How to Control Sample Temperature in Dynamic Light Scattering

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Temperature Control Background and Objectives

Dynamic Light Scattering (DLS) has evolved significantly since its inception in the 1960s, becoming an essential analytical technique for characterizing particles in suspension. The technique measures Brownian motion of particles and correlates it to particle size through the Stokes-Einstein equation, which explicitly includes temperature as a critical parameter. Temperature control in DLS measurements is fundamental as even minor temperature fluctuations can significantly impact measurement accuracy and reproducibility.

The historical development of temperature control in DLS systems reflects the growing recognition of its importance. Early DLS instruments operated at ambient conditions with minimal temperature regulation, leading to inconsistent results across different laboratory environments. As the technique gained prominence in pharmaceutical, biotechnology, and nanomaterial research, the demand for precise temperature control mechanisms increased substantially.

Temperature affects DLS measurements through multiple mechanisms: it directly influences the viscosity of the dispersing medium, alters the Brownian motion of particles, and can induce structural changes in temperature-sensitive samples such as proteins, polymers, and colloidal systems. Additionally, temperature gradients within samples can cause convection currents that introduce artifacts in DLS data.

The primary objective of temperature control in DLS is to maintain stable, uniform, and precisely regulated thermal conditions throughout the measurement process. This includes achieving rapid thermal equilibration, minimizing temperature gradients within the sample, and ensuring long-term stability during extended measurements. Ideally, modern DLS systems should maintain temperature stability within ±0.1°C or better.

Current technological trends are moving toward more sophisticated temperature control systems that offer wider temperature ranges (typically from 0°C to 90°C), faster equilibration times, and integration with automated measurement workflows. There is also growing interest in developing systems capable of performing temperature-dependent studies to investigate phase transitions, aggregation behaviors, and thermal stability of various colloidal systems.

The advancement of temperature control technologies in DLS aligns with broader industry trends toward increased automation, higher throughput capabilities, and integration with complementary analytical techniques. These developments aim to enhance the applicability of DLS across diverse research fields and industrial applications, from pharmaceutical formulation development to advanced materials characterization.

The historical development of temperature control in DLS systems reflects the growing recognition of its importance. Early DLS instruments operated at ambient conditions with minimal temperature regulation, leading to inconsistent results across different laboratory environments. As the technique gained prominence in pharmaceutical, biotechnology, and nanomaterial research, the demand for precise temperature control mechanisms increased substantially.

Temperature affects DLS measurements through multiple mechanisms: it directly influences the viscosity of the dispersing medium, alters the Brownian motion of particles, and can induce structural changes in temperature-sensitive samples such as proteins, polymers, and colloidal systems. Additionally, temperature gradients within samples can cause convection currents that introduce artifacts in DLS data.

The primary objective of temperature control in DLS is to maintain stable, uniform, and precisely regulated thermal conditions throughout the measurement process. This includes achieving rapid thermal equilibration, minimizing temperature gradients within the sample, and ensuring long-term stability during extended measurements. Ideally, modern DLS systems should maintain temperature stability within ±0.1°C or better.

Current technological trends are moving toward more sophisticated temperature control systems that offer wider temperature ranges (typically from 0°C to 90°C), faster equilibration times, and integration with automated measurement workflows. There is also growing interest in developing systems capable of performing temperature-dependent studies to investigate phase transitions, aggregation behaviors, and thermal stability of various colloidal systems.

The advancement of temperature control technologies in DLS aligns with broader industry trends toward increased automation, higher throughput capabilities, and integration with complementary analytical techniques. These developments aim to enhance the applicability of DLS across diverse research fields and industrial applications, from pharmaceutical formulation development to advanced materials characterization.

Market Analysis for Temperature-Controlled DLS Systems

The global market for temperature-controlled Dynamic Light Scattering (DLS) systems has been experiencing steady growth, driven by increasing demand for precise particle characterization across various industries. The market size for analytical instruments, including DLS systems, reached approximately $5.2 billion in 2022, with temperature-controlled systems representing a significant segment within this category.

