How to Outline Calibration Protocols for Dynamic Light Scattering

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Calibration Background and Objectives

Dynamic Light Scattering (DLS) has emerged as a cornerstone technique in particle characterization since its development in the 1960s. The technology leverages the Brownian motion of particles in suspension to determine their size distribution by analyzing the fluctuations in scattered light intensity. Over the decades, DLS has evolved from basic correlation spectroscopy to sophisticated multi-angle systems with advanced algorithms, enabling increasingly precise measurements across diverse applications.

The evolution of DLS technology has been driven by growing demands in pharmaceutical development, nanotechnology, and materials science, where precise particle characterization is critical for product performance and safety. Recent technological advancements have expanded DLS capabilities to measure not only size but also zeta potential, molecular weight, and even particle shape information, making it an indispensable analytical tool in modern research and quality control environments.

Despite its widespread adoption, DLS calibration remains a significant challenge in ensuring measurement accuracy and reproducibility. Calibration protocols have historically lacked standardization across different instrument manufacturers and laboratories, leading to inconsistencies in reported results and difficulties in cross-laboratory comparisons. This technical gap has become increasingly problematic as regulatory requirements for nanomaterials and biopharmaceuticals have become more stringent.

The primary objective of establishing comprehensive DLS calibration protocols is to ensure measurement traceability to international standards while accommodating the diverse range of sample types and experimental conditions encountered in practical applications. These protocols must address fundamental aspects including instrument performance verification, size standard selection, measurement parameter optimization, and data quality assessment.

Additionally, calibration protocols must account for the inherent limitations of DLS technology, such as its sensitivity to dust contamination, sample polydispersity, and concentration effects. Modern protocols need to incorporate strategies for identifying and mitigating these potential sources of measurement error to enhance overall data reliability.

Looking forward, the development of robust calibration protocols will need to anticipate emerging trends in DLS technology, including multi-detector systems, machine learning algorithms for data interpretation, and integration with complementary techniques. The ultimate goal is to establish a framework that not only ensures current measurement quality but also remains adaptable to technological innovations and expanding application domains.

Through systematic calibration approaches, researchers and industry professionals can maximize the valuable insights provided by DLS while maintaining confidence in the accuracy and comparability of their results across different instruments, operators, and laboratories.

The evolution of DLS technology has been driven by growing demands in pharmaceutical development, nanotechnology, and materials science, where precise particle characterization is critical for product performance and safety. Recent technological advancements have expanded DLS capabilities to measure not only size but also zeta potential, molecular weight, and even particle shape information, making it an indispensable analytical tool in modern research and quality control environments.

Despite its widespread adoption, DLS calibration remains a significant challenge in ensuring measurement accuracy and reproducibility. Calibration protocols have historically lacked standardization across different instrument manufacturers and laboratories, leading to inconsistencies in reported results and difficulties in cross-laboratory comparisons. This technical gap has become increasingly problematic as regulatory requirements for nanomaterials and biopharmaceuticals have become more stringent.

The primary objective of establishing comprehensive DLS calibration protocols is to ensure measurement traceability to international standards while accommodating the diverse range of sample types and experimental conditions encountered in practical applications. These protocols must address fundamental aspects including instrument performance verification, size standard selection, measurement parameter optimization, and data quality assessment.

Additionally, calibration protocols must account for the inherent limitations of DLS technology, such as its sensitivity to dust contamination, sample polydispersity, and concentration effects. Modern protocols need to incorporate strategies for identifying and mitigating these potential sources of measurement error to enhance overall data reliability.

Looking forward, the development of robust calibration protocols will need to anticipate emerging trends in DLS technology, including multi-detector systems, machine learning algorithms for data interpretation, and integration with complementary techniques. The ultimate goal is to establish a framework that not only ensures current measurement quality but also remains adaptable to technological innovations and expanding application domains.

Through systematic calibration approaches, researchers and industry professionals can maximize the valuable insights provided by DLS while maintaining confidence in the accuracy and comparability of their results across different instruments, operators, and laboratories.

