Dynamic Light Scattering for Industrial Lubricant Analysis

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Objectives

Dynamic Light Scattering (DLS) technology has evolved significantly since its theoretical foundation was established in the early 20th century through Einstein's work on Brownian motion. The technique gained practical application in the 1960s with the advent of laser technology, which provided the coherent light source necessary for precise measurements. Over subsequent decades, DLS has transitioned from bulky laboratory equipment to more compact, user-friendly systems suitable for industrial applications.

In the context of industrial lubricant analysis, DLS offers a non-invasive method to characterize particle size distributions in lubricant formulations, ranging from nanometers to micrometers. This capability is crucial as the performance and longevity of lubricants are directly influenced by their particulate composition, including additives, contaminants, and wear debris.

The technological evolution of DLS has been driven by advancements in laser technology, digital signal processing, and computational algorithms. Modern systems incorporate high-sensitivity detectors, sophisticated correlation techniques, and advanced software that can interpret complex scattering patterns with greater accuracy and resolution than earlier generations of equipment.

Current technological trends in DLS for lubricant analysis include miniaturization for on-site testing, integration with other analytical techniques for comprehensive characterization, and the development of automated systems capable of continuous monitoring in industrial settings. These innovations address the growing demand for real-time quality control and predictive maintenance in manufacturing and heavy machinery operations.

The primary technical objectives for DLS in lubricant analysis encompass several dimensions. First, enhancing measurement sensitivity to detect increasingly smaller particles that can impact lubricant performance. Second, improving data processing algorithms to distinguish between different types of particles based on their scattering properties. Third, developing robust calibration standards specific to lubricant matrices to ensure measurement accuracy across different formulations.

Additionally, there is a push toward systems that can operate reliably in challenging industrial environments characterized by vibration, temperature fluctuations, and potential electromagnetic interference. The ultimate goal is to establish DLS as a standard analytical tool in lubricant manufacturing and maintenance protocols, providing actionable insights that extend equipment life and optimize performance across various industrial applications.

In the context of industrial lubricant analysis, DLS offers a non-invasive method to characterize particle size distributions in lubricant formulations, ranging from nanometers to micrometers. This capability is crucial as the performance and longevity of lubricants are directly influenced by their particulate composition, including additives, contaminants, and wear debris.

The technological evolution of DLS has been driven by advancements in laser technology, digital signal processing, and computational algorithms. Modern systems incorporate high-sensitivity detectors, sophisticated correlation techniques, and advanced software that can interpret complex scattering patterns with greater accuracy and resolution than earlier generations of equipment.

Current technological trends in DLS for lubricant analysis include miniaturization for on-site testing, integration with other analytical techniques for comprehensive characterization, and the development of automated systems capable of continuous monitoring in industrial settings. These innovations address the growing demand for real-time quality control and predictive maintenance in manufacturing and heavy machinery operations.

The primary technical objectives for DLS in lubricant analysis encompass several dimensions. First, enhancing measurement sensitivity to detect increasingly smaller particles that can impact lubricant performance. Second, improving data processing algorithms to distinguish between different types of particles based on their scattering properties. Third, developing robust calibration standards specific to lubricant matrices to ensure measurement accuracy across different formulations.

Additionally, there is a push toward systems that can operate reliably in challenging industrial environments characterized by vibration, temperature fluctuations, and potential electromagnetic interference. The ultimate goal is to establish DLS as a standard analytical tool in lubricant manufacturing and maintenance protocols, providing actionable insights that extend equipment life and optimize performance across various industrial applications.

Market Demand Analysis for Lubricant Testing

The industrial lubricant testing market has witnessed substantial growth in recent years, driven primarily by the increasing complexity of machinery across various sectors and the growing emphasis on preventive maintenance strategies. The global lubricant testing market was valued at approximately 1.4 billion USD in 2022 and is projected to reach 2.1 billion USD by 2028, representing a compound annual growth rate of 6.8% during the forecast period.

The demand for advanced lubricant testing technologies, particularly Dynamic Light Scattering (DLS), is being fueled by several key factors. Manufacturing industries are increasingly adopting predictive maintenance approaches to minimize downtime and extend equipment lifespan, creating a significant need for precise lubricant analysis tools. The automotive sector remains the largest consumer of lubricant testing services, accounting for nearly 30% of the market share, followed closely by industrial manufacturing at 25%.

