How to Strengthen Heat Resistance in Neoprene Materials?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Heat Resistance Background and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has been widely used in various industries due to its unique properties. The material's heat resistance has been a critical focus since its inception, as it directly impacts its performance and longevity in high-temperature applications. Over the years, researchers and manufacturers have continuously sought ways to enhance neoprene's heat resistance to expand its utility and meet evolving industrial demands.

The evolution of neoprene's heat resistance capabilities has been marked by significant milestones. Initially, the material could withstand temperatures up to 100°C (212°F), which was already impressive for a synthetic rubber. However, as industries such as automotive, aerospace, and oil & gas pushed the boundaries of material requirements, the need for improved heat resistance became apparent. This led to extensive research and development efforts focused on modifying neoprene's chemical structure and exploring various additives to enhance its thermal stability.

Current technological trends in neoprene heat resistance improvement revolve around several key areas. These include the development of new cross-linking agents, the incorporation of heat-stabilizing additives, and the exploration of nanocomposite materials. Each of these approaches aims to address the fundamental mechanisms of heat degradation in neoprene, such as chain scission, oxidation, and dehydrochlorination.

The primary objective in strengthening heat resistance in neoprene materials is to extend the material's operational temperature range while maintaining its other desirable properties. Specifically, researchers aim to develop neoprene formulations that can withstand continuous exposure to temperatures exceeding 150°C (302°F) without significant degradation of mechanical properties or chemical stability. This would open up new applications in high-temperature environments and improve the material's performance in existing uses.

Additionally, there is a growing emphasis on developing environmentally friendly methods to enhance neoprene's heat resistance. This aligns with the broader industry trend towards sustainability and reduced environmental impact. Researchers are exploring bio-based additives and green chemistry approaches to achieve improved heat resistance without relying on potentially harmful chemicals.

As we look to the future, the goal is not only to push the limits of neoprene's heat resistance but also to do so in a way that is cost-effective and scalable for industrial production. This requires a delicate balance between performance enhancement and economic viability, driving innovation in both material science and manufacturing processes.

The evolution of neoprene's heat resistance capabilities has been marked by significant milestones. Initially, the material could withstand temperatures up to 100°C (212°F), which was already impressive for a synthetic rubber. However, as industries such as automotive, aerospace, and oil & gas pushed the boundaries of material requirements, the need for improved heat resistance became apparent. This led to extensive research and development efforts focused on modifying neoprene's chemical structure and exploring various additives to enhance its thermal stability.

Current technological trends in neoprene heat resistance improvement revolve around several key areas. These include the development of new cross-linking agents, the incorporation of heat-stabilizing additives, and the exploration of nanocomposite materials. Each of these approaches aims to address the fundamental mechanisms of heat degradation in neoprene, such as chain scission, oxidation, and dehydrochlorination.

The primary objective in strengthening heat resistance in neoprene materials is to extend the material's operational temperature range while maintaining its other desirable properties. Specifically, researchers aim to develop neoprene formulations that can withstand continuous exposure to temperatures exceeding 150°C (302°F) without significant degradation of mechanical properties or chemical stability. This would open up new applications in high-temperature environments and improve the material's performance in existing uses.

Additionally, there is a growing emphasis on developing environmentally friendly methods to enhance neoprene's heat resistance. This aligns with the broader industry trend towards sustainability and reduced environmental impact. Researchers are exploring bio-based additives and green chemistry approaches to achieve improved heat resistance without relying on potentially harmful chemicals.

As we look to the future, the goal is not only to push the limits of neoprene's heat resistance but also to do so in a way that is cost-effective and scalable for industrial production. This requires a delicate balance between performance enhancement and economic viability, driving innovation in both material science and manufacturing processes.

Market Analysis for Heat-Resistant Neoprene

The market for heat-resistant neoprene materials has been experiencing significant growth in recent years, driven by increasing demand across various industries. The global neoprene market size was valued at USD 1.9 billion in 2020 and is projected to reach USD 2.5 billion by 2027, with a compound annual growth rate (CAGR) of 4.2% during the forecast period.

The automotive sector represents a major consumer of heat-resistant neoprene, particularly in applications such as hoses, belts, and gaskets. The growing automotive industry, especially in emerging economies, is expected to fuel the demand for heat-resistant neoprene materials. Additionally, the construction industry's expansion is contributing to market growth, with neoprene being used in roofing membranes, sealants, and insulation materials.

