How to Tailor Dynamic Light Scattering for Custom Applications

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dynamic Light Scattering Technology Background and Objectives

Dynamic Light Scattering (DLS) emerged in the 1960s as a powerful analytical technique for characterizing particles in suspension. Initially developed for polymer science applications, DLS has evolved significantly over the past six decades, transforming from bulky laboratory equipment into sophisticated, compact systems with diverse applications across multiple industries. The fundamental principle of DLS relies on analyzing the Brownian motion of particles by measuring the fluctuations in scattered light intensity, which correlates with particle size.

The technology has experienced several evolutionary phases, beginning with simple correlation techniques and advancing to modern multi-angle systems with advanced algorithms. Recent developments have focused on miniaturization, automation, and integration with complementary techniques such as static light scattering and zeta potential measurements, creating more comprehensive analytical platforms.

Current technological trends in DLS include the development of machine learning algorithms for improved data interpretation, microfluidic integration for continuous monitoring, and the adaptation of DLS for specialized environments such as high-concentration samples and extreme temperature conditions. These advancements aim to overcome traditional limitations of DLS, including its challenges with polydisperse samples and sensitivity to contaminants.

The primary objective of tailoring DLS for custom applications is to extend its capabilities beyond conventional particle sizing to address specific industry challenges. This includes developing specialized sample handling systems for difficult materials, creating application-specific data analysis algorithms, and designing purpose-built hardware configurations that optimize performance for particular sample types or measurement conditions.

In biopharmaceutical applications, tailored DLS systems aim to provide enhanced protein aggregation detection and stability analysis. For nanomaterial research, the goal is to improve characterization of complex nanostructures with heterogeneous compositions. In environmental monitoring, objectives include developing robust field-deployable systems capable of real-time analysis of particulate matter in various media.

The long-term technological vision involves creating modular DLS platforms that can be rapidly configured for specific applications without sacrificing measurement quality or reliability. This includes developing standardized interfaces for custom sample handling modules, application-specific software packages, and adaptable optical configurations that can be optimized for particular measurement requirements.

The technology has experienced several evolutionary phases, beginning with simple correlation techniques and advancing to modern multi-angle systems with advanced algorithms. Recent developments have focused on miniaturization, automation, and integration with complementary techniques such as static light scattering and zeta potential measurements, creating more comprehensive analytical platforms.

Current technological trends in DLS include the development of machine learning algorithms for improved data interpretation, microfluidic integration for continuous monitoring, and the adaptation of DLS for specialized environments such as high-concentration samples and extreme temperature conditions. These advancements aim to overcome traditional limitations of DLS, including its challenges with polydisperse samples and sensitivity to contaminants.

The primary objective of tailoring DLS for custom applications is to extend its capabilities beyond conventional particle sizing to address specific industry challenges. This includes developing specialized sample handling systems for difficult materials, creating application-specific data analysis algorithms, and designing purpose-built hardware configurations that optimize performance for particular sample types or measurement conditions.

In biopharmaceutical applications, tailored DLS systems aim to provide enhanced protein aggregation detection and stability analysis. For nanomaterial research, the goal is to improve characterization of complex nanostructures with heterogeneous compositions. In environmental monitoring, objectives include developing robust field-deployable systems capable of real-time analysis of particulate matter in various media.

The long-term technological vision involves creating modular DLS platforms that can be rapidly configured for specific applications without sacrificing measurement quality or reliability. This includes developing standardized interfaces for custom sample handling modules, application-specific software packages, and adaptable optical configurations that can be optimized for particular measurement requirements.

Market Applications and Demand Analysis for Custom DLS Solutions

Dynamic Light Scattering (DLS) technology has witnessed significant market growth across various industries due to its versatility in particle size analysis. The global market for DLS equipment is experiencing robust expansion, driven by increasing applications in pharmaceuticals, biotechnology, and materials science. Current market valuations indicate that the DLS instrumentation sector has reached approximately 300 million USD, with projected annual growth rates between 5-7% over the next five years.