Market Analysis for DLS Calibration Solutions

The Dynamic Light Scattering (DLS) calibration solutions market has experienced significant growth over the past decade, driven primarily by increasing demand for accurate nanoparticle characterization across various industries. The global market value for DLS instrumentation and calibration materials reached approximately $320 million in 2022, with a compound annual growth rate of 6.8% projected through 2028.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for nearly 45% of the total market share. This dominance stems from stringent regulatory requirements for nanoparticle-based drug delivery systems and protein formulations, where precise size distribution measurements are critical for product quality and efficacy.

Academic and research institutions constitute the second-largest market segment at 25%, followed by material science applications at 15%. Environmental monitoring and food safety applications, while smaller segments currently, are showing the fastest growth rates as regulatory frameworks evolve to address nanomaterial safety concerns.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding pharmaceutical manufacturing capabilities and increasing research investments.

Customer needs analysis reveals three primary market drivers: regulatory compliance, research accuracy, and manufacturing quality control. End-users consistently prioritize traceability to international standards, measurement reproducibility, and system-to-system comparability as key purchasing factors for calibration solutions.

Price sensitivity varies significantly by segment, with industrial users willing to pay premium prices for solutions with comprehensive certification documentation, while academic users often seek more economical options. The average price point for standard DLS calibration kits ranges from $800 to $2,500, depending on certification level and particle composition.

Market competition analysis identifies approximately 15 significant suppliers, with three dominant players controlling nearly 60% of the global market. These established companies leverage their instrument manufacturing capabilities to offer proprietary calibration solutions, creating substantial entry barriers for new competitors.

Emerging market opportunities include the development of application-specific calibration standards for challenging sample types (high-concentration protein solutions, complex biological fluids) and multi-parameter reference materials that simultaneously calibrate size, concentration, and zeta potential measurements.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for nearly 45% of the total market share. This dominance stems from stringent regulatory requirements for nanoparticle-based drug delivery systems and protein formulations, where precise size distribution measurements are critical for product quality and efficacy.

Academic and research institutions constitute the second-largest market segment at 25%, followed by material science applications at 15%. Environmental monitoring and food safety applications, while smaller segments currently, are showing the fastest growth rates as regulatory frameworks evolve to address nanomaterial safety concerns.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding pharmaceutical manufacturing capabilities and increasing research investments.

Customer needs analysis reveals three primary market drivers: regulatory compliance, research accuracy, and manufacturing quality control. End-users consistently prioritize traceability to international standards, measurement reproducibility, and system-to-system comparability as key purchasing factors for calibration solutions.

Price sensitivity varies significantly by segment, with industrial users willing to pay premium prices for solutions with comprehensive certification documentation, while academic users often seek more economical options. The average price point for standard DLS calibration kits ranges from $800 to $2,500, depending on certification level and particle composition.

Market competition analysis identifies approximately 15 significant suppliers, with three dominant players controlling nearly 60% of the global market. These established companies leverage their instrument manufacturing capabilities to offer proprietary calibration solutions, creating substantial entry barriers for new competitors.

Emerging market opportunities include the development of application-specific calibration standards for challenging sample types (high-concentration protein solutions, complex biological fluids) and multi-parameter reference materials that simultaneously calibrate size, concentration, and zeta potential measurements.

Current Challenges in DLS Calibration Protocols

Despite significant advancements in Dynamic Light Scattering (DLS) technology, the field continues to face substantial challenges in establishing standardized calibration protocols. One of the primary obstacles is the inherent sensitivity of DLS measurements to environmental factors such as temperature fluctuations, sample contamination, and vibration interference. These variables can significantly impact measurement accuracy, making consistent calibration across different laboratory environments exceptionally difficult.

The lack of universally accepted reference materials presents another critical challenge. While polystyrene latex spheres are commonly used, their long-term stability and batch-to-batch consistency remain problematic. Additionally, these materials may not adequately represent the diverse range of samples analyzed in various industries, from pharmaceuticals to nanomaterials research, limiting their effectiveness as universal calibration standards.

