How to Analyze Polymers Under Stress with Dynamic Light Scattering

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Stress Analysis Background and Objectives

Dynamic Light Scattering (DLS) has emerged as a powerful analytical technique for studying polymer behavior under stress conditions since its initial development in the 1960s. The technique has evolved significantly from basic particle size measurements to sophisticated analyses of polymer dynamics, conformational changes, and mechanical responses. This evolution has been driven by advancements in laser technology, computational methods, and theoretical frameworks for interpreting light scattering data in complex systems.

The application of DLS to polymers under stress represents a critical intersection of materials science, physics, and engineering, addressing fundamental questions about how polymer structures respond to external forces. Understanding these responses is essential for developing advanced materials with tailored mechanical properties for applications ranging from biomedical devices to aerospace components.

Current technological trends in this field include the integration of DLS with rheological measurements, the development of multi-angle and time-resolved DLS systems, and the application of machine learning algorithms for data interpretation. These innovations are expanding the capabilities of DLS beyond traditional limitations, enabling researchers to probe polymer dynamics across multiple length and time scales simultaneously.

The primary objective of polymer stress analysis using DLS is to establish quantitative relationships between applied mechanical stress and resulting changes in polymer chain conformation, aggregation behavior, and molecular mobility. This includes characterizing the viscoelastic response of polymer solutions and melts, identifying critical stress thresholds for structural transitions, and monitoring relaxation processes following stress removal.

Secondary objectives include developing standardized protocols for sample preparation and measurement conditions, improving data analysis algorithms for extracting meaningful parameters from complex scattering patterns, and establishing correlations between DLS-derived parameters and macroscopic material properties. These efforts aim to transform DLS from a primarily academic research tool to a robust industrial quality control and materials development platform.

The ultimate goal is to leverage DLS technology to enable predictive modeling of polymer performance under various stress conditions, facilitating the rational design of new polymer materials with optimized mechanical properties. This would significantly reduce the time and cost associated with empirical trial-and-error approaches currently dominating polymer development processes, while opening new possibilities for creating materials with previously unattainable combinations of properties.

The application of DLS to polymers under stress represents a critical intersection of materials science, physics, and engineering, addressing fundamental questions about how polymer structures respond to external forces. Understanding these responses is essential for developing advanced materials with tailored mechanical properties for applications ranging from biomedical devices to aerospace components.

Current technological trends in this field include the integration of DLS with rheological measurements, the development of multi-angle and time-resolved DLS systems, and the application of machine learning algorithms for data interpretation. These innovations are expanding the capabilities of DLS beyond traditional limitations, enabling researchers to probe polymer dynamics across multiple length and time scales simultaneously.

The primary objective of polymer stress analysis using DLS is to establish quantitative relationships between applied mechanical stress and resulting changes in polymer chain conformation, aggregation behavior, and molecular mobility. This includes characterizing the viscoelastic response of polymer solutions and melts, identifying critical stress thresholds for structural transitions, and monitoring relaxation processes following stress removal.

Secondary objectives include developing standardized protocols for sample preparation and measurement conditions, improving data analysis algorithms for extracting meaningful parameters from complex scattering patterns, and establishing correlations between DLS-derived parameters and macroscopic material properties. These efforts aim to transform DLS from a primarily academic research tool to a robust industrial quality control and materials development platform.

The ultimate goal is to leverage DLS technology to enable predictive modeling of polymer performance under various stress conditions, facilitating the rational design of new polymer materials with optimized mechanical properties. This would significantly reduce the time and cost associated with empirical trial-and-error approaches currently dominating polymer development processes, while opening new possibilities for creating materials with previously unattainable combinations of properties.

Market Applications for Polymer Stress Analysis

The polymer stress analysis market spans multiple industries, with dynamic light scattering (DLS) techniques finding increasingly diverse applications. In the pharmaceutical sector, polymer stress analysis enables manufacturers to optimize drug delivery systems by monitoring how polymeric carriers respond to physiological stresses, ensuring consistent release profiles and improved bioavailability. This application segment is experiencing rapid growth due to the expanding market for controlled-release formulations and personalized medicine approaches.

