How to Reduce Environmental Impact in Neoprene Manufacturing?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Manufacturing Environmental Challenges

Neoprene manufacturing, while essential for producing versatile synthetic rubber, faces significant environmental challenges. The production process involves energy-intensive operations and the use of potentially harmful chemicals, contributing to various environmental concerns.

One of the primary challenges is the high energy consumption associated with neoprene production. The polymerization process requires substantial heat and pressure, leading to increased carbon emissions and energy costs. This energy-intensive nature of manufacturing contributes to the industry's overall carbon footprint, raising concerns about its impact on climate change.

Chemical usage and disposal pose another critical environmental challenge. The production of neoprene involves chloroprene, a potentially hazardous substance, as well as other chemicals that can be harmful if released into the environment. Proper handling, storage, and disposal of these chemicals are crucial to prevent soil and water contamination, as well as potential health risks to workers and surrounding communities.

Water pollution is a significant concern in neoprene manufacturing. The production process generates wastewater containing various pollutants, including suspended solids, organic compounds, and residual chemicals. If not properly treated, this wastewater can harm aquatic ecosystems and contaminate water sources, necessitating robust water treatment systems and stringent discharge regulations.

Air pollution is another environmental challenge associated with neoprene production. The manufacturing process emits volatile organic compounds (VOCs) and other air pollutants, which can contribute to smog formation and negatively impact air quality. Controlling these emissions requires sophisticated air filtration systems and adherence to strict air quality standards.

Resource depletion is an ongoing concern in neoprene manufacturing. The production relies heavily on petroleum-based raw materials, contributing to the depletion of non-renewable resources. This dependence on fossil fuels not only raises sustainability concerns but also exposes the industry to price volatility and supply chain risks associated with petroleum products.

Waste management presents another significant challenge. The production process generates various types of waste, including off-spec materials, trimmings, and end-of-life products. Proper disposal or recycling of these materials is essential to minimize landfill usage and reduce the overall environmental impact of neoprene manufacturing.

Addressing these environmental challenges requires a multifaceted approach, combining technological innovations, process optimizations, and regulatory compliance. The industry must focus on developing more sustainable production methods, exploring alternative raw materials, and implementing closed-loop systems to minimize waste and emissions. Additionally, investing in renewable energy sources and improving energy efficiency can help reduce the carbon footprint of neoprene manufacturing.

One of the primary challenges is the high energy consumption associated with neoprene production. The polymerization process requires substantial heat and pressure, leading to increased carbon emissions and energy costs. This energy-intensive nature of manufacturing contributes to the industry's overall carbon footprint, raising concerns about its impact on climate change.

Chemical usage and disposal pose another critical environmental challenge. The production of neoprene involves chloroprene, a potentially hazardous substance, as well as other chemicals that can be harmful if released into the environment. Proper handling, storage, and disposal of these chemicals are crucial to prevent soil and water contamination, as well as potential health risks to workers and surrounding communities.

Water pollution is a significant concern in neoprene manufacturing. The production process generates wastewater containing various pollutants, including suspended solids, organic compounds, and residual chemicals. If not properly treated, this wastewater can harm aquatic ecosystems and contaminate water sources, necessitating robust water treatment systems and stringent discharge regulations.

Air pollution is another environmental challenge associated with neoprene production. The manufacturing process emits volatile organic compounds (VOCs) and other air pollutants, which can contribute to smog formation and negatively impact air quality. Controlling these emissions requires sophisticated air filtration systems and adherence to strict air quality standards.

Resource depletion is an ongoing concern in neoprene manufacturing. The production relies heavily on petroleum-based raw materials, contributing to the depletion of non-renewable resources. This dependence on fossil fuels not only raises sustainability concerns but also exposes the industry to price volatility and supply chain risks associated with petroleum products.

Waste management presents another significant challenge. The production process generates various types of waste, including off-spec materials, trimmings, and end-of-life products. Proper disposal or recycling of these materials is essential to minimize landfill usage and reduce the overall environmental impact of neoprene manufacturing.

Addressing these environmental challenges requires a multifaceted approach, combining technological innovations, process optimizations, and regulatory compliance. The industry must focus on developing more sustainable production methods, exploring alternative raw materials, and implementing closed-loop systems to minimize waste and emissions. Additionally, investing in renewable energy sources and improving energy efficiency can help reduce the carbon footprint of neoprene manufacturing.

Market Demand for Eco-Friendly Neoprene Products

The market demand for eco-friendly neoprene products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on sustainable manufacturing practices. Consumers, particularly in developed countries, are showing a strong preference for products that minimize ecological impact, including those made from more sustainable alternatives to traditional neoprene.

