Dynamic Light Scattering for Insights in Microfluidics

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLS Technology Background and Objectives

Dynamic Light Scattering (DLS) has evolved significantly since its theoretical foundations were established in the early 20th century. Originally developed for studying Brownian motion and molecular diffusion, DLS has transformed into a sophisticated analytical technique capable of characterizing particles in various dispersions. The technology leverages the principle that particles in suspension undergo random thermal motion, causing fluctuations in scattered light intensity when illuminated by a coherent light source such as a laser.

The integration of DLS with microfluidic systems represents a convergence of two powerful technologies that has gained momentum over the past decade. Microfluidics, the science of manipulating fluids at the microscale, offers precise control over small sample volumes and enables high-throughput analysis. When combined with DLS, it creates unprecedented opportunities for real-time monitoring of particle dynamics in confined geometries.

Current technological trends indicate a shift toward miniaturization, automation, and integration of DLS systems. Modern instruments feature advanced correlation algorithms, multi-angle detection capabilities, and improved sensitivity for detecting nanoparticles below 10 nm. The development of compact, portable DLS devices has expanded applications beyond traditional laboratory settings into point-of-care diagnostics and field-deployable environmental monitoring.

The primary objective of DLS in microfluidic applications is to provide non-invasive, real-time characterization of particles, droplets, and macromolecules within microchannels. This includes determining size distributions, monitoring aggregation processes, assessing stability of colloidal systems, and investigating molecular interactions under flow conditions. These capabilities are particularly valuable for understanding dynamic processes that occur during microfluidic operations.

Another critical goal is enhancing the analytical power of microfluidic platforms by incorporating DLS as an in-line detection method. This integration aims to eliminate the need for sample extraction and external analysis, thereby preserving the integrity of delicate samples and enabling continuous monitoring of time-dependent phenomena. The ultimate vision is to develop fully integrated lab-on-a-chip devices with embedded DLS functionality for applications ranging from pharmaceutical development to biological research.

Technical objectives also include overcoming current limitations such as multiple scattering effects in concentrated samples, interference from channel walls, and challenges in data interpretation for polydisperse or non-spherical particles. Researchers are actively pursuing innovations in optical configurations, signal processing algorithms, and theoretical models to address these challenges and expand the applicability of DLS in complex microfluidic environments.

The integration of DLS with microfluidic systems represents a convergence of two powerful technologies that has gained momentum over the past decade. Microfluidics, the science of manipulating fluids at the microscale, offers precise control over small sample volumes and enables high-throughput analysis. When combined with DLS, it creates unprecedented opportunities for real-time monitoring of particle dynamics in confined geometries.

Current technological trends indicate a shift toward miniaturization, automation, and integration of DLS systems. Modern instruments feature advanced correlation algorithms, multi-angle detection capabilities, and improved sensitivity for detecting nanoparticles below 10 nm. The development of compact, portable DLS devices has expanded applications beyond traditional laboratory settings into point-of-care diagnostics and field-deployable environmental monitoring.

The primary objective of DLS in microfluidic applications is to provide non-invasive, real-time characterization of particles, droplets, and macromolecules within microchannels. This includes determining size distributions, monitoring aggregation processes, assessing stability of colloidal systems, and investigating molecular interactions under flow conditions. These capabilities are particularly valuable for understanding dynamic processes that occur during microfluidic operations.

Another critical goal is enhancing the analytical power of microfluidic platforms by incorporating DLS as an in-line detection method. This integration aims to eliminate the need for sample extraction and external analysis, thereby preserving the integrity of delicate samples and enabling continuous monitoring of time-dependent phenomena. The ultimate vision is to develop fully integrated lab-on-a-chip devices with embedded DLS functionality for applications ranging from pharmaceutical development to biological research.