Instrument-to-instrument variability further complicates calibration efforts. Different DLS systems from various manufacturers employ distinct optical configurations, detection methods, and data processing algorithms. This heterogeneity creates significant challenges in establishing cross-platform calibration protocols that can produce comparable results across different instruments, hindering data reproducibility and interlaboratory studies.

The complexity of data interpretation and analysis algorithms represents another significant hurdle. Current DLS systems utilize proprietary algorithms for converting correlation functions into particle size distributions, creating a "black box" effect where users have limited understanding of how raw data is processed. This opacity complicates efforts to standardize calibration approaches and validate measurement accuracy across platforms.

Time-dependent sample changes during measurement pose additional challenges for calibration protocols. Many biological and colloidal samples exhibit dynamic behaviors such as aggregation, sedimentation, or degradation during analysis. These temporal variations make it difficult to establish stable reference points for calibration and validation procedures.

Regulatory frameworks across different industries and regions lack harmonization regarding DLS calibration requirements. This regulatory fragmentation creates confusion and inefficiency, particularly for organizations operating globally or across multiple sectors with varying compliance standards.

The increasing application of DLS to complex, heterogeneous samples (such as biological fluids, food products, and environmental samples) further strains existing calibration approaches. Traditional calibration methods developed for monodisperse, spherical particles often prove inadequate for these complex systems, necessitating more sophisticated calibration strategies that can account for sample polydispersity and non-spherical particle geometries.

The lack of universally accepted reference materials presents another critical challenge. While polystyrene latex spheres are commonly used, their long-term stability and batch-to-batch consistency remain problematic. Additionally, these materials may not adequately represent the diverse range of samples analyzed in various industries, from pharmaceuticals to nanomaterials research, limiting their effectiveness as universal calibration standards.

Instrument-to-instrument variability further complicates calibration efforts. Different DLS systems from various manufacturers employ distinct optical configurations, detection methods, and data processing algorithms. This heterogeneity creates significant challenges in establishing cross-platform calibration protocols that can produce comparable results across different instruments, hindering data reproducibility and interlaboratory studies.

The complexity of data interpretation and analysis algorithms represents another significant hurdle. Current DLS systems utilize proprietary algorithms for converting correlation functions into particle size distributions, creating a "black box" effect where users have limited understanding of how raw data is processed. This opacity complicates efforts to standardize calibration approaches and validate measurement accuracy across platforms.

Time-dependent sample changes during measurement pose additional challenges for calibration protocols. Many biological and colloidal samples exhibit dynamic behaviors such as aggregation, sedimentation, or degradation during analysis. These temporal variations make it difficult to establish stable reference points for calibration and validation procedures.

Regulatory frameworks across different industries and regions lack harmonization regarding DLS calibration requirements. This regulatory fragmentation creates confusion and inefficiency, particularly for organizations operating globally or across multiple sectors with varying compliance standards.

The increasing application of DLS to complex, heterogeneous samples (such as biological fluids, food products, and environmental samples) further strains existing calibration approaches. Traditional calibration methods developed for monodisperse, spherical particles often prove inadequate for these complex systems, necessitating more sophisticated calibration strategies that can account for sample polydispersity and non-spherical particle geometries.

Standard DLS Calibration Approaches

01 Standard calibration methods for DLS instruments

Standard calibration protocols for Dynamic Light Scattering (DLS) instruments involve the use of reference materials with known particle sizes to verify instrument accuracy and precision. These protocols typically include measurement of polystyrene latex standards or other certified reference materials under controlled conditions. The calibration process ensures that the instrument can accurately measure particle size distributions across the intended measurement range and helps establish traceability to recognized standards.- Standardization and calibration methods for DLS instruments: Dynamic Light Scattering (DLS) instruments require standardized calibration protocols to ensure accurate and reproducible measurements. These protocols typically involve the use of reference materials with known particle sizes to calibrate the instrument's detection system. The calibration process includes verification of the scattering angle, laser wavelength stability, and detector response. Regular calibration helps maintain measurement accuracy and allows for comparison of results between different instruments.