Pharmaceutical and biotechnology sectors currently dominate the demand landscape, accounting for nearly 40% of the market share. This dominance stems from the critical need for accurate protein and biomolecule characterization under physiologically relevant conditions. Temperature control capabilities are particularly valued in these sectors as they enable studies of thermal stability, aggregation kinetics, and conformational changes in therapeutic proteins and drug delivery systems.

Academic research institutions constitute the second-largest market segment, representing about 25% of the total market. The growing focus on nanomaterials and colloidal science has fueled demand for advanced DLS systems with precise temperature control features. These institutions often require versatile systems capable of operating across wide temperature ranges to support diverse research applications.

Regional analysis reveals North America as the leading market for temperature-controlled DLS systems, holding approximately 35% of the global market share. This dominance is attributed to the region's robust pharmaceutical industry and substantial research funding. Europe follows closely with a 30% market share, driven by strong academic research networks and a growing biotechnology sector. The Asia-Pacific region represents the fastest-growing market, with annual growth rates exceeding 8%, primarily fueled by expanding research infrastructure in China, Japan, and India.

Market trends indicate increasing demand for integrated systems that combine temperature control with other functionalities such as automated sample handling and multi-angle detection capabilities. End-users are showing preference for systems offering temperature ranges from 0°C to 90°C with stability of ±0.1°C or better. Premium pricing is accepted for systems demonstrating superior temperature stability and rapid equilibration times.

Customer surveys reveal that reliability, accuracy, and user-friendly interfaces are the primary purchasing factors for temperature-controlled DLS systems. Service support and software capabilities for data analysis are increasingly important secondary considerations. The market is projected to grow at a compound annual growth rate of 6.5% over the next five years, with particularly strong growth in applications related to nanomedicine and advanced materials characterization.

Pharmaceutical and biotechnology sectors currently dominate the demand landscape, accounting for nearly 40% of the market share. This dominance stems from the critical need for accurate protein and biomolecule characterization under physiologically relevant conditions. Temperature control capabilities are particularly valued in these sectors as they enable studies of thermal stability, aggregation kinetics, and conformational changes in therapeutic proteins and drug delivery systems.

Academic research institutions constitute the second-largest market segment, representing about 25% of the total market. The growing focus on nanomaterials and colloidal science has fueled demand for advanced DLS systems with precise temperature control features. These institutions often require versatile systems capable of operating across wide temperature ranges to support diverse research applications.

Regional analysis reveals North America as the leading market for temperature-controlled DLS systems, holding approximately 35% of the global market share. This dominance is attributed to the region's robust pharmaceutical industry and substantial research funding. Europe follows closely with a 30% market share, driven by strong academic research networks and a growing biotechnology sector. The Asia-Pacific region represents the fastest-growing market, with annual growth rates exceeding 8%, primarily fueled by expanding research infrastructure in China, Japan, and India.

Market trends indicate increasing demand for integrated systems that combine temperature control with other functionalities such as automated sample handling and multi-angle detection capabilities. End-users are showing preference for systems offering temperature ranges from 0°C to 90°C with stability of ±0.1°C or better. Premium pricing is accepted for systems demonstrating superior temperature stability and rapid equilibration times.

Customer surveys reveal that reliability, accuracy, and user-friendly interfaces are the primary purchasing factors for temperature-controlled DLS systems. Service support and software capabilities for data analysis are increasingly important secondary considerations. The market is projected to grow at a compound annual growth rate of 6.5% over the next five years, with particularly strong growth in applications related to nanomedicine and advanced materials characterization.

Current Challenges in DLS Sample Temperature Regulation

Despite significant advancements in Dynamic Light Scattering (DLS) technology, temperature regulation of samples remains one of the most challenging aspects affecting measurement accuracy and reproducibility. The primary difficulty stems from the extreme sensitivity of DLS measurements to even minor temperature fluctuations, as these directly impact Brownian motion of particles, which is the fundamental physical phenomenon being measured.

Current commercial DLS systems typically employ Peltier-based temperature control mechanisms that, while functional, struggle to maintain precise temperature stability across the entire sample volume. Variations as small as 0.1°C can significantly alter diffusion coefficients, leading to erroneous size distribution calculations. This challenge is particularly pronounced when working with biological samples that require physiological temperatures (37°C) or temperature-sensitive materials.