Technical objectives also include overcoming current limitations such as multiple scattering effects in concentrated samples, interference from channel walls, and challenges in data interpretation for polydisperse or non-spherical particles. Researchers are actively pursuing innovations in optical configurations, signal processing algorithms, and theoretical models to address these challenges and expand the applicability of DLS in complex microfluidic environments.

Market Applications of DLS in Microfluidic Systems

Dynamic Light Scattering (DLS) technology has found significant applications across various market segments within microfluidic systems. The pharmaceutical industry represents one of the largest adopters, utilizing DLS-integrated microfluidic platforms for drug formulation analysis, protein aggregation studies, and quality control processes. These applications have demonstrated substantial market growth, with pharmaceutical companies increasingly incorporating DLS microfluidic systems into their standard analytical workflows.

The biotechnology sector has embraced DLS microfluidic systems for characterizing biomolecules, exosomes, and nanoparticle-based therapeutics. The ability to analyze samples with minimal volume requirements has proven particularly valuable for researchers working with rare or expensive biological materials. This market segment has shown consistent growth as precision medicine initiatives drive demand for advanced analytical capabilities.

In the field of nanomaterials and advanced materials development, DLS microfluidic systems offer manufacturers crucial insights into particle size distribution, stability, and surface characteristics. These applications support quality control processes and enable more efficient material optimization. The market for these applications continues to expand as nanomaterials find new uses across industries.

Clinical diagnostics represents an emerging but rapidly growing application area. DLS microfluidic systems are being developed for point-of-care diagnostics, enabling rapid analysis of biological samples for disease biomarkers. While still in early commercialization stages, this segment shows significant promise, particularly for applications in resource-limited settings where traditional analytical equipment is impractical.

The food and beverage industry has begun adopting DLS microfluidic technology for quality control applications, including emulsion stability analysis and detection of contaminants. This market segment, though smaller than pharmaceutical applications, demonstrates steady growth as food safety regulations become increasingly stringent worldwide.

Academic and research institutions constitute a substantial market segment, utilizing DLS microfluidic systems for fundamental research across disciplines. This segment drives innovation in application development, often pioneering techniques that later transition to industrial applications.

Environmental monitoring applications, including water quality assessment and detection of microplastics, represent a developing market segment with significant growth potential. The portability and reduced sample volume requirements of microfluidic DLS systems make them particularly suitable for field-based environmental analysis.

The market landscape for DLS microfluidic systems is characterized by a shift toward more integrated, automated platforms that require minimal user intervention. This trend aligns with broader industry movements toward high-throughput screening and automated analytical workflows, suggesting continued market expansion as technology accessibility improves and applications diversify.

The biotechnology sector has embraced DLS microfluidic systems for characterizing biomolecules, exosomes, and nanoparticle-based therapeutics. The ability to analyze samples with minimal volume requirements has proven particularly valuable for researchers working with rare or expensive biological materials. This market segment has shown consistent growth as precision medicine initiatives drive demand for advanced analytical capabilities.

In the field of nanomaterials and advanced materials development, DLS microfluidic systems offer manufacturers crucial insights into particle size distribution, stability, and surface characteristics. These applications support quality control processes and enable more efficient material optimization. The market for these applications continues to expand as nanomaterials find new uses across industries.

Clinical diagnostics represents an emerging but rapidly growing application area. DLS microfluidic systems are being developed for point-of-care diagnostics, enabling rapid analysis of biological samples for disease biomarkers. While still in early commercialization stages, this segment shows significant promise, particularly for applications in resource-limited settings where traditional analytical equipment is impractical.

The food and beverage industry has begun adopting DLS microfluidic technology for quality control applications, including emulsion stability analysis and detection of contaminants. This market segment, though smaller than pharmaceutical applications, demonstrates steady growth as food safety regulations become increasingly stringent worldwide.

Academic and research institutions constitute a substantial market segment, utilizing DLS microfluidic systems for fundamental research across disciplines. This segment drives innovation in application development, often pioneering techniques that later transition to industrial applications.