The aerospace and defense sectors are also key drivers of the heat-resistant neoprene market. These industries require materials that can withstand extreme temperatures and harsh environments, making neoprene an ideal choice for various components and protective gear. The increasing focus on lightweight materials in aerospace applications further boosts the demand for advanced neoprene formulations.

In the industrial sector, heat-resistant neoprene finds applications in conveyor belts, protective clothing, and electrical insulation. The growing emphasis on worker safety and stringent regulations regarding personal protective equipment (PPE) are driving the adoption of heat-resistant neoprene in industrial settings.

Geographically, North America and Europe are the leading markets for heat-resistant neoprene, owing to their well-established automotive, aerospace, and industrial sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India.

The market for heat-resistant neoprene is characterized by intense competition among key players, including DuPont, Lanxess, Tosoh Corporation, and Shanxi Synthetic Rubber Group Co., Ltd. These companies are focusing on research and development to enhance the heat resistance properties of neoprene and expand their product portfolios to cater to diverse industry needs.

Challenges in the market include fluctuating raw material prices and growing environmental concerns regarding the production and disposal of neoprene. However, ongoing efforts to develop eco-friendly alternatives and improve recycling processes are expected to address these issues and create new opportunities in the heat-resistant neoprene market.

The automotive sector represents a major consumer of heat-resistant neoprene, particularly in applications such as hoses, belts, and gaskets. The growing automotive industry, especially in emerging economies, is expected to fuel the demand for heat-resistant neoprene materials. Additionally, the construction industry's expansion is contributing to market growth, with neoprene being used in roofing membranes, sealants, and insulation materials.

The aerospace and defense sectors are also key drivers of the heat-resistant neoprene market. These industries require materials that can withstand extreme temperatures and harsh environments, making neoprene an ideal choice for various components and protective gear. The increasing focus on lightweight materials in aerospace applications further boosts the demand for advanced neoprene formulations.

In the industrial sector, heat-resistant neoprene finds applications in conveyor belts, protective clothing, and electrical insulation. The growing emphasis on worker safety and stringent regulations regarding personal protective equipment (PPE) are driving the adoption of heat-resistant neoprene in industrial settings.

Geographically, North America and Europe are the leading markets for heat-resistant neoprene, owing to their well-established automotive, aerospace, and industrial sectors. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India.

The market for heat-resistant neoprene is characterized by intense competition among key players, including DuPont, Lanxess, Tosoh Corporation, and Shanxi Synthetic Rubber Group Co., Ltd. These companies are focusing on research and development to enhance the heat resistance properties of neoprene and expand their product portfolios to cater to diverse industry needs.

Challenges in the market include fluctuating raw material prices and growing environmental concerns regarding the production and disposal of neoprene. However, ongoing efforts to develop eco-friendly alternatives and improve recycling processes are expected to address these issues and create new opportunities in the heat-resistant neoprene market.

Current Challenges in Neoprene Heat Resistance

Neoprene, a versatile synthetic rubber, faces significant challenges in maintaining its structural integrity and performance under high-temperature conditions. The primary obstacle lies in its inherent thermal degradation, which occurs when exposed to temperatures exceeding 100°C for extended periods. This degradation manifests as a breakdown of the polymer chains, leading to a loss of mechanical properties and potential failure of the material.

One of the key challenges is the trade-off between heat resistance and other desirable properties of neoprene. Attempts to enhance thermal stability often result in compromised flexibility, elasticity, or chemical resistance, which are crucial attributes for many neoprene applications. This balancing act requires innovative approaches to material engineering and formulation.

The current manufacturing processes also present limitations in achieving uniform heat resistance throughout the material. Inconsistencies in cross-linking density and the distribution of heat-stabilizing additives can create weak points that are more susceptible to thermal damage. Overcoming these processing challenges is essential for producing neoprene with consistent and reliable heat-resistant properties.

Another significant hurdle is the development of effective heat-stabilizing additives that are compatible with neoprene's chemical structure. While various additives have shown promise in laboratory settings, their long-term effectiveness and potential impact on other material properties remain areas of ongoing research and development.

