Dynamic Light Scattering for Studying Aqueous Phase Reactions

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Objectives

Dynamic Light Scattering (DLS) has evolved significantly since its theoretical foundations were established in the early 20th century through the work of Einstein and Smoluchowski on Brownian motion. The technique gained practical application in the 1960s with the advent of laser technology, which provided the coherent light source necessary for precise measurements. Over subsequent decades, DLS has transformed from a specialized academic tool into a versatile analytical method widely employed across multiple scientific disciplines.

The fundamental principle of DLS involves measuring the time-dependent fluctuations in scattered light intensity caused by particles undergoing Brownian motion in solution. These fluctuations contain valuable information about particle size, molecular interactions, and reaction kinetics in aqueous environments. Modern DLS systems can detect particles ranging from sub-nanometer to several micrometers in diameter, making the technique exceptionally versatile for studying diverse aqueous phase reactions.

Recent technological advancements have significantly enhanced DLS capabilities, particularly through improvements in detection sensitivity, data processing algorithms, and integration with complementary techniques. The development of multi-angle DLS systems has enabled more comprehensive characterization of complex samples, while advances in correlator technology have improved temporal resolution for studying fast reaction kinetics.

The primary technical objective in applying DLS to aqueous phase reactions is to monitor reaction progress in real-time by tracking changes in particle size distribution, concentration, or aggregation state. This non-invasive approach offers distinct advantages over traditional sampling methods, as it allows continuous observation of reaction dynamics without disturbing the system under investigation.

Another critical goal is to enhance the specificity and sensitivity of DLS for detecting subtle changes in molecular interactions during aqueous reactions. This includes improving signal-to-noise ratios, developing more sophisticated data analysis algorithms, and establishing standardized protocols for specific reaction types.

The integration of DLS with other analytical techniques represents an important trend in the field. Combining DLS with spectroscopic methods, microscopy, or chromatography creates powerful hybrid approaches that provide multidimensional insights into reaction mechanisms. These integrated systems aim to correlate particle size changes with chemical transformations, offering a more complete understanding of aqueous phase reaction pathways.

Looking forward, the technical trajectory of DLS is moving toward miniaturization, automation, and increased accessibility. Emerging microfluidic DLS platforms promise to reduce sample volumes and enable high-throughput screening of reaction conditions, while advances in artificial intelligence and machine learning are enhancing data interpretation capabilities, particularly for complex, multicomponent systems.

The fundamental principle of DLS involves measuring the time-dependent fluctuations in scattered light intensity caused by particles undergoing Brownian motion in solution. These fluctuations contain valuable information about particle size, molecular interactions, and reaction kinetics in aqueous environments. Modern DLS systems can detect particles ranging from sub-nanometer to several micrometers in diameter, making the technique exceptionally versatile for studying diverse aqueous phase reactions.

Recent technological advancements have significantly enhanced DLS capabilities, particularly through improvements in detection sensitivity, data processing algorithms, and integration with complementary techniques. The development of multi-angle DLS systems has enabled more comprehensive characterization of complex samples, while advances in correlator technology have improved temporal resolution for studying fast reaction kinetics.

The primary technical objective in applying DLS to aqueous phase reactions is to monitor reaction progress in real-time by tracking changes in particle size distribution, concentration, or aggregation state. This non-invasive approach offers distinct advantages over traditional sampling methods, as it allows continuous observation of reaction dynamics without disturbing the system under investigation.

Another critical goal is to enhance the specificity and sensitivity of DLS for detecting subtle changes in molecular interactions during aqueous reactions. This includes improving signal-to-noise ratios, developing more sophisticated data analysis algorithms, and establishing standardized protocols for specific reaction types.

The integration of DLS with other analytical techniques represents an important trend in the field. Combining DLS with spectroscopic methods, microscopy, or chromatography creates powerful hybrid approaches that provide multidimensional insights into reaction mechanisms. These integrated systems aim to correlate particle size changes with chemical transformations, offering a more complete understanding of aqueous phase reaction pathways.

Looking forward, the technical trajectory of DLS is moving toward miniaturization, automation, and increased accessibility. Emerging microfluidic DLS platforms promise to reduce sample volumes and enable high-throughput screening of reaction conditions, while advances in artificial intelligence and machine learning are enhancing data interpretation capabilities, particularly for complex, multicomponent systems.

