Raman Spectroscopy vs Atomic Spectroscopy: Measurement Precision

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spectroscopy Evolution and Precision Objectives

Spectroscopy has evolved significantly since its inception in the early 19th century with the discovery of spectral lines by Joseph von Fraunhofer. The journey from basic optical spectroscopy to today's sophisticated Raman and atomic spectroscopy techniques represents a remarkable technological progression driven by the quest for increasingly precise molecular and atomic measurements.

Raman spectroscopy, discovered by C.V. Raman in 1928, has transformed from a cumbersome laboratory technique to a versatile analytical tool with applications spanning materials science, pharmaceuticals, and biological research. The evolution of laser technology in the 1960s marked a pivotal advancement, enabling more powerful and monochromatic excitation sources that significantly enhanced measurement sensitivity and precision.

Atomic spectroscopy has followed a parallel but distinct evolutionary path, beginning with flame tests and advancing through atomic absorption, atomic emission, and atomic fluorescence techniques. The development of inductively coupled plasma (ICP) sources in the 1970s revolutionized the field, allowing for multi-element analysis with unprecedented detection limits.

Recent decades have witnessed remarkable technological convergence, with both spectroscopic approaches benefiting from advances in detector technology, data processing capabilities, and miniaturization. The transition from photomultiplier tubes to charge-coupled devices (CCDs) and complementary metal-oxide-semiconductor (CMOS) detectors has dramatically improved signal-to-noise ratios and measurement precision.

The primary objective in comparing Raman and atomic spectroscopy precision is to establish quantitative benchmarks for measurement accuracy, repeatability, and reproducibility across diverse analytical scenarios. This includes evaluating detection limits, quantification ranges, and susceptibility to interference effects under varying sample conditions.

A critical goal is to identify the optimal spectroscopic technique for specific analytical challenges, recognizing that precision requirements vary significantly across industries. For pharmaceutical quality control, precision at parts-per-billion levels may be essential, while environmental monitoring may demand parts-per-trillion sensitivity for certain contaminants.

The technological trajectory points toward hybrid systems that leverage the complementary strengths of both spectroscopic approaches. Future development aims to overcome current limitations in sample preparation requirements, matrix effects, and spectral interference that can compromise measurement precision.

Ultimately, the evolution of these spectroscopic techniques converges on the goal of achieving "absolute precision" – measurements that are not only highly reproducible but also traceable to fundamental physical standards, ensuring global consistency in analytical results across different laboratories, instruments, and methodologies.

Raman spectroscopy, discovered by C.V. Raman in 1928, has transformed from a cumbersome laboratory technique to a versatile analytical tool with applications spanning materials science, pharmaceuticals, and biological research. The evolution of laser technology in the 1960s marked a pivotal advancement, enabling more powerful and monochromatic excitation sources that significantly enhanced measurement sensitivity and precision.

Atomic spectroscopy has followed a parallel but distinct evolutionary path, beginning with flame tests and advancing through atomic absorption, atomic emission, and atomic fluorescence techniques. The development of inductively coupled plasma (ICP) sources in the 1970s revolutionized the field, allowing for multi-element analysis with unprecedented detection limits.

Recent decades have witnessed remarkable technological convergence, with both spectroscopic approaches benefiting from advances in detector technology, data processing capabilities, and miniaturization. The transition from photomultiplier tubes to charge-coupled devices (CCDs) and complementary metal-oxide-semiconductor (CMOS) detectors has dramatically improved signal-to-noise ratios and measurement precision.

The primary objective in comparing Raman and atomic spectroscopy precision is to establish quantitative benchmarks for measurement accuracy, repeatability, and reproducibility across diverse analytical scenarios. This includes evaluating detection limits, quantification ranges, and susceptibility to interference effects under varying sample conditions.

A critical goal is to identify the optimal spectroscopic technique for specific analytical challenges, recognizing that precision requirements vary significantly across industries. For pharmaceutical quality control, precision at parts-per-billion levels may be essential, while environmental monitoring may demand parts-per-trillion sensitivity for certain contaminants.

The technological trajectory points toward hybrid systems that leverage the complementary strengths of both spectroscopic approaches. Future development aims to overcome current limitations in sample preparation requirements, matrix effects, and spectral interference that can compromise measurement precision.

Ultimately, the evolution of these spectroscopic techniques converges on the goal of achieving "absolute precision" – measurements that are not only highly reproducible but also traceable to fundamental physical standards, ensuring global consistency in analytical results across different laboratories, instruments, and methodologies.