The environmental impact of heat-resistant neoprene formulations is an emerging concern. Many traditional heat stabilizers contain heavy metals or other environmentally harmful substances. Finding eco-friendly alternatives that provide comparable heat resistance without compromising sustainability goals is a pressing challenge for the industry.

Cost considerations also play a crucial role in the development of heat-resistant neoprene. Advanced formulations and manufacturing processes often lead to increased production costs, which can limit the commercial viability of improved materials. Striking a balance between enhanced heat resistance and economic feasibility is a persistent challenge for manufacturers and researchers alike.

Lastly, the diverse range of applications for neoprene, each with its specific heat resistance requirements, complicates the development of universally applicable solutions. Tailoring heat resistance properties to meet the needs of various industries, from automotive to aerospace, while maintaining neoprene's versatility, remains a complex challenge that requires ongoing research and innovation in material science and engineering.

One of the key challenges is the trade-off between heat resistance and other desirable properties of neoprene. Attempts to enhance thermal stability often result in compromised flexibility, elasticity, or chemical resistance, which are crucial attributes for many neoprene applications. This balancing act requires innovative approaches to material engineering and formulation.

The current manufacturing processes also present limitations in achieving uniform heat resistance throughout the material. Inconsistencies in cross-linking density and the distribution of heat-stabilizing additives can create weak points that are more susceptible to thermal damage. Overcoming these processing challenges is essential for producing neoprene with consistent and reliable heat-resistant properties.

Another significant hurdle is the development of effective heat-stabilizing additives that are compatible with neoprene's chemical structure. While various additives have shown promise in laboratory settings, their long-term effectiveness and potential impact on other material properties remain areas of ongoing research and development.

The environmental impact of heat-resistant neoprene formulations is an emerging concern. Many traditional heat stabilizers contain heavy metals or other environmentally harmful substances. Finding eco-friendly alternatives that provide comparable heat resistance without compromising sustainability goals is a pressing challenge for the industry.

Cost considerations also play a crucial role in the development of heat-resistant neoprene. Advanced formulations and manufacturing processes often lead to increased production costs, which can limit the commercial viability of improved materials. Striking a balance between enhanced heat resistance and economic feasibility is a persistent challenge for manufacturers and researchers alike.

Lastly, the diverse range of applications for neoprene, each with its specific heat resistance requirements, complicates the development of universally applicable solutions. Tailoring heat resistance properties to meet the needs of various industries, from automotive to aerospace, while maintaining neoprene's versatility, remains a complex challenge that requires ongoing research and innovation in material science and engineering.

Existing Heat Resistance Enhancement Techniques

01 Heat-resistant neoprene compositions

Improved neoprene compositions with enhanced heat resistance are developed by incorporating specific additives or modifying the polymer structure. These compositions can withstand higher temperatures while maintaining their mechanical properties, making them suitable for various high-temperature applications.- Heat-resistant neoprene compositions: Improved neoprene compositions with enhanced heat resistance can be achieved through the incorporation of specific additives or by modifying the polymer structure. These compositions often include heat stabilizers, antioxidants, or cross-linking agents to maintain the material's properties at elevated temperatures. The resulting neoprene materials exhibit better thermal stability and can withstand higher operating temperatures without significant degradation.

- Neoprene blends for improved heat resistance: Blending neoprene with other heat-resistant polymers or elastomers can significantly enhance its thermal properties. These blends often combine the flexibility and chemical resistance of neoprene with the heat resistance of other materials. The resulting composites offer improved performance in high-temperature applications while maintaining desirable neoprene characteristics.

- Surface treatments for heat-resistant neoprene: Various surface treatment techniques can be applied to neoprene materials to enhance their heat resistance. These treatments may include chemical modifications, coatings, or the application of heat-resistant layers. Such processes can create a protective barrier that improves the material's ability to withstand high temperatures and thermal cycling.

- Neoprene foams with improved thermal insulation: Specialized neoprene foam formulations can be developed to provide enhanced thermal insulation properties. These foams often incorporate closed-cell structures or additional insulating materials to improve heat resistance. The resulting products offer better thermal management in applications where both flexibility and heat resistance are required.

- Manufacturing processes for heat-resistant neoprene: Advanced manufacturing techniques can be employed to produce neoprene materials with improved heat resistance. These processes may involve specialized curing methods, controlled cooling, or the incorporation of reinforcing materials during production. By optimizing the manufacturing process, the resulting neoprene products can exhibit enhanced thermal stability and durability in high-temperature environments.