In the automotive and aerospace industries, polymer stress analysis serves critical safety and performance functions. Manufacturers utilize DLS to evaluate how polymer composites respond to mechanical stress, temperature variations, and chemical exposure, helping to predict material failure points and extend component lifespans. The growing shift toward lightweight materials in transportation has accelerated demand for advanced polymer testing capabilities, with market analysts noting a significant uptick in investment in this sector over the past five years.

The packaging industry represents another substantial market for polymer stress analysis. Manufacturers employ DLS techniques to develop packaging materials with optimal mechanical properties that maintain integrity throughout the supply chain while minimizing material usage. Sustainable packaging initiatives have further driven demand for precise polymer stress analysis, as companies seek to develop bio-based polymers with performance characteristics comparable to traditional plastics.

Electronics manufacturing constitutes a high-value application segment, where polymer stress analysis helps ensure the reliability of components under thermal cycling and mechanical strain. As devices continue to miniaturize while incorporating more complex functionality, the need for precise characterization of polymer behavior under stress has intensified, particularly in flexible electronics and wearable technology sectors.

The construction industry utilizes polymer stress analysis to evaluate the durability of polymer-modified concrete, sealants, and structural composites. DLS techniques help predict how these materials will perform under environmental stresses, including temperature fluctuations, moisture exposure, and mechanical loading, enabling more accurate lifecycle assessments and maintenance planning.

Biomedical applications represent one of the fastest-growing market segments, with polymer stress analysis being crucial for the development of implantable devices, tissue engineering scaffolds, and diagnostic platforms. Researchers use DLS to understand how polymeric biomaterials respond to physiological stresses, ensuring compatibility with biological systems and appropriate mechanical properties for specific applications.

In the automotive and aerospace industries, polymer stress analysis serves critical safety and performance functions. Manufacturers utilize DLS to evaluate how polymer composites respond to mechanical stress, temperature variations, and chemical exposure, helping to predict material failure points and extend component lifespans. The growing shift toward lightweight materials in transportation has accelerated demand for advanced polymer testing capabilities, with market analysts noting a significant uptick in investment in this sector over the past five years.

The packaging industry represents another substantial market for polymer stress analysis. Manufacturers employ DLS techniques to develop packaging materials with optimal mechanical properties that maintain integrity throughout the supply chain while minimizing material usage. Sustainable packaging initiatives have further driven demand for precise polymer stress analysis, as companies seek to develop bio-based polymers with performance characteristics comparable to traditional plastics.

Electronics manufacturing constitutes a high-value application segment, where polymer stress analysis helps ensure the reliability of components under thermal cycling and mechanical strain. As devices continue to miniaturize while incorporating more complex functionality, the need for precise characterization of polymer behavior under stress has intensified, particularly in flexible electronics and wearable technology sectors.

The construction industry utilizes polymer stress analysis to evaluate the durability of polymer-modified concrete, sealants, and structural composites. DLS techniques help predict how these materials will perform under environmental stresses, including temperature fluctuations, moisture exposure, and mechanical loading, enabling more accurate lifecycle assessments and maintenance planning.

Biomedical applications represent one of the fastest-growing market segments, with polymer stress analysis being crucial for the development of implantable devices, tissue engineering scaffolds, and diagnostic platforms. Researchers use DLS to understand how polymeric biomaterials respond to physiological stresses, ensuring compatibility with biological systems and appropriate mechanical properties for specific applications.

Current DLS Technology Limitations for Stressed Polymers

Dynamic Light Scattering (DLS) has emerged as a powerful technique for polymer analysis, yet it faces significant limitations when applied to polymers under stress conditions. The conventional DLS methodology was primarily designed for particles in equilibrium states, creating fundamental challenges when analyzing stressed polymer systems. These limitations stem from both theoretical assumptions and practical implementation constraints.

The primary theoretical limitation lies in the basic premise of DLS analysis, which assumes that scattering particles undergo Brownian motion in a state of thermodynamic equilibrium. When polymers are subjected to mechanical, thermal, or chemical stress, their motion deviates significantly from this assumption, leading to potentially misleading correlation functions and inaccurate size distributions.