The pharmaceutical and biotechnology sectors represent the largest market segments for custom DLS solutions, accounting for nearly 45% of the total market share. These industries require specialized DLS applications for protein aggregation studies, drug delivery system characterization, and quality control processes. The demand is particularly strong for DLS systems capable of analyzing highly concentrated samples and providing real-time monitoring capabilities.

Nanotechnology and advanced materials research constitute another rapidly growing market segment, representing about 25% of current demand. In these fields, researchers require customized DLS solutions that can accurately characterize nanoparticles with complex morphologies and surface properties. The ability to analyze particles in various dispersion media and under different environmental conditions is increasingly valued.

Academic and research institutions form a stable market base, contributing approximately 20% of the overall demand. These organizations typically seek flexible DLS platforms that can be adapted for diverse research applications while maintaining cost-effectiveness. The remaining market share is distributed across food and beverage, cosmetics, and environmental monitoring sectors.

Regional analysis reveals that North America leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding research infrastructure and increasing industrial applications of nanotechnology.

Customer needs assessment indicates several key requirements driving the demand for customized DLS solutions. These include enhanced sensitivity for detecting smaller particles (below 1 nm), improved resolution for polydisperse samples, compatibility with a wider range of solvents and sample types, and integration capabilities with other analytical techniques. Additionally, there is growing demand for portable and automated DLS systems that can be deployed in production environments for real-time quality control.

Market forecasts suggest that specialized DLS applications in biopharmaceutical development, particularly for characterizing protein-based therapeutics and gene delivery systems, will experience the strongest growth in the coming years. Similarly, environmental monitoring applications are expected to expand as regulatory requirements for nanoparticle detection in water and air become more stringent.

The pharmaceutical and biotechnology sectors represent the largest market segments for custom DLS solutions, accounting for nearly 45% of the total market share. These industries require specialized DLS applications for protein aggregation studies, drug delivery system characterization, and quality control processes. The demand is particularly strong for DLS systems capable of analyzing highly concentrated samples and providing real-time monitoring capabilities.

Nanotechnology and advanced materials research constitute another rapidly growing market segment, representing about 25% of current demand. In these fields, researchers require customized DLS solutions that can accurately characterize nanoparticles with complex morphologies and surface properties. The ability to analyze particles in various dispersion media and under different environmental conditions is increasingly valued.

Academic and research institutions form a stable market base, contributing approximately 20% of the overall demand. These organizations typically seek flexible DLS platforms that can be adapted for diverse research applications while maintaining cost-effectiveness. The remaining market share is distributed across food and beverage, cosmetics, and environmental monitoring sectors.

Regional analysis reveals that North America leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding research infrastructure and increasing industrial applications of nanotechnology.

Customer needs assessment indicates several key requirements driving the demand for customized DLS solutions. These include enhanced sensitivity for detecting smaller particles (below 1 nm), improved resolution for polydisperse samples, compatibility with a wider range of solvents and sample types, and integration capabilities with other analytical techniques. Additionally, there is growing demand for portable and automated DLS systems that can be deployed in production environments for real-time quality control.

Market forecasts suggest that specialized DLS applications in biopharmaceutical development, particularly for characterizing protein-based therapeutics and gene delivery systems, will experience the strongest growth in the coming years. Similarly, environmental monitoring applications are expected to expand as regulatory requirements for nanoparticle detection in water and air become more stringent.

Current Technical Limitations and Challenges in DLS Customization

Despite the significant advancements in Dynamic Light Scattering (DLS) technology, several technical limitations and challenges persist when customizing DLS for specific applications. One fundamental challenge is the inherent limitation in resolving polydisperse samples. DLS struggles to accurately differentiate particles with size differences less than a factor of 3-5, leading to resolution constraints when analyzing complex mixtures with closely sized particles.

Signal-to-noise ratio issues present significant obstacles, particularly when measuring samples with low concentration or small particles below 10 nm. This limitation becomes more pronounced in biological applications where protein aggregates or nanoparticles must be detected at physiologically relevant concentrations, often requiring sophisticated signal processing algorithms that may introduce artifacts.

Temperature control represents another critical challenge in DLS customization. Even minor temperature fluctuations (±0.1°C) can significantly affect Brownian motion measurements, leading to inconsistent results. This becomes particularly problematic for temperature-sensitive applications or when analyzing materials with temperature-dependent properties.