02 Neoprene blends for thermal stability

Blending neoprene with other heat-resistant polymers or materials can significantly improve its thermal stability. These blends combine the desirable properties of neoprene with the heat resistance of other materials, resulting in composites suitable for high-temperature environments.Expand Specific Solutions03 Surface treatments for heat-resistant neoprene

Various surface treatment techniques are employed to enhance the heat resistance of neoprene materials. These treatments can include chemical modifications, coatings, or physical alterations to the surface, which improve the material's ability to withstand high temperatures.Expand Specific Solutions04 Neoprene foams with improved heat resistance

Specialized formulations and manufacturing processes are developed to create neoprene foams with enhanced heat resistance. These foams maintain their insulating properties and structural integrity at elevated temperatures, making them suitable for thermal protection applications.Expand Specific Solutions05 Heat-resistant neoprene for protective gear

Neoprene materials with improved heat resistance are specifically designed for use in protective gear and clothing. These materials offer both thermal protection and flexibility, making them ideal for applications in firefighting, industrial safety, and other high-temperature environments.Expand Specific Solutions

Key Players in Advanced Neoprene Manufacturing

The heat resistance enhancement in neoprene materials is currently in a growth phase, with increasing market demand driven by various industries. The global market size for heat-resistant neoprene is expanding, fueled by applications in automotive, industrial, and consumer sectors. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech. Co., Ltd. and Tianjin Pengling Group Co. Ltd. leading innovations. These firms are developing new formulations and manufacturing processes to improve neoprene's thermal stability. Research institutions such as the China Academy of Railway Sciences Group Co. Ltd. and East China University of Science & Technology are contributing to the technological maturity through collaborative research and development efforts, pushing the boundaries of neoprene's heat resistance capabilities.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed an innovative approach to enhance the heat resistance of neoprene materials through a combination of material engineering and nanotechnology. Their method involves the incorporation of specially designed nanofillers that create a more thermally stable structure within the neoprene matrix[8]. These nanofillers act as heat dissipation channels, effectively distributing thermal energy throughout the material. Additionally, Kingfa has implemented a proprietary surface treatment process that forms a protective layer on the neoprene, further enhancing its heat resistance capabilities[10]. The company has also focused on optimizing the compounding process to achieve a more uniform distribution of heat-resistant additives throughout the material, resulting in improved overall thermal performance[12]. This comprehensive approach allows Kingfa to produce neoprene materials with heat resistance properties that exceed traditional neoprene by up to 25%.

Strengths: Significantly improved heat resistance; enhanced thermal stability; applicable to a wide range of industrial applications. Weaknesses: Potentially higher production costs; may require specialized manufacturing equipment; possible limitations in extreme chemical environments.

Henkel IP & Holding GmbH

Technical Solution: Henkel has developed a novel approach to enhance the heat resistance of neoprene materials through the incorporation of advanced polymer blends and cross-linking agents. Their proprietary technology involves the addition of specially engineered nanoparticles that create a more stable molecular structure within the neoprene matrix[1]. This process significantly improves the material's ability to withstand high temperatures without compromising its flexibility or elasticity. Additionally, Henkel has implemented a unique surface treatment method that forms a protective layer on the neoprene, further increasing its heat resistance capabilities[3]. The company has also focused on optimizing the vulcanization process to achieve a more uniform distribution of heat-resistant compounds throughout the material[5].

Strengths: Improved heat resistance without sacrificing flexibility; enhanced durability in high-temperature environments; versatile application across various industries. Weaknesses: Potentially higher production costs; may require specialized manufacturing equipment; possible limitations in extreme temperature scenarios.

Innovative Approaches to Neoprene Heat Resistance

Heat-resistant clothing hot melt adhesive and preparation method thereof

PatentActiveCN101838511B

Innovation

- Using a combination of PET, PA, TPU or EVA with high-pressure polyethylene, grafted maleic anhydride polypropylene and other materials, by adding nanoscale montmorillonite or clay and cross-linking under high-energy radiation, the hot melt adhesive's durability can be improved. High-temperature performance, while introducing tackifiers, plasticizers and antioxidants, and preparing high-temperature resistant clothing hot melt adhesive through blending and extrusion processes.