- Reference materials for DLS calibration: Specific reference materials are essential for accurate calibration of Dynamic Light Scattering systems. These materials include monodisperse polystyrene latex spheres, silica nanoparticles, and gold colloids with certified size distributions. The ideal reference materials exhibit stability over time, have narrow size distributions, and produce strong scattering signals. Selection of appropriate reference standards depends on the size range being measured and the specific application requirements.

- Automated calibration systems for DLS: Advanced DLS instruments incorporate automated calibration systems that streamline the calibration process and reduce operator error. These systems can automatically perform multiple measurements of reference standards, analyze the results, and adjust instrument parameters accordingly. Automated calibration may include temperature control verification, optical alignment checks, and detector sensitivity adjustments. Such systems often include software that guides users through the calibration procedure and maintains calibration records for quality assurance purposes.

- Multi-angle DLS calibration techniques: Multi-angle Dynamic Light Scattering systems require specialized calibration protocols that account for measurements at various scattering angles. These techniques involve calibrating each detection angle independently using appropriate standards and then verifying the consistency of measurements across all angles. The calibration process ensures that size measurements remain consistent regardless of the detection angle used. This approach is particularly important for characterizing non-spherical particles or complex mixtures where angular dependence provides additional structural information.

- Quality control and validation procedures for DLS measurements: Comprehensive quality control and validation procedures are essential components of DLS calibration protocols. These procedures include regular performance verification using certified reference materials, system suitability tests before critical measurements, and statistical analysis of measurement reproducibility. Documentation of calibration history, maintenance records, and measurement conditions ensures traceability and compliance with regulatory requirements. Interlaboratory comparison studies may also be conducted to validate the calibration approach and ensure consistency across different facilities.

02 Automated calibration systems for DLS

Automated calibration systems for Dynamic Light Scattering incorporate software algorithms and hardware components that streamline the calibration process. These systems can automatically adjust instrument parameters, perform reference measurements, and apply correction factors without significant user intervention. Automated calibration reduces human error, improves reproducibility, and enables more frequent calibration checks to maintain instrument performance over time.Expand Specific Solutions03 Temperature control in DLS calibration

Temperature control is critical in Dynamic Light Scattering calibration protocols as particle Brownian motion, which is the basis for size determination, is temperature-dependent. Calibration procedures must include precise temperature regulation systems to maintain sample stability and ensure measurement accuracy. Advanced protocols incorporate temperature verification steps, equilibration periods, and compensation algorithms to account for temperature effects on viscosity and diffusion coefficients.Expand Specific Solutions04 Multi-angle DLS calibration techniques

Multi-angle Dynamic Light Scattering calibration techniques involve performing measurements at various scattering angles to improve accuracy and extend the measurable size range. These protocols require calibration of each detection angle using appropriate standards and correlation of results across angles. Multi-angle calibration helps characterize non-spherical particles, polydisperse samples, and provides more comprehensive data validation compared to single-angle measurements.Expand Specific Solutions05 Validation and quality control for DLS measurements

Validation and quality control protocols for Dynamic Light Scattering ensure ongoing measurement reliability through systematic verification procedures. These include regular performance checks using reference materials, statistical analysis of measurement repeatability, and instrument response monitoring. Comprehensive validation protocols establish acceptance criteria for calibration results, define recalibration intervals, and include procedures for identifying and addressing instrument drift or malfunction.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Dynamic Light Scattering (DLS) calibration protocol development is currently in a growth phase, with the market expanding due to increasing applications in pharmaceutical, biotechnology, and materials science sectors. The global DLS market shows robust growth potential, estimated to reach significant value by 2030. Technologically, the field demonstrates varying maturity levels across different players. Companies like ASML Netherlands BV and Tokyo Electron Ltd. lead with advanced optical measurement technologies, while Malvern Panalytical (part of Spectris) remains the industry benchmark. Academic institutions such as South China Normal University and Xidian University contribute fundamental research. Emerging players include SYNCELL and trinamiX GmbH, who are developing innovative approaches to DLS calibration. The competitive landscape features both established instrumentation companies and specialized startups focusing on niche applications and improved calibration methodologies.