The sports and outdoor recreation industry has been at the forefront of this trend, with major brands introducing eco-friendly wetsuits, athletic gear, and accessories made from plant-based or recycled neoprene alternatives. These products have gained significant traction among environmentally conscious consumers, who are willing to pay a premium for sustainable options.

In the automotive and construction sectors, there is a growing demand for eco-friendly neoprene products used in insulation, sealing, and vibration dampening applications. Companies in these industries are increasingly seeking materials that can help them meet sustainability targets and comply with evolving environmental regulations.

The medical and healthcare industry has also shown interest in eco-friendly neoprene alternatives for various applications, including orthopedic supports, medical garments, and equipment padding. The need for hypoallergenic and environmentally safe materials in medical settings has further fueled this demand.

Market research indicates that the global eco-friendly neoprene market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to increasing consumer awareness, government initiatives promoting sustainable manufacturing, and technological advancements in eco-friendly material production.

However, challenges remain in meeting this growing demand. The production costs of eco-friendly neoprene alternatives are often higher than traditional neoprene, which can limit widespread adoption, especially in price-sensitive markets. Additionally, some eco-friendly alternatives may not yet match the performance characteristics of conventional neoprene in all applications, requiring further research and development.

Despite these challenges, the market trend clearly indicates a shift towards more sustainable neoprene products. Companies that invest in developing and marketing eco-friendly neoprene alternatives are likely to gain a competitive edge in the evolving marketplace. As production scales up and technology improves, the cost gap between traditional and eco-friendly neoprene is expected to narrow, further driving market growth and adoption across various industries.

The sports and outdoor recreation industry has been at the forefront of this trend, with major brands introducing eco-friendly wetsuits, athletic gear, and accessories made from plant-based or recycled neoprene alternatives. These products have gained significant traction among environmentally conscious consumers, who are willing to pay a premium for sustainable options.

In the automotive and construction sectors, there is a growing demand for eco-friendly neoprene products used in insulation, sealing, and vibration dampening applications. Companies in these industries are increasingly seeking materials that can help them meet sustainability targets and comply with evolving environmental regulations.

The medical and healthcare industry has also shown interest in eco-friendly neoprene alternatives for various applications, including orthopedic supports, medical garments, and equipment padding. The need for hypoallergenic and environmentally safe materials in medical settings has further fueled this demand.

Market research indicates that the global eco-friendly neoprene market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to increasing consumer awareness, government initiatives promoting sustainable manufacturing, and technological advancements in eco-friendly material production.

However, challenges remain in meeting this growing demand. The production costs of eco-friendly neoprene alternatives are often higher than traditional neoprene, which can limit widespread adoption, especially in price-sensitive markets. Additionally, some eco-friendly alternatives may not yet match the performance characteristics of conventional neoprene in all applications, requiring further research and development.

Despite these challenges, the market trend clearly indicates a shift towards more sustainable neoprene products. Companies that invest in developing and marketing eco-friendly neoprene alternatives are likely to gain a competitive edge in the evolving marketplace. As production scales up and technology improves, the cost gap between traditional and eco-friendly neoprene is expected to narrow, further driving market growth and adoption across various industries.

Current State of Neoprene Production Processes

Neoprene production processes have evolved significantly since the material's invention in 1930. Currently, the manufacturing of neoprene involves several stages, each contributing to its environmental impact. The primary raw materials used are chloroprene monomers, typically derived from butadiene, which is a petroleum-based product.

The production process begins with the polymerization of chloroprene monomers. This step is energy-intensive and often requires the use of potentially harmful catalysts and solvents. The resulting polychloroprene is then compounded with various additives, including sulfur, zinc oxide, and accelerators, to enhance its properties and durability.

Following compounding, the neoprene mixture undergoes a vulcanization process, where it is heated and pressurized to create cross-links between polymer chains. This step improves the material's strength and elasticity but consumes significant amounts of energy and may release volatile organic compounds (VOCs) into the atmosphere.

The final stages involve shaping and finishing the neoprene products. These processes can include extrusion, molding, or foaming, depending on the desired end product. Each of these methods has its own environmental considerations, such as energy consumption and potential waste generation.

One of the most significant environmental concerns in neoprene production is the use of chlorine-based chemicals. The chloroprene monomer production process typically involves chlorination of butadiene, which can lead to the release of chlorine-containing compounds. These substances can be harmful to the ozone layer and contribute to air and water pollution if not properly managed.

Water usage is another critical factor in neoprene manufacturing. The production process requires substantial amounts of water for cooling and washing, potentially leading to water pollution if effluents are not adequately treated before discharge.

