How to Minimize PMMA's Carbon Footprint?

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMMA Carbon Footprint Background and Objectives

Poly(methyl methacrylate), commonly known as PMMA or acrylic, is a versatile synthetic polymer widely used in various industries due to its excellent optical properties, durability, and weather resistance. However, the production and disposal of PMMA have raised concerns about its environmental impact, particularly its carbon footprint. As global efforts to combat climate change intensify, there is a growing need to address the environmental challenges associated with PMMA manufacturing and usage.

The primary objective of this technical research report is to explore innovative approaches and technologies that can effectively minimize the carbon footprint of PMMA throughout its lifecycle. This encompasses the entire value chain, from raw material extraction and production to end-use applications and recycling or disposal. By identifying and analyzing potential solutions, we aim to provide valuable insights for industry stakeholders to make informed decisions and implement sustainable practices.

To achieve this goal, it is crucial to first understand the current state of PMMA production and its environmental impact. PMMA is primarily derived from petrochemical feedstocks, which contribute significantly to its carbon footprint. The polymerization process and energy-intensive manufacturing techniques further add to the overall emissions. Additionally, the disposal of PMMA products at the end of their lifecycle poses challenges, as traditional recycling methods are often limited or economically unfeasible.

Recent technological advancements and growing environmental awareness have sparked interest in developing more sustainable alternatives and production methods for PMMA. These include the exploration of bio-based feedstocks, improved energy efficiency in manufacturing processes, and the development of advanced recycling technologies. Furthermore, the concept of circular economy principles is gaining traction, emphasizing the importance of designing products for easier recycling and reuse.

This report will delve into the historical context of PMMA production and its environmental impact, tracing the evolution of manufacturing techniques and their associated carbon emissions. We will examine the current industry practices and identify key areas where carbon footprint reduction efforts can be most effective. By analyzing emerging technologies and innovative approaches, we aim to provide a comprehensive overview of potential solutions and their feasibility in real-world applications.

Moreover, this research will consider the broader implications of reducing PMMA's carbon footprint, including potential economic benefits, regulatory compliance, and market competitiveness. As sustainability becomes an increasingly important factor in consumer and industrial decision-making, addressing the environmental impact of PMMA production could provide significant advantages for companies in the plastics industry.

The primary objective of this technical research report is to explore innovative approaches and technologies that can effectively minimize the carbon footprint of PMMA throughout its lifecycle. This encompasses the entire value chain, from raw material extraction and production to end-use applications and recycling or disposal. By identifying and analyzing potential solutions, we aim to provide valuable insights for industry stakeholders to make informed decisions and implement sustainable practices.

To achieve this goal, it is crucial to first understand the current state of PMMA production and its environmental impact. PMMA is primarily derived from petrochemical feedstocks, which contribute significantly to its carbon footprint. The polymerization process and energy-intensive manufacturing techniques further add to the overall emissions. Additionally, the disposal of PMMA products at the end of their lifecycle poses challenges, as traditional recycling methods are often limited or economically unfeasible.

Recent technological advancements and growing environmental awareness have sparked interest in developing more sustainable alternatives and production methods for PMMA. These include the exploration of bio-based feedstocks, improved energy efficiency in manufacturing processes, and the development of advanced recycling technologies. Furthermore, the concept of circular economy principles is gaining traction, emphasizing the importance of designing products for easier recycling and reuse.

This report will delve into the historical context of PMMA production and its environmental impact, tracing the evolution of manufacturing techniques and their associated carbon emissions. We will examine the current industry practices and identify key areas where carbon footprint reduction efforts can be most effective. By analyzing emerging technologies and innovative approaches, we aim to provide a comprehensive overview of potential solutions and their feasibility in real-world applications.

Moreover, this research will consider the broader implications of reducing PMMA's carbon footprint, including potential economic benefits, regulatory compliance, and market competitiveness. As sustainability becomes an increasingly important factor in consumer and industrial decision-making, addressing the environmental impact of PMMA production could provide significant advantages for companies in the plastics industry.