The Regents of the University of California

Technical Solution: The University of California has developed a comprehensive calibration framework for dynamic light scattering that emphasizes metrological traceability and uncertainty quantification. Their protocol begins with a thorough characterization of the optical system, including precise measurement of the scattering angle using a goniometer with 0.1-degree accuracy and laser wavelength verification. They employ a multi-standard approach using NIST-traceable nanospheres of different sizes (typically 20nm, 100nm, and 500nm) to verify linearity across the measurement range. Their methodology incorporates rigorous uncertainty analysis following GUM (Guide to the Expression of Uncertainty in Measurement) principles, accounting for contributions from temperature fluctuations, detector noise, and digital correlator timing accuracy. For dynamic measurements, they've implemented a novel drift correction algorithm that compensates for slow temporal changes in the optical alignment. The protocol includes verification of the autocorrelation function baseline stability and tests for detector linearity across the dynamic range. Their calibration procedure also addresses multiple scattering effects through a concentration series measurement and extrapolation to infinite dilution.

Strengths: Exceptional metrological rigor with comprehensive uncertainty quantification provides high confidence in measurement accuracy. The multi-standard approach ensures reliability across different size ranges. Weaknesses: The extensive calibration procedure is time-consuming and requires advanced technical expertise, making it less practical for routine industrial applications.

Otsuka Electronics Co., Ltd.

Technical Solution: Otsuka Electronics has developed advanced calibration protocols for their DLS-8000 series instruments, focusing on automated multi-angle dynamic light scattering measurements. Their approach incorporates reference standard validation using NIST-traceable polystyrene latex spheres at precisely defined concentrations and temperatures. The protocol includes a three-stage calibration process: initial instrument verification using water as a standard reference material to establish baseline scattering intensity, followed by size calibration using monodisperse standards, and finally a concentration-dependent measurement series to account for multiple scattering effects. Their system automatically adjusts laser power and detector sensitivity based on sample characteristics, ensuring optimal signal-to-noise ratio across diverse sample types. The calibration data is processed through their proprietary algorithms that incorporate temperature compensation factors and viscosity corrections to ensure measurement accuracy across different environmental conditions.

Strengths: Highly automated calibration process reduces operator error and improves reproducibility. Multi-angle measurement capability provides more comprehensive particle characterization than single-angle systems. Weaknesses: Proprietary calibration standards may increase operational costs, and the complex calibration procedure requires specialized training for optimal results.

Key Technical Innovations in DLS Calibration

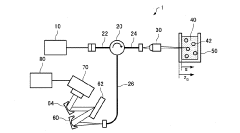

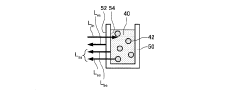

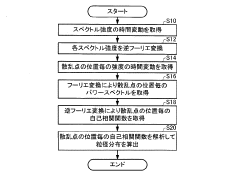

Dynamic light scattering measurement device and dynamic light scattering measurement method

PatentInactiveJP2016006397A

Innovation

- The device and method incorporate a reference surface on the optical path of the light irradiating the sample, allowing reflected light from the reference surface and scattered light from the sample to propagate along the same path, reducing vulnerability to disturbances and eliminating the need for optical path difference adjustment.

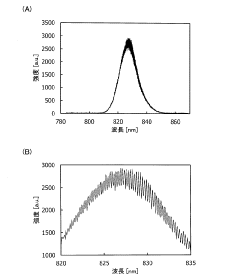

Dynamic light scattering measurement apparatus using phase modulation interference method

PatentInactiveUS7236250B2

Innovation

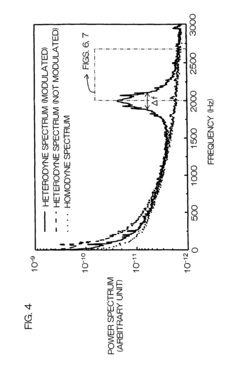

- A dynamic light scattering measurement apparatus using a low coherence light source and phase modulation interference method, where the light path length within the sample medium is normalized by the mean free path of particles to ensure that the light path length is not more than three times the mean free path, allowing for precise extraction of single scattering spectrum components from multiple scattering media.