Market Applications and Demand Analysis

The market for spectroscopic analysis technologies continues to expand rapidly, driven by increasing demands for precise measurement capabilities across multiple industries. Raman spectroscopy and atomic spectroscopy represent two distinct yet complementary analytical approaches, each addressing specific market needs with varying degrees of precision and application suitability.

In the pharmaceutical sector, demand for Raman spectroscopy has grown at a remarkable pace due to its non-destructive nature and ability to analyze samples through packaging materials. This capability significantly reduces contamination risks and preserves sample integrity, critical factors in drug development and quality control processes. The technology's ability to identify molecular structures with high specificity has positioned it as an essential tool for detecting counterfeit medications, with the pharmaceutical authentication market expected to reach substantial growth by 2025.

Atomic spectroscopy, meanwhile, dominates in environmental monitoring applications where trace element detection at parts-per-billion levels is required. Regulatory compliance across developed economies has strengthened demand for atomic absorption spectroscopy, inductively coupled plasma mass spectrometry (ICP-MS), and other atomic techniques that offer superior detection limits for heavy metals and other inorganic contaminants in water, soil, and air samples.

The food and beverage industry represents another significant market driver, with increasing consumer awareness regarding food safety creating demand for both technologies. Raman spectroscopy has found particular application in rapid, non-destructive testing of food composition and authenticity, while atomic spectroscopy remains the gold standard for detecting toxic elements in food products.

Academic and research institutions continue to be major consumers of both technologies, with funding allocations for analytical instrumentation showing steady growth. The precision measurement capabilities of both spectroscopic methods make them invaluable in materials science, chemistry, and physics research applications.

Geographically, North America and Europe currently represent the largest markets for high-precision spectroscopic equipment, though Asia-Pacific regions are showing the fastest growth rates. China and India, in particular, are investing heavily in analytical infrastructure for environmental monitoring, pharmaceutical development, and materials research.

The market is increasingly demanding integrated solutions that combine multiple spectroscopic techniques with advanced data analysis capabilities. This trend toward comprehensive analytical platforms reflects the growing complexity of research questions and industrial applications requiring multi-modal analysis approaches.

In the pharmaceutical sector, demand for Raman spectroscopy has grown at a remarkable pace due to its non-destructive nature and ability to analyze samples through packaging materials. This capability significantly reduces contamination risks and preserves sample integrity, critical factors in drug development and quality control processes. The technology's ability to identify molecular structures with high specificity has positioned it as an essential tool for detecting counterfeit medications, with the pharmaceutical authentication market expected to reach substantial growth by 2025.

Atomic spectroscopy, meanwhile, dominates in environmental monitoring applications where trace element detection at parts-per-billion levels is required. Regulatory compliance across developed economies has strengthened demand for atomic absorption spectroscopy, inductively coupled plasma mass spectrometry (ICP-MS), and other atomic techniques that offer superior detection limits for heavy metals and other inorganic contaminants in water, soil, and air samples.

The food and beverage industry represents another significant market driver, with increasing consumer awareness regarding food safety creating demand for both technologies. Raman spectroscopy has found particular application in rapid, non-destructive testing of food composition and authenticity, while atomic spectroscopy remains the gold standard for detecting toxic elements in food products.

Academic and research institutions continue to be major consumers of both technologies, with funding allocations for analytical instrumentation showing steady growth. The precision measurement capabilities of both spectroscopic methods make them invaluable in materials science, chemistry, and physics research applications.

Geographically, North America and Europe currently represent the largest markets for high-precision spectroscopic equipment, though Asia-Pacific regions are showing the fastest growth rates. China and India, in particular, are investing heavily in analytical infrastructure for environmental monitoring, pharmaceutical development, and materials research.

The market is increasingly demanding integrated solutions that combine multiple spectroscopic techniques with advanced data analysis capabilities. This trend toward comprehensive analytical platforms reflects the growing complexity of research questions and industrial applications requiring multi-modal analysis approaches.

Current Capabilities and Technical Limitations

Raman spectroscopy currently achieves measurement precision in the range of 0.1-1 cm^-1 for peak positions under optimal conditions, with relative standard deviations (RSDs) typically between 1-5% for quantitative analysis. This precision depends significantly on instrument calibration, sample preparation, and environmental controls. High-end Raman systems equipped with temperature stabilization and wavelength calibration standards can approach the lower end of this precision range, while portable or field instruments typically operate at the higher end.