Energy efficiency concerns and stringent environmental regulations are also driving market growth. As companies face pressure to reduce their carbon footprint, the optimization of lubricant performance becomes critical. DLS technology offers the advantage of detecting contaminants and monitoring particle size distribution in lubricants without requiring sample preparation that might alter the original properties of the fluid.

Regional analysis indicates that North America currently dominates the lubricant testing market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing adoption of advanced manufacturing technologies.

The market is also seeing a shift toward portable and on-site testing solutions. End-users are increasingly demanding real-time monitoring capabilities that allow for immediate decision-making regarding maintenance schedules. This trend presents a significant opportunity for DLS technology, which can be miniaturized and integrated into portable devices for field testing applications.

Customer segmentation reveals that large enterprises constitute about 65% of the current market for advanced lubricant testing, but small and medium enterprises (SMEs) represent the fastest-growing segment with an annual growth rate exceeding 8%. This shift is attributed to the decreasing cost of testing equipment and growing awareness about the cost benefits of preventive maintenance even among smaller operations.

The market is also witnessing increased demand for comprehensive testing services that combine multiple analytical techniques. DLS, when integrated with other spectroscopic methods, provides a more complete picture of lubricant health, creating opportunities for service providers offering bundled testing solutions.

The demand for advanced lubricant testing technologies, particularly Dynamic Light Scattering (DLS), is being fueled by several key factors. Manufacturing industries are increasingly adopting predictive maintenance approaches to minimize downtime and extend equipment lifespan, creating a significant need for precise lubricant analysis tools. The automotive sector remains the largest consumer of lubricant testing services, accounting for nearly 30% of the market share, followed closely by industrial manufacturing at 25%.

Energy efficiency concerns and stringent environmental regulations are also driving market growth. As companies face pressure to reduce their carbon footprint, the optimization of lubricant performance becomes critical. DLS technology offers the advantage of detecting contaminants and monitoring particle size distribution in lubricants without requiring sample preparation that might alter the original properties of the fluid.

Regional analysis indicates that North America currently dominates the lubricant testing market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing adoption of advanced manufacturing technologies.

The market is also seeing a shift toward portable and on-site testing solutions. End-users are increasingly demanding real-time monitoring capabilities that allow for immediate decision-making regarding maintenance schedules. This trend presents a significant opportunity for DLS technology, which can be miniaturized and integrated into portable devices for field testing applications.

Customer segmentation reveals that large enterprises constitute about 65% of the current market for advanced lubricant testing, but small and medium enterprises (SMEs) represent the fastest-growing segment with an annual growth rate exceeding 8%. This shift is attributed to the decreasing cost of testing equipment and growing awareness about the cost benefits of preventive maintenance even among smaller operations.

The market is also witnessing increased demand for comprehensive testing services that combine multiple analytical techniques. DLS, when integrated with other spectroscopic methods, provides a more complete picture of lubricant health, creating opportunities for service providers offering bundled testing solutions.

Current State and Challenges in DLS Implementation

Dynamic Light Scattering (DLS) technology for industrial lubricant analysis has reached a significant level of maturity in laboratory settings, but its widespread industrial implementation faces several challenges. Currently, DLS systems are predominantly utilized in research institutions and specialized testing facilities rather than in on-site industrial environments where real-time lubricant monitoring would be most beneficial.

The global landscape of DLS implementation shows regional disparities, with North America and Europe leading in adoption rates, followed by Asia-Pacific regions, particularly Japan and South Korea. China has shown rapid growth in DLS technology development over the past five years, primarily focused on cost reduction and system miniaturization.

A major technical challenge in DLS implementation for industrial lubricant analysis is the presence of multiple scattering effects in high-concentration samples typical of industrial lubricants. This phenomenon can significantly distort measurement results, leading to inaccurate particle size distribution assessments. Current solutions involve sample dilution, which may alter the original properties of the lubricant and reduce the relevance of the analysis.

Environmental factors present substantial obstacles for on-site DLS implementation. Vibrations from nearby machinery, temperature fluctuations in industrial settings, and electromagnetic interference can all compromise measurement accuracy. While laboratory DLS systems operate in controlled environments, industrial applications require robust designs that can maintain precision under harsh conditions.