Thermal gradients within samples represent another substantial obstacle. Even with sophisticated temperature control systems, achieving uniform temperature distribution throughout the sample remains difficult, especially in larger volume cells. These gradients can induce convection currents that dramatically interfere with the Brownian motion signal, creating artifacts in correlation functions and ultimately compromising data quality.

The time required to reach thermal equilibrium presents an additional challenge that is often underestimated. Many operators initiate measurements before samples have fully equilibrated, resulting in drift effects during data collection. This is particularly problematic for kinetic studies or when analyzing temperature-dependent phase transitions, where precise temperature control timing is critical.

External environmental factors further complicate temperature regulation. Laboratory ambient temperature fluctuations, air conditioning cycles, and even heat generated by nearby equipment can influence the sample environment. Most current DLS instruments lack sufficient insulation or compensation mechanisms to fully mitigate these external thermal influences.

For viscous samples or those with high thermal capacity, existing temperature control systems often struggle to achieve target temperatures within reasonable timeframes. This limitation restricts the practical temperature range for certain sample types and can extend experiment durations significantly.

The integration of temperature sensors also presents technical challenges. Current sensor placements typically measure the temperature of the sample holder rather than the actual sample, creating discrepancies between reported and actual sample temperatures. This systematic error is rarely accounted for in data analysis, leading to potential misinterpretation of results, particularly in temperature-dependent studies.

Current commercial DLS systems typically employ Peltier-based temperature control mechanisms that, while functional, struggle to maintain precise temperature stability across the entire sample volume. Variations as small as 0.1°C can significantly alter diffusion coefficients, leading to erroneous size distribution calculations. This challenge is particularly pronounced when working with biological samples that require physiological temperatures (37°C) or temperature-sensitive materials.

Thermal gradients within samples represent another substantial obstacle. Even with sophisticated temperature control systems, achieving uniform temperature distribution throughout the sample remains difficult, especially in larger volume cells. These gradients can induce convection currents that dramatically interfere with the Brownian motion signal, creating artifacts in correlation functions and ultimately compromising data quality.

The time required to reach thermal equilibrium presents an additional challenge that is often underestimated. Many operators initiate measurements before samples have fully equilibrated, resulting in drift effects during data collection. This is particularly problematic for kinetic studies or when analyzing temperature-dependent phase transitions, where precise temperature control timing is critical.

External environmental factors further complicate temperature regulation. Laboratory ambient temperature fluctuations, air conditioning cycles, and even heat generated by nearby equipment can influence the sample environment. Most current DLS instruments lack sufficient insulation or compensation mechanisms to fully mitigate these external thermal influences.

For viscous samples or those with high thermal capacity, existing temperature control systems often struggle to achieve target temperatures within reasonable timeframes. This limitation restricts the practical temperature range for certain sample types and can extend experiment durations significantly.

The integration of temperature sensors also presents technical challenges. Current sensor placements typically measure the temperature of the sample holder rather than the actual sample, creating discrepancies between reported and actual sample temperatures. This systematic error is rarely accounted for in data analysis, leading to potential misinterpretation of results, particularly in temperature-dependent studies.

Existing Temperature Control Solutions for DLS Applications

01 Temperature control systems for DLS measurements

Dynamic Light Scattering (DLS) measurements require precise temperature control to ensure accurate results, as temperature fluctuations can affect particle movement and scattering patterns. Advanced temperature control systems incorporate heating and cooling elements with feedback mechanisms to maintain stable sample temperatures during analysis. These systems often include thermal jackets, Peltier elements, or circulating baths that can regulate temperature within narrow ranges, typically ±0.1°C, which is essential for reproducible measurements of particle size and molecular interactions.- Temperature control systems for DLS measurements: Dynamic Light Scattering (DLS) measurements require precise temperature control to ensure accurate results, as temperature fluctuations can affect particle movement and scattering patterns. Advanced temperature control systems incorporate heating and cooling elements with feedback mechanisms to maintain stable sample temperatures during analysis. These systems often include thermal jackets, Peltier elements, or water circulation systems that can regulate temperatures within 0.1°C precision across a wide temperature range.