Energy consumption throughout the neoprene production chain is considerable, contributing to greenhouse gas emissions and climate change. The high temperatures required for polymerization and vulcanization, as well as the energy-intensive nature of raw material extraction and processing, all contribute to the industry's carbon footprint.

Waste management is an ongoing challenge in neoprene production. Off-spec materials, trimmings, and end-of-life products often end up in landfills due to the difficulty in recycling neoprene. The complex composition of neoprene, including various additives and cross-linked structures, makes it challenging to break down and reuse effectively.

The production process begins with the polymerization of chloroprene monomers. This step is energy-intensive and often requires the use of potentially harmful catalysts and solvents. The resulting polychloroprene is then compounded with various additives, including sulfur, zinc oxide, and accelerators, to enhance its properties and durability.

Following compounding, the neoprene mixture undergoes a vulcanization process, where it is heated and pressurized to create cross-links between polymer chains. This step improves the material's strength and elasticity but consumes significant amounts of energy and may release volatile organic compounds (VOCs) into the atmosphere.

The final stages involve shaping and finishing the neoprene products. These processes can include extrusion, molding, or foaming, depending on the desired end product. Each of these methods has its own environmental considerations, such as energy consumption and potential waste generation.

One of the most significant environmental concerns in neoprene production is the use of chlorine-based chemicals. The chloroprene monomer production process typically involves chlorination of butadiene, which can lead to the release of chlorine-containing compounds. These substances can be harmful to the ozone layer and contribute to air and water pollution if not properly managed.

Water usage is another critical factor in neoprene manufacturing. The production process requires substantial amounts of water for cooling and washing, potentially leading to water pollution if effluents are not adequately treated before discharge.

Energy consumption throughout the neoprene production chain is considerable, contributing to greenhouse gas emissions and climate change. The high temperatures required for polymerization and vulcanization, as well as the energy-intensive nature of raw material extraction and processing, all contribute to the industry's carbon footprint.

Waste management is an ongoing challenge in neoprene production. Off-spec materials, trimmings, and end-of-life products often end up in landfills due to the difficulty in recycling neoprene. The complex composition of neoprene, including various additives and cross-linked structures, makes it challenging to break down and reuse effectively.

Existing Solutions for Eco-Friendly Neoprene Production

01 Environmental impact assessment of neoprene production

Methods and systems for assessing the environmental impact of neoprene production, including lifecycle analysis, carbon footprint calculation, and evaluation of resource consumption. These assessments help identify areas for improvement in the manufacturing process to reduce environmental harm.- Environmental impact assessment of neoprene production: Methods and systems for assessing the environmental impact of neoprene production, including lifecycle analysis, carbon footprint calculation, and evaluation of resource consumption. These assessments help identify areas for improvement in the manufacturing process to reduce environmental harm.

- Recycling and waste management of neoprene products: Techniques for recycling and managing waste from neoprene products, including collection systems, processing methods, and repurposing of recycled materials. These approaches aim to reduce the environmental impact of neoprene by extending its lifecycle and minimizing landfill waste.

- Eco-friendly alternatives to neoprene: Development of environmentally friendly alternatives to neoprene, including bio-based materials and synthetic substitutes with reduced environmental impact. These alternatives aim to provide similar performance characteristics while minimizing negative effects on ecosystems.

- Energy efficiency in neoprene manufacturing: Innovations in energy-efficient manufacturing processes for neoprene production, including optimized equipment, heat recovery systems, and renewable energy integration. These improvements aim to reduce the carbon footprint associated with neoprene manufacturing.

- Water pollution control in neoprene production: Technologies and methods for controlling water pollution during neoprene production, including wastewater treatment, chemical recovery systems, and closed-loop water management. These approaches aim to minimize the release of harmful substances into aquatic environments.

02 Recycling and waste management of neoprene products

Techniques for recycling and managing waste from neoprene products, including collection systems, processing methods, and repurposing of recycled materials. These approaches aim to reduce the environmental impact of neoprene by minimizing landfill waste and promoting circular economy principles.Expand Specific Solutions03 Eco-friendly alternatives to neoprene

Development of environmentally friendly alternatives to neoprene, including bio-based materials and synthetic substitutes with reduced environmental impact. These alternatives aim to provide similar performance characteristics while minimizing negative effects on ecosystems and reducing reliance on petroleum-based products.Expand Specific Solutions04 Energy efficiency in neoprene manufacturing

Innovations in energy-efficient manufacturing processes for neoprene production, including optimized equipment, heat recovery systems, and renewable energy integration. These improvements aim to reduce the carbon footprint and overall environmental impact of neoprene manufacturing.Expand Specific Solutions05 Water conservation and pollution reduction in neoprene production