Market Applications in Aqueous Reaction Analysis

Dynamic Light Scattering (DLS) technology has established itself as a powerful analytical tool across multiple market segments where aqueous reaction analysis is critical. The pharmaceutical industry represents one of the largest application markets, utilizing DLS for protein aggregation studies, drug formulation stability, and quality control processes. This sector values DLS for its ability to detect subtle changes in particle size distribution during drug development, enabling researchers to optimize formulation conditions and predict shelf-life stability.

The biotechnology market has similarly embraced DLS technology for enzyme kinetics monitoring, biomolecular interaction studies, and characterization of biological macromolecules in solution. The non-invasive nature of DLS makes it particularly valuable for analyzing sensitive biological samples without disrupting their natural state, providing real-time insights into reaction dynamics that would be unattainable through traditional analytical methods.

Environmental monitoring represents a rapidly growing application area, where DLS enables the tracking of colloidal particles in natural water systems, assessment of water treatment processes, and monitoring of pollutant degradation reactions. Regulatory agencies and water treatment facilities increasingly rely on DLS data to verify compliance with environmental standards and optimize remediation strategies.

The materials science sector leverages DLS for studying polymerization reactions, sol-gel transitions, and nanoparticle synthesis in aqueous environments. This application has proven essential for industries developing advanced materials with precisely controlled properties, as it allows for real-time monitoring of particle growth and agglomeration during synthesis processes.

Academic research institutions constitute another significant market segment, utilizing DLS across diverse fields including physical chemistry, biochemistry, and colloid science. The versatility of DLS in studying various reaction types has made it a staple instrument in research laboratories worldwide, driving continuous innovation in experimental methodologies.

The food and beverage industry has also found valuable applications for DLS in studying emulsion stability, protein aggregation in food products, and quality control processes. Manufacturers use this technology to develop products with improved shelf-life and consistent sensory properties by monitoring molecular interactions in complex food matrices.

As industries continue to demand higher precision in understanding aqueous reaction mechanisms, the market for advanced DLS instrumentation and specialized software solutions continues to expand, with particular growth observed in integrated systems that combine DLS with complementary analytical techniques for comprehensive reaction characterization.

The biotechnology market has similarly embraced DLS technology for enzyme kinetics monitoring, biomolecular interaction studies, and characterization of biological macromolecules in solution. The non-invasive nature of DLS makes it particularly valuable for analyzing sensitive biological samples without disrupting their natural state, providing real-time insights into reaction dynamics that would be unattainable through traditional analytical methods.

Environmental monitoring represents a rapidly growing application area, where DLS enables the tracking of colloidal particles in natural water systems, assessment of water treatment processes, and monitoring of pollutant degradation reactions. Regulatory agencies and water treatment facilities increasingly rely on DLS data to verify compliance with environmental standards and optimize remediation strategies.

The materials science sector leverages DLS for studying polymerization reactions, sol-gel transitions, and nanoparticle synthesis in aqueous environments. This application has proven essential for industries developing advanced materials with precisely controlled properties, as it allows for real-time monitoring of particle growth and agglomeration during synthesis processes.

Academic research institutions constitute another significant market segment, utilizing DLS across diverse fields including physical chemistry, biochemistry, and colloid science. The versatility of DLS in studying various reaction types has made it a staple instrument in research laboratories worldwide, driving continuous innovation in experimental methodologies.

The food and beverage industry has also found valuable applications for DLS in studying emulsion stability, protein aggregation in food products, and quality control processes. Manufacturers use this technology to develop products with improved shelf-life and consistent sensory properties by monitoring molecular interactions in complex food matrices.

As industries continue to demand higher precision in understanding aqueous reaction mechanisms, the market for advanced DLS instrumentation and specialized software solutions continues to expand, with particular growth observed in integrated systems that combine DLS with complementary analytical techniques for comprehensive reaction characterization.

Current Capabilities and Technical Limitations

Dynamic Light Scattering (DLS) technology has evolved significantly in recent years, offering powerful capabilities for studying aqueous phase reactions. Current DLS systems can detect particles ranging from approximately 0.3 nm to 10 μm in diameter, making them suitable for analyzing a wide spectrum of molecular interactions and particle formations in aqueous solutions. Modern instruments achieve temporal resolution down to milliseconds, enabling real-time monitoring of reaction kinetics and transient intermediates during chemical transformations.

