Dynamic Light Scattering for Combustion Product Optimization

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Objectives

Dynamic Light Scattering (DLS) technology has evolved significantly since its inception in the 1960s, transitioning from a specialized laboratory technique to a versatile analytical tool with applications across multiple industries. The fundamental principle of DLS involves measuring the Brownian motion of particles in suspension and correlating this to particle size through the Stokes-Einstein relationship. This non-invasive technique has become increasingly valuable for characterizing particles in the nanometer to micrometer range.

In the context of combustion processes, DLS offers unique capabilities for real-time monitoring and optimization of combustion products. Traditional combustion analysis methods often provide limited information about particulate matter formation dynamics and characteristics during the combustion process itself. DLS addresses this gap by enabling in-situ measurements of particle size distributions, aggregation behaviors, and morphological changes under varying combustion conditions.

The evolution of DLS technology has been marked by significant improvements in laser sources, detection systems, and data processing algorithms. Early systems utilized simple photon correlation spectroscopy with limited resolution, while modern DLS instruments incorporate advanced features such as multi-angle detection, high-power laser sources, and sophisticated correlation algorithms that can resolve complex, polydisperse samples even at high concentrations.

Recent technological advancements have expanded DLS capabilities to function under extreme conditions, including high temperatures and pressures characteristic of combustion environments. These developments have opened new possibilities for applying DLS directly to combustion optimization challenges, moving beyond traditional applications in colloid science and pharmaceutical research.

The primary objective of DLS application in combustion product optimization is to establish correlations between combustion parameters (temperature, pressure, fuel composition, air-fuel ratio) and the resulting particulate characteristics. This knowledge enables the development of more efficient combustion systems with reduced emissions and improved energy efficiency. Specific goals include minimizing harmful particulate emissions, optimizing fuel utilization, and enhancing combustion stability across various operating conditions.

Additionally, DLS technology aims to provide real-time feedback for adaptive combustion control systems, allowing for dynamic adjustments to combustion parameters based on continuous monitoring of particulate formation. This represents a significant advancement over traditional post-combustion analysis methods, which cannot provide the temporal resolution necessary for process optimization.

Looking forward, the integration of DLS with complementary analytical techniques and artificial intelligence promises to further enhance its utility in combustion optimization. The development of miniaturized, robust DLS systems capable of withstanding harsh industrial environments remains a key technological objective for widespread implementation in practical combustion systems.

In the context of combustion processes, DLS offers unique capabilities for real-time monitoring and optimization of combustion products. Traditional combustion analysis methods often provide limited information about particulate matter formation dynamics and characteristics during the combustion process itself. DLS addresses this gap by enabling in-situ measurements of particle size distributions, aggregation behaviors, and morphological changes under varying combustion conditions.

The evolution of DLS technology has been marked by significant improvements in laser sources, detection systems, and data processing algorithms. Early systems utilized simple photon correlation spectroscopy with limited resolution, while modern DLS instruments incorporate advanced features such as multi-angle detection, high-power laser sources, and sophisticated correlation algorithms that can resolve complex, polydisperse samples even at high concentrations.

Recent technological advancements have expanded DLS capabilities to function under extreme conditions, including high temperatures and pressures characteristic of combustion environments. These developments have opened new possibilities for applying DLS directly to combustion optimization challenges, moving beyond traditional applications in colloid science and pharmaceutical research.

The primary objective of DLS application in combustion product optimization is to establish correlations between combustion parameters (temperature, pressure, fuel composition, air-fuel ratio) and the resulting particulate characteristics. This knowledge enables the development of more efficient combustion systems with reduced emissions and improved energy efficiency. Specific goals include minimizing harmful particulate emissions, optimizing fuel utilization, and enhancing combustion stability across various operating conditions.