Market Demand for Sustainable PMMA

The demand for sustainable PMMA (Polymethyl Methacrylate) has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on carbon emissions. As industries and consumers become more environmentally conscious, there is a significant shift towards materials with lower carbon footprints. PMMA, also known as acrylic, is widely used in various applications, including automotive, construction, electronics, and medical devices.

The global PMMA market is expected to grow substantially, with sustainability being a key factor influencing this growth. Market research indicates that the demand for eco-friendly PMMA is particularly strong in developed regions such as North America and Europe, where environmental regulations are more stringent. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in sustainable PMMA solutions.

One of the primary drivers for sustainable PMMA demand is the automotive industry. As vehicle manufacturers strive to reduce the overall weight of vehicles to improve fuel efficiency and reduce emissions, lightweight and recyclable materials like PMMA are gaining popularity. The construction sector is another significant contributor to the demand for sustainable PMMA, with architects and builders seeking energy-efficient and durable materials for windows, skylights, and facades.

The electronics industry is also fueling the demand for sustainable PMMA, particularly in the production of LED screens and displays. As consumers become more environmentally conscious, there is a growing preference for electronic devices made with eco-friendly materials. This trend is pushing manufacturers to adopt sustainable PMMA in their production processes.

In the medical field, there is an increasing demand for sustainable PMMA in the production of various medical devices and equipment. Hospitals and healthcare facilities are increasingly prioritizing environmentally friendly materials to reduce their carbon footprint and align with sustainability goals.

The packaging industry is another sector driving the demand for sustainable PMMA. As companies seek to reduce plastic waste and improve recyclability, there is a growing interest in PMMA as an alternative to traditional plastics. Its clarity, durability, and potential for recycling make it an attractive option for sustainable packaging solutions.

Market analysis suggests that consumers are willing to pay a premium for products made with sustainable materials, including PMMA with a lower carbon footprint. This consumer behavior is encouraging manufacturers to invest in research and development of more environmentally friendly PMMA production methods.

The demand for sustainable PMMA is also being influenced by government policies and initiatives aimed at reducing carbon emissions and promoting circular economy principles. Many countries have implemented or are considering regulations that incentivize the use of materials with lower environmental impacts, further driving the market for sustainable PMMA.

The global PMMA market is expected to grow substantially, with sustainability being a key factor influencing this growth. Market research indicates that the demand for eco-friendly PMMA is particularly strong in developed regions such as North America and Europe, where environmental regulations are more stringent. However, emerging economies in Asia-Pacific and Latin America are also showing increased interest in sustainable PMMA solutions.

One of the primary drivers for sustainable PMMA demand is the automotive industry. As vehicle manufacturers strive to reduce the overall weight of vehicles to improve fuel efficiency and reduce emissions, lightweight and recyclable materials like PMMA are gaining popularity. The construction sector is another significant contributor to the demand for sustainable PMMA, with architects and builders seeking energy-efficient and durable materials for windows, skylights, and facades.

The electronics industry is also fueling the demand for sustainable PMMA, particularly in the production of LED screens and displays. As consumers become more environmentally conscious, there is a growing preference for electronic devices made with eco-friendly materials. This trend is pushing manufacturers to adopt sustainable PMMA in their production processes.

In the medical field, there is an increasing demand for sustainable PMMA in the production of various medical devices and equipment. Hospitals and healthcare facilities are increasingly prioritizing environmentally friendly materials to reduce their carbon footprint and align with sustainability goals.

The packaging industry is another sector driving the demand for sustainable PMMA. As companies seek to reduce plastic waste and improve recyclability, there is a growing interest in PMMA as an alternative to traditional plastics. Its clarity, durability, and potential for recycling make it an attractive option for sustainable packaging solutions.

Market analysis suggests that consumers are willing to pay a premium for products made with sustainable materials, including PMMA with a lower carbon footprint. This consumer behavior is encouraging manufacturers to invest in research and development of more environmentally friendly PMMA production methods.