- Temperature-dependent particle characterization: DLS techniques can be used to study how particle properties change with temperature variations. By systematically altering sample temperature during measurement, researchers can observe temperature-dependent behaviors such as aggregation, phase transitions, or conformational changes in macromolecules. This approach is particularly valuable for analyzing thermosensitive materials, protein stability, and polymer solutions where particle size distribution and molecular interactions are influenced by thermal conditions.

- Sample preparation and handling at controlled temperatures: Proper sample preparation and handling procedures are essential for temperature-controlled DLS experiments. Techniques include equilibration periods to ensure thermal stability before measurement, specialized sample cells or cuvettes designed for temperature regulation, and methods to prevent condensation or evaporation at extreme temperatures. Some systems incorporate automated sample handling that maintains temperature consistency from preparation through measurement to prevent thermal gradients or shock.

- Multi-temperature DLS analysis for material characterization: Multi-temperature DLS analysis involves measuring samples across a temperature range to generate comprehensive material profiles. This approach enables researchers to determine critical transition temperatures, activation energies, and thermodynamic parameters of colloidal systems. The technique is valuable for characterizing temperature-responsive materials, studying protein denaturation processes, and investigating the thermal stability of nanoparticle formulations by tracking how hydrodynamic radius changes with temperature.

- Integration of temperature sensors and calibration methods: Advanced DLS instruments incorporate precise temperature sensors positioned close to the sample to ensure accurate temperature monitoring. These systems often include calibration protocols to verify temperature accuracy and compensate for potential measurement errors. Some designs feature multiple temperature probes to detect thermal gradients within the sample chamber and implement correction algorithms to account for temperature-induced changes in solvent viscosity, which directly affects the calculation of particle size from diffusion coefficients.

02 Temperature-dependent particle characterization techniques

Temperature variation in DLS experiments allows for the characterization of temperature-dependent properties of particles and macromolecules. By systematically changing the sample temperature during measurement, researchers can study phase transitions, thermal stability, aggregation behavior, and conformational changes of proteins, polymers, and colloidal systems. These techniques enable the determination of critical transition temperatures and thermodynamic parameters that govern particle interactions in solution, providing valuable insights for formulation development and material characterization.Expand Specific Solutions03 Sample preparation and handling for temperature-sensitive DLS analysis

Proper sample preparation and handling procedures are crucial for temperature-sensitive DLS analysis. This includes methods for equilibrating samples at target temperatures before measurement, preventing temperature gradients within the sample cell, and minimizing condensation or evaporation effects during heating or cooling cycles. Specialized sample holders and cuvettes designed with materials having good thermal conductivity ensure uniform temperature distribution throughout the sample volume, while automated sample handling systems can maintain temperature control during sample transfer and measurement sequences.Expand Specific Solutions04 Multi-temperature DLS for biomolecular interaction studies

Multi-temperature DLS protocols enable detailed studies of biomolecular interactions and stability profiles across temperature ranges. These approaches are particularly valuable for protein formulation development, thermal stability screening, and characterization of temperature-induced aggregation pathways. By monitoring changes in hydrodynamic radius, polydispersity, and scattering intensity as a function of temperature, researchers can identify optimal storage conditions, predict shelf-life, and understand denaturation mechanisms for biopharmaceuticals and other temperature-sensitive materials.Expand Specific Solutions05 Integration of temperature sensors and feedback systems in DLS instruments

Modern DLS instruments incorporate sophisticated temperature sensors and feedback systems to achieve precise temperature control during measurements. These systems typically include multiple temperature probes positioned at strategic locations within the sample chamber and optical path to monitor and correct for temperature variations in real-time. Advanced algorithms process temperature data to make instantaneous adjustments to heating or cooling elements, ensuring temperature stability throughout extended measurement periods. Some instruments also feature temperature gradient capabilities for automated thermal ramping experiments and temperature-jump studies of kinetic processes.Expand Specific Solutions