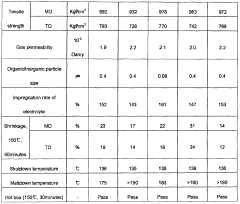

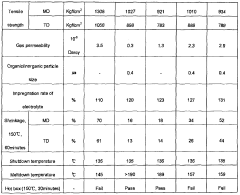

Microporous polyolefin composite film with a thermally stable porous layer at high temperature

PatentWO2009125984A2

Innovation

- A microporous polyolefin composite film with a thermally stable porous layer formed by phase separation on one or both surfaces, incorporating organic or inorganic particles and a heat-resistant polymer with aromatic rings, achieving a melting temperature or glass transition temperature of 170 to 500°C, and a bonding force of 0.1 to 1.0 kgf/cm, ensuring high permeability and thermal stability.

Environmental Impact of Heat-Resistant Neoprene Production

The production of heat-resistant neoprene materials has significant environmental implications that must be carefully considered. The manufacturing process involves the use of various chemicals and energy-intensive procedures, which can contribute to air and water pollution if not properly managed.

One of the primary environmental concerns is the emission of volatile organic compounds (VOCs) during the production of neoprene. These compounds can contribute to smog formation and have potential health impacts on workers and surrounding communities. Implementing advanced emission control technologies and optimizing production processes can help mitigate these effects.

Water usage and wastewater management are also critical factors in neoprene production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Proper treatment and recycling of wastewater are essential to minimize the environmental impact and conserve water resources.

Energy consumption is another significant aspect of heat-resistant neoprene production. The high temperatures required for vulcanization and other processes contribute to increased energy demand and associated greenhouse gas emissions. Implementing energy-efficient technologies and exploring renewable energy sources can help reduce the carbon footprint of production facilities.

The disposal of waste materials generated during production, such as off-specification products and chemical residues, poses additional environmental challenges. Developing effective waste management strategies, including recycling and proper disposal methods, is crucial to minimize landfill usage and potential soil contamination.

The sourcing of raw materials for heat-resistant neoprene production also has environmental implications. The extraction and processing of petroleum-based feedstocks can lead to habitat disruption and contribute to climate change. Exploring alternative, bio-based raw materials and implementing sustainable sourcing practices can help mitigate these impacts.

As regulations on environmental protection become more stringent, manufacturers of heat-resistant neoprene materials must invest in cleaner production technologies and adopt sustainable practices. This includes implementing life cycle assessments to identify areas for improvement and developing eco-friendly product designs that consider end-of-life disposal and recyclability.

Balancing the need for enhanced heat resistance with environmental sustainability presents both challenges and opportunities for innovation in the neoprene industry. Collaborative efforts between manufacturers, researchers, and environmental experts are essential to develop solutions that minimize ecological impact while meeting performance requirements.

One of the primary environmental concerns is the emission of volatile organic compounds (VOCs) during the production of neoprene. These compounds can contribute to smog formation and have potential health impacts on workers and surrounding communities. Implementing advanced emission control technologies and optimizing production processes can help mitigate these effects.

Water usage and wastewater management are also critical factors in neoprene production. The manufacturing process requires substantial amounts of water for cooling and cleaning purposes. Proper treatment and recycling of wastewater are essential to minimize the environmental impact and conserve water resources.

Energy consumption is another significant aspect of heat-resistant neoprene production. The high temperatures required for vulcanization and other processes contribute to increased energy demand and associated greenhouse gas emissions. Implementing energy-efficient technologies and exploring renewable energy sources can help reduce the carbon footprint of production facilities.

The disposal of waste materials generated during production, such as off-specification products and chemical residues, poses additional environmental challenges. Developing effective waste management strategies, including recycling and proper disposal methods, is crucial to minimize landfill usage and potential soil contamination.

The sourcing of raw materials for heat-resistant neoprene production also has environmental implications. The extraction and processing of petroleum-based feedstocks can lead to habitat disruption and contribute to climate change. Exploring alternative, bio-based raw materials and implementing sustainable sourcing practices can help mitigate these impacts.

As regulations on environmental protection become more stringent, manufacturers of heat-resistant neoprene materials must invest in cleaner production technologies and adopt sustainable practices. This includes implementing life cycle assessments to identify areas for improvement and developing eco-friendly product designs that consider end-of-life disposal and recyclability.