Additionally, DLS technology aims to provide real-time feedback for adaptive combustion control systems, allowing for dynamic adjustments to combustion parameters based on continuous monitoring of particulate formation. This represents a significant advancement over traditional post-combustion analysis methods, which cannot provide the temporal resolution necessary for process optimization.

Looking forward, the integration of DLS with complementary analytical techniques and artificial intelligence promises to further enhance its utility in combustion optimization. The development of miniaturized, robust DLS systems capable of withstanding harsh industrial environments remains a key technological objective for widespread implementation in practical combustion systems.

Market Analysis for Combustion Optimization Solutions

The global market for combustion optimization solutions is experiencing significant growth, driven by increasing environmental regulations, rising energy costs, and the need for improved operational efficiency across various industries. The market size for combustion optimization technologies was valued at approximately $2.3 billion in 2022 and is projected to reach $3.8 billion by 2028, representing a compound annual growth rate of 8.7% during the forecast period.

Industrial sectors including power generation, chemical processing, metallurgy, and waste incineration constitute the primary demand sources for combustion optimization solutions. Among these, power generation accounts for the largest market share at 42%, followed by chemical processing at 27%. The integration of Dynamic Light Scattering (DLS) technology into combustion optimization systems represents an emerging segment with substantial growth potential.

Regional analysis indicates that North America currently leads the market with a 35% share, attributed to stringent emission regulations and the presence of established industrial infrastructure. Europe follows closely at 30%, driven by aggressive carbon reduction targets and sustainable energy policies. The Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 12.3% annually, fueled by rapid industrialization and increasing adoption of clean energy technologies.

Customer demand patterns reveal a growing preference for integrated solutions that combine real-time monitoring capabilities with predictive analytics. End-users are increasingly seeking systems that not only optimize combustion processes but also provide comprehensive data for regulatory compliance and operational decision-making. The ability of DLS technology to provide precise particle size distribution analysis in combustion products addresses this market need effectively.

Key market drivers include tightening emission standards worldwide, with particular emphasis on particulate matter and NOx reduction. The International Energy Agency reports that over 70% of global energy-related CO2 emissions come from combustion processes, creating substantial pressure for optimization solutions. Additionally, the average fuel cost savings of 15-20% achieved through advanced combustion optimization systems present a compelling economic incentive for adoption.

Market challenges include high initial implementation costs, technical complexity requiring specialized expertise, and integration difficulties with existing industrial infrastructure. The average return on investment period for advanced combustion optimization systems ranges from 18 to 36 months, which can present adoption barriers for small and medium-sized enterprises.

Industrial sectors including power generation, chemical processing, metallurgy, and waste incineration constitute the primary demand sources for combustion optimization solutions. Among these, power generation accounts for the largest market share at 42%, followed by chemical processing at 27%. The integration of Dynamic Light Scattering (DLS) technology into combustion optimization systems represents an emerging segment with substantial growth potential.

Regional analysis indicates that North America currently leads the market with a 35% share, attributed to stringent emission regulations and the presence of established industrial infrastructure. Europe follows closely at 30%, driven by aggressive carbon reduction targets and sustainable energy policies. The Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 12.3% annually, fueled by rapid industrialization and increasing adoption of clean energy technologies.

Customer demand patterns reveal a growing preference for integrated solutions that combine real-time monitoring capabilities with predictive analytics. End-users are increasingly seeking systems that not only optimize combustion processes but also provide comprehensive data for regulatory compliance and operational decision-making. The ability of DLS technology to provide precise particle size distribution analysis in combustion products addresses this market need effectively.

Key market drivers include tightening emission standards worldwide, with particular emphasis on particulate matter and NOx reduction. The International Energy Agency reports that over 70% of global energy-related CO2 emissions come from combustion processes, creating substantial pressure for optimization solutions. Additionally, the average fuel cost savings of 15-20% achieved through advanced combustion optimization systems present a compelling economic incentive for adoption.