Atomic spectroscopy techniques demonstrate varying precision capabilities across their subtypes. Atomic Absorption Spectroscopy (AAS) typically achieves RSDs of 0.5-2% for concentration measurements, with detection limits in the parts per billion (ppb) range for many elements. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) pushes precision further, with RSDs of 0.5-1% and detection limits reaching parts per trillion (ppt) for some elements, representing the gold standard for trace elemental analysis.

Technical limitations for Raman spectroscopy include fluorescence interference, which can overwhelm the relatively weak Raman signal, particularly in biological samples or materials with fluorescent impurities. Sample heating from laser excitation can alter sample properties or cause degradation, affecting measurement accuracy. Additionally, the inherent weakness of the Raman effect necessitates longer acquisition times, limiting throughput in industrial applications.

For atomic spectroscopy, matrix effects represent a significant limitation, where the sample composition influences analyte signals, requiring matrix-matched calibration standards. Spectral interferences, particularly in complex samples, can compromise measurement accuracy. ICP techniques face challenges with polyatomic interferences and require extensive sample preparation, including digestion procedures that can introduce contamination or analyte loss.

Both techniques face common challenges in standardization and calibration. Raman spectroscopy lacks universally accepted intensity standards, complicating quantitative analysis across different instruments. Atomic spectroscopy requires certified reference materials that may not be available for all sample types, particularly for emerging applications in nanomaterials or biological systems.

Recent technological advances are addressing these limitations. Surface-enhanced Raman spectroscopy (SERS) has improved sensitivity by orders of magnitude, while time-resolved and spatially offset techniques are reducing fluorescence interference. In atomic spectroscopy, collision/reaction cells in ICP-MS and high-resolution spectrometers are mitigating spectral interferences, while automated sample preparation systems are reducing contamination risks and improving reproducibility.

Atomic spectroscopy techniques demonstrate varying precision capabilities across their subtypes. Atomic Absorption Spectroscopy (AAS) typically achieves RSDs of 0.5-2% for concentration measurements, with detection limits in the parts per billion (ppb) range for many elements. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) pushes precision further, with RSDs of 0.5-1% and detection limits reaching parts per trillion (ppt) for some elements, representing the gold standard for trace elemental analysis.

Technical limitations for Raman spectroscopy include fluorescence interference, which can overwhelm the relatively weak Raman signal, particularly in biological samples or materials with fluorescent impurities. Sample heating from laser excitation can alter sample properties or cause degradation, affecting measurement accuracy. Additionally, the inherent weakness of the Raman effect necessitates longer acquisition times, limiting throughput in industrial applications.

For atomic spectroscopy, matrix effects represent a significant limitation, where the sample composition influences analyte signals, requiring matrix-matched calibration standards. Spectral interferences, particularly in complex samples, can compromise measurement accuracy. ICP techniques face challenges with polyatomic interferences and require extensive sample preparation, including digestion procedures that can introduce contamination or analyte loss.

Both techniques face common challenges in standardization and calibration. Raman spectroscopy lacks universally accepted intensity standards, complicating quantitative analysis across different instruments. Atomic spectroscopy requires certified reference materials that may not be available for all sample types, particularly for emerging applications in nanomaterials or biological systems.

Recent technological advances are addressing these limitations. Surface-enhanced Raman spectroscopy (SERS) has improved sensitivity by orders of magnitude, while time-resolved and spatially offset techniques are reducing fluorescence interference. In atomic spectroscopy, collision/reaction cells in ICP-MS and high-resolution spectrometers are mitigating spectral interferences, while automated sample preparation systems are reducing contamination risks and improving reproducibility.

Comparative Analysis of Measurement Methodologies

01 Calibration techniques for improved spectroscopic precision

Various calibration methods are employed to enhance the precision of Raman and atomic spectroscopy measurements. These techniques include reference standards, internal calibration markers, and automated calibration procedures that compensate for instrumental drift and environmental variations. Proper calibration ensures consistent and reliable spectral data acquisition, reducing measurement uncertainty and improving quantitative analysis capabilities.- Calibration techniques for improved spectroscopic precision: Various calibration methods are employed to enhance the precision of Raman and atomic spectroscopy measurements. These include reference standards, internal calibration mechanisms, and automated calibration procedures that compensate for instrumental drift and environmental variations. Advanced algorithms can be implemented to correct systematic errors and improve measurement repeatability, resulting in higher precision across different samples and conditions.

