How to Integrate Carbonyl Chemistry in Circular Waste Models?

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Chemistry in Waste Circularity: Background and Objectives

Carbonyl chemistry plays a pivotal role in the development of circular waste models, offering innovative solutions to address the growing global waste management crisis. The integration of carbonyl chemistry into circular waste models represents a significant shift in how we approach waste treatment and resource recovery. This approach aligns with the principles of circular economy, aiming to minimize waste generation and maximize resource utilization.

The evolution of waste management strategies has led to the exploration of advanced chemical processes to transform waste materials into valuable resources. Carbonyl chemistry, with its focus on compounds containing the C=O functional group, provides a versatile platform for such transformations. The reactivity of carbonyl groups allows for a wide range of chemical modifications, enabling the conversion of waste materials into useful products or intermediates.

The primary objective of integrating carbonyl chemistry into circular waste models is to develop sustainable and efficient methods for waste valorization. This involves the design of chemical processes that can selectively target carbonyl-containing compounds in waste streams, facilitating their transformation into high-value products. Such an approach not only addresses waste reduction but also contributes to the creation of new material streams in a circular economy.

One of the key trends in this field is the development of catalytic systems that can efficiently activate carbonyl groups in complex waste mixtures. These catalysts are designed to operate under mild conditions, reducing energy consumption and improving the overall sustainability of the process. Additionally, there is a growing interest in bio-based catalysts and green solvents that align with the principles of green chemistry.

The integration of carbonyl chemistry in circular waste models also aims to address specific challenges in waste management. For instance, the treatment of plastic waste, particularly those containing polyester and polyurethane materials, can benefit from carbonyl chemistry approaches. These methods can potentially break down polymer chains at carbonyl linkages, facilitating recycling or upcycling processes.

Furthermore, the application of carbonyl chemistry in waste circularity extends to the treatment of organic waste from agricultural and food industries. The abundance of carbonyl-containing compounds in these waste streams presents opportunities for the production of platform chemicals, biofuels, and other value-added products.

As research in this field progresses, the goal is to develop scalable and economically viable processes that can be integrated into existing waste management infrastructure. This requires a multidisciplinary approach, combining expertise in organic chemistry, catalysis, process engineering, and environmental science. The ultimate aim is to create a more sustainable and resource-efficient economy by transforming waste materials into valuable resources through innovative carbonyl chemistry applications.

The evolution of waste management strategies has led to the exploration of advanced chemical processes to transform waste materials into valuable resources. Carbonyl chemistry, with its focus on compounds containing the C=O functional group, provides a versatile platform for such transformations. The reactivity of carbonyl groups allows for a wide range of chemical modifications, enabling the conversion of waste materials into useful products or intermediates.

The primary objective of integrating carbonyl chemistry into circular waste models is to develop sustainable and efficient methods for waste valorization. This involves the design of chemical processes that can selectively target carbonyl-containing compounds in waste streams, facilitating their transformation into high-value products. Such an approach not only addresses waste reduction but also contributes to the creation of new material streams in a circular economy.

One of the key trends in this field is the development of catalytic systems that can efficiently activate carbonyl groups in complex waste mixtures. These catalysts are designed to operate under mild conditions, reducing energy consumption and improving the overall sustainability of the process. Additionally, there is a growing interest in bio-based catalysts and green solvents that align with the principles of green chemistry.

The integration of carbonyl chemistry in circular waste models also aims to address specific challenges in waste management. For instance, the treatment of plastic waste, particularly those containing polyester and polyurethane materials, can benefit from carbonyl chemistry approaches. These methods can potentially break down polymer chains at carbonyl linkages, facilitating recycling or upcycling processes.

Furthermore, the application of carbonyl chemistry in waste circularity extends to the treatment of organic waste from agricultural and food industries. The abundance of carbonyl-containing compounds in these waste streams presents opportunities for the production of platform chemicals, biofuels, and other value-added products.

As research in this field progresses, the goal is to develop scalable and economically viable processes that can be integrated into existing waste management infrastructure. This requires a multidisciplinary approach, combining expertise in organic chemistry, catalysis, process engineering, and environmental science. The ultimate aim is to create a more sustainable and resource-efficient economy by transforming waste materials into valuable resources through innovative carbonyl chemistry applications.

Market Analysis for Circular Waste Solutions

The circular waste management market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. The integration of carbonyl chemistry in circular waste models presents a promising opportunity to enhance waste valorization and resource recovery. This market segment is expected to expand rapidly as industries seek innovative solutions to reduce waste and maximize resource efficiency.

Carbonyl chemistry, particularly in the context of circular waste models, offers potential applications in various sectors. The chemical industry stands to benefit greatly from improved recycling processes for carbonyl-containing compounds, such as plastics and polymers. Additionally, the food and beverage industry can leverage carbonyl chemistry for better management of organic waste streams, potentially converting them into valuable products or energy sources.

The market for circular waste solutions incorporating carbonyl chemistry is closely tied to the broader circular economy trend. As governments and corporations worldwide commit to sustainability goals, the demand for advanced waste management technologies is projected to rise. This creates a favorable environment for the development and adoption of carbonyl-based circular waste solutions.

Key market drivers include stringent environmental regulations, increasing corporate sustainability initiatives, and growing consumer awareness of environmental issues. These factors are pushing industries to seek more efficient and environmentally friendly waste management solutions, creating a robust market for innovative approaches like carbonyl chemistry integration.

The potential market size for circular waste solutions is substantial. The global waste management market is already valued in the hundreds of billions of dollars, with a significant portion dedicated to advanced recycling and resource recovery technologies. The integration of carbonyl chemistry into this sector represents a high-growth niche within the larger market.

Geographically, developed regions such as North America and Europe are likely to be early adopters of advanced circular waste solutions. However, rapidly industrializing countries in Asia and Latin America also present significant growth opportunities as they grapple with increasing waste generation and environmental challenges.

Challenges in the market include the need for substantial initial investments in research and development, as well as potential regulatory hurdles for new chemical processes. However, these challenges are balanced by the long-term economic and environmental benefits of successful carbonyl-based circular waste solutions.

