly feasible.

However, Raman spectroscopy faces several limitations in thermal analysis applications. Fluorescence interference remains a persistent challenge, particularly with organic materials, often overwhelming the weaker Raman signals. Sample heating from laser exposure can introduce artifacts or accelerate reactions, potentially compromising data integrity. Furthermore, quantitative analysis requires careful calibration and reference standards, limiting its application in certain quantitative thermal studies.

In contrast, TGA offers direct measurement of mass changes during controlled temperature programs, providing quantitative information about decomposition, dehydration, oxidation, and other thermally-induced processes. Modern TGA instruments achieve remarkable sensitivity (sub-microgram) and can operate across wide temperature ranges (ambient to 1600°C) with precisely controlled heating rates from 0.1°C/min to 100°C/min.

TGA's integration with other techniques, particularly mass spectrometry (TG-MS) and infrared spectroscopy (TG-FTIR), has enhanced its analytical capabilities by identifying evolved gases during thermal events. High-pressure TGA systems now enable measurements under various atmospheric conditions up to 300 bar, expanding applications to industrial processes simulation.

Nevertheless, TGA's limitations include its inability to directly identify chemical structures or distinguish between simultaneous thermal events with similar mass changes. Sample size constraints (typically 5-50 mg) may limit representativeness for heterogeneous materials. Additionally, buoyancy effects, particularly at high temperatures, can introduce measurement artifacts requiring careful baseline corrections.

The complementary nature of these techniques becomes evident when considering their combined application: Raman provides molecular structural insights while TGA offers quantitative mass change data, together delivering comprehensive thermal behavior characterization that neither technique could achieve independently.

The spatial resolution of modern Raman systems has reached sub-micron levels, enabling the analysis of heterogeneous samples with high precision. Additionally, temperature-controlled stages allow in-situ measurements at temperatures ranging from -196°C to over 1500°C, providing real-time monitoring of thermal events. Recent advancements in laser technology and detector sensitivity have significantly reduced acquisition times from minutes to seconds, making kinetic studies increasingly feasible.

However, Raman spectroscopy faces several limitations in thermal analysis applications. Fluorescence interference remains a persistent challenge, particularly with organic materials, often overwhelming the weaker Raman signals. Sample heating from laser exposure can introduce artifacts or accelerate reactions, potentially compromising data integrity. Furthermore, quantitative analysis requires careful calibration and reference standards, limiting its application in certain quantitative thermal studies.

In contrast, TGA offers direct measurement of mass changes during controlled temperature programs, providing quantitative information about decomposition, dehydration, oxidation, and other thermally-induced processes. Modern TGA instruments achieve remarkable sensitivity (sub-microgram) and can operate across wide temperature ranges (ambient to 1600°C) with precisely controlled heating rates from 0.1°C/min to 100°C/min.

TGA's integration with other techniques, particularly mass spectrometry (TG-MS) and infrared spectroscopy (TG-FTIR), has enhanced its analytical capabilities by identifying evolved gases during thermal events. High-pressure TGA systems now enable measurements under various atmospheric conditions up to 300 bar, expanding applications to industrial processes simulation.

Nevertheless, TGA's limitations include its inability to directly identify chemical structures or distinguish between simultaneous thermal events with similar mass changes. Sample size constraints (typically 5-50 mg) may limit representativeness for heterogeneous materials. Additionally, buoyancy effects, particularly at high temperatures, can introduce measurement artifacts requiring careful baseline corrections.

The complementary nature of these techniques becomes evident when considering their combined application: Raman provides molecular structural insights while TGA offers quantitative mass change data, together delivering comprehensive thermal behavior characterization that neither technique could achieve independently.

Comparative Analysis of Raman and TGA Implementation Approaches

01 Combined Raman spectroscopy and TGA for material characterization

The integration of Raman spectroscopy with thermogravimetric analysis (TGA) provides comprehensive characterization of materials by simultaneously analyzing molecular structure and thermal behavior. This combined approach allows for real-time monitoring of chemical changes during thermal decomposition, enabling deeper understanding of material properties, phase transitions, and degradation mechanisms. The technique is particularly valuable for complex materials where structural and thermal properties are interconnected.- Combined Raman spectroscopy and TGA for material characterization: The integration of Raman spectroscopy with thermogravimetric analysis (TGA) provides comprehensive characterization of materials by simultaneously analyzing molecular structure and thermal behavior. This combined approach allows for real-time monitoring of chemical changes during thermal processes, enabling deeper understanding of material properties, phase transitions, and decomposition mechanisms. The technique is particularly valuable for complex materials where structural and thermal properties are interconnected.