- Signal processing and enhancement techniques: Signal processing techniques play a crucial role in improving measurement precision in spectroscopy. These include noise reduction algorithms, baseline correction methods, peak detection and fitting algorithms, and multivariate analysis. Advanced computational methods such as machine learning and artificial intelligence can be applied to extract meaningful data from complex spectral information, thereby enhancing the precision of measurements even in challenging sample environments.

- Hardware innovations for precision enhancement: Hardware innovations significantly contribute to measurement precision in Raman and atomic spectroscopy. These include high-stability laser sources, temperature-controlled optical components, vibration isolation systems, and high-resolution detectors. Specialized optical configurations and sample handling systems are designed to minimize interference and maximize signal quality, resulting in more precise spectral measurements across diverse applications.

- Combined spectroscopic techniques for enhanced precision: Combining multiple spectroscopic techniques can significantly improve measurement precision. Hybrid systems that integrate Raman spectroscopy with atomic spectroscopy or other complementary methods provide more comprehensive data and cross-validation capabilities. This approach allows for the compensation of individual technique limitations and enhances overall measurement reliability through correlated data analysis and validation protocols.

- Environmental control and sample preparation methods: Environmental factors and sample preparation significantly impact measurement precision in spectroscopy. Controlled environments with regulated temperature, humidity, and atmospheric composition can minimize external interferences. Advanced sample preparation techniques, including standardized protocols for sample handling, mounting, and presentation to the instrument, ensure consistent measurement conditions. These approaches reduce variability and improve the reproducibility of spectroscopic measurements.

02 Signal processing algorithms for enhanced measurement precision

Advanced signal processing algorithms play a crucial role in improving the precision of spectroscopic measurements. These include noise reduction techniques, baseline correction methods, peak fitting algorithms, and multivariate analysis approaches. By effectively processing raw spectral data, these algorithms can extract meaningful information from complex spectra, enhance signal-to-noise ratios, and improve the detection limits and precision of both Raman and atomic spectroscopy techniques.Expand Specific Solutions03 Hardware innovations for precision enhancement

Hardware innovations significantly contribute to measurement precision in spectroscopic systems. These include high-stability laser sources, precision optical components, temperature-controlled sample stages, and advanced detector technologies with improved sensitivity and dynamic range. Specialized hardware designs minimize instrumental artifacts, reduce background interference, and enhance spectral resolution, resulting in more precise and reproducible measurements for both Raman and atomic spectroscopy applications.Expand Specific Solutions04 Combined spectroscopic techniques for comprehensive analysis

Integrating multiple spectroscopic methods, particularly combining Raman with atomic spectroscopy techniques, provides complementary information and improves overall measurement precision. These hybrid approaches leverage the strengths of each technique while compensating for their individual limitations. The combined data allows for more accurate material characterization, enhanced chemical specificity, and improved quantitative analysis, particularly for complex samples where a single spectroscopic method may be insufficient.Expand Specific Solutions05 In-situ and real-time monitoring applications

Advancements in in-situ and real-time spectroscopic monitoring systems have significantly improved measurement precision in dynamic environments. These systems incorporate rapid data acquisition capabilities, automated analysis workflows, and robust designs suitable for field deployment. Applications include process monitoring, environmental analysis, and quality control, where precise measurements must be made continuously or under challenging conditions. These technologies enable timely decision-making based on accurate spectroscopic data.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Raman vs Atomic Spectroscopy market is currently in a growth phase, with increasing demand for high-precision measurement technologies across pharmaceutical, petrochemical, and materials science sectors. The global spectroscopy market is projected to reach approximately $20 billion by 2025, with Raman spectroscopy showing faster growth due to its non-destructive analysis capabilities. Leading companies like Shimadzu Corp. and ChemImage are advancing Raman technology with enhanced precision and portability, while HP Development and Southwest Research Institute focus on atomic spectroscopy innovations. Academic institutions including Beihang University and University of Southampton are driving fundamental research, creating a competitive landscape where precision, application versatility, and integration with AI analytics are key differentiators in both technologies.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has developed advanced Raman and atomic spectroscopy systems with proprietary technologies for enhanced measurement precision. Their Raman spectroscopy solutions feature high-sensitivity CCD detectors and optimized optical designs that achieve spectral resolution down to 0.7 cm-1, enabling identification of closely spaced spectral features. Their atomic spectroscopy platforms incorporate dual-atomizer technology that automatically switches between flame and furnace modes, providing flexibility across concentration ranges from ppb to percentage levels. Shimadzu's ICPMS-2030 system combines plasma spectroscopy with quadrupole mass spectrometry, achieving detection limits in the sub-ppt range with proprietary interference removal technology. Their systems feature automated calibration and drift correction mechanisms that maintain measurement accuracy over extended operation periods, with reported precision improvements of up to 40% compared to previous generations. Shimadzu's software platforms integrate chemometric analysis tools that enhance signal processing capabilities, improving signal-to-noise ratios and measurement reproducibility across both spectroscopic techniques.