Advanced DLS systems now incorporate multi-angle detection capabilities, allowing for more accurate characterization of non-spherical particles and complex assemblies. This represents a significant improvement over traditional single-angle measurements that often provided incomplete structural information. Additionally, temperature control systems have been refined to maintain stability within ±0.1°C, crucial for studying temperature-dependent reaction mechanisms and thermodynamic parameters.

Despite these advancements, DLS faces several technical limitations when applied to aqueous phase reactions. Polydisperse samples remain challenging to analyze accurately, as the scattering intensity's strong dependence on particle size (proportional to d^6) causes larger particles to dominate the signal, potentially obscuring smaller reaction components. This becomes particularly problematic when studying reactions that generate products with broad size distributions.

Concentration sensitivity presents another significant limitation. DLS typically requires minimum concentrations of 0.1 mg/mL for proteins and similar macromolecules, which may exceed physiologically relevant conditions for many biochemical reactions. Conversely, high concentration samples can introduce multiple scattering effects that complicate data interpretation and reduce measurement accuracy.

Environmental factors substantially impact measurement reliability. Dust particles and microscopic contaminants can severely distort results, necessitating meticulous sample preparation protocols. Additionally, samples with high ionic strength or extreme pH values can affect particle interactions and alter scattering patterns, complicating the analysis of reactions occurring under such conditions.

The technique also struggles with distinguishing between different particle types in heterogeneous reaction mixtures. When multiple species coexist, DLS provides only an average hydrodynamic radius, making it difficult to track specific reaction components without complementary separation techniques. This limitation becomes particularly evident when studying complex biological systems or multi-component chemical reactions.

Real-time monitoring capabilities, while improved, still face temporal resolution constraints for extremely fast reactions occurring in the microsecond range. Furthermore, data interpretation remains somewhat subjective, requiring significant expertise to distinguish between genuine reaction-induced changes and experimental artifacts, especially in complex aqueous environments.

Advanced DLS systems now incorporate multi-angle detection capabilities, allowing for more accurate characterization of non-spherical particles and complex assemblies. This represents a significant improvement over traditional single-angle measurements that often provided incomplete structural information. Additionally, temperature control systems have been refined to maintain stability within ±0.1°C, crucial for studying temperature-dependent reaction mechanisms and thermodynamic parameters.

Despite these advancements, DLS faces several technical limitations when applied to aqueous phase reactions. Polydisperse samples remain challenging to analyze accurately, as the scattering intensity's strong dependence on particle size (proportional to d^6) causes larger particles to dominate the signal, potentially obscuring smaller reaction components. This becomes particularly problematic when studying reactions that generate products with broad size distributions.

Concentration sensitivity presents another significant limitation. DLS typically requires minimum concentrations of 0.1 mg/mL for proteins and similar macromolecules, which may exceed physiologically relevant conditions for many biochemical reactions. Conversely, high concentration samples can introduce multiple scattering effects that complicate data interpretation and reduce measurement accuracy.

Environmental factors substantially impact measurement reliability. Dust particles and microscopic contaminants can severely distort results, necessitating meticulous sample preparation protocols. Additionally, samples with high ionic strength or extreme pH values can affect particle interactions and alter scattering patterns, complicating the analysis of reactions occurring under such conditions.

The technique also struggles with distinguishing between different particle types in heterogeneous reaction mixtures. When multiple species coexist, DLS provides only an average hydrodynamic radius, making it difficult to track specific reaction components without complementary separation techniques. This limitation becomes particularly evident when studying complex biological systems or multi-component chemical reactions.

Real-time monitoring capabilities, while improved, still face temporal resolution constraints for extremely fast reactions occurring in the microsecond range. Furthermore, data interpretation remains somewhat subjective, requiring significant expertise to distinguish between genuine reaction-induced changes and experimental artifacts, especially in complex aqueous environments.