The demand for sustainable PMMA is also being influenced by government policies and initiatives aimed at reducing carbon emissions and promoting circular economy principles. Many countries have implemented or are considering regulations that incentivize the use of materials with lower environmental impacts, further driving the market for sustainable PMMA.

Current PMMA Production Challenges

The production of Poly(methyl methacrylate) (PMMA), commonly known as acrylic or plexiglass, faces several significant challenges in terms of its carbon footprint. The primary issue lies in the energy-intensive nature of the manufacturing process, which relies heavily on fossil fuel-derived raw materials and consumes substantial amounts of electricity.

One of the major challenges is the production of methyl methacrylate (MMA), the key monomer used in PMMA synthesis. The conventional acetone cyanohydrin (ACH) process, which is widely used for MMA production, involves multiple steps and generates significant amounts of byproducts and waste. This process not only contributes to increased carbon emissions but also raises concerns about resource efficiency and environmental impact.

Another challenge is the polymerization process itself, which requires precise temperature control and often involves the use of energy-intensive equipment. The bulk polymerization method, commonly employed for PMMA production, demands careful management of the exothermic reaction to prevent thermal runaway, necessitating sophisticated cooling systems that further increase energy consumption.

The use of petroleum-based raw materials in PMMA production presents an additional hurdle in reducing its carbon footprint. The reliance on non-renewable resources not only contributes to greenhouse gas emissions but also raises concerns about long-term sustainability and supply chain vulnerabilities in the face of fluctuating oil prices and geopolitical tensions.

Furthermore, the purification and processing stages of PMMA production pose challenges in terms of energy efficiency. Techniques such as distillation and extrusion, used to refine the polymer and shape it into various forms, are energy-intensive processes that contribute significantly to the overall carbon footprint of PMMA manufacturing.

The disposal and recycling of PMMA products at the end of their lifecycle present additional environmental challenges. While PMMA is theoretically recyclable, the current infrastructure and technologies for recycling acrylic products are limited, leading to a significant portion of PMMA waste ending up in landfills or being incinerated, further contributing to carbon emissions.

Addressing these challenges requires a multifaceted approach, including the development of more efficient production processes, the exploration of bio-based alternatives for raw materials, and the implementation of advanced recycling technologies. Innovations in catalysis, process intensification, and renewable energy integration are crucial areas of focus for minimizing the carbon footprint of PMMA production.

One of the major challenges is the production of methyl methacrylate (MMA), the key monomer used in PMMA synthesis. The conventional acetone cyanohydrin (ACH) process, which is widely used for MMA production, involves multiple steps and generates significant amounts of byproducts and waste. This process not only contributes to increased carbon emissions but also raises concerns about resource efficiency and environmental impact.

Another challenge is the polymerization process itself, which requires precise temperature control and often involves the use of energy-intensive equipment. The bulk polymerization method, commonly employed for PMMA production, demands careful management of the exothermic reaction to prevent thermal runaway, necessitating sophisticated cooling systems that further increase energy consumption.

The use of petroleum-based raw materials in PMMA production presents an additional hurdle in reducing its carbon footprint. The reliance on non-renewable resources not only contributes to greenhouse gas emissions but also raises concerns about long-term sustainability and supply chain vulnerabilities in the face of fluctuating oil prices and geopolitical tensions.

Furthermore, the purification and processing stages of PMMA production pose challenges in terms of energy efficiency. Techniques such as distillation and extrusion, used to refine the polymer and shape it into various forms, are energy-intensive processes that contribute significantly to the overall carbon footprint of PMMA manufacturing.

The disposal and recycling of PMMA products at the end of their lifecycle present additional environmental challenges. While PMMA is theoretically recyclable, the current infrastructure and technologies for recycling acrylic products are limited, leading to a significant portion of PMMA waste ending up in landfills or being incinerated, further contributing to carbon emissions.