Strengths: Superior optical engineering providing exceptional spectral resolution; integrated automation features that reduce operator variability; comprehensive software suite for advanced data analysis. Weaknesses: Higher initial investment compared to basic systems; requires specialized training for optimal operation; some models have higher power consumption requirements than competitors.

ChemImage Corp.

Technical Solution: ChemImage Corporation has pioneered innovative approaches to Raman spectroscopy with their patented Molecular Chemical Imaging (MCI) technology that combines Raman spectroscopy with digital imaging for enhanced measurement precision. Their systems utilize proprietary liquid crystal tunable filters and advanced algorithms to achieve spatial resolution down to 250 nm while maintaining spectral precision. ChemImage's Raman technology incorporates real-time background fluorescence suppression algorithms that significantly improve signal quality in complex biological samples, achieving signal-to-noise improvements of up to 300% compared to conventional systems. Their VeriSpray™ platform integrates Raman analysis with automated sampling systems, reducing sample preparation variability and improving measurement reproducibility with reported relative standard deviations below 1.5% for pharmaceutical applications. ChemImage has developed specialized reference materials and calibration protocols specifically designed for Raman applications, enabling traceable measurements with documented uncertainty values. Their systems feature proprietary baseline correction and peak identification algorithms that enhance measurement precision particularly for overlapping spectral features in complex mixtures.

Strengths: Exceptional capabilities in fluorescence rejection that enables analysis of challenging biological samples; integrated imaging capabilities providing spatial context to spectral data; specialized software for pharmaceutical and forensic applications. Weaknesses: Systems are optimized primarily for Raman rather than atomic spectroscopy; higher complexity may present steeper learning curve; specialized consumables may increase operational costs.

Breakthrough Technologies in Spectroscopic Precision

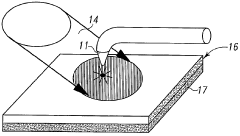

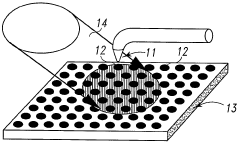

Raman imaging and sensing apparatus employing nanoantennas

PatentWO2005020803A2

Innovation

- The use of metal tip-substrate nanoantennas to enhance Raman scattering by inducing plasmon resonance, allowing for sub-wavelength imaging and single-molecule detection, combining the advantages of surface-enhanced Raman scattering and near-field scanning optical microscopy.