Environmental monitoring applications, including water quality assessment and detection of microplastics, represent a developing market segment with significant growth potential. The portability and reduced sample volume requirements of microfluidic DLS systems make them particularly suitable for field-based environmental analysis.

The market landscape for DLS microfluidic systems is characterized by a shift toward more integrated, automated platforms that require minimal user intervention. This trend aligns with broader industry movements toward high-throughput screening and automated analytical workflows, suggesting continued market expansion as technology accessibility improves and applications diversify.

Current Challenges in DLS Implementation

Despite the significant potential of Dynamic Light Scattering (DLS) in microfluidic applications, several technical challenges currently impede its widespread implementation and optimal performance. The miniaturization of DLS systems for integration with microfluidic platforms presents substantial engineering difficulties, particularly in maintaining optical alignment precision at microscale dimensions. Conventional DLS setups require bulky optical components that are not readily compatible with the compact nature of microfluidic devices.

Signal-to-noise ratio (SNR) optimization remains a critical challenge, as the reduced sample volumes in microfluidic channels significantly diminish the scattered light intensity. This issue is further exacerbated when analyzing samples with low particle concentrations or particles with small scattering cross-sections, making reliable data acquisition problematic in many practical scenarios.

The presence of multiple scattering effects in concentrated samples introduces considerable complexity in data interpretation. While microfluidic systems often work with concentrated samples to compensate for small volumes, these higher concentrations can lead to light scattering from multiple particles, complicating the extraction of meaningful size distribution information and reducing measurement accuracy.

Flow-induced artifacts represent another significant challenge. The inherent flow dynamics in microfluidic channels can introduce additional motion components that interfere with Brownian motion measurements, the fundamental basis of DLS analysis. Distinguishing between Brownian motion and flow-induced particle movement requires sophisticated algorithms and careful experimental design that are not yet fully developed.

Temperature control and stability present technical hurdles that affect measurement reliability. DLS measurements are inherently sensitive to temperature fluctuations as they directly influence particle diffusion coefficients. Maintaining precise temperature control within microfluidic channels is challenging due to their small thermal mass and potential for localized heating from focused laser sources.

Integration with existing microfluidic fabrication processes poses compatibility issues. Many microfluidic devices are fabricated using materials with suboptimal optical properties for DLS measurements, such as PDMS which can exhibit autofluorescence or scattering that interferes with DLS signals. Additionally, the incorporation of optical windows or interfaces for light transmission without distortion adds complexity to device design and fabrication.

Real-time analysis capabilities remain limited by computational demands and algorithm efficiency. The processing of DLS data typically requires complex correlation analysis and inversion algorithms that are computationally intensive, creating barriers to real-time monitoring applications in dynamic microfluidic processes where immediate feedback is essential.

Signal-to-noise ratio (SNR) optimization remains a critical challenge, as the reduced sample volumes in microfluidic channels significantly diminish the scattered light intensity. This issue is further exacerbated when analyzing samples with low particle concentrations or particles with small scattering cross-sections, making reliable data acquisition problematic in many practical scenarios.

The presence of multiple scattering effects in concentrated samples introduces considerable complexity in data interpretation. While microfluidic systems often work with concentrated samples to compensate for small volumes, these higher concentrations can lead to light scattering from multiple particles, complicating the extraction of meaningful size distribution information and reducing measurement accuracy.

Flow-induced artifacts represent another significant challenge. The inherent flow dynamics in microfluidic channels can introduce additional motion components that interfere with Brownian motion measurements, the fundamental basis of DLS analysis. Distinguishing between Brownian motion and flow-induced particle movement requires sophisticated algorithms and careful experimental design that are not yet fully developed.

Temperature control and stability present technical hurdles that affect measurement reliability. DLS measurements are inherently sensitive to temperature fluctuations as they directly influence particle diffusion coefficients. Maintaining precise temperature control within microfluidic channels is challenging due to their small thermal mass and potential for localized heating from focused laser sources.