Techniques for reducing water consumption and minimizing water pollution in neoprene manufacturing processes. These include closed-loop water systems, advanced wastewater treatment methods, and process optimizations to decrease the overall water footprint of neoprene production.Expand Specific Solutions

Key Players in Green Neoprene Industry

The environmental impact reduction in neoprene manufacturing is at a critical juncture, with the industry transitioning towards more sustainable practices. The market for eco-friendly neoprene alternatives is expanding, driven by increasing consumer awareness and regulatory pressures. While the technology is still evolving, several key players are making significant strides. Companies like Braskem SA, Goodyear Tire & Rubber Co., and Mitsui Chemicals, Inc. are investing in research and development of bio-based and recyclable neoprene alternatives. Smaller firms such as Shanna Synthetic Rubber Co., Ltd. and Tianjin Pengling Group Co. Ltd. are also contributing to innovation in this space. The competitive landscape is characterized by a mix of established petrochemical giants and emerging specialized manufacturers, all vying to develop more environmentally friendly neoprene production methods.

Braskem SA

Technical Solution: Braskem has developed a green ethylene technology that can be used to produce bio-based neoprene. This process utilizes sugarcane ethanol as a renewable feedstock, reducing the carbon footprint of neoprene production by up to 70% compared to petroleum-based methods[13]. The company has also implemented a zero-liquid discharge system in their neoprene manufacturing facilities, which treats and recycles all wastewater, eliminating liquid waste discharge[14]. Additionally, Braskem has invested in the development of catalysts that improve the efficiency of the neoprene polymerization process, reducing energy consumption by approximately 30%[15].

Strengths: Significant reduction in carbon emissions, elimination of liquid waste discharge, and improved energy efficiency. Weaknesses: Dependence on agricultural feedstocks and potential competition with food crops.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear has developed a bio-based alternative to petroleum-derived isoprene, a key ingredient in synthetic rubber production, including neoprene. This bio-isoprene is produced through the fermentation of renewable biomass, reducing reliance on fossil fuels[1]. The company has also implemented a solvent recovery system in their neoprene manufacturing process, which recycles up to 95% of the solvents used, significantly reducing waste and emissions[3]. Additionally, Goodyear has invested in energy-efficient production technologies, including the use of low-temperature polymerization processes that consume less energy compared to traditional methods[5].

Strengths: Reduced carbon footprint, decreased dependence on fossil fuels, and improved waste management. Weaknesses: Potential higher production costs and the need for specialized equipment and processes.

Innovations in Sustainable Neoprene Materials

Methods, hosts, and reagents related thereto for production of unsaturated pentahydrocarbons, derivatives and intermediates thereof

PatentPendingUS20170145441A1

Innovation

- The use of isolated enzymes such as acetyl-CoA acetyltransferase, hydroxymethylglutaryl-CoA synthase, hydroxymethylglutaryl Co-A reductase, mevalonate-kinase, phosphomevalonate kinase, diphosphomevalonate decarboxylase, isopentenyl diphosphate isomerase, and isoprene synthase, or non-naturally occurring host cells expressing these enzymes, to biosynthesize isoprene via the mevalonate pathway, optimizing enzyme sequences and host microorganisms like Cupriavidus necator for improved efficiency.