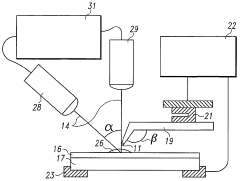

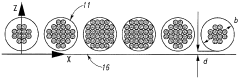

Raman spectroscopic analysis method and microscopic raman spectroscopy device

PatentPendingEP4394363A1

Innovation

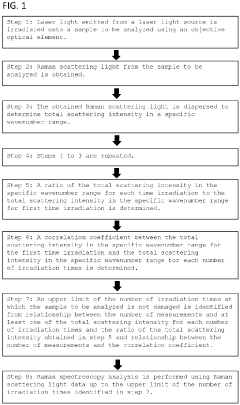

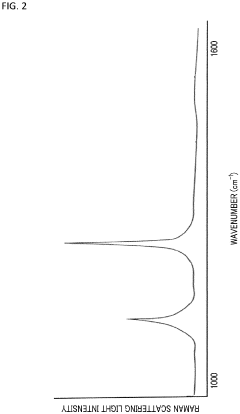

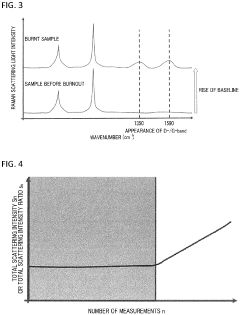

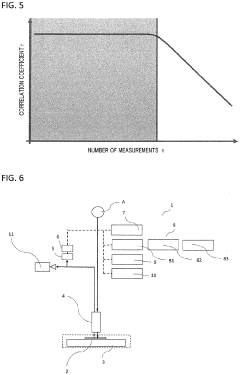

- A method involving the determination of total scattering intensity and correlation coefficients in specific wavenumber ranges to identify the upper limit of laser irradiation times that prevent sample damage, using a Raman spectroscopy analysis method and device with components for calculating and displaying these parameters to determine the safe number of irradiations.

Calibration Standards and Quality Assurance

Calibration is a critical component in both Raman and atomic spectroscopy systems, directly impacting measurement precision and reliability. For Raman spectroscopy, wavelength calibration typically employs standard materials with well-characterized Raman shifts, such as silicon, polystyrene, or cyclohexane. These standards provide reference peaks at known positions, enabling accurate calibration across the spectral range.

Atomic spectroscopy requires different calibration approaches depending on the specific technique. Atomic Absorption Spectroscopy (AAS) typically utilizes single-element or multi-element standard solutions of known concentrations to establish calibration curves. Inductively Coupled Plasma (ICP) techniques often employ certified reference materials that closely match the matrix of the samples being analyzed.

Quality assurance protocols for both spectroscopic methods include regular verification of instrument performance using certified reference materials. For Raman spectroscopy, this involves checking spectral resolution, peak position accuracy, and signal-to-noise ratios. Atomic spectroscopy quality assurance focuses on detection limits, sensitivity, and linearity of response across concentration ranges.

The traceability of calibration standards to national or international reference materials is essential for ensuring measurement accuracy. Organizations such as NIST (USA), BAM (Germany), and NMIJ (Japan) provide certified reference materials that serve as the foundation for reliable calibration protocols in both spectroscopic techniques.

Method validation represents another crucial aspect of quality assurance. This includes determining limits of detection and quantification, assessing measurement uncertainty, and evaluating method robustness. For Raman spectroscopy, this may involve analyzing samples with varying concentrations of the analyte of interest to establish the linear dynamic range. In atomic spectroscopy, method validation often includes spike recovery tests and analysis of certified reference materials.

Interlaboratory comparison studies provide an external quality assessment mechanism for both techniques. These studies involve multiple laboratories analyzing identical samples, with results compared to evaluate consistency and identify potential systematic errors. Such exercises are particularly valuable for establishing measurement precision across different instruments and operators.

Digital calibration management systems are increasingly being implemented to maintain calibration records, schedule routine calibrations, and track instrument performance over time. These systems help ensure compliance with regulatory requirements and facilitate the early detection of instrument drift or malfunction that could compromise measurement precision.

Atomic spectroscopy requires different calibration approaches depending on the specific technique. Atomic Absorption Spectroscopy (AAS) typically utilizes single-element or multi-element standard solutions of known concentrations to establish calibration curves. Inductively Coupled Plasma (ICP) techniques often employ certified reference materials that closely match the matrix of the samples being analyzed.

Quality assurance protocols for both spectroscopic methods include regular verification of instrument performance using certified reference materials. For Raman spectroscopy, this involves checking spectral resolution, peak position accuracy, and signal-to-noise ratios. Atomic spectroscopy quality assurance focuses on detection limits, sensitivity, and linearity of response across concentration ranges.

The traceability of calibration standards to national or international reference materials is essential for ensuring measurement accuracy. Organizations such as NIST (USA), BAM (Germany), and NMIJ (Japan) provide certified reference materials that serve as the foundation for reliable calibration protocols in both spectroscopic techniques.

Method validation represents another crucial aspect of quality assurance. This includes determining limits of detection and quantification, assessing measurement uncertainty, and evaluating method robustness. For Raman spectroscopy, this may involve analyzing samples with varying concentrations of the analyte of interest to establish the linear dynamic range. In atomic spectroscopy, method validation often includes spike recovery tests and analysis of certified reference materials.

Interlaboratory comparison studies provide an external quality assessment mechanism for both techniques. These studies involve multiple laboratories analyzing identical samples, with results compared to evaluate consistency and identify potential systematic errors. Such exercises are particularly valuable for establishing measurement precision across different instruments and operators.