- In-situ Raman spectroscopy during thermal analysis: In-situ Raman spectroscopy during thermal analysis enables real-time observation of molecular changes as materials undergo heating or cooling. This approach provides dynamic information about structural transformations, chemical reactions, and phase changes that occur at specific temperatures. The technique offers advantages over conventional post-analysis methods by capturing transient states and reaction intermediates that might otherwise be missed, resulting in more accurate characterization of thermal behavior and reaction mechanisms.

- Advanced instrumentation for coupled spectroscopic and thermal techniques: Specialized instrumentation has been developed to integrate Raman spectroscopy with thermal analysis techniques. These systems feature precise temperature control, optimized optical configurations for spectral acquisition during heating/cooling, and synchronized data collection. Advanced designs incorporate features such as automated sample handling, multiple laser excitation sources, and environmental control chambers to accommodate various experimental conditions. Such instrumentation enables high-resolution analysis of materials under controlled thermal conditions.

- Applications in pharmaceutical and biomedical analysis: The combination of Raman spectroscopy and thermal analysis offers significant advantages in pharmaceutical and biomedical research. This approach enables characterization of drug polymorphism, crystallinity, stability, and degradation pathways under various thermal conditions. It provides critical information for formulation development, quality control, and shelf-life determination. The non-destructive nature of Raman spectroscopy, coupled with the quantitative thermal data from TGA, makes this combined technique valuable for analyzing biological samples, drug delivery systems, and medical materials.

- Data analysis methods for correlating spectral and thermal information: Advanced data analysis methods have been developed to correlate and interpret the complex datasets generated by combined Raman spectroscopy and thermal analysis. These include multivariate statistical techniques, machine learning algorithms, and chemometric approaches that can identify patterns and relationships between spectral features and thermal events. Such methods enable automated identification of phase transitions, decomposition processes, and reaction kinetics, enhancing the ability to extract meaningful information from large datasets and improving the accuracy of material characterization.

02 In-situ Raman spectroscopy during thermal analysis

In-situ Raman spectroscopy during thermal analysis enables real-time observation of molecular changes as materials undergo heating or cooling. This approach provides dynamic information about structural transformations, chemical reactions, and phase changes that occur at specific temperatures. The technique allows researchers to correlate spectral changes with weight loss events, offering insights into reaction mechanisms and kinetics that would be impossible to obtain with either technique alone.Expand Specific Solutions03 Raman and TGA for pharmaceutical and biological sample analysis

The combination of Raman spectroscopy and thermogravimetric analysis is particularly valuable for pharmaceutical and biological samples, allowing for identification of polymorphs, assessment of drug stability, and characterization of biomaterials. This integrated approach helps in quality control of pharmaceuticals, detection of counterfeit drugs, and understanding of biological tissue composition. The non-destructive nature of Raman spectroscopy complements the quantitative thermal data from TGA to provide comprehensive analysis of complex biological systems.Expand Specific Solutions04 Advanced instrumentation for coupled Raman-TGA measurements

Specialized instrumentation has been developed to enable simultaneous or sequential Raman spectroscopy and thermogravimetric analysis. These systems feature integrated sample chambers, temperature-controlled stages, and synchronized data acquisition capabilities. Advanced designs incorporate fiber optic probes, automated sample handling, and software for correlative data analysis. Such instrumentation allows for precise control of experimental conditions while minimizing sample handling and environmental interference.Expand Specific Solutions05 Industrial applications of combined Raman and thermal analysis

Combined Raman spectroscopy and thermogravimetric analysis finds extensive applications in various industries including materials science, polymer development, catalysis research, and quality control. The technique is used for analyzing composite materials, investigating catalyst performance under thermal conditions, characterizing polymers and their degradation pathways, and monitoring industrial processes. This analytical approach helps in optimizing manufacturing processes, improving product quality, and developing new materials with enhanced thermal stability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermal Analysis