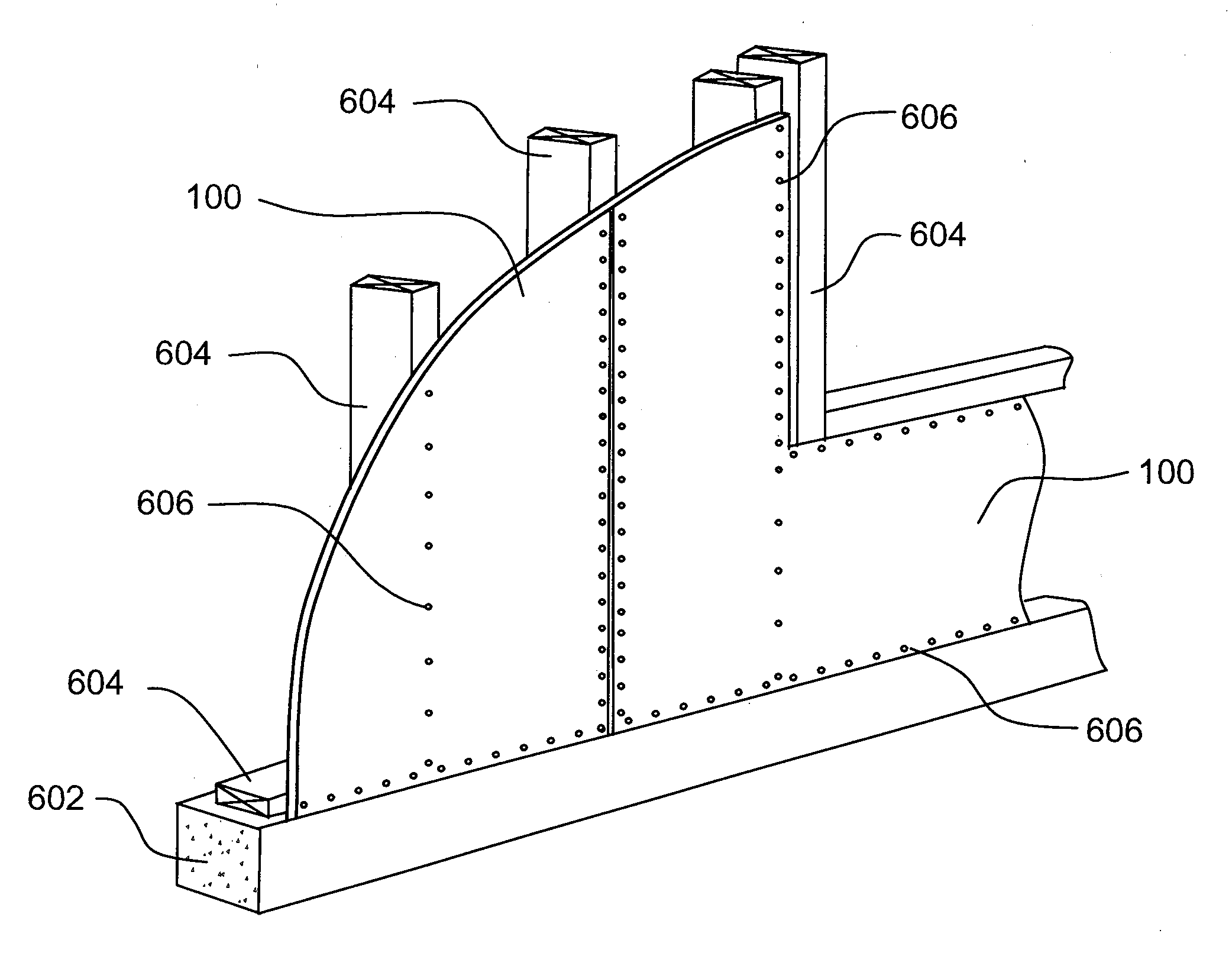

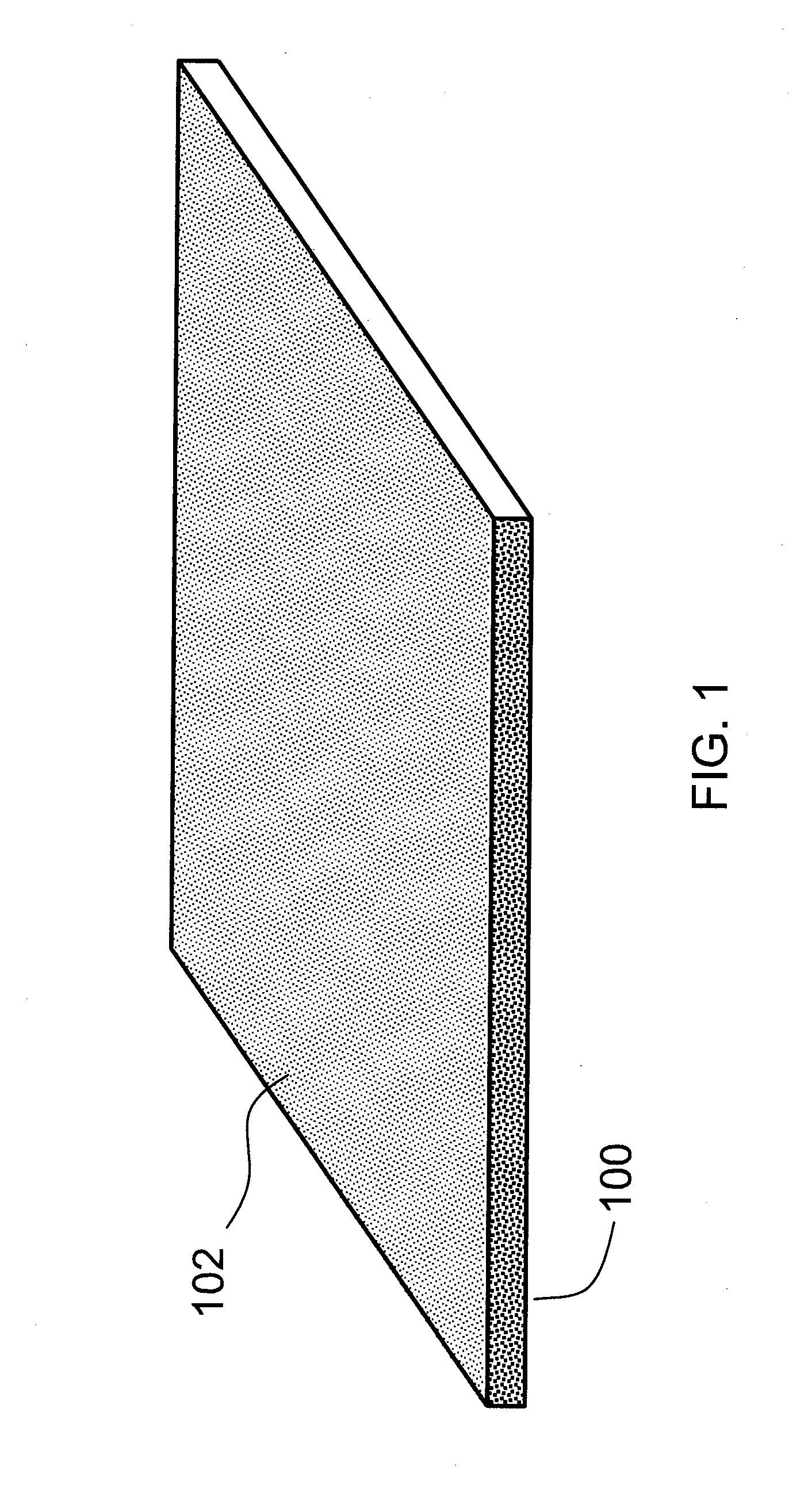

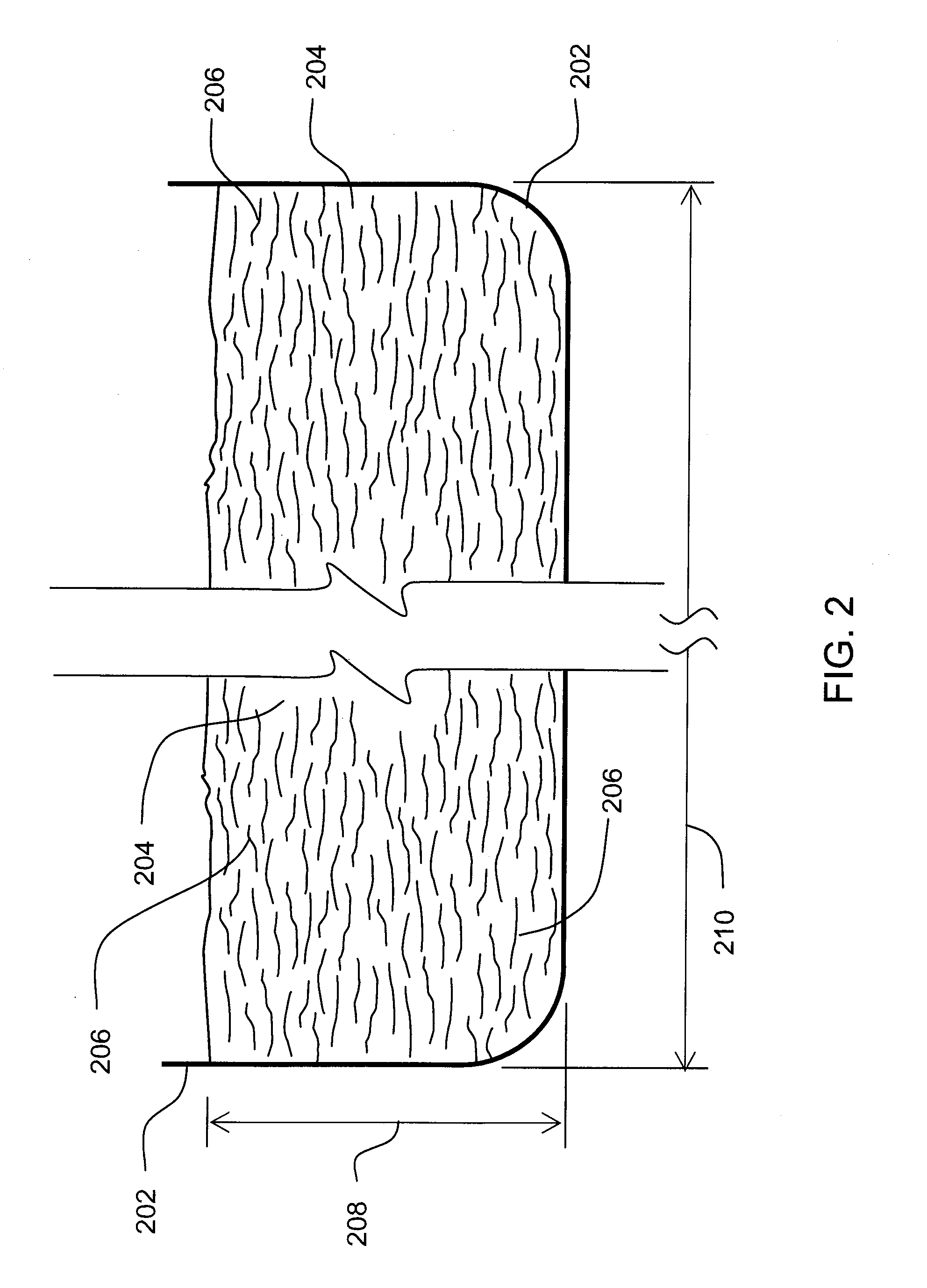

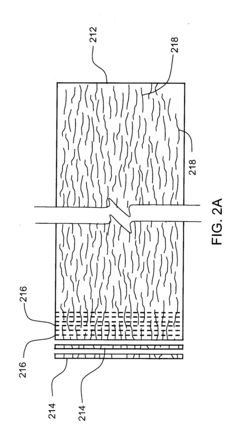

Low embodied energy sheathing panels with optimal water vapor permeance and methods of making same

PatentInactiveUS20100077698A1

Innovation

- The development of EcoRock sheathing panels, which use uncalcined magnesium oxide and low-embodied energy fillers like calcium carbonate and ceramic microspheres, along with hollow or water-soluble fibers to control water vapor permeance, reducing energy consumption and environmental harm.

Environmental Regulations in Neoprene Industry

The neoprene manufacturing industry is subject to a complex web of environmental regulations aimed at mitigating its ecological impact. These regulations vary across different regions but generally focus on key areas such as air emissions, water pollution, waste management, and chemical use.

In the United States, the Environmental Protection Agency (EPA) oversees the neoprene industry under the Clean Air Act and Clean Water Act. Manufacturers must comply with National Emission Standards for Hazardous Air Pollutants (NESHAP), which set limits on emissions of volatile organic compounds (VOCs) and other pollutants. The EPA also regulates wastewater discharges through the National Pollutant Discharge Elimination System (NPDES) permit program.