The sensitivity of current DLS instruments to contaminants poses another significant challenge. Industrial lubricants often contain various additives and contaminants that can interfere with light scattering patterns, complicating data interpretation. Advanced algorithms for signal processing and contaminant identification are being developed but have not yet achieved the reliability required for autonomous industrial applications.

Miniaturization and cost reduction represent ongoing challenges in DLS technology development. Current high-precision DLS systems remain relatively expensive ($20,000-$100,000) and bulky, limiting their integration into continuous monitoring systems. Recent advancements in photonic integrated circuits and microfluidics show promise for more compact and affordable solutions, but commercial viability remains several years away.

Data interpretation and correlation with lubricant performance metrics constitute perhaps the most significant barrier to widespread adoption. While DLS effectively measures particle size distributions, translating these measurements into actionable insights about lubricant condition, remaining useful life, or maintenance requirements demands sophisticated correlation models that are still under development. Industry-specific calibration standards and reference materials for DLS measurements of lubricants are also lacking, hampering standardization efforts across different sectors.

The global landscape of DLS implementation shows regional disparities, with North America and Europe leading in adoption rates, followed by Asia-Pacific regions, particularly Japan and South Korea. China has shown rapid growth in DLS technology development over the past five years, primarily focused on cost reduction and system miniaturization.

A major technical challenge in DLS implementation for industrial lubricant analysis is the presence of multiple scattering effects in high-concentration samples typical of industrial lubricants. This phenomenon can significantly distort measurement results, leading to inaccurate particle size distribution assessments. Current solutions involve sample dilution, which may alter the original properties of the lubricant and reduce the relevance of the analysis.

Environmental factors present substantial obstacles for on-site DLS implementation. Vibrations from nearby machinery, temperature fluctuations in industrial settings, and electromagnetic interference can all compromise measurement accuracy. While laboratory DLS systems operate in controlled environments, industrial applications require robust designs that can maintain precision under harsh conditions.

The sensitivity of current DLS instruments to contaminants poses another significant challenge. Industrial lubricants often contain various additives and contaminants that can interfere with light scattering patterns, complicating data interpretation. Advanced algorithms for signal processing and contaminant identification are being developed but have not yet achieved the reliability required for autonomous industrial applications.

Miniaturization and cost reduction represent ongoing challenges in DLS technology development. Current high-precision DLS systems remain relatively expensive ($20,000-$100,000) and bulky, limiting their integration into continuous monitoring systems. Recent advancements in photonic integrated circuits and microfluidics show promise for more compact and affordable solutions, but commercial viability remains several years away.

Data interpretation and correlation with lubricant performance metrics constitute perhaps the most significant barrier to widespread adoption. While DLS effectively measures particle size distributions, translating these measurements into actionable insights about lubricant condition, remaining useful life, or maintenance requirements demands sophisticated correlation models that are still under development. Industry-specific calibration standards and reference materials for DLS measurements of lubricants are also lacking, hampering standardization efforts across different sectors.

Current DLS Solutions for Industrial Applications

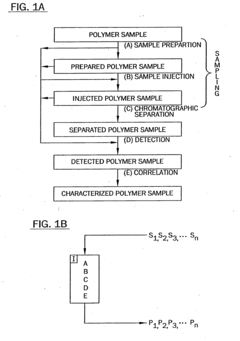

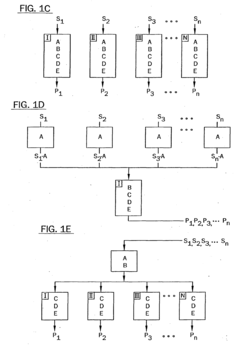

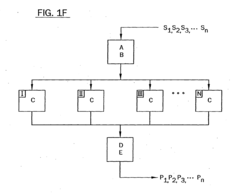

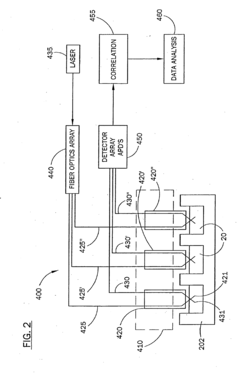

01 Principles and apparatus for dynamic light scattering measurements

Dynamic light scattering (DLS) is a technique used to measure the size distribution of particles in suspension. The basic principle involves analyzing the fluctuations in scattered light intensity caused by Brownian motion of particles. Advanced DLS apparatus typically includes a light source (usually a laser), optical components for beam focusing, a sample holder, detection systems, and signal processing units. These systems can measure particle sizes ranging from nanometers to micrometers with high precision.- Principles and fundamentals of Dynamic Light Scattering technology: Dynamic Light Scattering (DLS) is a non-invasive technique used to measure the size and size distribution of molecules and particles in suspension. The technique analyzes the intensity fluctuations in scattered light caused by Brownian motion of particles. By measuring these fluctuations, information about particle size, molecular weight, and diffusion coefficients can be determined. This fundamental technology serves as the basis for various applications in particle characterization across multiple industries.