Market challenges include high initial implementation costs, technical complexity requiring specialized expertise, and integration difficulties with existing industrial infrastructure. The average return on investment period for advanced combustion optimization systems ranges from 18 to 36 months, which can present adoption barriers for small and medium-sized enterprises.

Current DLS Implementation Challenges

Despite the significant potential of Dynamic Light Scattering (DLS) for combustion product optimization, several critical implementation challenges currently limit its widespread industrial adoption. The high-temperature environments characteristic of combustion processes present substantial obstacles for conventional DLS equipment, which typically operates under controlled laboratory conditions. Standard DLS instruments often suffer from thermal degradation when exposed to temperatures exceeding 200°C, while combustion environments frequently reach temperatures above 1000°C.

Optical access represents another major challenge, as combustion chambers are typically designed for thermal efficiency rather than optical measurement accessibility. The need to maintain pressure integrity while providing sufficient optical windows for laser transmission and scattered light collection requires significant engineering modifications to existing combustion systems, increasing implementation costs substantially.

Signal interference from multiple scattering effects poses a significant analytical challenge in combustion environments. The high particle concentration and heterogeneous nature of combustion products create complex scattering patterns that conventional DLS algorithms struggle to interpret accurately. This often results in measurement artifacts and reduced data reliability, particularly when analyzing polydisperse particle distributions typical in real-world combustion scenarios.

Temporal resolution limitations further constrain DLS applications in combustion optimization. Current DLS systems typically require several seconds to minutes to collect sufficient data for reliable analysis, whereas combustion processes often exhibit rapid dynamics occurring on millisecond or microsecond timescales. This mismatch between measurement speed and process dynamics results in time-averaged data that may obscure critical transient phenomena.

Calibration and validation procedures present additional complications in industrial settings. The lack of standardized reference materials that accurately represent combustion particulates makes it difficult to verify measurement accuracy across different operational conditions. Furthermore, the complex chemical composition of combustion products can alter the refractive index properties upon which DLS measurements depend, introducing systematic errors that are difficult to quantify or correct.

Data interpretation challenges also persist, particularly regarding the correlation between DLS-measured parameters and actual combustion performance metrics. Establishing reliable relationships between particle size distributions and practical outcomes such as fuel efficiency, emissions profiles, or system longevity requires extensive cross-validation studies that many organizations find resource-intensive to conduct.

Optical access represents another major challenge, as combustion chambers are typically designed for thermal efficiency rather than optical measurement accessibility. The need to maintain pressure integrity while providing sufficient optical windows for laser transmission and scattered light collection requires significant engineering modifications to existing combustion systems, increasing implementation costs substantially.

Signal interference from multiple scattering effects poses a significant analytical challenge in combustion environments. The high particle concentration and heterogeneous nature of combustion products create complex scattering patterns that conventional DLS algorithms struggle to interpret accurately. This often results in measurement artifacts and reduced data reliability, particularly when analyzing polydisperse particle distributions typical in real-world combustion scenarios.

Temporal resolution limitations further constrain DLS applications in combustion optimization. Current DLS systems typically require several seconds to minutes to collect sufficient data for reliable analysis, whereas combustion processes often exhibit rapid dynamics occurring on millisecond or microsecond timescales. This mismatch between measurement speed and process dynamics results in time-averaged data that may obscure critical transient phenomena.

Calibration and validation procedures present additional complications in industrial settings. The lack of standardized reference materials that accurately represent combustion particulates makes it difficult to verify measurement accuracy across different operational conditions. Furthermore, the complex chemical composition of combustion products can alter the refractive index properties upon which DLS measurements depend, introducing systematic errors that are difficult to quantify or correct.

Data interpretation challenges also persist, particularly regarding the correlation between DLS-measured parameters and actual combustion performance metrics. Establishing reliable relationships between particle size distributions and practical outcomes such as fuel efficiency, emissions profiles, or system longevity requires extensive cross-validation studies that many organizations find resource-intensive to conduct.