In conclusion, the market analysis for circular waste solutions, particularly those integrating carbonyl chemistry, indicates a growing and potentially lucrative sector. As industries and governments increasingly prioritize sustainable waste management, the demand for innovative solutions in this space is expected to surge, creating significant opportunities for technological advancement and market growth.

Carbonyl chemistry, particularly in the context of circular waste models, offers potential applications in various sectors. The chemical industry stands to benefit greatly from improved recycling processes for carbonyl-containing compounds, such as plastics and polymers. Additionally, the food and beverage industry can leverage carbonyl chemistry for better management of organic waste streams, potentially converting them into valuable products or energy sources.

The market for circular waste solutions incorporating carbonyl chemistry is closely tied to the broader circular economy trend. As governments and corporations worldwide commit to sustainability goals, the demand for advanced waste management technologies is projected to rise. This creates a favorable environment for the development and adoption of carbonyl-based circular waste solutions.

Key market drivers include stringent environmental regulations, increasing corporate sustainability initiatives, and growing consumer awareness of environmental issues. These factors are pushing industries to seek more efficient and environmentally friendly waste management solutions, creating a robust market for innovative approaches like carbonyl chemistry integration.

The potential market size for circular waste solutions is substantial. The global waste management market is already valued in the hundreds of billions of dollars, with a significant portion dedicated to advanced recycling and resource recovery technologies. The integration of carbonyl chemistry into this sector represents a high-growth niche within the larger market.

Geographically, developed regions such as North America and Europe are likely to be early adopters of advanced circular waste solutions. However, rapidly industrializing countries in Asia and Latin America also present significant growth opportunities as they grapple with increasing waste generation and environmental challenges.

Challenges in the market include the need for substantial initial investments in research and development, as well as potential regulatory hurdles for new chemical processes. However, these challenges are balanced by the long-term economic and environmental benefits of successful carbonyl-based circular waste solutions.

In conclusion, the market analysis for circular waste solutions, particularly those integrating carbonyl chemistry, indicates a growing and potentially lucrative sector. As industries and governments increasingly prioritize sustainable waste management, the demand for innovative solutions in this space is expected to surge, creating significant opportunities for technological advancement and market growth.

Current Challenges in Carbonyl-based Waste Recycling

The integration of carbonyl chemistry in circular waste models faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the heterogeneous nature of waste streams, which often contain a complex mixture of organic compounds with varying carbonyl content. This diversity makes it difficult to develop universal recycling processes that can effectively target and utilize all carbonyl-containing molecules.

Another major challenge lies in the stability and reactivity of carbonyl compounds. Many carbonyl-containing waste materials are prone to degradation or unwanted side reactions during storage and processing. This instability can lead to reduced efficiency in recycling processes and potentially generate harmful by-products, necessitating additional purification steps and increasing overall costs.

The energy requirements for carbonyl-based recycling processes pose a significant hurdle. Many reactions involving carbonyl groups require high temperatures or pressures, which can be energy-intensive and economically unfavorable. Developing more energy-efficient catalysts and reaction conditions remains a critical area of research to make these processes more sustainable and economically viable.

Selectivity in carbonyl chemistry is another key challenge. Achieving high selectivity for desired products while minimizing unwanted side reactions is crucial for efficient recycling. This is particularly challenging when dealing with mixed waste streams, where multiple carbonyl-containing compounds may compete for reactants or catalysts.

The presence of contaminants in waste streams can significantly impact the effectiveness of carbonyl-based recycling processes. Impurities can poison catalysts, interfere with desired reactions, or lead to the formation of undesirable by-products. Developing robust purification methods and catalysts that can tolerate a range of impurities is essential for improving the overall efficiency of these recycling systems.

Scale-up and process integration present additional challenges. Many carbonyl-based recycling techniques that show promise in laboratory settings face difficulties when scaled up to industrial levels. Issues such as heat and mass transfer limitations, reactor design, and process control become more pronounced at larger scales, requiring significant engineering efforts to overcome.

Lastly, the economic viability of carbonyl-based waste recycling remains a significant hurdle. The costs associated with collection, sorting, and processing of carbonyl-containing waste materials can be substantial. Developing cost-effective technologies and creating markets for recycled products are crucial for the long-term sustainability of these circular waste models.

Another major challenge lies in the stability and reactivity of carbonyl compounds. Many carbonyl-containing waste materials are prone to degradation or unwanted side reactions during storage and processing. This instability can lead to reduced efficiency in recycling processes and potentially generate harmful by-products, necessitating additional purification steps and increasing overall costs.

The energy requirements for carbonyl-based recycling processes pose a significant hurdle. Many reactions involving carbonyl groups require high temperatures or pressures, which can be energy-intensive and economically unfavorable. Developing more energy-efficient catalysts and reaction conditions remains a critical area of research to make these processes more sustainable and economically viable.

Selectivity in carbonyl chemistry is another key challenge. Achieving high selectivity for desired products while minimizing unwanted side reactions is crucial for efficient recycling. This is particularly challenging when dealing with mixed waste streams, where multiple carbonyl-containing compounds may compete for reactants or catalysts.

The presence of contaminants in waste streams can significantly impact the effectiveness of carbonyl-based recycling processes. Impurities can poison catalysts, interfere with desired reactions, or lead to the formation of undesirable by-products. Developing robust purification methods and catalysts that can tolerate a range of impurities is essential for improving the overall efficiency of these recycling systems.

Scale-up and process integration present additional challenges. Many carbonyl-based recycling techniques that show promise in laboratory settings face difficulties when scaled up to industrial levels. Issues such as heat and mass transfer limitations, reactor design, and process control become more pronounced at larger scales, requiring significant engineering efforts to overcome.

Lastly, the economic viability of carbonyl-based waste recycling remains a significant hurdle. The costs associated with collection, sorting, and processing of carbonyl-containing waste materials can be substantial. Developing cost-effective technologies and creating markets for recycled products are crucial for the long-term sustainability of these circular waste models.