International Standards and Compliance Requirements

Dynamic Light Scattering (DLS) calibration protocols must adhere to stringent international standards to ensure measurement reliability and cross-laboratory comparability. The International Organization for Standardization (ISO) has established several key standards specifically addressing DLS measurements, including ISO 22412:2017, which provides comprehensive guidelines for particle size analysis using dynamic light scattering methods. This standard outlines specific calibration requirements, acceptable reference materials, and validation procedures essential for accurate DLS measurements.

The American Society for Testing and Materials (ASTM) has developed complementary standards, particularly ASTM E2490, which details standard guide for measurement of particle size distribution of nanomaterials in suspension by photon correlation spectroscopy. These standards specify calibration frequency, environmental conditions, and performance verification protocols that manufacturers and laboratories must follow.

Regulatory bodies worldwide have incorporated these standards into their compliance frameworks. The European Medicines Agency (EMA) and the U.S. Food and Drug Administration (FDA) both reference ISO standards for DLS in their guidelines for characterization of nanomaterials in pharmaceutical applications. The FDA's Nanotechnology Task Force specifically recommends adherence to standardized calibration protocols for all DLS measurements used in regulatory submissions.

Japanese Industrial Standards (JIS) and Chinese National Standards (GB) have also adopted similar requirements, though with regional variations that must be considered when developing globally compliant calibration protocols. These variations primarily concern reporting requirements and uncertainty calculations rather than fundamental calibration methodologies.

International metrology organizations, including the National Institute of Standards and Technology (NIST) in the US and the National Physical Laboratory (NPL) in the UK, provide certified reference materials specifically designed for DLS calibration. These materials, typically consisting of monodisperse polystyrene latex spheres with precisely characterized size distributions, are essential components of any compliant calibration protocol.

The International Bureau of Weights and Measures (BIPM) coordinates international comparisons of DLS measurements to ensure global consistency. Participation in these comparison studies is increasingly becoming a requirement for laboratories seeking accreditation under ISO/IEC 17025 for DLS testing services. This standard specifies general requirements for the competence of testing and calibration laboratories, including specific provisions for equipment calibration traceability.

Emerging regulations for nanomaterials characterization, such as the EU's REACH regulation and similar frameworks in Canada and Australia, are increasingly specifying DLS as a required analytical technique, further emphasizing the importance of standardized calibration approaches that meet international requirements.

The American Society for Testing and Materials (ASTM) has developed complementary standards, particularly ASTM E2490, which details standard guide for measurement of particle size distribution of nanomaterials in suspension by photon correlation spectroscopy. These standards specify calibration frequency, environmental conditions, and performance verification protocols that manufacturers and laboratories must follow.

Regulatory bodies worldwide have incorporated these standards into their compliance frameworks. The European Medicines Agency (EMA) and the U.S. Food and Drug Administration (FDA) both reference ISO standards for DLS in their guidelines for characterization of nanomaterials in pharmaceutical applications. The FDA's Nanotechnology Task Force specifically recommends adherence to standardized calibration protocols for all DLS measurements used in regulatory submissions.

Japanese Industrial Standards (JIS) and Chinese National Standards (GB) have also adopted similar requirements, though with regional variations that must be considered when developing globally compliant calibration protocols. These variations primarily concern reporting requirements and uncertainty calculations rather than fundamental calibration methodologies.

International metrology organizations, including the National Institute of Standards and Technology (NIST) in the US and the National Physical Laboratory (NPL) in the UK, provide certified reference materials specifically designed for DLS calibration. These materials, typically consisting of monodisperse polystyrene latex spheres with precisely characterized size distributions, are essential components of any compliant calibration protocol.

The International Bureau of Weights and Measures (BIPM) coordinates international comparisons of DLS measurements to ensure global consistency. Participation in these comparison studies is increasingly becoming a requirement for laboratories seeking accreditation under ISO/IEC 17025 for DLS testing services. This standard specifies general requirements for the competence of testing and calibration laboratories, including specific provisions for equipment calibration traceability.