For polymers under shear stress, the non-random directional movement introduces anisotropic scattering patterns that standard DLS algorithms struggle to interpret correctly. The correlation functions become complex mixtures of relaxation processes that cannot be easily deconvoluted using traditional cumulant or CONTIN analysis methods.

Temporal resolution presents another significant challenge. Many stress-induced conformational changes in polymers occur on timescales that conventional DLS instruments cannot adequately capture. The typical acquisition times of several minutes make it difficult to monitor rapid structural transitions that may occur within seconds or milliseconds under dynamic stress conditions.

Signal-to-noise ratio deterioration becomes particularly problematic for stressed polymers. As polymers deform under stress, their scattering intensity often decreases while polydispersity increases, resulting in broader correlation functions with lower signal quality. This effect is especially pronounced for dilute solutions or when analyzing smaller polymer segments.

Multiple scattering effects introduce additional complications. Stressed polymers frequently form temporary aggregates or exhibit increased local concentration fluctuations, leading to multiple scattering events that violate the single-scattering assumption fundamental to standard DLS analysis algorithms.

The temperature control systems in conventional DLS instruments often lack the precision required for stress-related studies. Even minor temperature fluctuations can significantly affect polymer conformation under stress, introducing artifacts that are difficult to distinguish from genuine stress-induced changes.

Sample preparation protocols for stressed polymers remain largely unstandardized. The act of transferring a stressed polymer sample to a DLS measurement cell can itself alter the stress state, raising questions about data validity and reproducibility. This becomes particularly challenging for in-situ measurements of polymers under continuous stress application.

Finally, data interpretation frameworks for stressed polymers are underdeveloped. Current DLS software packages typically lack specialized algorithms for distinguishing between thermal fluctuations, stress-induced conformational changes, and potential aggregation phenomena, leaving researchers with ambiguous results that require extensive complementary techniques for validation.

The primary theoretical limitation lies in the basic premise of DLS analysis, which assumes that scattering particles undergo Brownian motion in a state of thermodynamic equilibrium. When polymers are subjected to mechanical, thermal, or chemical stress, their motion deviates significantly from this assumption, leading to potentially misleading correlation functions and inaccurate size distributions.

For polymers under shear stress, the non-random directional movement introduces anisotropic scattering patterns that standard DLS algorithms struggle to interpret correctly. The correlation functions become complex mixtures of relaxation processes that cannot be easily deconvoluted using traditional cumulant or CONTIN analysis methods.

Temporal resolution presents another significant challenge. Many stress-induced conformational changes in polymers occur on timescales that conventional DLS instruments cannot adequately capture. The typical acquisition times of several minutes make it difficult to monitor rapid structural transitions that may occur within seconds or milliseconds under dynamic stress conditions.

Signal-to-noise ratio deterioration becomes particularly problematic for stressed polymers. As polymers deform under stress, their scattering intensity often decreases while polydispersity increases, resulting in broader correlation functions with lower signal quality. This effect is especially pronounced for dilute solutions or when analyzing smaller polymer segments.

Multiple scattering effects introduce additional complications. Stressed polymers frequently form temporary aggregates or exhibit increased local concentration fluctuations, leading to multiple scattering events that violate the single-scattering assumption fundamental to standard DLS analysis algorithms.

The temperature control systems in conventional DLS instruments often lack the precision required for stress-related studies. Even minor temperature fluctuations can significantly affect polymer conformation under stress, introducing artifacts that are difficult to distinguish from genuine stress-induced changes.

Sample preparation protocols for stressed polymers remain largely unstandardized. The act of transferring a stressed polymer sample to a DLS measurement cell can itself alter the stress state, raising questions about data validity and reproducibility. This becomes particularly challenging for in-situ measurements of polymers under continuous stress application.

Finally, data interpretation frameworks for stressed polymers are underdeveloped. Current DLS software packages typically lack specialized algorithms for distinguishing between thermal fluctuations, stress-induced conformational changes, and potential aggregation phenomena, leaving researchers with ambiguous results that require extensive complementary techniques for validation.

