How to Maximize PMMA's Value in Construction?

PMMA in Construction: Background and Objectives

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has been a versatile material in the construction industry for decades. Its journey began in the 1930s when it was first developed as a shatter-resistant alternative to glass. Since then, PMMA has evolved significantly, finding applications in various construction elements due to its unique properties.

The evolution of PMMA in construction has been driven by advancements in polymer science and manufacturing techniques. Early applications were limited to simple glazing and signage, but as production methods improved, PMMA's use expanded to more complex architectural elements. The material's ability to be molded into various shapes and its excellent light transmission properties have made it increasingly popular in modern architecture.

In recent years, the construction industry has faced growing demands for sustainable, energy-efficient, and aesthetically pleasing materials. This has led to a renewed focus on maximizing PMMA's value in construction applications. The material's lightweight nature, durability, and recyclability align well with these industry trends, positioning it as a potential solution for many contemporary construction challenges.

The primary objective in maximizing PMMA's value in construction is to leverage its unique properties while addressing its limitations. This involves exploring new formulations to enhance its performance characteristics, such as improved weather resistance, fire retardancy, and structural strength. Additionally, there is a growing emphasis on developing innovative applications that can fully utilize PMMA's transparency, formability, and insulation properties.

Another key goal is to integrate PMMA more effectively with other construction materials and systems. This includes developing new joining techniques, exploring hybrid materials, and creating modular construction elements that incorporate PMMA. By doing so, the industry aims to expand the material's use beyond traditional applications and into more structural and functional roles within buildings.

Furthermore, there is a focus on enhancing PMMA's sustainability profile. This involves improving its recyclability, reducing energy consumption in its production, and exploring bio-based alternatives. The aim is to position PMMA as a material of choice for green building initiatives and to meet increasingly stringent environmental regulations in the construction sector.

As we look to the future, the trajectory of PMMA in construction is likely to be shaped by emerging technologies such as 3D printing, smart materials, and advanced coating technologies. These developments promise to unlock new possibilities for PMMA, potentially revolutionizing its role in the built environment and further maximizing its value in construction applications.

Market Analysis for PMMA in Building Materials

The global market for PMMA (Polymethyl Methacrylate) in building materials has been experiencing steady growth, driven by the material's unique properties and versatile applications in construction. PMMA, also known as acrylic or plexiglass, offers excellent transparency, weather resistance, and durability, making it an attractive choice for various architectural and design elements.

In recent years, the construction industry has shown an increased demand for lightweight, energy-efficient, and aesthetically pleasing materials. PMMA fits these requirements perfectly, contributing to its growing market share in building applications. The material is widely used in skylights, windows, facades, and interior design elements, offering architects and designers a high-performance alternative to traditional glass.

The market for PMMA in building materials is segmented based on application, including windows, skylights, partitions, signage, and decorative elements. Among these, windows and skylights represent the largest market share due to PMMA's superior light transmission properties and impact resistance. The growing trend towards energy-efficient buildings has further boosted the demand for PMMA-based windows and skylights, as they provide excellent insulation and reduce heating and cooling costs.

Geographically, the Asia-Pacific region dominates the PMMA market in building materials, followed by North America and Europe. The rapid urbanization and infrastructure development in emerging economies like China and India are driving the demand for PMMA in construction applications. In mature markets like North America and Europe, the focus on sustainable and energy-efficient building practices is fueling the adoption of PMMA-based products.

The market is characterized by intense competition among key players, including Evonik Industries, Mitsubishi Chemical Corporation, Arkema Group, and Sumitomo Chemical Co., Ltd. These companies are investing heavily in research and development to improve PMMA's properties and expand its applications in the construction sector. Innovations in PMMA formulations, such as impact-modified grades and UV-resistant variants, are opening up new opportunities in the building materials market.

Despite the positive outlook, the PMMA market faces challenges such as volatility in raw material prices and competition from alternative materials like polycarbonate. However, the ongoing technological advancements and the material's eco-friendly characteristics are expected to sustain its growth in the construction industry. The increasing focus on sustainable building practices and the growing demand for energy-efficient materials are likely to drive the PMMA market in building materials in the coming years.

Current Applications and Challenges of PMMA

Polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass, has found widespread applications in the construction industry due to its unique properties. In recent years, PMMA has been increasingly utilized in various construction applications, ranging from architectural elements to functional components.

One of the primary applications of PMMA in construction is as a lightweight and shatter-resistant alternative to glass. It is commonly used in skylights, windows, and transparent roofing materials, offering excellent light transmission while providing better insulation than traditional glass. PMMA's durability and resistance to weathering make it an ideal choice for outdoor applications, such as signage and protective barriers.