- Advanced DLS instrumentation and apparatus design: Innovations in DLS instrumentation focus on improving measurement accuracy, sensitivity, and versatility. These advancements include novel optical configurations, detection systems, and signal processing methods. Modern DLS instruments incorporate features such as multi-angle detection, fiber optic technology, and integrated temperature control systems. These design improvements enable more precise particle characterization, expanded measurement ranges, and enhanced ability to analyze complex or highly concentrated samples.

- Applications of DLS in biological and pharmaceutical research: Dynamic Light Scattering has become an essential tool in biological and pharmaceutical research for characterizing biomolecules, drug delivery systems, and protein formulations. The technique enables researchers to monitor protein aggregation, stability of drug formulations, and interactions between biomolecules. DLS provides critical information about particle size distribution in biological samples, helping in quality control of biopharmaceuticals and understanding disease mechanisms related to protein misfolding and aggregation.

- DLS for nanoparticle characterization and quality control: Dynamic Light Scattering is widely used for characterizing nanoparticles across various industries. The technique provides rapid and accurate measurement of nanoparticle size distributions, stability, and surface properties. This application is particularly valuable in quality control processes for nanomaterials, ensuring batch-to-batch consistency and product performance. DLS enables monitoring of nanoparticle behavior under different environmental conditions, helping to optimize formulation and manufacturing processes.

- Integration of DLS with complementary analytical techniques: Modern analytical approaches often combine Dynamic Light Scattering with complementary techniques to provide more comprehensive characterization of complex samples. These integrated systems may combine DLS with techniques such as Raman spectroscopy, size exclusion chromatography, or static light scattering. Such combinations enable simultaneous measurement of multiple parameters including size, molecular weight, structure, and chemical composition. This multi-parameter approach provides deeper insights into material properties and behavior than would be possible with DLS alone.

02 Applications of DLS in biological and pharmaceutical research

Dynamic light scattering has become an essential analytical tool in biological and pharmaceutical research. It is used for characterizing biomolecules such as proteins, antibodies, and liposomes, determining their size, stability, and aggregation behavior. In pharmaceutical development, DLS helps in formulation studies, quality control of drug delivery systems, and monitoring the stability of therapeutic proteins. The non-invasive nature of DLS makes it particularly valuable for analyzing sensitive biological samples without disrupting their native state.Expand Specific Solutions03 Advanced signal processing and data analysis methods for DLS

Modern dynamic light scattering systems employ sophisticated signal processing and data analysis methods to extract meaningful information from scattered light signals. These include autocorrelation functions, cumulant analysis, and distribution algorithms that can resolve multiple particle populations. Machine learning and artificial intelligence approaches are increasingly being integrated to improve data interpretation, particularly for complex polydisperse samples. Advanced algorithms can compensate for measurement artifacts and provide more accurate size distributions even in challenging sample conditions.Expand Specific Solutions04 Combination of DLS with other analytical techniques

The integration of dynamic light scattering with complementary analytical techniques has expanded its capabilities and applications. Hybrid systems combining DLS with static light scattering, zeta potential measurements, or spectroscopic methods provide comprehensive characterization of colloidal systems. Multi-angle DLS setups enhance the resolution and accuracy of size measurements. These combined approaches allow researchers to simultaneously obtain information about particle size, molecular weight, shape, and surface properties, offering a more complete understanding of complex systems.Expand Specific Solutions05 Innovations in DLS for industrial and environmental applications

Recent innovations have expanded the use of dynamic light scattering beyond laboratory settings into industrial and environmental applications. Portable and automated DLS systems enable on-site analysis in manufacturing processes, environmental monitoring, and field research. Specialized adaptations allow for measurements in concentrated suspensions, non-transparent media, and extreme conditions. These developments have made DLS valuable for quality control in various industries, monitoring of environmental particles, and analysis of complex industrial formulations such as emulsions and dispersions.Expand Specific Solutions