Emerging regulations for nanomaterials characterization, such as the EU's REACH regulation and similar frameworks in Canada and Australia, are increasingly specifying DLS as a required analytical technique, further emphasizing the importance of standardized calibration approaches that meet international requirements.

Validation Metrics and Performance Evaluation

Establishing robust validation metrics and performance evaluation frameworks is essential for ensuring the reliability of Dynamic Light Scattering (DLS) calibration protocols. The primary validation metrics for DLS systems include measurement accuracy, precision, reproducibility, and resolution capabilities. Accuracy can be quantified by comparing DLS measurements with reference materials of known size distributions, typically traceable to national or international standards. Precision metrics should evaluate both intra-day and inter-day variability, with coefficient of variation (CV) values below 5% generally considered acceptable for most applications.

Performance evaluation should incorporate linearity assessment across the instrument's claimed measurement range, typically from a few nanometers to several micrometers. This involves analyzing a series of size standards at different concentrations to establish the linear dynamic range and determine the limits of detection and quantification. Signal-to-noise ratio (SNR) calculations provide valuable insights into the instrument's sensitivity, particularly for samples with low scattering intensity or polydisperse populations.

Resolution testing represents another critical validation parameter, typically assessed using bimodal or multimodal particle mixtures with known size ratios. The ability to resolve closely spaced particle populations (peak resolution) directly impacts the instrument's practical utility in complex sample analysis. Modern DLS systems should demonstrate resolution capabilities of distinguishing populations with diameter ratios of approximately 1:3 or better.

Statistical robustness evaluations must be incorporated into validation protocols, including assessments of measurement uncertainty and confidence intervals. This involves multiple replicate measurements under varying conditions to establish statistical significance and identify potential sources of systematic error. Bland-Altman analysis can be particularly useful when comparing different DLS instruments or methodologies.

Long-term stability monitoring represents an often-overlooked aspect of performance evaluation. Tracking the measurement drift of reference standards over extended periods helps identify gradual system deterioration or calibration shifts. Implementation of control charts with defined action and warning limits enables systematic monitoring of instrument performance and facilitates timely intervention when deviations occur.

Cross-validation with orthogonal techniques such as electron microscopy, nanoparticle tracking analysis, or analytical ultracentrifugation provides additional confidence in DLS calibration protocols. While perfect agreement between different methodologies is rarely achieved due to fundamental measurement principles, consistent trends and correlations should be established to verify the validity of DLS results across diverse sample types.

Performance evaluation should incorporate linearity assessment across the instrument's claimed measurement range, typically from a few nanometers to several micrometers. This involves analyzing a series of size standards at different concentrations to establish the linear dynamic range and determine the limits of detection and quantification. Signal-to-noise ratio (SNR) calculations provide valuable insights into the instrument's sensitivity, particularly for samples with low scattering intensity or polydisperse populations.

Resolution testing represents another critical validation parameter, typically assessed using bimodal or multimodal particle mixtures with known size ratios. The ability to resolve closely spaced particle populations (peak resolution) directly impacts the instrument's practical utility in complex sample analysis. Modern DLS systems should demonstrate resolution capabilities of distinguishing populations with diameter ratios of approximately 1:3 or better.

Statistical robustness evaluations must be incorporated into validation protocols, including assessments of measurement uncertainty and confidence intervals. This involves multiple replicate measurements under varying conditions to establish statistical significance and identify potential sources of systematic error. Bland-Altman analysis can be particularly useful when comparing different DLS instruments or methodologies.

Long-term stability monitoring represents an often-overlooked aspect of performance evaluation. Tracking the measurement drift of reference standards over extended periods helps identify gradual system deterioration or calibration shifts. Implementation of control charts with defined action and warning limits enables systematic monitoring of instrument performance and facilitates timely intervention when deviations occur.

Cross-validation with orthogonal techniques such as electron microscopy, nanoparticle tracking analysis, or analytical ultracentrifugation provides additional confidence in DLS calibration protocols. While perfect agreement between different methodologies is rarely achieved due to fundamental measurement principles, consistent trends and correlations should be established to verify the validity of DLS results across diverse sample types.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!