In interior design, PMMA is frequently employed for decorative elements, including wall panels, partitions, and furniture. Its versatility allows for creative designs and the ability to be molded into various shapes and forms. The material's clarity and ability to be colored or tinted provide architects and designers with a wide range of aesthetic options.

PMMA's use in construction extends to functional applications as well. It is utilized in light fixtures and diffusers, taking advantage of its high light transmission properties. The material is also employed in sanitary ware, such as bathtubs and sinks, due to its resistance to chemicals and ease of cleaning.

Despite its numerous advantages, PMMA faces several challenges in the construction industry. One significant issue is its relatively high cost compared to traditional materials like glass or certain plastics. This cost factor can limit its adoption in large-scale projects or budget-conscious developments.

Another challenge is PMMA's lower scratch resistance compared to glass. While it offers better impact resistance, its surface can be more easily marred, potentially affecting its long-term appearance and clarity. This necessitates careful handling during installation and maintenance to preserve its aesthetic qualities.

PMMA's thermal expansion properties also present challenges in construction applications. The material expands and contracts more than glass or metal in response to temperature changes, requiring careful consideration in design and installation to accommodate these movements and prevent structural issues.

Fire safety is another concern with PMMA. Although it can be manufactured with fire-retardant additives, its flammability is generally higher than that of glass, necessitating additional fire safety measures in building designs incorporating large amounts of PMMA.

Lastly, while PMMA is recyclable, the process is not as straightforward as with some other materials. Ensuring proper recycling and disposal of PMMA products at the end of their lifecycle remains a challenge for the construction industry, particularly in the context of increasing focus on sustainability and circular economy principles.

Existing PMMA Construction Solutions

01 PMMA synthesis and production methods

Various methods for synthesizing and producing PMMA are described, including polymerization techniques, reactor designs, and process optimizations to improve yield and quality. These methods aim to enhance the efficiency of PMMA production and tailor its properties for specific applications.- PMMA synthesis and production methods: Various methods for synthesizing and producing PMMA are described, including polymerization techniques, reactor designs, and process optimizations. These methods aim to improve the quality, efficiency, and cost-effectiveness of PMMA production.

- PMMA applications in optical and electronic devices: PMMA is widely used in optical and electronic applications due to its excellent optical properties and processability. This includes its use in LED encapsulation, optical lenses, displays, and other photonic devices.

- PMMA-based composites and blends: The development of PMMA-based composites and blends with other materials to enhance specific properties such as impact resistance, thermal stability, or electrical conductivity. These composites find applications in various industries including automotive and construction.

- PMMA recycling and sustainability: Methods for recycling PMMA and improving its sustainability are explored. This includes chemical recycling processes, mechanical recycling techniques, and the development of bio-based or biodegradable PMMA alternatives.

- PMMA surface modification and functionalization: Techniques for modifying and functionalizing PMMA surfaces to enhance its properties or add new functionalities. This includes plasma treatment, chemical grafting, and the incorporation of nanoparticles or other functional materials onto PMMA surfaces.

02 PMMA composite materials and blends

Development of PMMA-based composite materials and blends with other polymers or additives to enhance specific properties such as strength, thermal stability, or optical characteristics. These composites expand the range of applications for PMMA in various industries.Expand Specific Solutions03 PMMA surface modification and functionalization

Techniques for modifying the surface of PMMA to improve its compatibility with other materials, enhance its adhesion properties, or introduce specific functionalities. These modifications expand the versatility of PMMA in applications such as coatings, adhesives, and biomedical devices.Expand Specific Solutions04 PMMA recycling and sustainability

Methods for recycling PMMA waste and improving the sustainability of PMMA production and use. These approaches aim to reduce environmental impact and increase the circular economy potential of PMMA-based products.Expand Specific Solutions05 PMMA applications in optical and electronic devices

Utilization of PMMA in various optical and electronic applications, including lenses, displays, and light-guiding components. The material's optical clarity, processability, and customizable properties make it valuable in these high-tech fields.Expand Specific Solutions

Key Players in PMMA Construction Industry

The market for PMMA in construction is in a growth phase, driven by increasing demand for lightweight, durable, and aesthetically pleasing materials. The global PMMA market size is projected to expand significantly, with the construction sector being a key driver. Technologically, PMMA is mature but continues to evolve, with companies like DuPont, Röhm GmbH, and Arkema France SA leading innovation. Chinese firms such as Sinopec and Wanhua Chemical are also making strides in PMMA technology, while research institutions like the Chinese Academy of Sciences are contributing to advancements in material properties and applications.

DuPont de Nemours, Inc.