Integration with existing microfluidic fabrication processes poses compatibility issues. Many microfluidic devices are fabricated using materials with suboptimal optical properties for DLS measurements, such as PDMS which can exhibit autofluorescence or scattering that interferes with DLS signals. Additionally, the incorporation of optical windows or interfaces for light transmission without distortion adds complexity to device design and fabrication.

Real-time analysis capabilities remain limited by computational demands and algorithm efficiency. The processing of DLS data typically requires complex correlation analysis and inversion algorithms that are computationally intensive, creating barriers to real-time monitoring applications in dynamic microfluidic processes where immediate feedback is essential.

Current DLS Integration Solutions

01 Fundamental principles and apparatus for Dynamic Light Scattering

Dynamic Light Scattering (DLS) is a technique used to measure the size distribution of particles in suspension or polymers in solution. The fundamental principles involve analyzing the intensity fluctuations of scattered light from particles undergoing Brownian motion. Various apparatus designs incorporate laser light sources, detectors, and optical components to capture and analyze these fluctuations. The technology enables precise measurement of particle sizes ranging from nanometers to micrometers by correlating the scattered light intensity over time.- Principles and Applications of Dynamic Light Scattering: Dynamic Light Scattering (DLS) is a technique used to measure the size distribution of particles in suspension or polymers in solution. It works by analyzing the intensity fluctuations in scattered light caused by Brownian motion of particles. This technique provides insights into particle size, molecular weight, and aggregation behavior, making it valuable for characterizing nanoparticles, proteins, and colloidal systems. DLS measurements can be performed in various environments and conditions to study particle behavior under different circumstances.

- Advanced DLS Instrumentation and Methodology: Advancements in DLS instrumentation have led to improved sensitivity, resolution, and data analysis capabilities. Modern DLS systems incorporate sophisticated optical components, detectors, and signal processing algorithms to enhance measurement accuracy. These improvements include multi-angle detection systems, correlation techniques, and automated sample handling. Enhanced methodologies allow for measurements in complex media, at different temperatures, and with higher precision, expanding the applicability of DLS across various scientific and industrial fields.

- DLS for Biological and Pharmaceutical Applications: Dynamic Light Scattering has become an essential tool in biological and pharmaceutical research for characterizing biomolecules and drug delivery systems. It enables the analysis of protein stability, aggregation, and interactions in solution. In pharmaceutical development, DLS helps in formulation optimization, quality control, and stability assessment of drug products. The non-invasive nature of DLS makes it particularly suitable for analyzing delicate biological samples without disrupting their native state, providing valuable insights into biomolecular behavior under physiologically relevant conditions.

- Integration of DLS with Other Analytical Techniques: Combining Dynamic Light Scattering with complementary analytical techniques creates powerful hybrid approaches for comprehensive sample characterization. Integration with techniques such as static light scattering, microscopy, spectroscopy, or chromatography provides multidimensional data about particle properties. These integrated systems offer simultaneous measurements of size, structure, composition, and other physical parameters. The synergistic use of multiple techniques overcomes the limitations of individual methods and provides more complete insights into complex systems across various scientific disciplines.

- Data Processing and Computational Approaches in DLS: Advanced computational methods have revolutionized data processing and interpretation in Dynamic Light Scattering. Machine learning algorithms, statistical models, and specialized software enable more accurate analysis of complex scattering data. These computational approaches improve the resolution of multimodal distributions, enhance signal-to-noise ratios, and facilitate the extraction of meaningful information from raw data. Cloud-based platforms and automated analysis workflows have made DLS data processing more accessible and efficient, allowing researchers to gain deeper insights from their measurements with greater confidence.