Leading Manufacturers and Research Groups in DLS Technology

Dynamic Light Scattering (DLS) temperature control technology is in a mature growth phase, with a global market valued at approximately $400-500 million and growing at 5-7% annually. The competitive landscape features established leaders like Malvern Panalytical and Wyatt Technology who have developed sophisticated temperature control systems with precision down to 0.1°C. Mid-tier players including Agilent Technologies and Hitachi High-Tech offer integrated solutions, while specialized innovators such as Refeyn and Ningaloo Biosystems are advancing temperature-sensitive applications for biopharmaceuticals. Academic institutions like Swiss Federal Institute of Technology and Shandong University contribute fundamental research, pushing the technology toward applications in complex biological systems and nanomaterials characterization where precise temperature control is critical for accurate molecular dynamics measurements.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed advanced temperature control systems for their dynamic light scattering (DLS) instruments, particularly in their Zetasizer series. Their technology employs Peltier elements that provide precise temperature control from 0°C to 90°C with accuracy of ±0.1°C. The system includes pre-equilibration protocols that ensure samples reach thermal equilibrium before measurements begin, critical for temperature-sensitive samples like proteins and polymers. Their NanoSampler accessory allows for automated temperature trend analysis across multiple samples, enabling temperature-dependent characterization of particle size distributions and molecular interactions. The company has also implemented temperature ramping capabilities that can perform measurements at programmed intervals during heating or cooling cycles, providing insights into thermal stability and aggregation behavior of colloidal systems.

Strengths: Exceptional temperature precision (±0.1°C) and wide temperature range capability. Their systems feature built-in equilibration verification to ensure measurement accuracy. Weaknesses: Higher cost compared to simpler systems, and the advanced temperature control features require significant power consumption, potentially limiting portability for field applications.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has pioneered temperature control in DLS through their DynaPro® NanoStar® and DynaPro® Plate Reader instruments. Their approach integrates temperature management directly into the optical bench design, utilizing a combination of liquid circulation systems and precision electronic temperature controllers that maintain stability within ±0.05°C over extended measurement periods. The company's DYNAMICS® software includes temperature-dependent analysis algorithms that automatically compensate for viscosity changes with temperature, ensuring accurate size determinations across varying conditions. For high-throughput applications, their plate reader technology incorporates individual well temperature monitoring to detect and correct for well-to-well variations. Wyatt has also developed specialized low-volume quartz cuvettes with enhanced thermal conductivity properties to ensure rapid temperature equilibration even with minimal sample volumes (as little as 1.25 μL), addressing a critical challenge in protein and biopharmaceutical analysis.

Strengths: Superior temperature stability (±0.05°C) and specialized solutions for microvolume samples. Their software automatically adjusts for temperature effects on solvent properties. Weaknesses: Their high-precision temperature control systems add complexity to instrument operation and maintenance, potentially requiring more specialized user training.

Key Technical Innovations in DLS Temperature Management

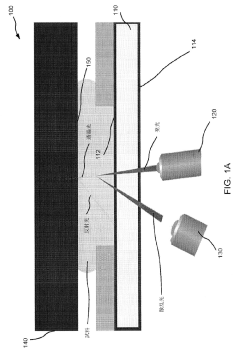

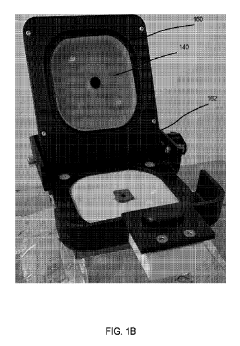

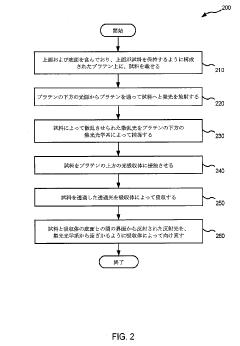

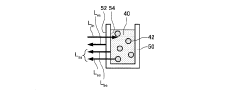

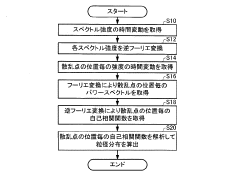

Measurement of dynamic light scattering of samples

PatentInactiveJP2023541897A

Innovation

- An apparatus and method that utilize a platen with polished optical surfaces, a light source, collection optics, and a light absorber to capture scattered light and redirect reflected light away from the optical system, ensuring a controlled light path and minimizing interference, while allowing for precise temperature control and small sample volumes.