Raman Spectroscopy vs TGA in thermal analysis represents a growing niche market currently in its growth phase, with an estimated global market size of $1.2-1.5 billion and annual growth of 6-8%. The competitive landscape features established analytical instrument manufacturers like Rigaku Corp., Mettler-Toledo GmbH, and TA Instruments-Waters LLC dominating with comprehensive thermal analysis portfolios. These companies have achieved high technical maturity in both technologies, with recent innovations focusing on combined systems. Academic institutions including Tsinghua University and Kyushu University are advancing fundamental research, while industrial players like Sinopec and China Petroleum & Chemical Corp. are driving application-specific developments. The market is seeing increased integration of AI and automation capabilities to enhance analytical precision and user experience.

Rigaku Corp.

Technical Solution: Rigaku has pioneered the development of integrated thermal-Raman systems through their Thermo-Raman™ platform. Their technology employs temperature-controlled stages with precise thermal management (±0.5°C accuracy) coupled with high-resolution confocal Raman spectrometers. The system features specialized sample chambers that maintain controlled atmospheres while allowing optical access for Raman measurements. Rigaku's approach incorporates simultaneous differential scanning calorimetry (DSC) measurements alongside Raman spectroscopy, providing complementary thermal and structural information. Their proprietary software platform enables real-time correlation between thermal events and spectral changes, facilitating the identification of phase transitions, crystallization processes, and chemical reactions. The company has developed specialized algorithms for background subtraction and fluorescence rejection that enhance spectral quality during thermal experiments. Their systems can operate across a wide temperature range (-196°C to 1000°C) with heating/cooling rates from 0.1 to 100°C/min, making them suitable for diverse material characterization applications.

Strengths: Exceptional spectral resolution (down to 0.5 cm⁻¹) even at elevated temperatures; robust temperature control systems; advanced software for multivariate analysis of complex data sets. Weaknesses: Higher initial investment compared to standalone systems; requires specialized knowledge for optimal operation; limited sample throughput due to longer analysis times.

Mettler-Toledo GmbH

Technical Solution: Mettler-Toledo has developed advanced integrated systems combining Raman spectroscopy with thermal analysis techniques. Their FlexRaman™ coupled with thermal analyzers provides real-time molecular structure information during thermal events. The system features in-situ Raman probes that can withstand high temperatures (up to 600°C) and are positioned to capture spectral data directly from samples undergoing thermal analysis. Their proprietary software platform enables simultaneous data acquisition and correlation between spectral changes and thermal events, allowing researchers to identify phase transitions, decomposition mechanisms, and chemical reactions with unprecedented detail. The company has also pioneered automated calibration routines that ensure measurement accuracy across wide temperature ranges, addressing a common challenge in combined spectroscopic-thermal techniques. Their systems incorporate reference materials for temperature and enthalpy calibration that compensate for thermal gradients between the sample and the measurement sensors.

Strengths: Superior integration of both technologies with synchronized data acquisition and analysis capabilities; excellent temperature control precision (±0.1°C); robust calibration protocols ensuring measurement reliability. Weaknesses: Higher cost compared to standalone systems; complex setup requiring specialized training; limited sample throughput due to longer analysis times when both techniques are used simultaneously.

Key Patents and Scientific Breakthroughs in Thermal Characterization

Compositions containing, methods involving, and uses of non-natural amino acids and polypeptides

PatentWO2008077079A1

Innovation

- Development of methods and compositions involving non-natural amino acids and polypeptides that allow for chemical, biological, or physical derivatization, including regioselective and stoichiometric incorporation of functional groups, enabling the formation of stable linkages and heterocycles, such as indole-containing linkages, for various therapeutic, diagnostic, and industrial uses.

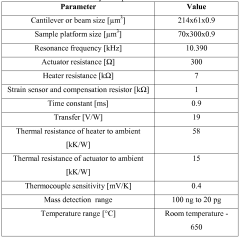

Thermogravimetric device

PatentWO2011062491A1

Innovation

- A thermogravimetric MEMS device design that separates thermal and mechanical energy regimes by spatially decoupling the heating element from the resonator element, using thermal isolation, specific materials, and gas mixtures to maintain a constant resonance frequency, thereby isolating the sample platform from temperature-induced stress and strain.