Sample preparation challenges further complicate DLS customization efforts. Dust particles, air bubbles, or large aggregates can disproportionately influence measurements due to the intensity of scattered light scaling with the sixth power of particle diameter. This necessitates meticulous sample preparation protocols that may not be feasible in all application environments.

The mathematical models underlying DLS analysis present additional limitations. Most commercial systems rely on simplified assumptions about particle shape (typically spherical) and homogeneity. When analyzing non-spherical particles, biological macromolecules, or heterogeneous systems, these assumptions introduce systematic errors that are difficult to quantify or correct.

Instrument design constraints also impact customization capabilities. Most commercial DLS systems are optimized for general-purpose applications, with fixed detection angles (typically 90° or 173°) that cannot be easily modified. This limits the ability to optimize scattering conditions for specific sample types or research questions.

Data interpretation challenges persist across DLS applications. Converting correlation functions to size distributions involves complex mathematical transformations that can amplify noise and introduce artifacts. Different mathematical approaches (CONTIN, NNLS, etc.) may yield significantly different results from the same raw data, creating uncertainty in analysis outcomes.

Finally, integration challenges arise when attempting to combine DLS with complementary techniques like static light scattering, viscometry, or spectroscopic methods. Hardware and software compatibility issues, along with data fusion complexities, often require custom engineering solutions that increase system complexity and cost while potentially compromising measurement reliability.

Signal-to-noise ratio issues present significant obstacles, particularly when measuring samples with low concentration or small particles below 10 nm. This limitation becomes more pronounced in biological applications where protein aggregates or nanoparticles must be detected at physiologically relevant concentrations, often requiring sophisticated signal processing algorithms that may introduce artifacts.

Temperature control represents another critical challenge in DLS customization. Even minor temperature fluctuations (±0.1°C) can significantly affect Brownian motion measurements, leading to inconsistent results. This becomes particularly problematic for temperature-sensitive applications or when analyzing materials with temperature-dependent properties.

Sample preparation challenges further complicate DLS customization efforts. Dust particles, air bubbles, or large aggregates can disproportionately influence measurements due to the intensity of scattered light scaling with the sixth power of particle diameter. This necessitates meticulous sample preparation protocols that may not be feasible in all application environments.

The mathematical models underlying DLS analysis present additional limitations. Most commercial systems rely on simplified assumptions about particle shape (typically spherical) and homogeneity. When analyzing non-spherical particles, biological macromolecules, or heterogeneous systems, these assumptions introduce systematic errors that are difficult to quantify or correct.

Instrument design constraints also impact customization capabilities. Most commercial DLS systems are optimized for general-purpose applications, with fixed detection angles (typically 90° or 173°) that cannot be easily modified. This limits the ability to optimize scattering conditions for specific sample types or research questions.

Data interpretation challenges persist across DLS applications. Converting correlation functions to size distributions involves complex mathematical transformations that can amplify noise and introduce artifacts. Different mathematical approaches (CONTIN, NNLS, etc.) may yield significantly different results from the same raw data, creating uncertainty in analysis outcomes.

Finally, integration challenges arise when attempting to combine DLS with complementary techniques like static light scattering, viscometry, or spectroscopic methods. Hardware and software compatibility issues, along with data fusion complexities, often require custom engineering solutions that increase system complexity and cost while potentially compromising measurement reliability.

Current Customization Approaches for DLS Applications

01 Principles and apparatus for dynamic light scattering measurements

Dynamic light scattering (DLS) is a technique used to measure the size distribution of particles in suspension. The basic principle involves analyzing the fluctuations in scattered light intensity caused by Brownian motion of particles. Advanced DLS apparatus typically includes a light source (usually a laser), optical components for beam focusing, a sample holder, detection systems, and signal processing units. These systems can measure particles ranging from nanometers to micrometers in size by analyzing the temporal correlation of scattered light.- Principles and fundamentals of Dynamic Light Scattering technology: Dynamic Light Scattering (DLS) is a technique used to determine the size distribution of particles in suspension or polymers in solution by measuring the fluctuations in scattered light intensity. The technology relies on the Brownian motion of particles and analyzes the time-dependent fluctuations in the intensity of scattered light to determine particle size distribution. This fundamental approach enables the characterization of particles ranging from nanometers to micrometers in size.