Existing Carbonyl-based Circular Waste Models

01 Carbonyl compound synthesis and reactions

This category focuses on the synthesis and reactions of carbonyl compounds, including aldehydes and ketones. It covers various methods for preparing these compounds and their subsequent transformations, such as oxidation, reduction, and condensation reactions. The chemistry of carbonyl groups plays a crucial role in organic synthesis and the development of new materials.- Carbonyl compound synthesis and reactions: This category focuses on the synthesis and reactions of carbonyl compounds, including aldehydes and ketones. It covers various methods for preparing these compounds and their subsequent transformations, such as oxidation, reduction, and condensation reactions. The chemistry of carbonyl groups plays a crucial role in organic synthesis and the development of new materials.

- Carbonyl-based sensors and detection methods: This area involves the development of sensors and detection methods based on carbonyl chemistry. It includes the design of molecular probes and analytical techniques for detecting and quantifying carbonyl compounds in various samples. These methods are important for environmental monitoring, food safety, and medical diagnostics.

- Carbonyl-containing polymers and materials: This category encompasses the synthesis and applications of polymers and materials containing carbonyl groups. It includes the development of new monomers, polymerization techniques, and the modification of existing materials through carbonyl chemistry. These materials find applications in various fields, such as coatings, adhesives, and biomedical materials.

- Carbonyl chemistry in biological systems: This area focuses on the role of carbonyl compounds in biological systems, including their involvement in metabolic processes, protein modifications, and cellular signaling. It covers the study of enzymes that catalyze carbonyl-related reactions and the development of therapeutic approaches targeting carbonyl-mediated processes in diseases.

- Carbonyl-based energy storage and conversion: This category involves the application of carbonyl chemistry in energy storage and conversion technologies. It includes the development of redox-active materials for batteries, fuel cells, and other energy-related applications. The unique properties of carbonyl compounds are exploited to create efficient and sustainable energy systems.

02 Carbonyl-based sensors and detection methods

This area involves the development of sensors and detection methods based on carbonyl chemistry. It includes the design of molecular probes that can selectively interact with carbonyl compounds, as well as analytical techniques for identifying and quantifying these molecules in various samples. These methods are important for environmental monitoring, food safety, and medical diagnostics.Expand Specific Solutions03 Carbonyl chemistry in materials science

This category explores the application of carbonyl chemistry in materials science. It includes the use of carbonyl-containing compounds in the synthesis of polymers, coatings, and advanced materials. The unique reactivity of carbonyl groups allows for the creation of materials with specific properties and functionalities, such as self-healing polymers or stimuli-responsive materials.Expand Specific Solutions04 Carbonyl chemistry in biological systems

This area focuses on the role of carbonyl chemistry in biological systems and its applications in biotechnology. It includes the study of carbonyl-containing biomolecules, such as sugars and proteins, as well as the development of carbonyl-based drugs and therapeutic agents. Understanding carbonyl reactions in biological contexts is crucial for drug discovery and the development of new medical treatments.Expand Specific Solutions05 Carbonyl chemistry in energy applications

This category explores the use of carbonyl chemistry in energy-related applications. It includes the development of carbonyl-based materials for energy storage and conversion, such as battery electrodes or catalysts for fuel cells. The unique properties of carbonyl compounds make them valuable components in the design of more efficient and sustainable energy technologies.Expand Specific Solutions

Key Players in Circular Economy and Carbonyl Chemistry

The integration of carbonyl chemistry in circular waste models is an emerging field at the intersection of sustainable chemistry and waste management. The market is in its early stages, with growing interest driven by environmental concerns and circular economy initiatives. While the market size is still relatively small, it is expected to expand rapidly as regulations tighten and companies seek innovative solutions for waste valorization. Technologically, the field is evolving, with companies like CNOOC Tianjin Chemical Research & Design Institute, Sinopec Beijing Research Institute, and UOP LLC leading research efforts. Universities such as Sichuan University and Tongji University are also contributing to advancing the technology. The involvement of major players like China Petroleum & Chemical Corp and CNOOC indicates the potential for scaling up and commercialization in the near future.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to integrate carbonyl chemistry in circular waste models. Their technology focuses on converting waste plastics and biomass into valuable chemicals through catalytic oxidation and carbonylation processes. Sinopec's method utilizes a novel metal-organic framework (MOF) catalyst that selectively oxidizes waste polymers into aldehydes and ketones[1]. These carbonyl compounds are then further processed through carbonylation reactions to produce high-value chemicals such as acetic acid and its derivatives[3]. The process achieves a carbon utilization efficiency of up to 85%, significantly higher than traditional recycling methods[5].

Strengths: High carbon utilization efficiency, production of valuable chemicals, utilization of diverse waste feedstocks. Weaknesses: High energy requirements, potential catalyst deactivation issues, complex separation processes for product purification.

UOP LLC

Technical Solution: UOP LLC has developed a proprietary technology called "Carbonyl Waste-to-Chemicals" (CWC) to integrate carbonyl chemistry in circular waste models. The CWC process utilizes a combination of catalytic oxidation and carbonylation reactions to convert mixed plastic waste and biomass into valuable chemical intermediates. UOP's approach employs a dual-function catalyst system that first oxidizes the waste materials into a mixture of aldehydes and ketones[2]. These carbonyl compounds are then selectively carbonylated using syngas (CO + H2) to produce a range of carboxylic acids and esters[4]. The process achieves a carbon conversion efficiency of over 90% and can handle a wide variety of waste feedstocks, including polyolefins, PET, and lignocellulosic biomass[6].

Strengths: High carbon conversion efficiency, versatility in handling different waste types, production of diverse chemical intermediates. Weaknesses: Requires a stable supply of syngas, potential issues with catalyst longevity, high capital costs for initial plant setup.