Established DLS Methodologies for Reaction Monitoring

01 Principles and apparatus for dynamic light scattering measurements

Dynamic light scattering (DLS) is a technique used to measure the size distribution of particles in suspension. The fundamental principles involve analyzing the fluctuations in scattered light intensity caused by Brownian motion of particles. Advanced apparatus designs incorporate laser sources, detectors, and optical components to improve measurement accuracy and sensitivity. These systems often include specialized algorithms for data processing to extract particle size information from the scattered light patterns.- Principles and apparatus for Dynamic Light Scattering measurement: Dynamic Light Scattering (DLS) is a technique used to measure the size distribution of particles in suspension. The basic principle involves analyzing the fluctuations in scattered light intensity caused by Brownian motion of particles. Various apparatus designs incorporate laser light sources, detectors, and optical components to accurately measure these fluctuations. Advanced systems may include multiple angle detection capabilities and specialized signal processing algorithms to improve measurement accuracy and resolution.

- Applications of DLS in biological and pharmaceutical analysis: Dynamic Light Scattering is widely applied in biological and pharmaceutical research for characterizing biomolecules, drug delivery systems, and protein formulations. The technique enables the measurement of protein aggregation, stability assessment of drug formulations, and quality control of biopharmaceuticals. DLS provides valuable information about particle size distribution, molecular interactions, and solution behavior under various conditions, making it an essential tool for drug development and biological research.

- Advanced data processing algorithms for DLS: Sophisticated data processing algorithms have been developed to enhance the capabilities of Dynamic Light Scattering. These algorithms improve the resolution of particle size distributions, especially in polydisperse samples, and enable more accurate analysis of complex mixtures. Machine learning approaches, correlation function analysis techniques, and mathematical models are employed to extract meaningful information from raw DLS data. These advanced processing methods allow for better differentiation between particle populations and more reliable measurements in challenging sample conditions.

- Integration of DLS with other analytical techniques: The integration of Dynamic Light Scattering with complementary analytical techniques creates powerful hybrid systems for comprehensive particle characterization. Combinations with techniques such as Raman spectroscopy, size exclusion chromatography, or static light scattering provide multidimensional data about particle properties. These integrated approaches allow simultaneous measurement of size, structure, composition, and other physical properties, offering more complete characterization of complex samples than any single technique alone.

- Miniaturization and automation of DLS systems: Recent innovations in Dynamic Light Scattering technology focus on miniaturization and automation to enhance accessibility and throughput. Compact DLS systems incorporate microfluidic components, integrated optics, and simplified user interfaces for point-of-use applications. Automated platforms enable high-throughput screening with minimal user intervention, featuring sample handling robotics, automated data analysis, and quality control algorithms. These developments make DLS more accessible for routine analysis in various industries and research settings.

02 Applications of DLS in biological and pharmaceutical analysis

Dynamic light scattering is widely applied in biological and pharmaceutical fields for characterizing biomolecules, drug delivery systems, and protein formulations. The technique enables non-invasive analysis of protein aggregation, stability assessment of drug formulations, and quality control of biopharmaceuticals. DLS provides valuable information about the hydrodynamic size, polydispersity, and molecular interactions in biological samples, making it an essential tool for research and development in these industries.Expand Specific Solutions03 Advanced data processing and analysis methods for DLS

Modern dynamic light scattering systems employ sophisticated data processing algorithms to enhance measurement accuracy and extract additional information from scattering data. These methods include multi-angle detection, correlation function analysis, and machine learning approaches for data interpretation. Advanced computational techniques allow for improved resolution of multimodal particle distributions, better handling of polydisperse samples, and more reliable measurements in complex media with potential interferents.Expand Specific Solutions04 Integration of DLS with other analytical techniques

Combining dynamic light scattering with complementary analytical methods creates powerful hybrid systems for comprehensive particle characterization. These integrated approaches may pair DLS with techniques such as Raman spectroscopy, size exclusion chromatography, or electrophoretic methods. Such combinations provide multidimensional data about particle properties, including size, composition, structure, and surface characteristics, enabling more complete analysis of complex samples and colloidal systems.Expand Specific Solutions05 Innovations in DLS for specialized applications