Balancing the need for enhanced heat resistance with environmental sustainability presents both challenges and opportunities for innovation in the neoprene industry. Collaborative efforts between manufacturers, researchers, and environmental experts are essential to develop solutions that minimize ecological impact while meeting performance requirements.

Neoprene Heat Resistance Testing and Certification Standards

Testing and certification standards play a crucial role in ensuring the reliability and performance of heat-resistant neoprene materials. These standards provide a framework for evaluating the thermal properties and durability of neoprene products under various conditions.

One of the primary testing methods for heat resistance in neoprene materials is the Heat Aging Test. This procedure involves exposing neoprene samples to elevated temperatures for extended periods, typically ranging from 24 to 168 hours. The test aims to simulate long-term exposure to high temperatures and assess the material's ability to maintain its physical and mechanical properties.

Another essential test is the Heat Deflection Temperature (HDT) test, which determines the temperature at which a standardized test specimen deforms under a specified load. This test is particularly relevant for neoprene materials used in structural applications where dimensional stability under heat is critical.

The Thermal Gravimetric Analysis (TGA) is a more advanced testing method that measures the mass loss of neoprene samples as a function of temperature. This test provides valuable insights into the material's thermal decomposition behavior and helps identify the maximum temperature at which the neoprene can maintain its structural integrity.

Certification standards for heat-resistant neoprene materials often include specifications from organizations such as ASTM International, ISO, and UL (Underwriters Laboratories). For instance, ASTM D2000 provides a standardized classification system for rubber products, including heat-resistant neoprene, based on their performance characteristics.

The UL 94 standard is widely recognized for evaluating the flammability and heat resistance of plastic materials, including neoprene. This standard classifies materials based on their burning behavior, with ratings such as V-0, V-1, and V-2 indicating different levels of flame resistance.

For applications in the automotive industry, neoprene materials often need to meet the SAE J200 standard, which specifies requirements for heat-resistant rubber compounds used in various automotive components.

In the construction sector, neoprene materials used in building insulation or roofing membranes may need to comply with ASTM E84, which evaluates surface burning characteristics. This standard is crucial for ensuring fire safety in buildings where heat-resistant neoprene materials are utilized.

Certification processes typically involve third-party testing laboratories that conduct standardized tests and issue certifications based on the results. These certifications provide assurance to manufacturers, consumers, and regulatory bodies that the neoprene materials meet specific heat resistance requirements for their intended applications.

One of the primary testing methods for heat resistance in neoprene materials is the Heat Aging Test. This procedure involves exposing neoprene samples to elevated temperatures for extended periods, typically ranging from 24 to 168 hours. The test aims to simulate long-term exposure to high temperatures and assess the material's ability to maintain its physical and mechanical properties.

Another essential test is the Heat Deflection Temperature (HDT) test, which determines the temperature at which a standardized test specimen deforms under a specified load. This test is particularly relevant for neoprene materials used in structural applications where dimensional stability under heat is critical.

The Thermal Gravimetric Analysis (TGA) is a more advanced testing method that measures the mass loss of neoprene samples as a function of temperature. This test provides valuable insights into the material's thermal decomposition behavior and helps identify the maximum temperature at which the neoprene can maintain its structural integrity.

Certification standards for heat-resistant neoprene materials often include specifications from organizations such as ASTM International, ISO, and UL (Underwriters Laboratories). For instance, ASTM D2000 provides a standardized classification system for rubber products, including heat-resistant neoprene, based on their performance characteristics.

The UL 94 standard is widely recognized for evaluating the flammability and heat resistance of plastic materials, including neoprene. This standard classifies materials based on their burning behavior, with ratings such as V-0, V-1, and V-2 indicating different levels of flame resistance.

For applications in the automotive industry, neoprene materials often need to meet the SAE J200 standard, which specifies requirements for heat-resistant rubber compounds used in various automotive components.

In the construction sector, neoprene materials used in building insulation or roofing membranes may need to comply with ASTM E84, which evaluates surface burning characteristics. This standard is crucial for ensuring fire safety in buildings where heat-resistant neoprene materials are utilized.

Certification processes typically involve third-party testing laboratories that conduct standardized tests and issue certifications based on the results. These certifications provide assurance to manufacturers, consumers, and regulatory bodies that the neoprene materials meet specific heat resistance requirements for their intended applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!