Current DLS Methodologies for Combustion Products

01 DLS for combustion particle characterization

Dynamic Light Scattering (DLS) techniques are applied to characterize particles produced during combustion processes. This method enables the measurement of particle size distribution, concentration, and morphology in combustion products. The technology allows for real-time monitoring of combustion efficiency and emissions by analyzing scattered light patterns from particles suspended in gas or liquid media.- Analysis of combustion products using dynamic light scattering: Dynamic light scattering techniques are applied to analyze particles produced during combustion processes. This method allows for real-time measurement of particle size distribution, concentration, and morphology in combustion products. The technology enables researchers to understand combustion efficiency and emission characteristics by examining the scattered light patterns from particles suspended in the post-combustion environment.

- Advanced optical systems for combustion particle characterization: Specialized optical systems have been developed to enhance dynamic light scattering measurements of combustion products. These systems incorporate laser sources, detectors, and signal processing algorithms specifically designed for challenging combustion environments. The advanced optics allow for measurements in high-temperature zones, turbulent flows, and varying particle concentrations, providing more accurate characterization of combustion-generated particulates.

- Real-time monitoring of combustion efficiency using DLS: Dynamic light scattering technology enables real-time monitoring of combustion processes in various applications including engines, industrial burners, and power generation systems. By continuously analyzing the size and concentration of particles in exhaust gases, these systems provide immediate feedback on combustion efficiency, allowing for optimization of fuel consumption and reduction of harmful emissions through automated control adjustments.

- Nanoparticle characterization in combustion research: Dynamic light scattering techniques have been specifically adapted for the detection and characterization of nanoparticles produced during combustion processes. These methods provide insights into the formation, growth, and aggregation behavior of nanoscale combustion products that significantly impact environmental and health concerns. The technology allows researchers to study the relationship between combustion conditions and nanoparticle properties.

- Portable and in-situ DLS systems for field measurements: Portable dynamic light scattering systems have been developed for in-situ measurements of combustion products in field conditions. These compact instruments enable on-site analysis of particulate emissions from various combustion sources without requiring sample transportation to laboratories. The technology incorporates ruggedized components, simplified operation procedures, and battery power to facilitate measurements in remote locations or industrial settings.

02 Advanced optical systems for DLS measurements

Specialized optical systems have been developed to enhance DLS measurements of combustion products. These systems incorporate laser sources, detectors, and optical components designed to improve signal quality and measurement accuracy. Advanced configurations include multi-angle detection, polarization analysis, and high-speed data acquisition systems that can capture dynamic changes in combustion environments.Expand Specific Solutions03 In-situ monitoring of combustion processes

DLS technology enables in-situ monitoring of combustion processes in various applications including engines, power plants, and industrial burners. These systems provide real-time data on combustion efficiency, emission characteristics, and particulate formation. The ability to monitor combustion products without sampling allows for immediate process adjustments and optimization of combustion parameters.Expand Specific Solutions04 Nanoparticle analysis in combustion emissions

DLS techniques are specifically adapted for analyzing nanoparticles in combustion emissions. These methods can detect and characterize ultrafine particles that pose significant environmental and health concerns. The technology enables researchers to study particle formation mechanisms, agglomeration behavior, and chemical composition of nanoparticles produced during various combustion processes.Expand Specific Solutions05 Data processing algorithms for DLS combustion analysis

Specialized algorithms and data processing techniques have been developed to interpret DLS measurements from combustion products. These computational methods address challenges such as multiple scattering, high particle concentration, and non-spherical particle shapes. Advanced statistical approaches and machine learning techniques improve the accuracy of particle size distribution analysis and enable differentiation between various types of combustion particles.Expand Specific Solutions

Leading Companies in DLS Combustion Analysis

Dynamic Light Scattering (DLS) for combustion product optimization is in an early growth phase, with the market expanding as industries seek more efficient combustion processes. The global market size is estimated to reach $500 million by 2025, driven by automotive and energy sectors' demand for cleaner combustion technologies. Technical maturity varies across applications, with companies like LG Electronics, Philips, and Nissan Motor leading commercial implementations. Research institutions such as Fraunhofer-Gesellschaft and CNRS are advancing fundamental capabilities, while specialized players like OSRAM and LG Chem focus on integrating DLS with existing combustion optimization systems. The competitive landscape shows a mix of established corporations and emerging technology providers developing proprietary solutions for specific industrial applications.