Addressing these challenges requires a multifaceted approach, including the development of more efficient production processes, the exploration of bio-based alternatives for raw materials, and the implementation of advanced recycling technologies. Innovations in catalysis, process intensification, and renewable energy integration are crucial areas of focus for minimizing the carbon footprint of PMMA production.

Existing Carbon Reduction Strategies for PMMA

01 Recycling and reuse of PMMA to reduce carbon footprint

Recycling and reusing PMMA materials can significantly reduce the carbon footprint associated with their production and disposal. This approach involves collecting used PMMA products, processing them, and reintegrating the recycled material into new products. By implementing efficient recycling processes, the overall environmental impact of PMMA can be minimized.- Recycling and reuse of PMMA to reduce carbon footprint: Recycling and reusing PMMA materials can significantly reduce the carbon footprint associated with their production and disposal. This approach involves collecting used PMMA products, processing them, and reintegrating the recycled material into new products. By implementing efficient recycling processes, the overall environmental impact of PMMA can be minimized.

- Improving PMMA production processes for lower emissions: Enhancing the efficiency of PMMA production processes can lead to reduced energy consumption and lower carbon emissions. This includes optimizing polymerization techniques, implementing more energy-efficient equipment, and utilizing cleaner energy sources in manufacturing facilities. These improvements can significantly decrease the carbon footprint associated with PMMA production.

- Developing bio-based alternatives to traditional PMMA: Research into bio-based alternatives to petroleum-derived PMMA can lead to more environmentally friendly options with lower carbon footprints. These alternatives may use renewable resources as raw materials, reducing reliance on fossil fuels and potentially offering biodegradable properties. The development of such materials could significantly reduce the overall environmental impact of PMMA-like products.

- Incorporating fillers and additives to reduce PMMA content: Adding fillers and additives to PMMA can reduce the overall amount of the polymer needed in a product, thereby lowering its carbon footprint. These additives can include natural materials, recycled content, or other low-impact substances that maintain or enhance the desired properties of PMMA while decreasing the environmental impact of the final product.

- Life cycle assessment and carbon footprint analysis of PMMA products: Conducting comprehensive life cycle assessments and carbon footprint analyses for PMMA products can identify areas for improvement in reducing environmental impact. These studies consider all stages of a product's life, from raw material extraction to disposal or recycling. By understanding the carbon footprint at each stage, manufacturers can implement targeted strategies to reduce emissions and improve sustainability throughout the PMMA product lifecycle.

02 Improving PMMA production processes for lower emissions

Enhancing the efficiency of PMMA production processes can lead to reduced carbon emissions. This includes optimizing polymerization techniques, using more energy-efficient equipment, and implementing cleaner technologies in manufacturing. By focusing on process improvements, the carbon footprint associated with PMMA production can be significantly decreased.Expand Specific Solutions03 Developing bio-based alternatives to traditional PMMA

Research into bio-based alternatives to petroleum-derived PMMA can help reduce the overall carbon footprint. These alternatives use renewable resources as raw materials, potentially offering a more sustainable option. By developing and implementing bio-based PMMA or similar materials, the reliance on fossil fuels and associated carbon emissions can be reduced.Expand Specific Solutions04 Carbon capture and utilization in PMMA production

Incorporating carbon capture and utilization technologies in PMMA production processes can help mitigate carbon emissions. This approach involves capturing CO2 emissions from production facilities and either storing them or using them as raw materials in other processes. By implementing these technologies, the net carbon footprint of PMMA production can be reduced.Expand Specific Solutions05 Life cycle assessment and carbon footprint reduction strategies

Conducting comprehensive life cycle assessments of PMMA products can identify areas for carbon footprint reduction. This involves analyzing the environmental impact of PMMA from raw material extraction to end-of-life disposal. By using these assessments, manufacturers can develop targeted strategies to reduce carbon emissions throughout the PMMA life cycle, including improved product design, energy-efficient transportation, and sustainable packaging.Expand Specific Solutions