Key Industry Players in Lubricant Analysis

The Dynamic Light Scattering (DLS) market for industrial lubricant analysis is in a growth phase, with increasing adoption across petroleum and chemical industries. The market size is expanding due to rising demand for precise lubricant characterization in manufacturing and automotive sectors. Technologically, the field shows moderate maturity with established players like Malvern Panalytical and Wyatt Technology leading with advanced instrumentation, while petroleum giants such as China Petroleum & Chemical Corp., Saudi Aramco, and ExxonMobil are driving application-specific innovations. Research institutions including Changchun Institute of Optics and Lanzhou Institute of Chemical Physics are contributing to technological advancements, while companies like Shimadzu and Bruker AXS are enhancing analytical capabilities through integrated systems, positioning DLS as a critical tool for industrial lubricant quality control and development.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed advanced Dynamic Light Scattering (DLS) systems specifically optimized for industrial lubricant analysis. Their Zetasizer series incorporates non-invasive back-scatter (NIBS) technology that enables accurate particle size measurements in concentrated lubricant samples without requiring excessive dilution. The company's proprietary Multiple Narrow Modes algorithm allows for detection of multimodal distributions commonly found in complex lubricant formulations, distinguishing between base oil components, additives, and contaminants in the 0.3nm to 10μm range. Their adaptive correlation technology automatically adjusts measurement parameters based on sample characteristics, ensuring optimal signal quality even with dark or highly viscous lubricants. Recent innovations include temperature gradient capabilities that simulate real-world operating conditions from -5°C to 120°C, allowing analysis of lubricant behavior across typical industrial temperature ranges.

Strengths: Superior resolution for multimodal distributions in complex lubricant formulations; advanced temperature control simulating real operating conditions; proprietary algorithms for handling concentrated samples. Weaknesses: Higher equipment cost compared to conventional light scattering systems; requires more specialized operator training; measurement accuracy can be affected by fluorescent additives in some lubricant formulations.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has pioneered multi-angle dynamic light scattering (MADLS) technology specifically adapted for industrial lubricant analysis. Their DynaPro® NanoStar® system combines traditional DLS with proprietary DYNAMICS® software featuring regularization algorithms that provide enhanced resolution for polydisperse lubricant samples. The system employs fiber optic technology with a 120mW laser source operating at 658nm wavelength, allowing penetration through dark lubricant samples while maintaining signal integrity. Wyatt's temperature control module enables precise analysis across -15°C to 150°C range with ±0.01°C stability, critical for studying viscosity-dependent behavior of lubricants under varying operating conditions. Their patented online filtration system prevents contamination during measurement, addressing a common challenge in lubricant analysis. Recent developments include integration with automated sample handling systems that enable high-throughput screening of multiple lubricant formulations with minimal operator intervention.

Strengths: Superior resolution for polydisperse samples through multi-angle detection; excellent temperature stability for studying temperature-dependent behaviors; automated filtration reduces contamination issues. Weaknesses: Higher complexity and cost compared to single-angle DLS systems; requires larger sample volumes than some competing technologies; more complex data interpretation requiring specialized expertise.

Core Technical Innovations in Light Scattering

Fiber optic apparatus and use thereof in combinatorial material science

PatentInactiveEP1837642A2

Innovation

- The development of systems and protocols for rapid characterization of liquid samples using light-scattering methods, including dynamic and static light scattering, with fiber optic probes that allow for parallel and serial analysis of multiple samples without immersion, enabling near-real-time characterization of particle size, distribution, and other properties.

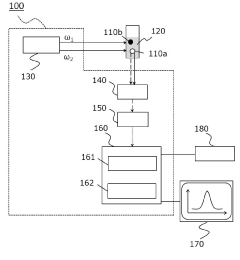

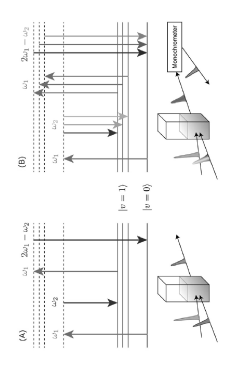

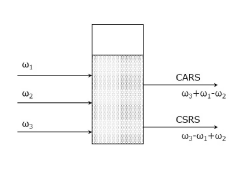

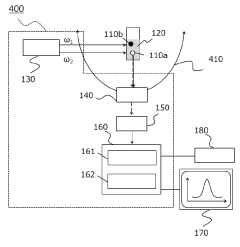

Dynamic light scattering measurement device, dynamic light scattering measurement analysis method, and measurement program

PatentPendingJP2022184699A

Innovation

- A dynamic light scattering measurement device using synchronized pulsed laser beams with specific angular frequencies to induce Coherent Anti-Stokes Raman Scattering (CARS) or Coherent Stokes Raman Scattering (CSRS) photons, combined with a separation device and photon detection, allows for molecularly selective measurement of particle sizes and distributions by calculating time correlation functions.