Innovative Carbonyl Reactions for Waste Valorization

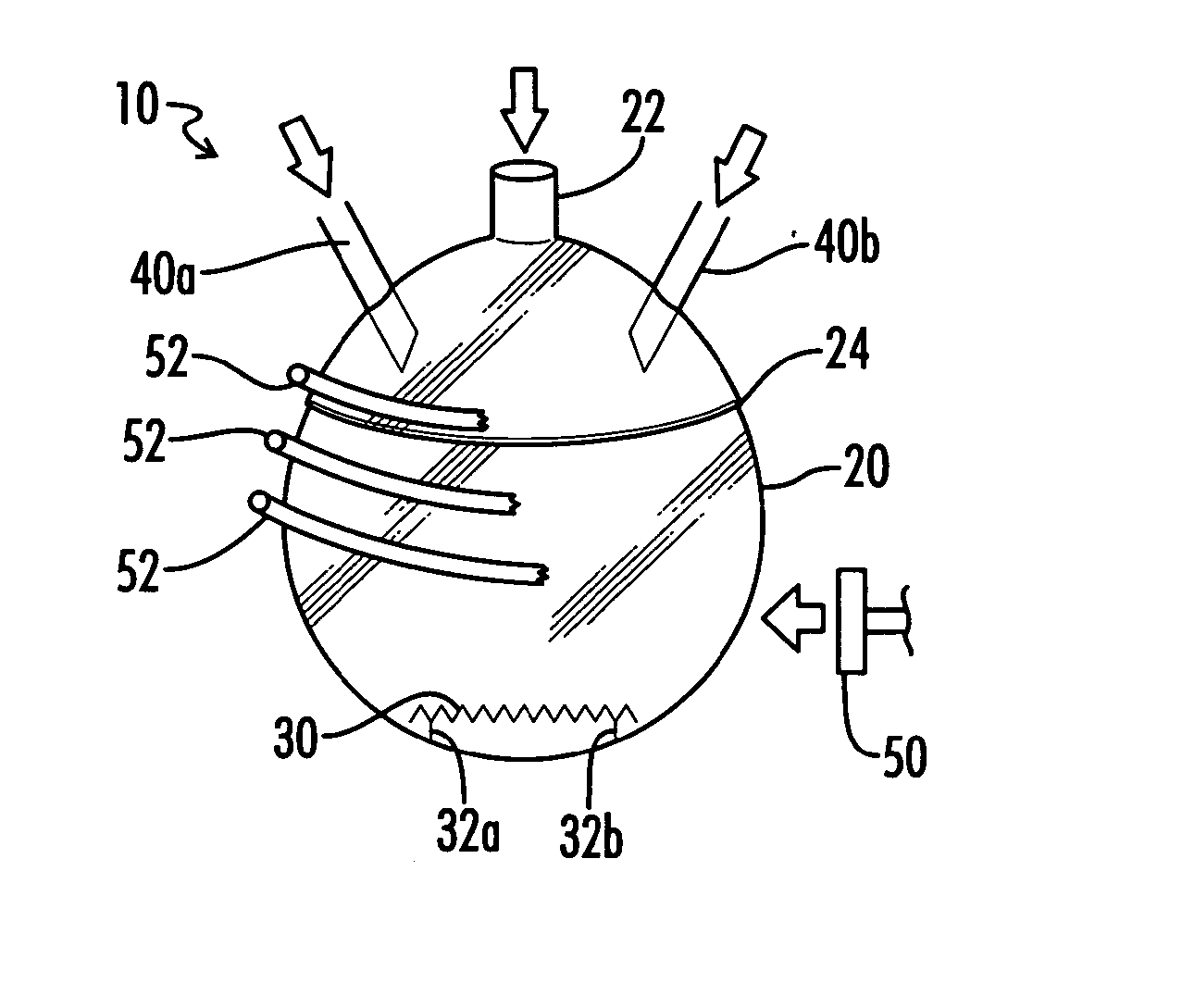

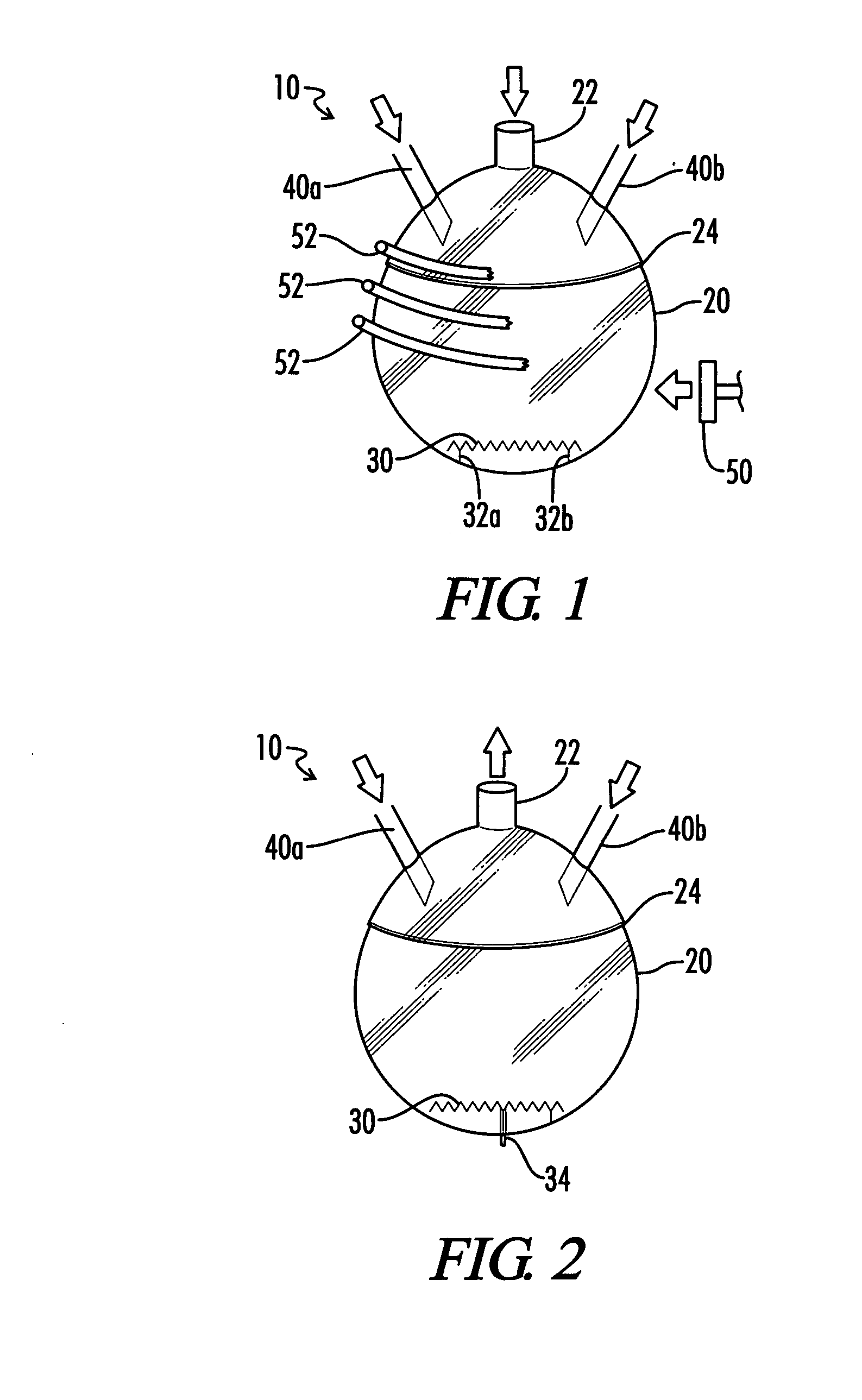

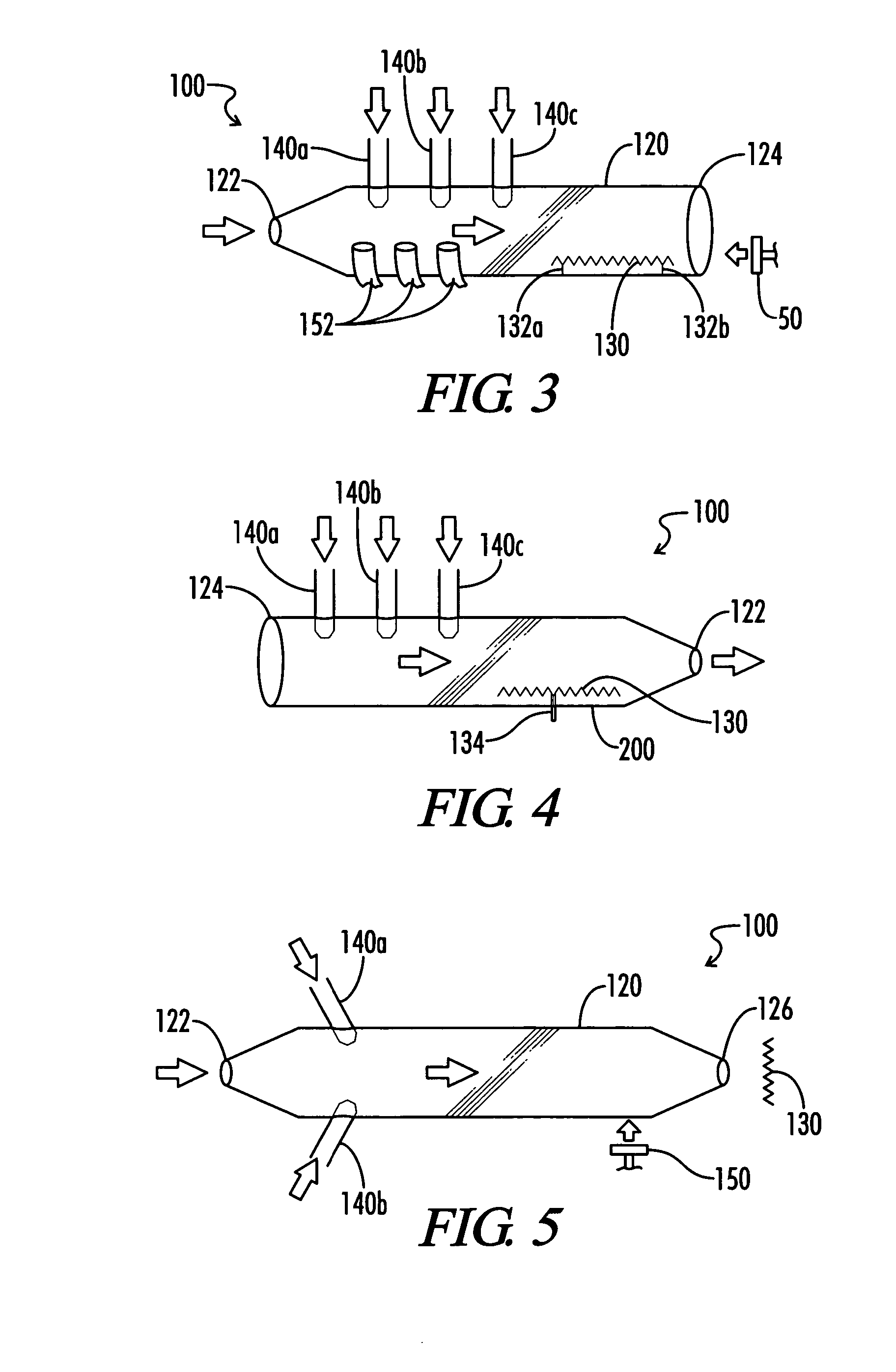

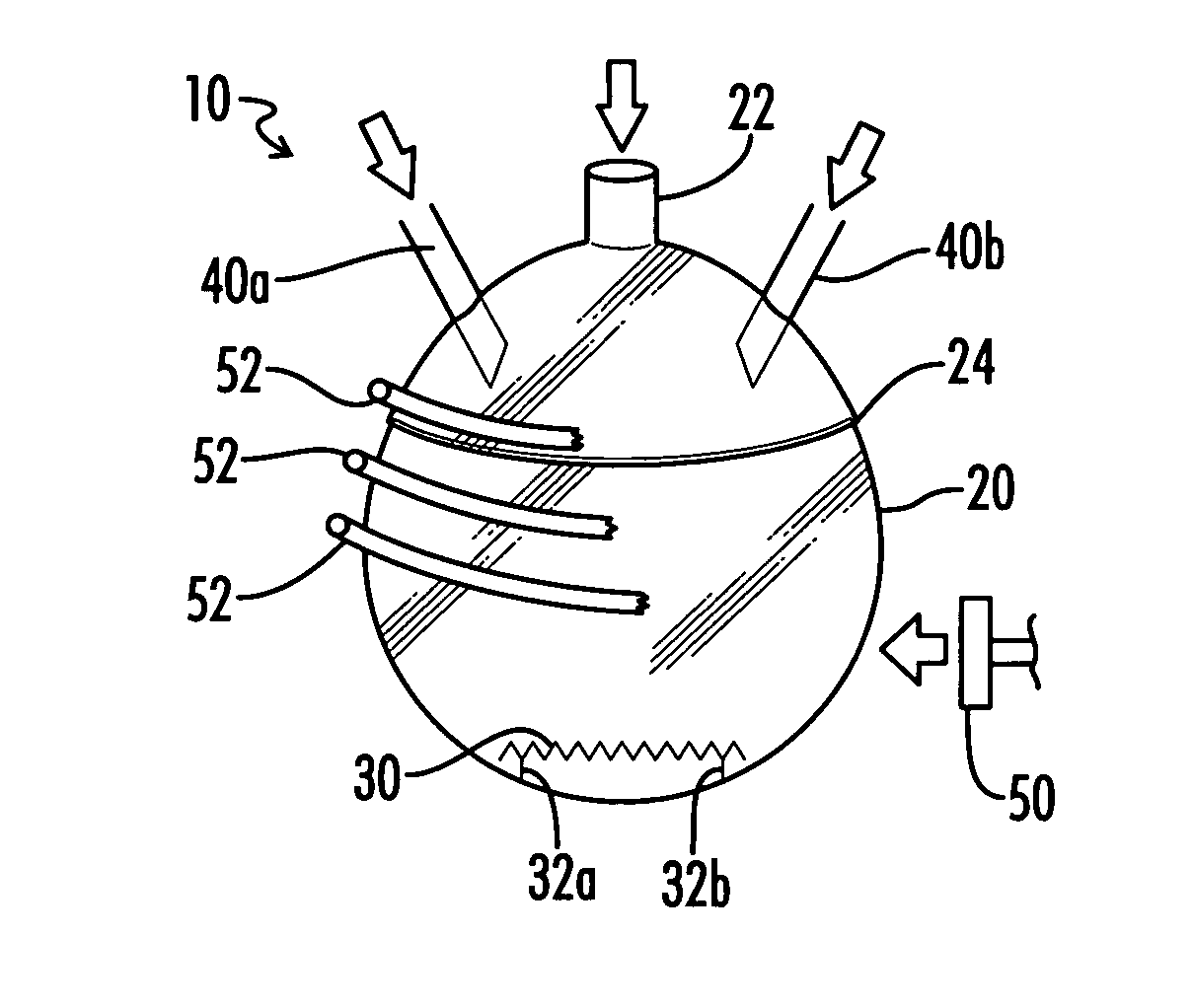

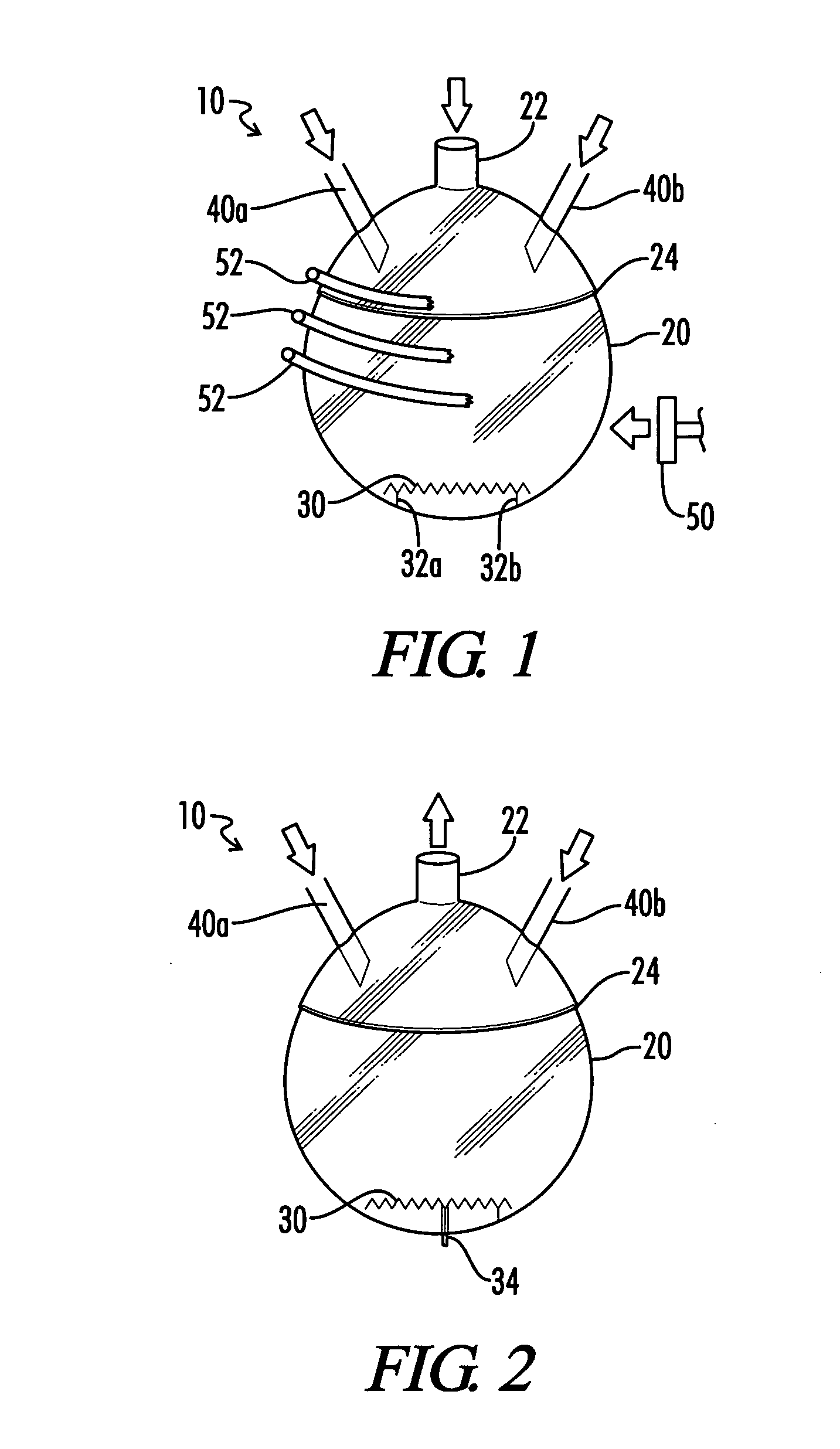

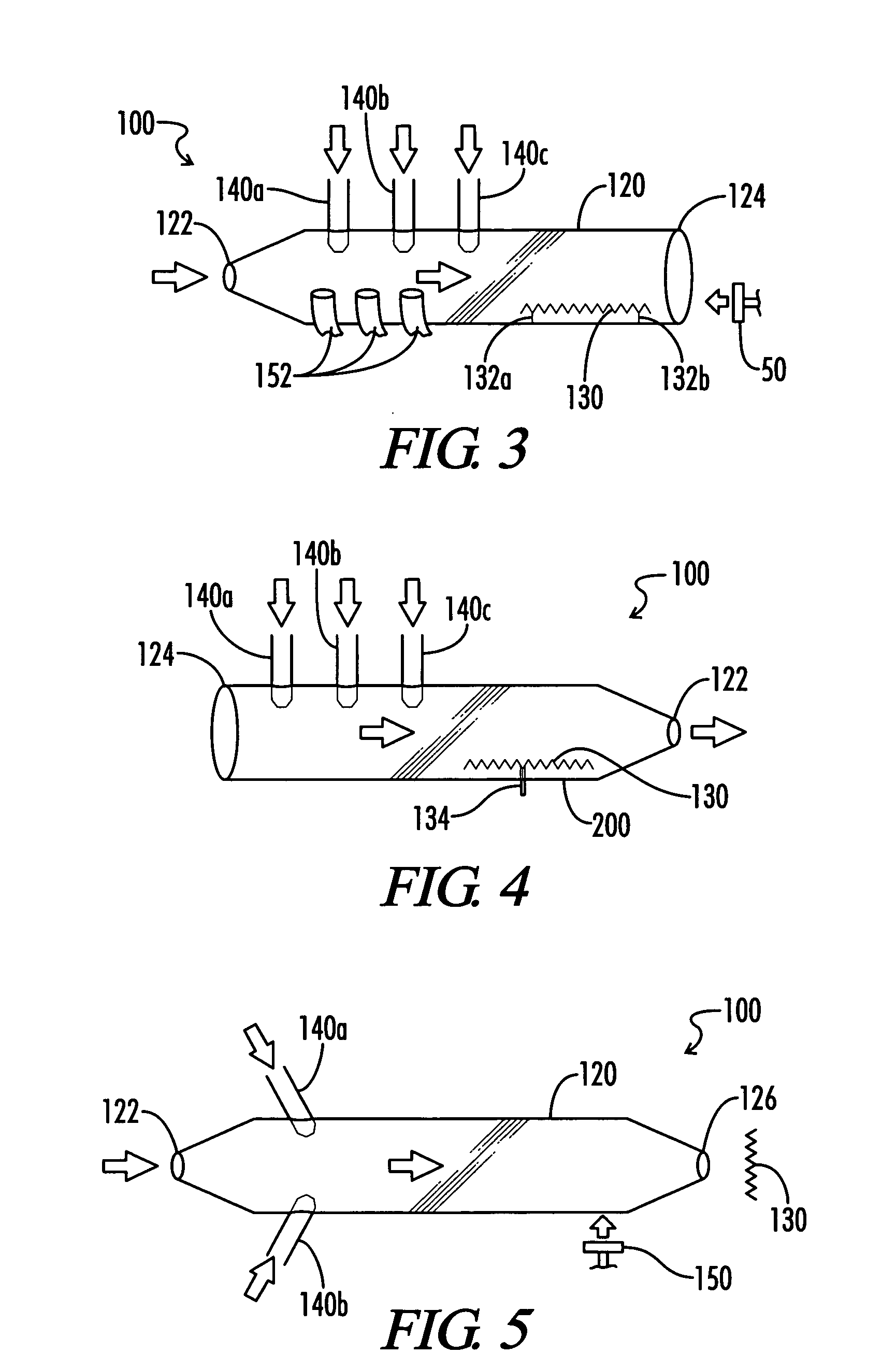

Continuous process for the use of metal carbonyls for the production of nano-scale metal particles formed of non-noble metals

PatentInactiveUS20070283784A1

Innovation

- A continuous process using metal carbonyls to produce non-noble metal nano-scale particles by decomposing them in a reactor vessel with controlled energy sources, allowing for deposition on a support or collection without the need