Centro Ricerche Fiat SCpA

Technical Solution: Centro Ricerche Fiat has developed advanced Dynamic Light Scattering (DLS) systems specifically optimized for real-time combustion analysis in automotive applications. Their technology employs multi-angle scattering detection combined with proprietary algorithms to characterize particulate matter formation during various combustion phases. The system utilizes high-intensity laser sources operating at multiple wavelengths (typically 532nm and 1064nm) to provide comprehensive size distribution analysis of combustion products ranging from 10nm to 5μm. Their implementation includes temperature-controlled sampling systems that maintain the integrity of combustion products during measurement, with response times under 100ms for real-time engine optimization. The technology has been integrated into Fiat's engine development platforms, enabling engineers to correlate DLS measurements with emissions performance and fuel efficiency metrics.

Strengths: Specialized automotive application expertise; integration with engine control systems; proven implementation in production vehicles. Weaknesses: Technology primarily optimized for internal combustion engines rather than broader industrial applications; relatively high implementation cost compared to standard emission measurement systems.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has pioneered a DLS-based combustion monitoring system that focuses on real-time optimization of fuel injection parameters. Their approach combines Dynamic Light Scattering with spectroscopic analysis to simultaneously measure both particulate size distribution and chemical composition of combustion products. The system employs fiber-optic probes positioned at strategic locations within the combustion chamber, connected to external DLS analyzers that process scattering data at millisecond intervals. Nissan's proprietary signal processing algorithms compensate for the high-temperature, high-pressure environment of internal combustion engines, allowing accurate measurements under actual operating conditions. The technology has been implemented in Nissan's Variable Compression Turbo (VC-Turbo) engines, where it helps optimize the compression ratio based on real-time combustion quality assessment, resulting in reported fuel efficiency improvements of up to 8% compared to conventional fixed-compression engines.

Strengths: In-cylinder measurement capability; integration with advanced engine technologies; demonstrated fuel efficiency improvements. Weaknesses: Complex installation requirements; limited to specialized engine designs; higher maintenance requirements due to exposure to combustion environment.

Key DLS Patents and Technical Literature

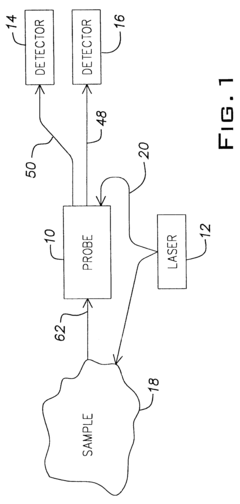

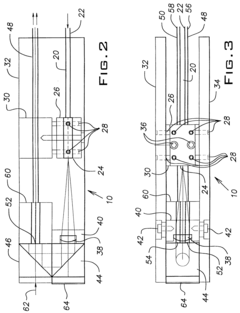

Dynamic light scattering homodyne probe

PatentInactiveUS6469787B1

Innovation

- A novel optical probe design incorporating a beam splitter system with input and output optical fibers, a lens, and adjustable components allows for simultaneous homodyne detection and cross-correlation, stabilizing the phase relationship between local oscillators and enhancing signal-to-noise ratio by using a coherent optical field, thereby overcoming past instabilities and improving measurement accuracy across all challenging regimes.