Recent innovations in dynamic light scattering technology address specialized measurement needs across various industries. These developments include miniaturized DLS systems for point-of-use testing, high-throughput configurations for industrial quality control, and adaptations for challenging sample types such as highly concentrated suspensions or non-transparent media. Specialized DLS instruments may incorporate temperature control, pressure chambers, or flow cells to study particles under varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Dynamic Light Scattering (DLS) for studying aqueous phase reactions is in a growth phase, with increasing market adoption driven by its ability to analyze nanoparticle size, stability, and reaction kinetics in solution. The global market is expanding as applications diversify across pharmaceutical, materials science, and environmental sectors. Technologically, companies like Malvern Panalytical, Wyatt Technology, and Shimadzu lead with advanced instrumentation, while Agilent Technologies and FUJIFILM contribute significant innovations. Academic institutions including California Institute of Technology and University of Stuttgart collaborate with industry players to enhance capabilities. The technology has reached moderate maturity with standardized protocols, but continues evolving through integration with AI analytics and multi-parameter measurement systems, creating opportunities for specialized applications.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has developed advanced Dynamic Light Scattering (DLS) instruments specifically optimized for studying aqueous phase reactions. Their DYNAMICS platform incorporates proprietary QELS (Quasi-Elastic Light Scattering) technology that enables real-time monitoring of reaction kinetics in aqueous solutions. The system features temperature-controlled sample chambers (4-70°C) allowing precise control of reaction conditions and automated time-series measurements to track reaction progress. Their DynaPro® NanoStar® instrument combines DLS with static light scattering capabilities, enabling simultaneous determination of both molecular size (hydrodynamic radius) and molecular weight during aqueous reactions. Wyatt has also developed specialized software algorithms that can deconvolute complex multi-component reactions, distinguishing between different particle populations as reactions proceed. Their technology incorporates online filtration systems to minimize dust contamination which is critical for accurate measurements in aqueous environments[1][3].

Strengths: Industry-leading sensitivity for detecting sub-nanometer changes in particle size; exceptional temperature stability for reaction monitoring; proprietary algorithms for multi-component analysis. Weaknesses: Higher cost compared to basic DLS systems; requires more extensive user training; some limitations in extremely dilute reaction environments.

Shimadzu Corp.

Technical Solution: Shimadzu has developed the SALD-7500nano DLS system specifically engineered for monitoring aqueous phase reactions. Their technology utilizes a unique Wide-Angle Light Scattering Detection system that captures scattered light across multiple angles simultaneously (from 9° to 173°), providing comprehensive characterization of reaction dynamics across different particle size regimes. The system incorporates Shimadzu's proprietary Induced Grating Method (IGM) which enhances measurement sensitivity for detecting subtle changes in particle size distribution during reaction progression. Their platform features specialized flow cells designed for continuous monitoring of reactions with automated sampling capabilities that can extract aliquots at predetermined reaction timepoints. Shimadzu's advanced signal processing algorithms employ Adaptive Baseline Correction technology that compensates for gradual changes in background scattering, critical for long-duration reaction monitoring. Their LabSolutions software includes dedicated reaction kinetics modules with mathematical modeling capabilities to extract rate constants and reaction mechanisms from time-resolved DLS data[7][9].

Strengths: Exceptional wide-angle detection capabilities; specialized flow cells for continuous monitoring; advanced baseline correction for long experiments; integrated kinetics modeling software. Weaknesses: Slightly lower sensitivity for very small particles compared to some specialized competitors; more complex operation for basic applications; higher maintenance requirements for the multi-angle detection system.

Key Patents and Scientific Breakthroughs

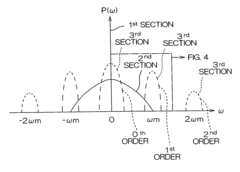

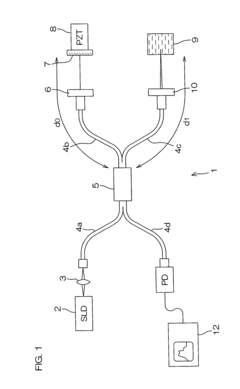

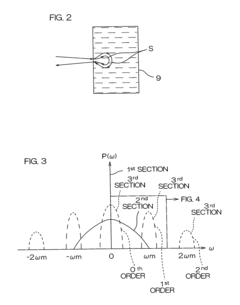

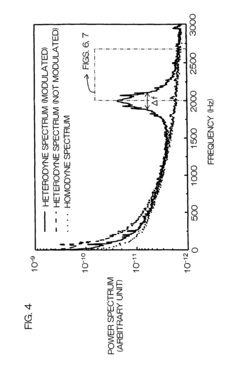

Dynamic light scattering measurement apparatus using phase modulation interference method

PatentInactiveUS7236250B2

Innovation

- A dynamic light scattering measurement apparatus using a low coherence light source and phase modulation interference method, where the light path length within the sample medium is normalized by the mean free path of particles to ensure that the light path length is not more than three times the mean free path, allowing for precise extraction of single scattering spectrum components from multiple scattering media.