Röhm GmbH

Innovative PMMA Applications in Building

- A PMMA body produced by radical polymerization of a composition comprising 88-95% methyl methacrylate, 0-7% plasticizer, 0.01-0.5% HALS compound, and 0.1-10% active component, such as alcohols or vinyl compounds, is used as a glazing material to enhance UV transmission and promote plant growth.

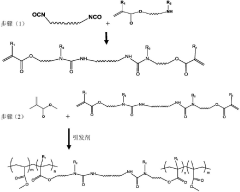

- Using the preparation method of partially cross-linked PMMA, an intermediate product is generated through the polyurea reaction of diisocyanate and hindered amine acrylate, and is copolymerized with MMA monomer under the action of an initiator to form partially cross-linked PMMA, thereby achieving cross-linking of PMMA molecular chains. , improve its mechanical properties.

Environmental Impact of PMMA in Construction

The environmental impact of PMMA in construction is a critical consideration for maximizing its value in the industry. PMMA, or polymethyl methacrylate, offers several environmental advantages over traditional construction materials. Its durability and longevity contribute to reduced waste and resource consumption over time. PMMA's lightweight nature also leads to lower transportation emissions and energy requirements during installation.

However, the production of PMMA does have environmental implications. The manufacturing process involves petrochemical-based raw materials and energy-intensive polymerization, resulting in greenhouse gas emissions and potential air pollution. Despite this, advancements in production technologies have led to more efficient processes, reducing the overall environmental footprint.

PMMA's recyclability is a significant environmental benefit. Unlike many other plastics, PMMA can be depolymerized back into its monomer form, allowing for near-infinite recycling without significant loss of quality. This characteristic aligns well with circular economy principles and helps minimize waste in the construction sector.

The material's energy efficiency properties also contribute positively to its environmental profile. PMMA's excellent light transmission and thermal insulation capabilities can reduce energy consumption in buildings, particularly when used in windows, skylights, or facade systems. This energy-saving potential over a building's lifetime can offset the initial environmental costs of production.

When considering end-of-life scenarios, PMMA presents both challenges and opportunities. While it is recyclable, proper collection and processing infrastructure must be in place to realize this benefit. Improper disposal can lead to environmental pollution, as PMMA does not biodegrade readily. However, when compared to materials with shorter lifespans or those that cannot be recycled, PMMA's overall lifecycle impact can be favorable.

The use of PMMA in construction also indirectly impacts the environment through its performance characteristics. Its resistance to weathering, UV radiation, and chemical degradation means less frequent replacement and maintenance, reducing the need for additional resources and associated environmental impacts over time.

As the construction industry moves towards more sustainable practices, the environmental impact of PMMA will likely continue to improve. Research into bio-based alternatives and more environmentally friendly production methods is ongoing, promising to further enhance PMMA's environmental profile in the future.

Cost-Benefit Analysis of PMMA Usage

The cost-benefit analysis of PMMA usage in construction reveals a complex interplay of economic factors that must be carefully considered. Initially, the upfront costs of PMMA materials may appear higher compared to traditional alternatives. However, a comprehensive evaluation demonstrates significant long-term benefits that can offset these initial expenses.

PMMA's durability and resistance to weathering contribute to reduced maintenance costs over the lifespan of a structure. This longevity translates into fewer replacements and repairs, resulting in substantial savings on labor and materials. Additionally, PMMA's lightweight nature can lead to reduced transportation and installation costs, particularly in large-scale projects.

Energy efficiency is another crucial factor in the cost-benefit equation. PMMA's excellent thermal insulation properties can contribute to lower heating and cooling expenses in buildings. This energy conservation not only reduces operational costs but also aligns with sustainable construction practices, potentially qualifying projects for green building certifications and associated incentives.

The optical clarity and UV resistance of PMMA offer aesthetic advantages that can enhance property value. In commercial structures, these properties can create more appealing spaces, potentially increasing rental or resale values. For residential applications, PMMA's ability to maintain transparency over time can contribute to improved natural lighting and reduced artificial lighting needs, further impacting energy costs.

When considering safety features, PMMA's shatter-resistant properties can reduce the risk of injury and associated liability costs. This aspect is particularly valuable in high-traffic areas or regions prone to extreme weather conditions. The material's fire-resistant qualities may also contribute to lower insurance premiums for buildings incorporating PMMA elements.

From a lifecycle perspective, PMMA's recyclability presents an opportunity for cost recovery at the end of its useful life. The ability to repurpose or recycle PMMA components aligns with circular economy principles, potentially offering financial benefits through material recovery or compliance with environmental regulations.

However, it is essential to acknowledge that the cost-benefit ratio of PMMA usage can vary depending on specific project requirements, local market conditions, and regulatory environments. Factors such as climate, building design, and intended use must be carefully evaluated to determine the optimal application of PMMA in construction projects.