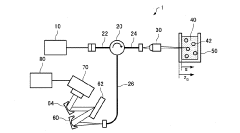

Dynamic light scattering measurement device and dynamic light scattering measurement method

PatentInactiveJP2016006397A

Innovation

- The device and method incorporate a reference surface on the optical path of the light irradiating the sample, allowing reflected light from the reference surface and scattered light from the sample to propagate along the same path, reducing vulnerability to disturbances and eliminating the need for optical path difference adjustment.

Thermal Stability Impact on DLS Measurement Accuracy

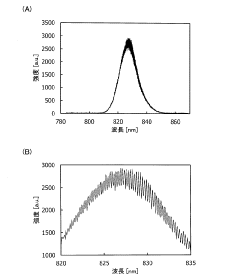

Temperature stability represents a critical factor in the accuracy and reliability of Dynamic Light Scattering (DLS) measurements. The Brownian motion of particles, which forms the fundamental basis for DLS analysis, is directly influenced by thermal energy. Even minor temperature fluctuations can significantly alter the diffusion coefficient of particles in solution, leading to substantial measurement errors and inconsistent results.

When temperature increases, particles move more rapidly due to higher kinetic energy, resulting in faster diffusion rates. Conversely, temperature decreases slow particle movement. This temperature-dependent behavior creates a fundamental challenge for DLS measurements, as the technique relies on precise correlation of scattered light intensity fluctuations over time to determine particle size distributions.

Research has demonstrated that a temperature variation of just 1°C can cause measurement deviations of 2-5% in calculated hydrodynamic diameter values. For applications requiring high precision, such as pharmaceutical formulation characterization or nanoparticle synthesis quality control, this level of variability can lead to erroneous conclusions about sample properties and stability.

Temperature gradients within the sample cell present another significant challenge. Non-uniform temperature distribution can create convection currents that introduce artificial motion patterns unrelated to Brownian movement. These convection effects are particularly problematic for samples containing larger particles (>500nm), where thermally-induced fluid flow can mask the natural diffusion behavior being measured.

The viscosity of the dispersing medium, a parameter directly incorporated into the Stokes-Einstein equation used for DLS calculations, also exhibits strong temperature dependence. Without precise temperature control and accurate viscosity compensation algorithms, the calculated particle sizes will contain systematic errors that compromise data interpretation.

For temperature-sensitive samples such as protein solutions, liposomes, or certain polymer dispersions, measurement accuracy becomes even more challenging. These systems may undergo structural changes, aggregation, or phase transitions within narrow temperature ranges, fundamentally altering the scattering properties during measurement if thermal stability is not maintained.

Modern DLS instruments incorporate sophisticated temperature control systems, typically achieving stability of ±0.1°C or better. However, achieving true thermal equilibrium throughout the entire sample volume remains challenging, particularly for samples with high thermal mass or those requiring measurements at temperatures significantly different from ambient conditions.

When temperature increases, particles move more rapidly due to higher kinetic energy, resulting in faster diffusion rates. Conversely, temperature decreases slow particle movement. This temperature-dependent behavior creates a fundamental challenge for DLS measurements, as the technique relies on precise correlation of scattered light intensity fluctuations over time to determine particle size distributions.

Research has demonstrated that a temperature variation of just 1°C can cause measurement deviations of 2-5% in calculated hydrodynamic diameter values. For applications requiring high precision, such as pharmaceutical formulation characterization or nanoparticle synthesis quality control, this level of variability can lead to erroneous conclusions about sample properties and stability.

Temperature gradients within the sample cell present another significant challenge. Non-uniform temperature distribution can create convection currents that introduce artificial motion patterns unrelated to Brownian movement. These convection effects are particularly problematic for samples containing larger particles (>500nm), where thermally-induced fluid flow can mask the natural diffusion behavior being measured.

The viscosity of the dispersing medium, a parameter directly incorporated into the Stokes-Einstein equation used for DLS calculations, also exhibits strong temperature dependence. Without precise temperature control and accurate viscosity compensation algorithms, the calculated particle sizes will contain systematic errors that compromise data interpretation.