02 Advanced data processing methods for DLS measurements

Advanced computational techniques have been developed to enhance the analysis of Dynamic Light Scattering data. These methods include sophisticated algorithms for signal processing, noise reduction, and statistical analysis of correlation functions. Machine learning approaches are increasingly being applied to interpret complex DLS data, particularly for polydisperse samples. Modern data processing techniques enable more accurate particle size distribution determination, improved resolution between different particle populations, and better handling of background interference in challenging sample environments.Expand Specific Solutions03 Applications of DLS in pharmaceutical and biological research

Dynamic Light Scattering has become an essential analytical tool in pharmaceutical development and biological research. It is widely used for characterizing drug delivery systems, protein formulations, and nanoparticle-based therapeutics. The technique provides critical insights into protein aggregation, stability of biological macromolecules, and interactions between biomolecules in solution. DLS enables researchers to monitor changes in particle size and distribution under various conditions, supporting formulation development, quality control, and understanding of biological processes at the molecular level.Expand Specific Solutions04 Integration of DLS with complementary analytical techniques

Modern analytical systems increasingly combine Dynamic Light Scattering with complementary techniques to provide more comprehensive characterization of complex samples. These integrated approaches may combine DLS with static light scattering, zeta potential measurements, rheology, spectroscopy, or microscopy techniques. Such multi-modal analysis provides correlated information about particle size, structure, composition, and behavior in solution. The integration of multiple analytical methods enhances the reliability of measurements and provides deeper insights into complex colloidal and macromolecular systems.Expand Specific Solutions05 Recent innovations in DLS technology and methodology

Recent advancements in Dynamic Light Scattering technology have expanded its capabilities and applications. Innovations include miniaturized and portable DLS systems, high-throughput platforms for multiple sample analysis, and specialized instruments for challenging sample types. Methodological improvements have enhanced the ability to analyze highly concentrated samples, non-spherical particles, and heterogeneous mixtures. New approaches also focus on real-time monitoring of dynamic processes, such as aggregation kinetics, particle interactions, and phase transitions, providing temporal insights into evolving systems.Expand Specific Solutions

Leading Companies in DLS Instrumentation

Dynamic Light Scattering (DLS) in microfluidics is currently in a growth phase, with the market expanding as applications in nanoparticle characterization and biomolecular analysis increase. The global market is estimated at approximately $500 million, growing at 8-10% annually. Leading companies like Malvern Panalytical and Wyatt Technology have established mature DLS technologies, while academic institutions such as Huazhong University of Science & Technology and Zhejiang University are advancing fundamental research. Companies including Shimadzu, Agilent Technologies, and Robert Bosch are integrating DLS into microfluidic platforms for commercial applications. The technology is transitioning from research-focused to industry-standard applications, with increasing adoption in pharmaceutical development, material science, and biomedical diagnostics.

Wyatt Technology LLC

Technical Solution: Wyatt Technology has pioneered advanced Dynamic Light Scattering (DLS) solutions specifically optimized for microfluidic applications. Their DAWN® and Mobius® instruments integrate multi-angle light scattering with DLS capabilities to provide real-time, in-flow particle characterization. The company's technology employs proprietary algorithms that compensate for flow-induced effects on scattering patterns, allowing accurate size distribution measurements even in continuous flow environments. Their microfluidic-compatible DLS systems feature specialized flow cells with optimized optical geometries that minimize wall effects and maximize signal quality. Wyatt has also developed adaptive correlation techniques that can distinguish between Brownian motion and flow-induced movement, enabling true particle characterization in dynamic microfluidic environments. Their systems achieve detection limits down to nanometer-scale particles even in complex biological samples, making them particularly valuable for protein aggregation studies and nanoparticle characterization in lab-on-chip applications.

Strengths: Superior resolution for polydisperse samples through multi-angle detection capabilities; exceptional sensitivity for biomolecular applications; seamless integration with existing microfluidic platforms. Weaknesses: Higher price point compared to conventional DLS systems; requires more sophisticated data interpretation; limited throughput for high-volume industrial applications.