Key PMMA Manufacturers and Innovators

The competition landscape for minimizing PMMA's carbon footprint is evolving rapidly, reflecting the industry's early stage of development in this area. The market size is growing as sustainability becomes a key focus, though exact figures are not readily available. Technologically, solutions are still emerging, with varying levels of maturity across different approaches. Key players like Arkema, Röhm, and Wanhua Chemical are investing in research and development to improve PMMA's environmental profile. Universities such as Zhejiang University and Fudan University are contributing to fundamental research. Smaller specialized companies like Zhejiang Longyou Zhayu Acrylic and Jiangsu Huasheng New Material Technology are also entering the field with innovative solutions.

Arkema France SA

Technical Solution: Arkema has developed a comprehensive approach to minimize PMMA's carbon footprint. They focus on three main areas: raw material sourcing, production process optimization, and end-of-life solutions. For raw materials, Arkema uses bio-based and recycled feedstocks to reduce reliance on fossil resources. In production, they have implemented energy-efficient technologies and increased the use of renewable energy sources, reducing CO2 emissions by up to 30% [1]. Arkema has also developed a proprietary depolymerization process that allows for the recycling of PMMA, creating a circular economy model. This process can recover up to 90% of PMMA's raw materials, significantly reducing the overall carbon footprint [2].

Strengths: Comprehensive approach covering the entire lifecycle, innovative recycling technology, significant reduction in CO2 emissions. Weaknesses: Potential higher costs associated with bio-based materials and recycling processes, market acceptance of recycled PMMA products.

Röhm GmbH

Technical Solution: Röhm GmbH has implemented a multi-faceted strategy to reduce PMMA's carbon footprint. They have invested in energy-efficient production technologies, including advanced extrusion and polymerization processes that consume up to 40% less energy compared to conventional methods [3]. Röhm has also developed a chemical recycling process for PMMA, which can process post-consumer and industrial waste into high-quality raw materials. This closed-loop system can reduce CO2 emissions by up to 80% compared to virgin PMMA production [4]. Additionally, Röhm is exploring the use of renewable energy sources in their production facilities and has set ambitious targets to reduce their overall carbon emissions by 50% by 2030 [5].

Strengths: Advanced energy-efficient production technologies, established chemical recycling process, clear long-term sustainability goals. Weaknesses: High initial investment costs for new technologies, potential challenges in scaling up recycling operations to meet market demand.

Breakthrough Technologies in PMMA Sustainability

Moulding compositions resistant to stress cracks based on PMMA/SAN-blends

PatentInactiveEP0627461A1

Innovation

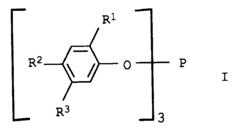

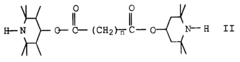

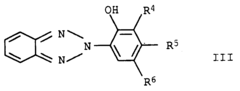

- A molding composition comprising 49-99% of a polymer from C₁-C₂₀ alkyl esters of methacrylic or acrylic acid, 0.95-50% of a vinyl aromatic monomer copolymer with acrylonitrile, and 0.05-1% of a mixture containing triaryl phosphite, amine, and benzotriazole, which are combined to enhance stress cracking resistance and weathering stability.