- Advanced DLS instrumentation and apparatus design: Innovations in DLS instrumentation focus on improving measurement accuracy, sensitivity, and versatility. These advancements include novel optical configurations, detection systems, and signal processing methods. Modern DLS instruments incorporate features such as multi-angle detection, fiber optic technology, and integrated temperature control systems to enhance measurement capabilities. These design improvements allow for more precise particle characterization across diverse sample types and environmental conditions.

- DLS applications in biological and pharmaceutical research: Dynamic Light Scattering has become an essential tool in biological and pharmaceutical research for characterizing biomolecules, drug delivery systems, and protein formulations. The technique enables researchers to monitor protein aggregation, stability of drug formulations, and interactions between biomolecules in solution. DLS provides valuable information about the size, polydispersity, and molecular weight of biological samples, supporting drug development and quality control processes in pharmaceutical manufacturing.

- Integration of DLS with other analytical techniques: Combining Dynamic Light Scattering with complementary analytical methods creates powerful hybrid systems for comprehensive particle characterization. These integrated approaches may combine DLS with techniques such as Raman spectroscopy, size exclusion chromatography, or electrophoretic measurements. Such combinations provide multidimensional data about particle properties, including size, structure, composition, and surface characteristics, enabling more complete material characterization than would be possible with any single technique alone.

- Data processing and analysis algorithms for DLS measurements: Advanced algorithms and computational methods have been developed to improve the analysis of DLS data and extract more accurate and detailed information about particle characteristics. These innovations include novel mathematical models for interpreting correlation functions, machine learning approaches for data analysis, and algorithms that can handle complex, polydisperse samples. Improved data processing techniques enable researchers to obtain more reliable size distributions, better distinguish between different particle populations, and achieve higher resolution measurements even in challenging sample conditions.

02 Applications of DLS in biological and pharmaceutical research

Dynamic light scattering has become an essential analytical tool in biological and pharmaceutical research. It is used for characterizing proteins, liposomes, viruses, and drug delivery systems. The technique helps in determining protein aggregation, stability of formulations, and quality control of biopharmaceuticals. DLS enables researchers to monitor changes in particle size distribution under various conditions such as temperature, pH, and concentration, providing valuable insights into biomolecular interactions and formulation development.Expand Specific Solutions03 Advanced signal processing and data analysis methods for DLS

Modern dynamic light scattering systems employ sophisticated signal processing and data analysis methods to extract meaningful information from scattered light data. These include autocorrelation functions, cumulant analysis, CONTIN algorithms, and machine learning approaches. Advanced computational methods help in resolving multimodal distributions, improving measurement accuracy for polydisperse samples, and reducing noise interference. Real-time data processing allows for continuous monitoring of dynamic systems and detection of subtle changes in particle characteristics.Expand Specific Solutions04 Integration of DLS with other analytical techniques

The integration of dynamic light scattering with complementary analytical techniques has expanded its capabilities and applications. Hybrid systems combining DLS with static light scattering, Raman spectroscopy, rheology measurements, or microscopy techniques provide comprehensive characterization of complex materials. These integrated approaches allow simultaneous measurement of multiple parameters such as size, molecular weight, structure, and interactions, offering a more complete understanding of colloidal and macromolecular systems.Expand Specific Solutions05 Miniaturization and automation of DLS technology

Recent advances in dynamic light scattering technology have focused on miniaturization and automation, making the technique more accessible and user-friendly. Compact, portable DLS devices enable on-site measurements in various environments. Automated sampling systems, microfluidic integration, and high-throughput capabilities allow for rapid analysis of multiple samples with minimal user intervention. These developments have expanded the use of DLS in quality control, process monitoring, and field applications where traditional laboratory equipment would be impractical.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DLS Technology

Dynamic Light Scattering (DLS) technology is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in pharmaceuticals, biotechnology, and materials science. The global DLS market demonstrates moderate maturity with established core technologies, yet continues to evolve through customization capabilities. Companies like Malvern Panalytical Ltd. lead with comprehensive DLS solutions, while specialized players such as PULSTEC INDUSTRIAL and Otsuka Electronics focus on niche applications. Academic institutions including Johns Hopkins University and South China Normal University contribute fundamental research advancing the field. The competitive landscape shows diversification with companies like Corning and TDK Electronics integrating DLS into broader technology portfolios, while emerging players develop application-specific innovations tailored to industries ranging from pharmaceuticals to semiconductor manufacturing.