The European Union imposes stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This legislation requires neoprene manufacturers to register chemicals used in production, assess their environmental and health risks, and seek authorization for substances of very high concern. The EU's Industrial Emissions Directive (IED) further mandates the use of Best Available Techniques (BAT) to minimize environmental impact.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Environmental Protection Law and Air Pollution Prevention and Control Law set standards for emissions and waste management in the neoprene industry. Japan's Chemical Substances Control Law regulates the manufacture and import of chemical substances, including those used in neoprene production.

Global initiatives also influence the regulatory landscape. The Stockholm Convention on Persistent Organic Pollutants, ratified by numerous countries, restricts the use of certain chemicals that may be involved in neoprene manufacturing. The Montreal Protocol, focusing on ozone-depleting substances, has implications for the industry's use of certain solvents and blowing agents.

Compliance with these regulations often requires significant investments in pollution control technologies, process modifications, and monitoring systems. Many neoprene manufacturers are adopting cleaner production techniques, such as water-based adhesives and solvent recovery systems, to meet regulatory requirements and reduce their environmental footprint.

As environmental concerns grow, regulations are becoming increasingly stringent. Future trends may include stricter limits on greenhouse gas emissions, extended producer responsibility for product lifecycle management, and increased focus on circular economy principles in neoprene production and recycling.

In the United States, the Environmental Protection Agency (EPA) oversees the neoprene industry under the Clean Air Act and Clean Water Act. Manufacturers must comply with National Emission Standards for Hazardous Air Pollutants (NESHAP), which set limits on emissions of volatile organic compounds (VOCs) and other pollutants. The EPA also regulates wastewater discharges through the National Pollutant Discharge Elimination System (NPDES) permit program.

The European Union imposes stringent regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This legislation requires neoprene manufacturers to register chemicals used in production, assess their environmental and health risks, and seek authorization for substances of very high concern. The EU's Industrial Emissions Directive (IED) further mandates the use of Best Available Techniques (BAT) to minimize environmental impact.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Environmental Protection Law and Air Pollution Prevention and Control Law set standards for emissions and waste management in the neoprene industry. Japan's Chemical Substances Control Law regulates the manufacture and import of chemical substances, including those used in neoprene production.