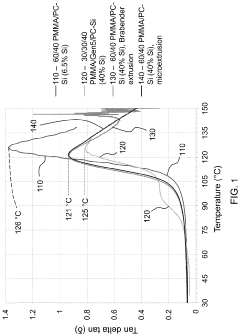

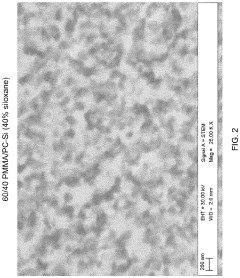

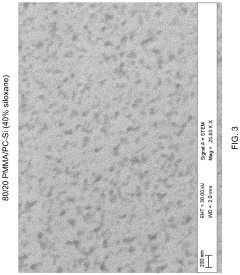

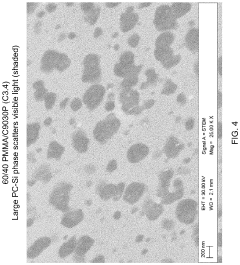

Transparent and flexible blends of PMMA and polycarbonate-siloxane copolymer

PatentActiveUS11760878B2

Innovation

- A thermoplastic composition comprising 30 wt % to 95 wt % PMMA and 5 wt % to 70 wt % of a poly(carbonate-siloxane) copolymer with a siloxane content of 25 wt % to 45 wt %, which can be melt-processed at lower temperatures, resulting in a transparent and flexible blend with a single Tg.

Life Cycle Assessment of PMMA

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of PMMA (Polymethyl Methacrylate) throughout its entire lifecycle. This comprehensive analysis encompasses raw material extraction, production, use, and end-of-life stages, providing valuable insights into the carbon footprint of PMMA.

The production phase of PMMA typically contributes significantly to its overall carbon footprint. This stage involves energy-intensive processes such as polymerization and extrusion. The primary raw material, methyl methacrylate (MMA), is derived from fossil fuels, further increasing the carbon impact. Manufacturers can reduce emissions by optimizing production processes, implementing energy-efficient technologies, and exploring alternative raw material sources.

During the use phase, PMMA's durability and lightweight properties can contribute to reduced environmental impact in certain applications. For instance, when used in automotive components, PMMA's light weight can improve fuel efficiency, potentially offsetting some of the initial production emissions over the vehicle's lifespan.

End-of-life management plays a critical role in PMMA's overall carbon footprint. While PMMA is recyclable, the current recycling rates are relatively low. Improving collection and recycling infrastructure can significantly reduce the carbon impact associated with waste disposal and the need for virgin material production.

Transportation throughout the lifecycle, including raw material delivery, product distribution, and waste collection, also contributes to PMMA's carbon footprint. Optimizing logistics and exploring local production options can help minimize these emissions.

To effectively reduce PMMA's carbon footprint, a holistic approach is necessary. This includes improving energy efficiency in production, increasing the use of renewable energy sources, enhancing recycling rates, and exploring bio-based alternatives for raw materials. Additionally, designing products for longevity and easy disassembly can facilitate better end-of-life management.

Conducting a detailed LCA allows for the identification of hotspots in PMMA's carbon footprint, enabling targeted interventions. It also provides a baseline for measuring improvements and comparing PMMA with alternative materials. By leveraging LCA insights, stakeholders can make informed decisions to minimize the environmental impact of PMMA across its entire lifecycle.

The production phase of PMMA typically contributes significantly to its overall carbon footprint. This stage involves energy-intensive processes such as polymerization and extrusion. The primary raw material, methyl methacrylate (MMA), is derived from fossil fuels, further increasing the carbon impact. Manufacturers can reduce emissions by optimizing production processes, implementing energy-efficient technologies, and exploring alternative raw material sources.

During the use phase, PMMA's durability and lightweight properties can contribute to reduced environmental impact in certain applications. For instance, when used in automotive components, PMMA's light weight can improve fuel efficiency, potentially offsetting some of the initial production emissions over the vehicle's lifespan.

End-of-life management plays a critical role in PMMA's overall carbon footprint. While PMMA is recyclable, the current recycling rates are relatively low. Improving collection and recycling infrastructure can significantly reduce the carbon impact associated with waste disposal and the need for virgin material production.

Transportation throughout the lifecycle, including raw material delivery, product distribution, and waste collection, also contributes to PMMA's carbon footprint. Optimizing logistics and exploring local production options can help minimize these emissions.

To effectively reduce PMMA's carbon footprint, a holistic approach is necessary. This includes improving energy efficiency in production, increasing the use of renewable energy sources, enhancing recycling rates, and exploring bio-based alternatives for raw materials. Additionally, designing products for longevity and easy disassembly can facilitate better end-of-life management.