PULSTEC INDUSTRIAL CO., LTD.

Technical Solution: PULSTEC has developed specialized DLS systems focused on industrial applications requiring robust performance in challenging environments. Their DLS-8000 series features patented optical configurations that maintain alignment stability under vibration and temperature fluctuations, making them suitable for production environments. The company has implemented real-time monitoring capabilities with continuous sampling systems that allow for process integration in manufacturing settings, particularly for quality control in pharmaceutical and chemical production. Their systems incorporate automated dilution modules that expand the concentration range for measurements without manual sample preparation, handling samples from 0.001% to 40% concentration. PULSTEC's proprietary algorithms are optimized for specific industrial materials including ceramics, metal oxides, and polymer emulsions, with material-specific reference databases for rapid quality assessment. Their DLS platforms feature industrial communication protocols (including OPC-UA and Modbus) for seamless integration with manufacturing execution systems and process control infrastructure.

Strengths: Exceptional stability in industrial environments with vibration resistance; seamless integration with manufacturing processes; specialized algorithms for industrial materials and quality control applications. Weaknesses: Less versatile for research applications requiring highest sensitivity; fewer options for biological sample analysis; limited customization for novel research applications compared to academic-focused systems.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed advanced Dynamic Light Scattering (DLS) platforms that allow for customization across multiple applications. Their Zetasizer series incorporates adaptive correlation technology that optimizes measurement parameters based on sample characteristics, enabling precise particle size analysis from 0.3nm to 10μm. The company's Non-Invasive Back-Scatter (NIBS) technology significantly improves signal-to-noise ratio by detecting scattered light at a 173° angle, reducing multiple scattering effects in concentrated samples. Their systems feature temperature control modules (15-90°C) allowing for temperature-dependent studies of particle behavior and stability. Malvern's software suite enables application-specific analysis protocols with customizable reporting templates for pharmaceuticals, nanomaterials, and protein characterization. Their multi-angle DLS capabilities permit simultaneous measurements at different scattering angles, providing more comprehensive structural information for complex systems.

Strengths: Industry-leading sensitivity for measuring low concentration and small particle samples; extensive customization options for different industries; robust data analysis algorithms for complex dispersions. Weaknesses: Higher price point compared to some competitors; some advanced features require significant user expertise; system optimization for specific applications may require specialized training.

Key Technical Innovations in Tailored DLS Systems

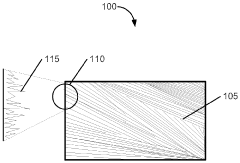

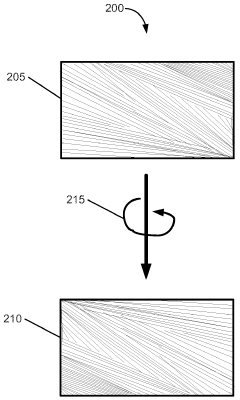

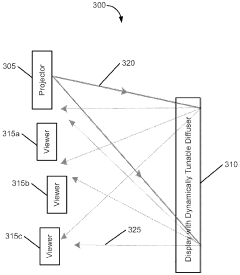

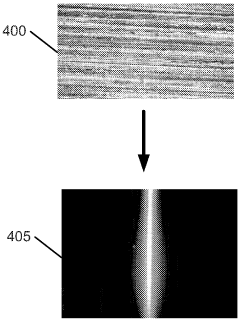

A diffuser with a dynamically tunable scattering angle

PatentWO2012105954A1

Innovation

- The development of an optical diffuser with two diffusers, each having a scattering angle of nearly zero degrees in the horizontal direction and over thirty degrees in the vertical direction, with microstructures rotated relative to each other to control the total scattering angle, allowing for real-time adjustment to suit different viewing conditions.