Data Processing Algorithms and Software Solutions

Data processing in Dynamic Light Scattering (DLS) for aqueous phase reaction studies has evolved significantly with advancements in computational capabilities. Modern DLS systems employ sophisticated algorithms to extract meaningful information from scattered light signals. The correlation function analysis remains fundamental, with autocorrelation techniques transforming raw intensity fluctuations into particle size distributions. These algorithms typically implement cumulant analysis for monodisperse systems and CONTIN algorithms for polydisperse samples, enabling researchers to monitor reaction kinetics with unprecedented precision.

Machine learning approaches have recently revolutionized DLS data processing, particularly for complex aqueous reactions. Neural networks and support vector machines now enhance signal-to-noise ratios and identify subtle pattern changes during reaction progression. These AI-driven solutions can detect reaction intermediates that traditional algorithms might miss, providing deeper insights into reaction mechanisms and kinetics in aqueous environments.

Commercial software packages have become increasingly specialized for reaction monitoring applications. Platforms like Malvern's Zetasizer Ultra software and Brookhaven Instruments' Particle Solutions incorporate reaction-specific modules with time-resolved measurement capabilities. These solutions offer real-time data visualization and automated analysis workflows specifically designed for tracking dynamic changes in particle characteristics during aqueous phase reactions.

Open-source alternatives have gained traction in research communities, with packages like DLSanalysis and PyDLS providing customizable frameworks for specialized reaction studies. These platforms allow researchers to modify algorithms for specific reaction conditions and integrate with other analytical techniques, fostering collaborative development of more sophisticated analysis methods tailored to unique reaction systems.

Cloud-based processing solutions represent the newest frontier, enabling distributed computing approaches for handling large datasets from continuous reaction monitoring. These platforms facilitate remote access to processing capabilities and collaborative analysis, particularly valuable for multi-site research projects studying complex aqueous reactions under varying conditions.

Validation protocols have become standardized components of DLS data processing workflows, with statistical methods for uncertainty quantification now integrated into most software solutions. These protocols ensure reliable interpretation of reaction kinetics data by providing confidence intervals and identifying potential artifacts that could lead to misinterpretation of reaction mechanisms or rates.

Machine learning approaches have recently revolutionized DLS data processing, particularly for complex aqueous reactions. Neural networks and support vector machines now enhance signal-to-noise ratios and identify subtle pattern changes during reaction progression. These AI-driven solutions can detect reaction intermediates that traditional algorithms might miss, providing deeper insights into reaction mechanisms and kinetics in aqueous environments.

Commercial software packages have become increasingly specialized for reaction monitoring applications. Platforms like Malvern's Zetasizer Ultra software and Brookhaven Instruments' Particle Solutions incorporate reaction-specific modules with time-resolved measurement capabilities. These solutions offer real-time data visualization and automated analysis workflows specifically designed for tracking dynamic changes in particle characteristics during aqueous phase reactions.

Open-source alternatives have gained traction in research communities, with packages like DLSanalysis and PyDLS providing customizable frameworks for specialized reaction studies. These platforms allow researchers to modify algorithms for specific reaction conditions and integrate with other analytical techniques, fostering collaborative development of more sophisticated analysis methods tailored to unique reaction systems.

Cloud-based processing solutions represent the newest frontier, enabling distributed computing approaches for handling large datasets from continuous reaction monitoring. These platforms facilitate remote access to processing capabilities and collaborative analysis, particularly valuable for multi-site research projects studying complex aqueous reactions under varying conditions.

Validation protocols have become standardized components of DLS data processing workflows, with statistical methods for uncertainty quantification now integrated into most software solutions. These protocols ensure reliable interpretation of reaction kinetics data by providing confidence intervals and identifying potential artifacts that could lead to misinterpretation of reaction mechanisms or rates.