Conducting a detailed LCA allows for the identification of hotspots in PMMA's carbon footprint, enabling targeted interventions. It also provides a baseline for measuring improvements and comparing PMMA with alternative materials. By leveraging LCA insights, stakeholders can make informed decisions to minimize the environmental impact of PMMA across its entire lifecycle.

Circular Economy Approaches for PMMA

Circular economy approaches for PMMA (polymethyl methacrylate) offer promising solutions to minimize its carbon footprint. These strategies focus on reducing waste, maximizing resource efficiency, and extending the lifecycle of PMMA products.

One key approach is the implementation of closed-loop recycling systems. This involves collecting post-consumer PMMA products and reprocessing them into new materials. Advanced sorting technologies and chemical recycling methods can help maintain the quality of recycled PMMA, ensuring its suitability for high-value applications. By reducing the need for virgin raw materials, this approach significantly decreases energy consumption and carbon emissions associated with PMMA production.

Another circular economy strategy is the design for disassembly and recyclability. This involves creating PMMA products that can be easily taken apart at the end of their life, facilitating more efficient recycling processes. Incorporating modular designs and avoiding composite materials that are difficult to separate can greatly enhance the recyclability of PMMA products.

The development of bio-based PMMA alternatives is also gaining traction. These materials, derived from renewable resources such as sugarcane or corn, have the potential to reduce the carbon footprint of PMMA production. While still in the early stages, research into bio-based PMMA shows promise for creating more sustainable alternatives without compromising performance characteristics.

Extending the lifespan of PMMA products is another crucial aspect of circular economy approaches. This can be achieved through improved durability, repair services, and refurbishment programs. By keeping PMMA products in use for longer periods, the demand for new production is reduced, thereby lowering overall carbon emissions.

The implementation of take-back schemes and product-as-a-service models can also contribute to a more circular economy for PMMA. These approaches incentivize manufacturers to design products for longevity and recyclability, as they retain responsibility for the product throughout its lifecycle. This shift in business models can lead to more efficient use of resources and reduced waste generation.

Collaboration across the value chain is essential for the success of these circular economy approaches. Manufacturers, recyclers, and end-users must work together to establish effective collection and recycling systems, share best practices, and drive innovation in sustainable PMMA production and use.

One key approach is the implementation of closed-loop recycling systems. This involves collecting post-consumer PMMA products and reprocessing them into new materials. Advanced sorting technologies and chemical recycling methods can help maintain the quality of recycled PMMA, ensuring its suitability for high-value applications. By reducing the need for virgin raw materials, this approach significantly decreases energy consumption and carbon emissions associated with PMMA production.

Another circular economy strategy is the design for disassembly and recyclability. This involves creating PMMA products that can be easily taken apart at the end of their life, facilitating more efficient recycling processes. Incorporating modular designs and avoiding composite materials that are difficult to separate can greatly enhance the recyclability of PMMA products.

The development of bio-based PMMA alternatives is also gaining traction. These materials, derived from renewable resources such as sugarcane or corn, have the potential to reduce the carbon footprint of PMMA production. While still in the early stages, research into bio-based PMMA shows promise for creating more sustainable alternatives without compromising performance characteristics.

Extending the lifespan of PMMA products is another crucial aspect of circular economy approaches. This can be achieved through improved durability, repair services, and refurbishment programs. By keeping PMMA products in use for longer periods, the demand for new production is reduced, thereby lowering overall carbon emissions.

The implementation of take-back schemes and product-as-a-service models can also contribute to a more circular economy for PMMA. These approaches incentivize manufacturers to design products for longevity and recyclability, as they retain responsibility for the product throughout its lifecycle. This shift in business models can lead to more efficient use of resources and reduced waste generation.

Collaboration across the value chain is essential for the success of these circular economy approaches. Manufacturers, recyclers, and end-users must work together to establish effective collection and recycling systems, share best practices, and drive innovation in sustainable PMMA production and use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!