Quality Control Standards and Compliance

The implementation of Dynamic Light Scattering (DLS) for industrial lubricant analysis necessitates adherence to stringent quality control standards and compliance frameworks. International standards organizations, including ISO, ASTM, and SAE, have established specific protocols for lubricant testing methodologies. ISO 11500:2008 specifically addresses the determination of particulate contamination by automatic particle counting methods, providing a foundation for DLS applications in lubricant analysis.

Quality control in industrial lubricant analysis using DLS must comply with ISO 4406, which classifies the level of contamination in lubricants by counting particles of different size ranges. This standard is particularly crucial for hydraulic fluids and lubricating oils where particle contamination directly impacts system performance and component longevity. Additionally, ASTM D7647 outlines standard test methods for automatic particle counting of lubricating and hydraulic fluids using dilution techniques.

For manufacturing facilities implementing DLS technology, compliance with ISO 9001 quality management systems is essential to ensure consistent and reliable analytical results. This framework requires documented procedures, regular calibration of equipment, and validation of testing methods. Furthermore, laboratories conducting DLS analysis should consider accreditation under ISO/IEC 17025, which specifies general requirements for the competence of testing and calibration laboratories.

Environmental considerations are increasingly important in quality control standards. Regulations such as REACH in Europe and similar frameworks in other regions impose restrictions on certain substances in lubricants. DLS testing protocols must be designed to detect non-compliant additives or contaminants, supporting manufacturers in meeting these environmental compliance requirements.

Traceability represents another critical aspect of quality control in DLS implementation. Reference materials certified by national metrology institutes provide calibration standards for DLS instruments. NIST (USA), PTB (Germany), and other national bodies offer certified reference materials with precisely characterized particle size distributions that enable accurate calibration and verification of DLS systems used in lubricant analysis.

Data integrity and reporting standards constitute the final pillar of quality control compliance. GLP (Good Laboratory Practice) principles should govern data collection, storage, and reporting processes. Electronic records from DLS analysis must comply with data integrity requirements, including audit trails, electronic signatures, and secure data storage as outlined in regulations such as 21 CFR Part 11 in the United States or equivalent standards in other jurisdictions.

Quality control in industrial lubricant analysis using DLS must comply with ISO 4406, which classifies the level of contamination in lubricants by counting particles of different size ranges. This standard is particularly crucial for hydraulic fluids and lubricating oils where particle contamination directly impacts system performance and component longevity. Additionally, ASTM D7647 outlines standard test methods for automatic particle counting of lubricating and hydraulic fluids using dilution techniques.

For manufacturing facilities implementing DLS technology, compliance with ISO 9001 quality management systems is essential to ensure consistent and reliable analytical results. This framework requires documented procedures, regular calibration of equipment, and validation of testing methods. Furthermore, laboratories conducting DLS analysis should consider accreditation under ISO/IEC 17025, which specifies general requirements for the competence of testing and calibration laboratories.

Environmental considerations are increasingly important in quality control standards. Regulations such as REACH in Europe and similar frameworks in other regions impose restrictions on certain substances in lubricants. DLS testing protocols must be designed to detect non-compliant additives or contaminants, supporting manufacturers in meeting these environmental compliance requirements.

Traceability represents another critical aspect of quality control in DLS implementation. Reference materials certified by national metrology institutes provide calibration standards for DLS instruments. NIST (USA), PTB (Germany), and other national bodies offer certified reference materials with precisely characterized particle size distributions that enable accurate calibration and verification of DLS systems used in lubricant analysis.

Data integrity and reporting standards constitute the final pillar of quality control compliance. GLP (Good Laboratory Practice) principles should govern data collection, storage, and reporting processes. Electronic records from DLS analysis must comply with data integrity requirements, including audit trails, electronic signatures, and secure data storage as outlined in regulations such as 21 CFR Part 11 in the United States or equivalent standards in other jurisdictions.