for extreme conditions, utilizing a reactor system that can operate at atmospheric pressure and moderate temperatures.

Continuous process for the use of metal carbonyls for the production of nano-scale metal particles

PatentInactiveUS20070034049A1

Innovation

- A continuous process using metal carbonyls, where the carbonyls are decomposed in a reactor vessel with controlled energy to produce nano-scale metal particles that can be deposited on a support or collected, operating at relatively low temperatures and atmospheric pressure.

Environmental Impact Assessment of Carbonyl-based Recycling

The environmental impact assessment of carbonyl-based recycling is a critical component in evaluating the sustainability and viability of integrating carbonyl chemistry into circular waste models. This assessment encompasses various aspects of the recycling process, from raw material extraction to end-of-life disposal, with a focus on the unique characteristics of carbonyl compounds.

One of the primary considerations in this assessment is the energy consumption associated with carbonyl-based recycling processes. These processes often require high temperatures and pressures, which can lead to significant energy expenditure. However, when compared to traditional recycling methods or the production of virgin materials, carbonyl-based recycling may offer energy savings in certain applications. The assessment must quantify these energy requirements and compare them across different recycling technologies to determine the most efficient approach.

Greenhouse gas emissions are another crucial factor in the environmental impact assessment. Carbonyl compounds, particularly aldehydes and ketones, can contribute to atmospheric pollution if not properly managed. The assessment should evaluate the potential for emissions during the recycling process, as well as any emissions reductions achieved through the displacement of virgin material production. This analysis should include a comprehensive life cycle assessment to account for both direct and indirect emissions associated with carbonyl-based recycling.