Industry-Specific Applications and Case Studies

Raman spectroscopy and Thermogravimetric Analysis (TGA) have found extensive applications across various industries, each leveraging the unique capabilities of these analytical techniques to address specific challenges.

In the pharmaceutical industry, Raman spectroscopy has revolutionized quality control processes by enabling non-destructive identification of active pharmaceutical ingredients (APIs) and excipients. A notable case study involves Pfizer's implementation of Raman technology for real-time monitoring of crystallization processes, resulting in a 30% reduction in batch failures. Conversely, TGA has been instrumental in stability testing and degradation studies of drug formulations, with AstraZeneca utilizing TGA to optimize the thermal stability of extended-release formulations.

The polymer and materials science sector has embraced both techniques with equal enthusiasm. DuPont researchers employed Raman spectroscopy to characterize polymer blends and composites, particularly in identifying phase separations and molecular orientations that affect mechanical properties. Meanwhile, BASF has documented successful application of TGA in determining the thermal decomposition profiles of novel flame-retardant polymers, directly influencing product development cycles.

In the semiconductor industry, Raman spectroscopy has proven invaluable for stress measurements in silicon wafers and characterization of 2D materials. Intel's case study demonstrated how Raman mapping identified strain variations in transistor channels, correlating directly with device performance. TGA, though less prominent in this field, has been utilized by Samsung for analyzing thermal stability of packaging materials and adhesives critical to device reliability.

The energy sector presents compelling applications, particularly in battery technology. Tesla's battery research division has implemented in-situ Raman spectroscopy to monitor electrode-electrolyte interfaces during charging cycles, providing insights into degradation mechanisms. Complementarily, TGA has been employed by CATL to evaluate the thermal stability of cathode materials, directly informing safety protocols for large-scale battery installations.

Environmental monitoring represents another significant application area. The EPA has documented the use of portable Raman systems for rapid identification of environmental contaminants in field settings, while TGA has been utilized by waste management companies to characterize municipal solid waste composition for optimizing incineration parameters.

These industry-specific applications highlight the complementary nature of Raman spectroscopy and TGA, with the former excelling in molecular identification and structural analysis, while the latter provides quantitative thermal stability data crucial for product development and safety assessments.

In the pharmaceutical industry, Raman spectroscopy has revolutionized quality control processes by enabling non-destructive identification of active pharmaceutical ingredients (APIs) and excipients. A notable case study involves Pfizer's implementation of Raman technology for real-time monitoring of crystallization processes, resulting in a 30% reduction in batch failures. Conversely, TGA has been instrumental in stability testing and degradation studies of drug formulations, with AstraZeneca utilizing TGA to optimize the thermal stability of extended-release formulations.

The polymer and materials science sector has embraced both techniques with equal enthusiasm. DuPont researchers employed Raman spectroscopy to characterize polymer blends and composites, particularly in identifying phase separations and molecular orientations that affect mechanical properties. Meanwhile, BASF has documented successful application of TGA in determining the thermal decomposition profiles of novel flame-retardant polymers, directly influencing product development cycles.

In the semiconductor industry, Raman spectroscopy has proven invaluable for stress measurements in silicon wafers and characterization of 2D materials. Intel's case study demonstrated how Raman mapping identified strain variations in transistor channels, correlating directly with device performance. TGA, though less prominent in this field, has been utilized by Samsung for analyzing thermal stability of packaging materials and adhesives critical to device reliability.

The energy sector presents compelling applications, particularly in battery technology. Tesla's battery research division has implemented in-situ Raman spectroscopy to monitor electrode-electrolyte interfaces during charging cycles, providing insights into degradation mechanisms. Complementarily, TGA has been employed by CATL to evaluate the thermal stability of cathode materials, directly informing safety protocols for large-scale battery installations.

Environmental monitoring represents another significant application area. The EPA has documented the use of portable Raman systems for rapid identification of environmental contaminants in field settings, while TGA has been utilized by waste management companies to characterize municipal solid waste composition for optimizing incineration parameters.