Calibration and Validation Protocols for Custom DLS Systems

Establishing robust calibration and validation protocols is essential for ensuring the reliability and accuracy of custom Dynamic Light Scattering (DLS) systems. These protocols must be meticulously designed to account for the specific requirements of tailored applications, as standard commercial protocols may not address unique experimental conditions or sample characteristics.

The foundation of any calibration protocol begins with the selection of appropriate reference materials. For custom DLS applications, these should include monodisperse standards with well-characterized size distributions that span the measurement range of interest. Polystyrene latex beads, silica nanoparticles, and gold colloids are commonly employed, with NIST-traceable standards providing the highest level of confidence. The reference materials should match the refractive index and viscosity conditions of the intended application environment whenever possible.

Temperature calibration represents another critical aspect, particularly for applications involving temperature-sensitive materials or requiring precise temperature control. This involves verifying the accuracy of temperature sensors and establishing correction factors if necessary. For custom systems, temperature gradients within the sample chamber must be mapped and minimized to prevent convection currents that can distort measurements.

Validation protocols should incorporate both system suitability tests and method validation components. System suitability encompasses laser stability verification, detector response linearity assessment, and optical alignment confirmation. These parameters should be monitored regularly using control charts to detect drift or degradation in system performance. For custom applications, additional parameters specific to the application requirements may need monitoring, such as sample chamber cleanliness for ultra-sensitive measurements or background scattering levels for low-concentration samples.

Method validation for custom DLS applications must address accuracy, precision, reproducibility, and robustness across the intended operational range. This includes evaluating the system's performance with samples that mimic the complexity of real-world materials. Cross-validation with orthogonal techniques such as electron microscopy, analytical ultracentrifugation, or size exclusion chromatography provides additional confidence in the custom system's performance.

Documentation of calibration and validation procedures is paramount, particularly for regulated environments. Standard operating procedures should detail step-by-step instructions, acceptance criteria, and corrective actions when specifications are not met. For custom applications, these documents should also include application-specific considerations and potential interferences that may affect measurement quality.

Regular revalidation schedules must be established based on system stability, usage frequency, and application criticality. More frequent validation may be necessary for novel applications where long-term performance characteristics are not yet well understood or when environmental conditions fluctuate significantly.

The foundation of any calibration protocol begins with the selection of appropriate reference materials. For custom DLS applications, these should include monodisperse standards with well-characterized size distributions that span the measurement range of interest. Polystyrene latex beads, silica nanoparticles, and gold colloids are commonly employed, with NIST-traceable standards providing the highest level of confidence. The reference materials should match the refractive index and viscosity conditions of the intended application environment whenever possible.

Temperature calibration represents another critical aspect, particularly for applications involving temperature-sensitive materials or requiring precise temperature control. This involves verifying the accuracy of temperature sensors and establishing correction factors if necessary. For custom systems, temperature gradients within the sample chamber must be mapped and minimized to prevent convection currents that can distort measurements.

Validation protocols should incorporate both system suitability tests and method validation components. System suitability encompasses laser stability verification, detector response linearity assessment, and optical alignment confirmation. These parameters should be monitored regularly using control charts to detect drift or degradation in system performance. For custom applications, additional parameters specific to the application requirements may need monitoring, such as sample chamber cleanliness for ultra-sensitive measurements or background scattering levels for low-concentration samples.

Method validation for custom DLS applications must address accuracy, precision, reproducibility, and robustness across the intended operational range. This includes evaluating the system's performance with samples that mimic the complexity of real-world materials. Cross-validation with orthogonal techniques such as electron microscopy, analytical ultracentrifugation, or size exclusion chromatography provides additional confidence in the custom system's performance.

Documentation of calibration and validation procedures is paramount, particularly for regulated environments. Standard operating procedures should detail step-by-step instructions, acceptance criteria, and corrective actions when specifications are not met. For custom applications, these documents should also include application-specific considerations and potential interferences that may affect measurement quality.