Malvern Panalytical Ltd.

Technical Solution: Malvern Panalytical has developed the Zetasizer series, which incorporates advanced DLS technology specifically adapted for microfluidic applications. Their proprietary Non-Invasive Back Scatter (NIBS) technology optimizes signal detection by automatically adjusting the measurement position within microfluidic channels to obtain the best signal-to-noise ratio. The company's microfluidic DLS solutions feature patented optical arrangements that minimize multiple scattering effects, crucial for accurate measurements in confined geometries. Their systems incorporate adaptive correlation algorithms that can compensate for flow conditions, enabling reliable measurements even in dynamic microfluidic environments. Malvern has also pioneered the integration of DLS with Raman spectroscopy in microfluidic platforms, allowing simultaneous size and chemical composition analysis. Their technology enables continuous monitoring of particle size distributions, zeta potential, and molecular interactions within microfluidic devices, with applications ranging from protein characterization to nanoparticle synthesis monitoring. Recent developments include machine learning algorithms that improve data interpretation for complex biological samples in microfluidic channels.

Strengths: Exceptional measurement reproducibility; comprehensive software suite for data analysis; versatile application range from proteins to nanoparticles. Weaknesses: Systems require careful calibration for microfluidic applications; performance can be affected by sample concentration limitations; integration with some third-party microfluidic platforms may require custom adaptations.

Key Patents and Innovations in DLS Technology

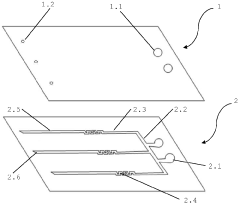

MICROFLUID DEVICE FOR OPTICAL SENSING

PatentActiveBR102019020984A2

Innovation

- A microfluidic device utilizing dynamic light scattering with a single optical fiber for each perfusion chamber, featuring modular and reversible design, allowing continuous monitoring of microbial kinetics without the need for complex alignment and enabling efficient mixing to prevent agglomeration.

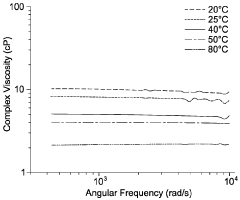

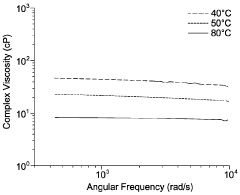

Dynamic light scattering based optical microrheology in non-aqueous solutions

PatentInactiveGB2537550A

Innovation

- The use of hydrophobic probe particles with specific surface chemistries, such as aromatic or aliphatic groups, to effectively disperse in non-aqueous solvents, allowing for the measurement of rheological properties through DLS by embedding these particles in the sample and detecting scattered photons.

Miniaturization Trends and Opportunities

The miniaturization of Dynamic Light Scattering (DLS) technology represents a significant frontier in microfluidic analysis systems. Current trends show a decisive shift toward compact, portable DLS devices that maintain high sensitivity while reducing overall footprint. This evolution is driven by the increasing demand for point-of-care diagnostics and on-site analytical capabilities across pharmaceutical development, environmental monitoring, and biomedical research.

Industry forecasts indicate that the market for miniaturized DLS systems is expected to grow at a CAGR of approximately 8.5% through 2028, with particular acceleration in applications requiring real-time particle characterization in confined spaces. The integration of microelectromechanical systems (MEMS) with DLS technology has enabled significant reductions in optical component sizes while maintaining measurement precision for particles in the nanometer range.

Recent technological breakthroughs have focused on overcoming the traditional limitations of miniaturized light scattering systems, particularly regarding signal-to-noise ratios and detection sensitivity. Advanced photonic integrated circuits (PICs) are emerging as key enablers, allowing for the consolidation of multiple optical components onto single chips measuring just a few square millimeters. These developments have reduced power requirements by up to 70% compared to conventional benchtop DLS systems.