For temperature-sensitive samples such as protein solutions, liposomes, or certain polymer dispersions, measurement accuracy becomes even more challenging. These systems may undergo structural changes, aggregation, or phase transitions within narrow temperature ranges, fundamentally altering the scattering properties during measurement if thermal stability is not maintained.

Modern DLS instruments incorporate sophisticated temperature control systems, typically achieving stability of ±0.1°C or better. However, achieving true thermal equilibrium throughout the entire sample volume remains challenging, particularly for samples with high thermal mass or those requiring measurements at temperatures significantly different from ambient conditions.

Integration of Advanced Materials in DLS Temperature Systems

The integration of advanced materials in DLS temperature control systems represents a significant frontier in enhancing measurement precision and expanding application capabilities. Recent developments in nanomaterials have revolutionized thermal management in DLS instruments, with graphene-based components demonstrating superior thermal conductivity properties. These materials facilitate more rapid temperature transitions and stabilization, critical for studying temperature-dependent phenomena in colloidal systems.

Ceramic-polymer composites have emerged as particularly valuable for DLS sample holders, offering excellent thermal stability while maintaining the optical clarity necessary for accurate light scattering measurements. These composites minimize thermal gradients across samples, addressing one of the persistent challenges in temperature-controlled DLS experiments.

Thermally responsive polymers represent another innovative material class being incorporated into DLS systems. These smart materials can change their properties in response to temperature variations, enabling novel approaches to temperature control. Some advanced systems utilize these polymers as active elements in feedback control mechanisms, providing more responsive and precise temperature regulation than conventional methods.

Metal-organic frameworks (MOFs) with tailored thermal properties are being explored for specialized DLS applications. Their highly ordered porous structures can be engineered to exhibit specific thermal behaviors, making them valuable for applications requiring precise temperature control in complex sample environments, such as biological specimens or temperature-sensitive nanomaterials.

Diamond-like carbon coatings on critical optical components have improved thermal stability in high-power DLS systems. These coatings minimize thermal distortion of optical elements while maintaining excellent light transmission properties, enhancing measurement reliability across wider temperature ranges.

Aerogel-based insulation materials are increasingly being incorporated into DLS temperature control systems to improve thermal isolation. Their extremely low thermal conductivity helps maintain stable sample temperatures by minimizing environmental influences, particularly important for measurements at extreme temperatures or in fluctuating ambient conditions.

The integration of phase-change materials (PCMs) represents a promising direction for passive temperature stabilization in portable DLS instruments. These materials can absorb or release thermal energy during phase transitions, helping to buffer temperature fluctuations without requiring continuous power input, thus extending operational capabilities in field applications or resource-limited settings.

Ceramic-polymer composites have emerged as particularly valuable for DLS sample holders, offering excellent thermal stability while maintaining the optical clarity necessary for accurate light scattering measurements. These composites minimize thermal gradients across samples, addressing one of the persistent challenges in temperature-controlled DLS experiments.

Thermally responsive polymers represent another innovative material class being incorporated into DLS systems. These smart materials can change their properties in response to temperature variations, enabling novel approaches to temperature control. Some advanced systems utilize these polymers as active elements in feedback control mechanisms, providing more responsive and precise temperature regulation than conventional methods.

Metal-organic frameworks (MOFs) with tailored thermal properties are being explored for specialized DLS applications. Their highly ordered porous structures can be engineered to exhibit specific thermal behaviors, making them valuable for applications requiring precise temperature control in complex sample environments, such as biological specimens or temperature-sensitive nanomaterials.

Diamond-like carbon coatings on critical optical components have improved thermal stability in high-power DLS systems. These coatings minimize thermal distortion of optical elements while maintaining excellent light transmission properties, enhancing measurement reliability across wider temperature ranges.

Aerogel-based insulation materials are increasingly being incorporated into DLS temperature control systems to improve thermal isolation. Their extremely low thermal conductivity helps maintain stable sample temperatures by minimizing environmental influences, particularly important for measurements at extreme temperatures or in fluctuating ambient conditions.

The integration of phase-change materials (PCMs) represents a promising direction for passive temperature stabilization in portable DLS instruments. These materials can absorb or release thermal energy during phase transitions, helping to buffer temperature fluctuations without requiring continuous power input, thus extending operational capabilities in field applications or resource-limited settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!