Cost-Benefit Analysis of DLS Implementation

Implementing Dynamic Light Scattering (DLS) technology for industrial lubricant analysis requires careful consideration of financial implications. Initial investment costs for DLS equipment typically range from $30,000 to $100,000 depending on system sophistication, measurement capabilities, and additional features such as temperature control or automated sample handling. Beyond hardware acquisition, organizations must account for installation expenses, facility modifications, and staff training, which collectively may add 15-25% to the base equipment cost.

Operational expenses include maintenance contracts ($2,000-5,000 annually), consumables, calibration standards, and potential software licensing fees. Personnel costs represent another significant consideration, as specialized technicians commanding salaries of $60,000-80,000 annually may be required to operate advanced DLS systems and interpret complex data outputs.

Against these expenditures, DLS implementation offers substantial quantifiable benefits. Predictive maintenance enabled by precise lubricant condition monitoring can reduce equipment downtime by 30-45%, translating to savings of hundreds of thousands of dollars annually for manufacturing operations. Early detection of lubricant degradation extends oil change intervals by 20-40%, reducing both material costs and environmental impact through decreased waste oil generation.

Quality improvements represent another significant return on investment. DLS analysis helps maintain optimal lubricant performance, extending equipment lifespan by 15-25% and reducing replacement part expenses. For high-value industrial equipment, this extension can yield returns exceeding the initial DLS investment within 12-24 months.

The technology also delivers efficiency gains through rapid analysis capabilities. Traditional laboratory testing often requires 24-48 hours for results, while DLS can provide actionable data in minutes. This acceleration enables real-time decision-making and process adjustments, particularly valuable in continuous manufacturing environments where production interruptions carry substantial costs.

Risk mitigation constitutes a final, though less easily quantified, benefit. By identifying potential lubrication issues before catastrophic failure, DLS technology helps prevent accidents, associated liability, and reputational damage. Organizations implementing comprehensive lubricant monitoring programs report 40-60% reductions in unexpected equipment failures, significantly enhancing operational reliability and safety profiles.

Return on investment calculations typically show DLS systems achieving breakeven within 1-3 years, with faster returns in high-throughput industrial settings where lubricant quality directly impacts production capacity and product quality. This favorable cost-benefit ratio explains the accelerating adoption of DLS technology across manufacturing, energy production, and transportation sectors.

Operational expenses include maintenance contracts ($2,000-5,000 annually), consumables, calibration standards, and potential software licensing fees. Personnel costs represent another significant consideration, as specialized technicians commanding salaries of $60,000-80,000 annually may be required to operate advanced DLS systems and interpret complex data outputs.

Against these expenditures, DLS implementation offers substantial quantifiable benefits. Predictive maintenance enabled by precise lubricant condition monitoring can reduce equipment downtime by 30-45%, translating to savings of hundreds of thousands of dollars annually for manufacturing operations. Early detection of lubricant degradation extends oil change intervals by 20-40%, reducing both material costs and environmental impact through decreased waste oil generation.

Quality improvements represent another significant return on investment. DLS analysis helps maintain optimal lubricant performance, extending equipment lifespan by 15-25% and reducing replacement part expenses. For high-value industrial equipment, this extension can yield returns exceeding the initial DLS investment within 12-24 months.

The technology also delivers efficiency gains through rapid analysis capabilities. Traditional laboratory testing often requires 24-48 hours for results, while DLS can provide actionable data in minutes. This acceleration enables real-time decision-making and process adjustments, particularly valuable in continuous manufacturing environments where production interruptions carry substantial costs.

Risk mitigation constitutes a final, though less easily quantified, benefit. By identifying potential lubrication issues before catastrophic failure, DLS technology helps prevent accidents, associated liability, and reputational damage. Organizations implementing comprehensive lubricant monitoring programs report 40-60% reductions in unexpected equipment failures, significantly enhancing operational reliability and safety profiles.

Return on investment calculations typically show DLS systems achieving breakeven within 1-3 years, with faster returns in high-throughput industrial settings where lubricant quality directly impacts production capacity and product quality. This favorable cost-benefit ratio explains the accelerating adoption of DLS technology across manufacturing, energy production, and transportation sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!