These industry-specific applications highlight the complementary nature of Raman spectroscopy and TGA, with the former excelling in molecular identification and structural analysis, while the latter provides quantitative thermal stability data crucial for product development and safety assessments.

Cost-Benefit Analysis and ROI Considerations

When evaluating the implementation of Raman spectroscopy versus Thermogravimetric Analysis (TGA) for thermal analysis applications, organizations must conduct a thorough cost-benefit analysis to determine the most economically viable solution for their specific needs.

Initial investment for Raman spectroscopy systems typically ranges from $50,000 to $200,000, depending on resolution, sensitivity, and automation capabilities. In contrast, TGA instruments generally cost between $30,000 and $100,000. This significant capital expenditure difference must be weighed against operational benefits and long-term value generation.

Operational costs present another critical consideration. Raman spectroscopy requires minimal sample preparation and consumables, resulting in lower per-analysis costs (approximately $5-15 per sample). TGA, while requiring sample holders and purge gases, typically costs $15-30 per analysis. Additionally, Raman systems generally consume less power and require less frequent calibration, further reducing operational expenses.

Return on investment calculations must account for productivity enhancements. Raman spectroscopy offers non-destructive, rapid analysis (often under 1 minute per sample) with minimal sample preparation, enabling higher throughput. TGA analyses typically require 30-90 minutes per sample, limiting daily processing capacity. Organizations handling large sample volumes may achieve ROI with Raman systems in 2-3 years despite higher initial costs.

Maintenance considerations significantly impact long-term economics. Raman systems typically require annual maintenance contracts costing 8-12% of the initial investment, while TGA systems generally require 10-15%. However, Raman systems often demonstrate greater reliability with fewer moving parts, resulting in less downtime and associated productivity losses.

Multi-purpose utilization enhances ROI potential. Raman spectroscopy offers versatility beyond thermal analysis, including chemical identification, crystallinity assessment, and quality control applications. This multi-functionality allows cost distribution across various departments or applications, improving overall economic justification compared to the more specialized TGA.

Risk mitigation value must also factor into economic assessments. Raman's non-destructive nature preserves samples for additional testing or archiving, potentially preventing costly re-sampling or production errors. This preservation capability represents significant but often overlooked economic value, particularly in regulated industries where sample documentation is critical.

Initial investment for Raman spectroscopy systems typically ranges from $50,000 to $200,000, depending on resolution, sensitivity, and automation capabilities. In contrast, TGA instruments generally cost between $30,000 and $100,000. This significant capital expenditure difference must be weighed against operational benefits and long-term value generation.

Operational costs present another critical consideration. Raman spectroscopy requires minimal sample preparation and consumables, resulting in lower per-analysis costs (approximately $5-15 per sample). TGA, while requiring sample holders and purge gases, typically costs $15-30 per analysis. Additionally, Raman systems generally consume less power and require less frequent calibration, further reducing operational expenses.

Return on investment calculations must account for productivity enhancements. Raman spectroscopy offers non-destructive, rapid analysis (often under 1 minute per sample) with minimal sample preparation, enabling higher throughput. TGA analyses typically require 30-90 minutes per sample, limiting daily processing capacity. Organizations handling large sample volumes may achieve ROI with Raman systems in 2-3 years despite higher initial costs.

Maintenance considerations significantly impact long-term economics. Raman systems typically require annual maintenance contracts costing 8-12% of the initial investment, while TGA systems generally require 10-15%. However, Raman systems often demonstrate greater reliability with fewer moving parts, resulting in less downtime and associated productivity losses.

Multi-purpose utilization enhances ROI potential. Raman spectroscopy offers versatility beyond thermal analysis, including chemical identification, crystallinity assessment, and quality control applications. This multi-functionality allows cost distribution across various departments or applications, improving overall economic justification compared to the more specialized TGA.

Risk mitigation value must also factor into economic assessments. Raman's non-destructive nature preserves samples for additional testing or archiving, potentially preventing costly re-sampling or production errors. This preservation capability represents significant but often overlooked economic value, particularly in regulated industries where sample documentation is critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!