The convergence of microfluidic platforms with miniaturized DLS presents unique opportunities for continuous monitoring applications. Lab-on-a-chip devices incorporating DLS detection zones can now analyze sub-microliter sample volumes, representing orders of magnitude reduction in required sample quantities. This capability is particularly valuable in biological applications where sample volumes are inherently limited, such as exosome characterization or protein aggregation studies.

Opportunities for further miniaturization lie in several promising directions. The development of vertical-cavity surface-emitting lasers (VCSELs) specifically optimized for DLS applications offers potential for further size reduction while maintaining coherence properties essential for accurate measurements. Additionally, advances in complementary metal-oxide-semiconductor (CMOS) detector arrays are enabling higher sensitivity in smaller form factors, potentially eliminating the need for bulky photomultiplier tubes in next-generation devices.

Cross-disciplinary collaboration between optical engineering, microfluidics, and data science is accelerating innovation in this space. Machine learning algorithms are increasingly being employed to extract meaningful information from noisy DLS signals in miniaturized systems, compensating for some of the physical limitations imposed by smaller optical paths and detection areas. This computational approach to signal enhancement represents a paradigm shift in how miniaturization challenges are addressed.

Industry forecasts indicate that the market for miniaturized DLS systems is expected to grow at a CAGR of approximately 8.5% through 2028, with particular acceleration in applications requiring real-time particle characterization in confined spaces. The integration of microelectromechanical systems (MEMS) with DLS technology has enabled significant reductions in optical component sizes while maintaining measurement precision for particles in the nanometer range.

Recent technological breakthroughs have focused on overcoming the traditional limitations of miniaturized light scattering systems, particularly regarding signal-to-noise ratios and detection sensitivity. Advanced photonic integrated circuits (PICs) are emerging as key enablers, allowing for the consolidation of multiple optical components onto single chips measuring just a few square millimeters. These developments have reduced power requirements by up to 70% compared to conventional benchtop DLS systems.

The convergence of microfluidic platforms with miniaturized DLS presents unique opportunities for continuous monitoring applications. Lab-on-a-chip devices incorporating DLS detection zones can now analyze sub-microliter sample volumes, representing orders of magnitude reduction in required sample quantities. This capability is particularly valuable in biological applications where sample volumes are inherently limited, such as exosome characterization or protein aggregation studies.

Opportunities for further miniaturization lie in several promising directions. The development of vertical-cavity surface-emitting lasers (VCSELs) specifically optimized for DLS applications offers potential for further size reduction while maintaining coherence properties essential for accurate measurements. Additionally, advances in complementary metal-oxide-semiconductor (CMOS) detector arrays are enabling higher sensitivity in smaller form factors, potentially eliminating the need for bulky photomultiplier tubes in next-generation devices.

Cross-disciplinary collaboration between optical engineering, microfluidics, and data science is accelerating innovation in this space. Machine learning algorithms are increasingly being employed to extract meaningful information from noisy DLS signals in miniaturized systems, compensating for some of the physical limitations imposed by smaller optical paths and detection areas. This computational approach to signal enhancement represents a paradigm shift in how miniaturization challenges are addressed.

Data Analysis Algorithms for Real-time DLS Measurements

Real-time Dynamic Light Scattering (DLS) measurements in microfluidic environments require sophisticated data analysis algorithms to extract meaningful information from scattered light signals. These algorithms must process complex correlation functions and transform raw intensity fluctuation data into particle size distributions with high accuracy and minimal latency.

The cornerstone of DLS data analysis is the autocorrelation function (ACF), which quantifies the similarity between scattered light intensity at different time intervals. Modern algorithms employ multiple approaches to analyze these correlation functions, including the method of cumulants, CONTIN, maximum entropy methods, and non-negative least squares (NNLS). Each method offers distinct advantages depending on the specific microfluidic application and sample characteristics.