Digital calibration management systems are increasingly being implemented to maintain calibration records, schedule routine calibrations, and track instrument performance over time. These systems help ensure compliance with regulatory requirements and facilitate the early detection of instrument drift or malfunction that could compromise measurement precision.

Industrial Implementation Challenges and Solutions

The implementation of Raman and Atomic Spectroscopy in industrial settings presents distinct challenges that significantly impact their practical utility. For Raman spectroscopy, the primary industrial challenge lies in signal interference from fluorescence and ambient light, which can overwhelm the relatively weak Raman signals. This necessitates sophisticated optical filtering systems and sample preparation protocols, adding complexity to industrial deployments.

Equipment cost represents another substantial barrier, particularly for high-precision Raman systems with enhanced sensitivity. While portable Raman devices have emerged, they typically sacrifice measurement precision for mobility, creating a challenging trade-off for industries requiring both field deployment and accurate measurements.

Atomic spectroscopy faces different implementation hurdles, notably the requirement for specialized sample preparation. Many industrial samples must undergo dissolution or digestion processes before analysis, introducing potential contamination risks and extending analysis timeframes. This preparation complexity often necessitates dedicated laboratory facilities and trained personnel, limiting point-of-use applications.

Environmental control presents challenges for both technologies but manifests differently. Atomic spectroscopy requires stable temperature conditions and protection from vibration to maintain calibration integrity. Raman systems, while generally more robust against environmental variations, remain susceptible to thermal drift affecting laser stability and optical alignment.

Industry-specific solutions have emerged to address these challenges. For pharmaceutical manufacturing, hybrid systems combining Raman spectroscopy with chemometric algorithms have been developed to compensate for signal variability while maintaining measurement precision. These systems incorporate real-time background correction and automated calibration routines to ensure consistent performance in production environments.

In metallurgical applications, specialized sample handling systems for atomic spectroscopy have reduced preparation requirements while maintaining measurement integrity. Innovations include direct solid sampling techniques and automated sample preparation units that minimize human intervention and associated variability.

The semiconductor industry has pioneered environmental control solutions for both technologies, developing vibration-isolated platforms and temperature-stabilized enclosures that maintain measurement precision in production environments. These engineering solutions, while effective, add significant cost to implementation, creating adoption barriers for smaller industrial operations.

Recent advances in machine learning algorithms have shown promise in addressing signal processing challenges for both technologies, potentially reducing hardware requirements while maintaining measurement precision. These computational approaches may ultimately democratize access to high-precision spectroscopic analysis across diverse industrial settings.

Equipment cost represents another substantial barrier, particularly for high-precision Raman systems with enhanced sensitivity. While portable Raman devices have emerged, they typically sacrifice measurement precision for mobility, creating a challenging trade-off for industries requiring both field deployment and accurate measurements.

Atomic spectroscopy faces different implementation hurdles, notably the requirement for specialized sample preparation. Many industrial samples must undergo dissolution or digestion processes before analysis, introducing potential contamination risks and extending analysis timeframes. This preparation complexity often necessitates dedicated laboratory facilities and trained personnel, limiting point-of-use applications.

Environmental control presents challenges for both technologies but manifests differently. Atomic spectroscopy requires stable temperature conditions and protection from vibration to maintain calibration integrity. Raman systems, while generally more robust against environmental variations, remain susceptible to thermal drift affecting laser stability and optical alignment.

Industry-specific solutions have emerged to address these challenges. For pharmaceutical manufacturing, hybrid systems combining Raman spectroscopy with chemometric algorithms have been developed to compensate for signal variability while maintaining measurement precision. These systems incorporate real-time background correction and automated calibration routines to ensure consistent performance in production environments.

In metallurgical applications, specialized sample handling systems for atomic spectroscopy have reduced preparation requirements while maintaining measurement integrity. Innovations include direct solid sampling techniques and automated sample preparation units that minimize human intervention and associated variability.

The semiconductor industry has pioneered environmental control solutions for both technologies, developing vibration-isolated platforms and temperature-stabilized enclosures that maintain measurement precision in production environments. These engineering solutions, while effective, add significant cost to implementation, creating adoption barriers for smaller industrial operations.

Recent advances in machine learning algorithms have shown promise in addressing signal processing challenges for both technologies, potentially reducing hardware requirements while maintaining measurement precision. These computational approaches may ultimately democratize access to high-precision spectroscopic analysis across diverse industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!