Water usage and pollution are also significant concerns in carbonyl-based recycling. The assessment must consider the water requirements for the recycling process, including any purification or treatment steps necessary to handle carbonyl-containing waste streams. Additionally, the potential for water contamination by carbonyl compounds or their byproducts should be thoroughly evaluated, with particular attention paid to the toxicity and persistence of these substances in aquatic environments.

The impact on land use and biodiversity is another important aspect of the environmental assessment. While carbonyl-based recycling may reduce the need for landfill space, the facilities required for these processes could potentially impact local ecosystems. The assessment should examine the land requirements for recycling plants, as well as any potential effects on surrounding flora and fauna.

Resource depletion is a key consideration in the context of circular waste models. The environmental impact assessment should evaluate how carbonyl-based recycling contributes to resource conservation by reducing the demand for virgin materials. This analysis should include an examination of the recyclability and reusability of carbonyl-derived products, as well as the potential for creating closed-loop systems that minimize waste and maximize resource efficiency.

One of the primary considerations in this assessment is the energy consumption associated with carbonyl-based recycling processes. These processes often require high temperatures and pressures, which can lead to significant energy expenditure. However, when compared to traditional recycling methods or the production of virgin materials, carbonyl-based recycling may offer energy savings in certain applications. The assessment must quantify these energy requirements and compare them across different recycling technologies to determine the most efficient approach.

Greenhouse gas emissions are another crucial factor in the environmental impact assessment. Carbonyl compounds, particularly aldehydes and ketones, can contribute to atmospheric pollution if not properly managed. The assessment should evaluate the potential for emissions during the recycling process, as well as any emissions reductions achieved through the displacement of virgin material production. This analysis should include a comprehensive life cycle assessment to account for both direct and indirect emissions associated with carbonyl-based recycling.

Water usage and pollution are also significant concerns in carbonyl-based recycling. The assessment must consider the water requirements for the recycling process, including any purification or treatment steps necessary to handle carbonyl-containing waste streams. Additionally, the potential for water contamination by carbonyl compounds or their byproducts should be thoroughly evaluated, with particular attention paid to the toxicity and persistence of these substances in aquatic environments.

The impact on land use and biodiversity is another important aspect of the environmental assessment. While carbonyl-based recycling may reduce the need for landfill space, the facilities required for these processes could potentially impact local ecosystems. The assessment should examine the land requirements for recycling plants, as well as any potential effects on surrounding flora and fauna.

Resource depletion is a key consideration in the context of circular waste models. The environmental impact assessment should evaluate how carbonyl-based recycling contributes to resource conservation by reducing the demand for virgin materials. This analysis should include an examination of the recyclability and reusability of carbonyl-derived products, as well as the potential for creating closed-loop systems that minimize waste and maximize resource efficiency.

Policy Framework for Circular Waste Management

The policy framework for circular waste management plays a crucial role in integrating carbonyl chemistry into circular waste models. Effective policies can drive innovation, encourage sustainable practices, and create a supportive environment for implementing advanced chemical processes in waste management systems.

A comprehensive policy framework should address multiple aspects of circular waste management. Firstly, it should establish clear guidelines for waste collection and sorting, emphasizing the separation of carbonyl-containing materials. This step is essential for maximizing the potential of carbonyl chemistry in waste processing and recycling.

Secondly, the framework should incentivize research and development in carbonyl chemistry applications for waste management. This can be achieved through targeted funding programs, tax incentives, and public-private partnerships. By fostering innovation, policymakers can accelerate the development of new technologies that leverage carbonyl chemistry in circular waste models.

Environmental regulations form another critical component of the policy framework. These regulations should set stringent standards for emissions and waste disposal, encouraging industries to adopt cleaner production methods and explore circular economy principles. By incorporating carbonyl chemistry considerations into these regulations, policymakers can promote more efficient and environmentally friendly waste management practices.

The framework should also address the economic aspects of circular waste management. This includes implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products. Such policies can drive the integration of carbonyl chemistry principles into product design and manufacturing processes, facilitating easier recycling and waste reduction.

Education and awareness programs should be incorporated into the policy framework. These initiatives can help inform stakeholders about the benefits of integrating carbonyl chemistry in circular waste models and promote behavioral changes that support sustainable waste management practices.

Lastly, the policy framework should establish mechanisms for monitoring and evaluating the effectiveness of circular waste management strategies. This includes setting key performance indicators, conducting regular assessments, and adjusting policies based on outcomes. By maintaining a flexible and adaptive approach, policymakers can ensure that the integration of carbonyl chemistry in circular waste models remains aligned with evolving technological advancements and societal needs.

A comprehensive policy framework should address multiple aspects of circular waste management. Firstly, it should establish clear guidelines for waste collection and sorting, emphasizing the separation of carbonyl-containing materials. This step is essential for maximizing the potential of carbonyl chemistry in waste processing and recycling.

Secondly, the framework should incentivize research and development in carbonyl chemistry applications for waste management. This can be achieved through targeted funding programs, tax incentives, and public-private partnerships. By fostering innovation, policymakers can accelerate the development of new technologies that leverage carbonyl chemistry in circular waste models.

Environmental regulations form another critical component of the policy framework. These regulations should set stringent standards for emissions and waste disposal, encouraging industries to adopt cleaner production methods and explore circular economy principles. By incorporating carbonyl chemistry considerations into these regulations, policymakers can promote more efficient and environmentally friendly waste management practices.

The framework should also address the economic aspects of circular waste management. This includes implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products. Such policies can drive the integration of carbonyl chemistry principles into product design and manufacturing processes, facilitating easier recycling and waste reduction.

Education and awareness programs should be incorporated into the policy framework. These initiatives can help inform stakeholders about the benefits of integrating carbonyl chemistry in circular waste models and promote behavioral changes that support sustainable waste management practices.

Lastly, the policy framework should establish mechanisms for monitoring and evaluating the effectiveness of circular waste management strategies. This includes setting key performance indicators, conducting regular assessments, and adjusting policies based on outcomes. By maintaining a flexible and adaptive approach, policymakers can ensure that the integration of carbonyl chemistry in circular waste models remains aligned with evolving technological advancements and societal needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!