For monodisperse samples in microfluidic channels, the cumulants method provides efficient analysis by fitting the correlation function to a single exponential decay. This approach yields the z-average hydrodynamic diameter and polydispersity index rapidly enough for real-time feedback in microfluidic separations. However, more complex samples require advanced algorithms capable of resolving multimodal distributions.

Machine learning approaches have recently revolutionized DLS data processing in microfluidic applications. Neural networks trained on vast datasets of correlation functions can now identify particle size distributions with remarkable accuracy, even in challenging flow conditions. These AI-enhanced algorithms can compensate for flow-induced distortions in the correlation function that traditionally complicated microfluidic DLS measurements.

Signal filtering techniques represent another critical component of real-time DLS analysis algorithms. Adaptive filters that respond to changing flow conditions can significantly improve signal-to-noise ratios in microfluidic environments. Wavelet transforms and Kalman filtering have proven particularly effective for extracting meaningful DLS data from noisy microfluidic signals, enabling reliable measurements even at low particle concentrations.

Hardware acceleration through FPGAs and GPUs has dramatically reduced processing times for computationally intensive DLS algorithms. This advancement enables truly real-time analysis in microfluidic devices, with latencies below 10 milliseconds for complete size distribution calculations. Such capabilities are essential for applications requiring immediate feedback, such as droplet sorting or quality control in continuous microfluidic manufacturing.

Integration of these algorithms with microfluidic control systems creates powerful feedback loops for process optimization. By continuously analyzing particle characteristics through DLS and adjusting flow parameters accordingly, these systems can maintain optimal conditions for applications ranging from nanoparticle synthesis to protein aggregation studies. The development of standardized software interfaces has further facilitated this integration, allowing researchers to implement sophisticated DLS analysis without specialized programming expertise.

The cornerstone of DLS data analysis is the autocorrelation function (ACF), which quantifies the similarity between scattered light intensity at different time intervals. Modern algorithms employ multiple approaches to analyze these correlation functions, including the method of cumulants, CONTIN, maximum entropy methods, and non-negative least squares (NNLS). Each method offers distinct advantages depending on the specific microfluidic application and sample characteristics.

For monodisperse samples in microfluidic channels, the cumulants method provides efficient analysis by fitting the correlation function to a single exponential decay. This approach yields the z-average hydrodynamic diameter and polydispersity index rapidly enough for real-time feedback in microfluidic separations. However, more complex samples require advanced algorithms capable of resolving multimodal distributions.

Machine learning approaches have recently revolutionized DLS data processing in microfluidic applications. Neural networks trained on vast datasets of correlation functions can now identify particle size distributions with remarkable accuracy, even in challenging flow conditions. These AI-enhanced algorithms can compensate for flow-induced distortions in the correlation function that traditionally complicated microfluidic DLS measurements.

Signal filtering techniques represent another critical component of real-time DLS analysis algorithms. Adaptive filters that respond to changing flow conditions can significantly improve signal-to-noise ratios in microfluidic environments. Wavelet transforms and Kalman filtering have proven particularly effective for extracting meaningful DLS data from noisy microfluidic signals, enabling reliable measurements even at low particle concentrations.

Hardware acceleration through FPGAs and GPUs has dramatically reduced processing times for computationally intensive DLS algorithms. This advancement enables truly real-time analysis in microfluidic devices, with latencies below 10 milliseconds for complete size distribution calculations. Such capabilities are essential for applications requiring immediate feedback, such as droplet sorting or quality control in continuous microfluidic manufacturing.

Integration of these algorithms with microfluidic control systems creates powerful feedback loops for process optimization. By continuously analyzing particle characteristics through DLS and adjusting flow parameters accordingly, these systems can maintain optimal conditions for applications ranging from nanoparticle synthesis to protein aggregation studies. The development of standardized software interfaces has further facilitated this integration, allowing researchers to implement sophisticated DLS analysis without specialized programming expertise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!