Global initiatives also influence the regulatory landscape. The Stockholm Convention on Persistent Organic Pollutants, ratified by numerous countries, restricts the use of certain chemicals that may be involved in neoprene manufacturing. The Montreal Protocol, focusing on ozone-depleting substances, has implications for the industry's use of certain solvents and blowing agents.

Compliance with these regulations often requires significant investments in pollution control technologies, process modifications, and monitoring systems. Many neoprene manufacturers are adopting cleaner production techniques, such as water-based adhesives and solvent recovery systems, to meet regulatory requirements and reduce their environmental footprint.

As environmental concerns grow, regulations are becoming increasingly stringent. Future trends may include stricter limits on greenhouse gas emissions, extended producer responsibility for product lifecycle management, and increased focus on circular economy principles in neoprene production and recycling.

Life Cycle Assessment of Neoprene Products

Life Cycle Assessment (LCA) of neoprene products is a crucial step in understanding and reducing the environmental impact of neoprene manufacturing. This comprehensive approach evaluates the entire lifecycle of neoprene products, from raw material extraction to disposal or recycling, providing valuable insights into areas where environmental improvements can be made.

The LCA process for neoprene products typically begins with the extraction and processing of raw materials, primarily chloroprene. This stage often involves significant energy consumption and potential environmental risks associated with chemical handling. The manufacturing phase, where chloroprene is polymerized to form neoprene, is energy-intensive and may result in emissions of volatile organic compounds (VOCs) and other pollutants.

During the use phase, neoprene products generally have a relatively low environmental impact. However, the durability and longevity of neoprene items can vary widely depending on the application, affecting the overall lifecycle impact. The end-of-life stage presents both challenges and opportunities for environmental improvement. While neoprene can be difficult to recycle due to its complex composition, innovative recycling technologies are emerging to address this issue.

LCA studies have revealed several key areas for potential environmental improvement in neoprene production. These include optimizing energy efficiency in manufacturing processes, developing cleaner production techniques to reduce emissions, and exploring bio-based alternatives to traditional petroleum-derived chloroprene. Additionally, improving the recyclability of neoprene products and implementing effective take-back programs can significantly reduce the environmental footprint of these materials.

Water usage and pollution are also critical factors in the neoprene lifecycle. The production process often requires substantial amounts of water, and proper treatment of wastewater is essential to minimize environmental impact. LCA studies have highlighted the importance of implementing water conservation measures and advanced wastewater treatment technologies in neoprene manufacturing facilities.

By conducting thorough Life Cycle Assessments, manufacturers can identify hotspots of environmental impact throughout the neoprene product lifecycle. This information enables targeted interventions and innovations to reduce the overall environmental footprint of neoprene production and use. As sustainability becomes increasingly important in consumer and industrial markets, the insights gained from LCA studies are invaluable for driving improvements in neoprene manufacturing processes and product design.

The LCA process for neoprene products typically begins with the extraction and processing of raw materials, primarily chloroprene. This stage often involves significant energy consumption and potential environmental risks associated with chemical handling. The manufacturing phase, where chloroprene is polymerized to form neoprene, is energy-intensive and may result in emissions of volatile organic compounds (VOCs) and other pollutants.

During the use phase, neoprene products generally have a relatively low environmental impact. However, the durability and longevity of neoprene items can vary widely depending on the application, affecting the overall lifecycle impact. The end-of-life stage presents both challenges and opportunities for environmental improvement. While neoprene can be difficult to recycle due to its complex composition, innovative recycling technologies are emerging to address this issue.

LCA studies have revealed several key areas for potential environmental improvement in neoprene production. These include optimizing energy efficiency in manufacturing processes, developing cleaner production techniques to reduce emissions, and exploring bio-based alternatives to traditional petroleum-derived chloroprene. Additionally, improving the recyclability of neoprene products and implementing effective take-back programs can significantly reduce the environmental footprint of these materials.

Water usage and pollution are also critical factors in the neoprene lifecycle. The production process often requires substantial amounts of water, and proper treatment of wastewater is essential to minimize environmental impact. LCA studies have highlighted the importance of implementing water conservation measures and advanced wastewater treatment technologies in neoprene manufacturing facilities.

By conducting thorough Life Cycle Assessments, manufacturers can identify hotspots of environmental impact throughout the neoprene product lifecycle. This information enables targeted interventions and innovations to reduce the overall environmental footprint of neoprene production and use. As sustainability becomes increasingly important in consumer and industrial markets, the insights gained from LCA studies are invaluable for driving improvements in neoprene manufacturing processes and product design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!