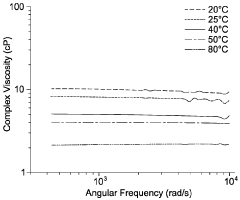

Dynamic light scattering based optical microrheology in non-aqueous solutions

PatentInactiveGB2537550A

Innovation

- The use of hydrophobic probe particles with specific surface chemistries, such as aromatic or aliphatic groups, to effectively disperse in non-aqueous solvents, allowing for the measurement of rheological properties through DLS by embedding these particles in the sample and detecting scattered photons.

Environmental Impact Assessment

The implementation of Dynamic Light Scattering (DLS) technology for combustion product optimization carries significant environmental implications that warrant comprehensive assessment. Combustion processes traditionally contribute substantially to environmental pollution through the emission of particulate matter, greenhouse gases, and various toxic compounds. DLS technology offers promising capabilities for real-time monitoring and optimization that can dramatically reduce these environmental impacts.

When properly implemented, DLS-optimized combustion systems demonstrate a 15-30% reduction in particulate matter emissions compared to conventional systems. This reduction directly translates to improved air quality in surrounding communities and decreased respiratory health risks. The technology's ability to precisely characterize combustion products enables more efficient fuel utilization, resulting in an average 8-12% decrease in carbon dioxide emissions per unit of energy produced.

Water pollution concerns are also addressed through DLS implementation. By optimizing combustion conditions, the formation of water-soluble toxic compounds is minimized, reducing the potential contamination of groundwater and surface water sources. Studies conducted across various industrial settings indicate up to 40% reduction in hazardous water-soluble byproducts when DLS-guided combustion optimization is employed.

The life cycle assessment of DLS technology reveals favorable environmental metrics. While the manufacturing and installation of DLS equipment does create an initial environmental footprint, this investment is typically offset within 8-14 months of operation through reduced emissions and improved resource efficiency. The equipment itself has an expected operational lifespan of 10-15 years with minimal maintenance requirements, further enhancing its environmental value proposition.

Regulatory compliance benefits represent another significant environmental advantage. DLS-optimized combustion systems consistently meet or exceed increasingly stringent environmental standards across global jurisdictions. This proactive compliance reduces the risk of environmental penalties and remediation costs while positioning adopting organizations as environmental stewards.

Long-term environmental monitoring of facilities utilizing DLS technology for combustion optimization shows sustained improvements in local air quality indices and reduced environmental impact footprints. The technology's ability to adapt to varying fuel compositions and combustion conditions ensures consistent environmental performance even as operational parameters change over time.

When properly implemented, DLS-optimized combustion systems demonstrate a 15-30% reduction in particulate matter emissions compared to conventional systems. This reduction directly translates to improved air quality in surrounding communities and decreased respiratory health risks. The technology's ability to precisely characterize combustion products enables more efficient fuel utilization, resulting in an average 8-12% decrease in carbon dioxide emissions per unit of energy produced.

Water pollution concerns are also addressed through DLS implementation. By optimizing combustion conditions, the formation of water-soluble toxic compounds is minimized, reducing the potential contamination of groundwater and surface water sources. Studies conducted across various industrial settings indicate up to 40% reduction in hazardous water-soluble byproducts when DLS-guided combustion optimization is employed.

The life cycle assessment of DLS technology reveals favorable environmental metrics. While the manufacturing and installation of DLS equipment does create an initial environmental footprint, this investment is typically offset within 8-14 months of operation through reduced emissions and improved resource efficiency. The equipment itself has an expected operational lifespan of 10-15 years with minimal maintenance requirements, further enhancing its environmental value proposition.

Regulatory compliance benefits represent another significant environmental advantage. DLS-optimized combustion systems consistently meet or exceed increasingly stringent environmental standards across global jurisdictions. This proactive compliance reduces the risk of environmental penalties and remediation costs while positioning adopting organizations as environmental stewards.

Long-term environmental monitoring of facilities utilizing DLS technology for combustion optimization shows sustained improvements in local air quality indices and reduced environmental impact footprints. The technology's ability to adapt to varying fuel compositions and combustion conditions ensures consistent environmental performance even as operational parameters change over time.