Environmental Impact and Sustainability Considerations

The application of Dynamic Light Scattering (DLS) in studying aqueous phase reactions carries significant environmental implications that warrant careful consideration. As analytical technologies evolve, their environmental footprint becomes increasingly important in research and industrial contexts. DLS offers notable advantages in this regard, primarily due to its non-destructive nature and minimal sample requirements, which substantially reduce waste generation compared to traditional analytical methods.

The reduced chemical consumption in DLS analysis represents a meaningful contribution to green chemistry principles. Traditional reaction monitoring often requires multiple sampling events and chemical treatments, generating considerable waste. In contrast, DLS typically requires microliter-scale samples and eliminates the need for many chemical additives, significantly decreasing the environmental burden of analytical processes.

Energy efficiency constitutes another environmental advantage of modern DLS instrumentation. Contemporary systems have been optimized to operate with lower power requirements than many alternative analytical technologies. This efficiency becomes particularly relevant when considering the cumulative energy consumption across thousands of analyses performed in research and quality control settings annually.

When implementing DLS for aqueous reaction studies, opportunities exist to further enhance sustainability through thoughtful experimental design. Recirculating sample systems can minimize waste, while careful selection of solvents and reagents compatible with DLS can reduce the use of environmentally problematic chemicals. These approaches align with broader sustainability initiatives in laboratory practices.

The lifecycle assessment of DLS instrumentation reveals both challenges and opportunities. While the manufacturing of precision optical components and electronics carries environmental costs, the extended operational lifespan of modern DLS systems—often exceeding a decade with proper maintenance—distributes this impact over numerous analyses. End-of-life considerations for electronic components remain an industry-wide challenge that manufacturers are increasingly addressing through take-back programs and recyclable design approaches.

In industrial applications, DLS implementation can contribute to process optimization, potentially reducing resource consumption and waste generation in manufacturing contexts. By enabling more precise reaction monitoring and control, DLS supports the development of more efficient chemical processes with smaller environmental footprints, particularly in pharmaceutical and specialty chemical production.

Future developments in DLS technology are increasingly focused on enhancing environmental performance through miniaturization, increased sensitivity, and integration with other analytical methods. These advancements promise to further reduce sample volumes, energy requirements, and overall environmental impact while maintaining or improving analytical capabilities.

The reduced chemical consumption in DLS analysis represents a meaningful contribution to green chemistry principles. Traditional reaction monitoring often requires multiple sampling events and chemical treatments, generating considerable waste. In contrast, DLS typically requires microliter-scale samples and eliminates the need for many chemical additives, significantly decreasing the environmental burden of analytical processes.

Energy efficiency constitutes another environmental advantage of modern DLS instrumentation. Contemporary systems have been optimized to operate with lower power requirements than many alternative analytical technologies. This efficiency becomes particularly relevant when considering the cumulative energy consumption across thousands of analyses performed in research and quality control settings annually.

When implementing DLS for aqueous reaction studies, opportunities exist to further enhance sustainability through thoughtful experimental design. Recirculating sample systems can minimize waste, while careful selection of solvents and reagents compatible with DLS can reduce the use of environmentally problematic chemicals. These approaches align with broader sustainability initiatives in laboratory practices.

The lifecycle assessment of DLS instrumentation reveals both challenges and opportunities. While the manufacturing of precision optical components and electronics carries environmental costs, the extended operational lifespan of modern DLS systems—often exceeding a decade with proper maintenance—distributes this impact over numerous analyses. End-of-life considerations for electronic components remain an industry-wide challenge that manufacturers are increasingly addressing through take-back programs and recyclable design approaches.

In industrial applications, DLS implementation can contribute to process optimization, potentially reducing resource consumption and waste generation in manufacturing contexts. By enabling more precise reaction monitoring and control, DLS supports the development of more efficient chemical processes with smaller environmental footprints, particularly in pharmaceutical and specialty chemical production.

Future developments in DLS technology are increasingly focused on enhancing environmental performance through miniaturization, increased sensitivity, and integration with other analytical methods. These advancements promise to further reduce sample volumes, energy requirements, and overall environmental impact while maintaining or improving analytical capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!