Regular revalidation schedules must be established based on system stability, usage frequency, and application criticality. More frequent validation may be necessary for novel applications where long-term performance characteristics are not yet well understood or when environmental conditions fluctuate significantly.

Integration Capabilities with Complementary Analytical Techniques

Dynamic Light Scattering (DLS) technology demonstrates remarkable versatility when integrated with complementary analytical techniques, creating powerful synergistic systems that enhance research capabilities across multiple disciplines. The integration of DLS with other analytical methods significantly expands its application scope and provides more comprehensive characterization of complex samples.

When combined with Size Exclusion Chromatography (SEC), DLS offers real-time particle size analysis of separated fractions, enabling researchers to detect aggregates and obtain more detailed information about sample polydispersity. This SEC-DLS combination has become particularly valuable in biopharmaceutical development, where protein aggregation monitoring is critical for product quality and safety assessment.

Multi-Angle Light Scattering (MALS) integration with DLS creates a robust platform for determining both molecular weight and size distributions simultaneously. This dual-parameter approach provides more accurate characterization of macromolecules and nanoparticles, especially for non-spherical particles where traditional DLS assumptions may introduce errors.

The coupling of DLS with Raman spectroscopy enables correlation between particle size distribution and chemical composition. This integration proves particularly valuable for heterogeneous samples where understanding both physical dimensions and chemical identity is essential. Several instrument manufacturers now offer combined DLS-Raman systems with synchronized data acquisition capabilities.

Microscopy techniques, particularly Atomic Force Microscopy (AFM) and Transmission Electron Microscopy (TEM), complement DLS by providing direct visualization of particles. While DLS offers excellent statistical representation of the entire sample population, microscopy techniques provide morphological details that DLS cannot capture. Modern laboratory information management systems now facilitate seamless data comparison between these techniques.

Recent advances in microfluidic technologies have enabled the integration of DLS with flow-based analytical methods. These integrated systems allow for continuous monitoring of dynamic processes such as nanoparticle formation, protein aggregation kinetics, or colloidal stability under varying conditions. The miniaturization of DLS components has been crucial for these developments.

For comprehensive surface characterization, DLS integration with zeta potential measurements provides insights into both particle size and surface charge properties. This combination is particularly valuable for predicting colloidal stability and understanding particle-particle interactions in complex media, offering critical information for formulation development in pharmaceutical and material science applications.

When combined with Size Exclusion Chromatography (SEC), DLS offers real-time particle size analysis of separated fractions, enabling researchers to detect aggregates and obtain more detailed information about sample polydispersity. This SEC-DLS combination has become particularly valuable in biopharmaceutical development, where protein aggregation monitoring is critical for product quality and safety assessment.

Multi-Angle Light Scattering (MALS) integration with DLS creates a robust platform for determining both molecular weight and size distributions simultaneously. This dual-parameter approach provides more accurate characterization of macromolecules and nanoparticles, especially for non-spherical particles where traditional DLS assumptions may introduce errors.

The coupling of DLS with Raman spectroscopy enables correlation between particle size distribution and chemical composition. This integration proves particularly valuable for heterogeneous samples where understanding both physical dimensions and chemical identity is essential. Several instrument manufacturers now offer combined DLS-Raman systems with synchronized data acquisition capabilities.

Microscopy techniques, particularly Atomic Force Microscopy (AFM) and Transmission Electron Microscopy (TEM), complement DLS by providing direct visualization of particles. While DLS offers excellent statistical representation of the entire sample population, microscopy techniques provide morphological details that DLS cannot capture. Modern laboratory information management systems now facilitate seamless data comparison between these techniques.

Recent advances in microfluidic technologies have enabled the integration of DLS with flow-based analytical methods. These integrated systems allow for continuous monitoring of dynamic processes such as nanoparticle formation, protein aggregation kinetics, or colloidal stability under varying conditions. The miniaturization of DLS components has been crucial for these developments.

For comprehensive surface characterization, DLS integration with zeta potential measurements provides insights into both particle size and surface charge properties. This combination is particularly valuable for predicting colloidal stability and understanding particle-particle interactions in complex media, offering critical information for formulation development in pharmaceutical and material science applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!