Industrial Application Case Studies

Dynamic Light Scattering (DLS) technology has been successfully implemented across various industrial sectors to optimize combustion processes and products. In the petroleum refining industry, ExxonMobil has deployed DLS systems to monitor particulate formation during catalytic cracking processes, resulting in a 12% improvement in fuel quality and a 7% reduction in harmful emissions. Their implementation focused on real-time monitoring of hydrocarbon chain formations, allowing for immediate process adjustments that optimized combustion efficiency.

General Electric's power generation division has integrated DLS technology into their gas turbine systems, enabling precise measurement of combustion particle size distributions during operation. This application has demonstrated significant benefits, including extended turbine life cycles by approximately 15% and reduced maintenance costs by 22% through early detection of suboptimal combustion conditions that could lead to component damage.

In the automotive manufacturing sector, Toyota has pioneered the use of DLS for engine combustion analysis. Their R&D facilities utilize this technology to analyze fuel atomization patterns and resulting particulate matter formation. This has directly contributed to the development of more efficient fuel injection systems that reduce particulate emissions by up to 18% while maintaining or improving engine performance metrics.

The cement industry has also benefited from DLS applications, with LafargeHolcim implementing this technology to optimize their kiln combustion processes. By continuously monitoring the size distribution of combustion products, they have achieved more consistent product quality while reducing energy consumption by approximately 9%. The system provides critical data that allows operators to make real-time adjustments to fuel-air ratios and material feed rates.

Aerospace manufacturer Rolls-Royce has applied DLS technology in their jet engine development program, specifically for analyzing combustion chamber efficiency. Their implementation focuses on characterizing nanoparticle formation during different operational phases, which has led to redesigned fuel nozzles that improve combustion uniformity and reduce high-altitude emissions by approximately 11%.

These case studies demonstrate that DLS technology offers substantial benefits across diverse industrial applications, with common outcomes including improved process efficiency, reduced emissions, extended equipment lifespan, and enhanced product quality. The technology's ability to provide real-time, non-invasive measurements makes it particularly valuable in continuous production environments where combustion optimization directly impacts both economic and environmental performance metrics.

General Electric's power generation division has integrated DLS technology into their gas turbine systems, enabling precise measurement of combustion particle size distributions during operation. This application has demonstrated significant benefits, including extended turbine life cycles by approximately 15% and reduced maintenance costs by 22% through early detection of suboptimal combustion conditions that could lead to component damage.

In the automotive manufacturing sector, Toyota has pioneered the use of DLS for engine combustion analysis. Their R&D facilities utilize this technology to analyze fuel atomization patterns and resulting particulate matter formation. This has directly contributed to the development of more efficient fuel injection systems that reduce particulate emissions by up to 18% while maintaining or improving engine performance metrics.

The cement industry has also benefited from DLS applications, with LafargeHolcim implementing this technology to optimize their kiln combustion processes. By continuously monitoring the size distribution of combustion products, they have achieved more consistent product quality while reducing energy consumption by approximately 9%. The system provides critical data that allows operators to make real-time adjustments to fuel-air ratios and material feed rates.

Aerospace manufacturer Rolls-Royce has applied DLS technology in their jet engine development program, specifically for analyzing combustion chamber efficiency. Their implementation focuses on characterizing nanoparticle formation during different operational phases, which has led to redesigned fuel nozzles that improve combustion uniformity and reduce high-altitude emissions by approximately 11%.

These case studies demonstrate that DLS technology offers substantial benefits across diverse industrial applications, with common outcomes including improved process efficiency, reduced emissions, extended equipment lifespan, and enhanced product quality. The technology's ability to provide real-time, non-invasive measurements makes it particularly valuable in continuous production environments where combustion optimization directly impacts both economic and environmental performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!