Established DLS Methodologies for Polymer Analysis

01 DLS techniques for polymer characterization under stress

Dynamic Light Scattering (DLS) techniques can be used to characterize polymers under various stress conditions. These methods allow for the measurement of particle size, molecular weight, and structural changes when polymers are subjected to mechanical, thermal, or chemical stress. The techniques provide real-time monitoring of polymer behavior under stress conditions, enabling researchers to understand degradation mechanisms and stability profiles.- DLS techniques for polymer characterization under stress: Dynamic Light Scattering (DLS) techniques can be used to characterize polymers under various stress conditions. These methods allow for the measurement of particle size, molecular weight, and structural changes when polymers are subjected to mechanical, thermal, or chemical stress. The techniques provide real-time monitoring of polymer behavior under stress, enabling researchers to understand degradation mechanisms and stability profiles.

- Instrumentation for stress-induced polymer analysis: Specialized instrumentation has been developed for analyzing polymers under stress conditions using Dynamic Light Scattering. These instruments combine DLS capabilities with stress-inducing mechanisms such as temperature control systems, mechanical stretching devices, or pressure chambers. The integration of these components allows for simultaneous application of stress and measurement of the resulting changes in polymer properties.

- Data processing methods for DLS polymer stress analysis: Advanced data processing algorithms and computational methods have been developed to analyze the complex data obtained from Dynamic Light Scattering of polymers under stress. These methods include correlation function analysis, size distribution calculations, and statistical approaches to interpret scattering patterns. The processing techniques help in extracting meaningful information about polymer behavior, aggregation, and structural changes under various stress conditions.

- Applications of DLS in polymer stability assessment: Dynamic Light Scattering is widely applied to assess the stability of polymers under stress conditions in various industries. Applications include pharmaceutical formulation stability, polymer degradation studies in environmental conditions, material aging assessments, and quality control in manufacturing processes. The technique provides valuable insights into how polymers respond to stress factors such as heat, light, oxidation, and mechanical forces.

- Combined analytical approaches with DLS for comprehensive polymer characterization: Dynamic Light Scattering can be combined with other analytical techniques to provide comprehensive characterization of polymers under stress. These complementary approaches include spectroscopic methods, thermal analysis, rheological measurements, and microscopy techniques. The integration of multiple analytical methods offers a more complete understanding of polymer behavior, structure-property relationships, and degradation mechanisms under stress conditions.

02 Stress-induced polymer aggregation analysis

DLS can be used to analyze the aggregation behavior of polymers when subjected to stress. This includes monitoring the formation of aggregates, changes in particle size distribution, and the kinetics of aggregation processes. The technique is particularly valuable for understanding how environmental factors like temperature, pH, and mechanical forces affect polymer stability and performance in various applications.Expand Specific Solutions03 Temperature-dependent polymer analysis using DLS

Temperature is a critical stress factor that can significantly affect polymer behavior. DLS systems designed for temperature-dependent analysis allow researchers to monitor changes in polymer properties across temperature ranges. These systems can detect phase transitions, thermal degradation, and temperature-induced conformational changes in polymer structures, providing insights into thermal stability and performance under varying temperature conditions.Expand Specific Solutions04 Advanced DLS instrumentation for polymer stress testing

Specialized DLS instruments have been developed specifically for analyzing polymers under controlled stress conditions. These instruments incorporate features such as stress application mechanisms, environmental control chambers, and advanced detection systems. They enable precise measurement of polymer responses to various stressors, including mechanical deformation, shear forces, and pressure changes, facilitating comprehensive characterization of polymer behavior under real-world conditions.Expand Specific Solutions05 Data processing methods for stress-related DLS measurements

Advanced data processing algorithms and computational methods have been developed to interpret DLS data from polymers under stress. These methods include correlation analysis, size distribution calculations, and statistical approaches to extract meaningful information from complex scattering patterns. Software solutions enable researchers to analyze time-dependent changes in polymer properties, identify critical stress thresholds, and model polymer behavior under various stress scenarios.Expand Specific Solutions

Leading Research Groups and Instrument Manufacturers

The dynamic light scattering polymer analysis market is in a growth phase, with increasing demand driven by advancements in materials science and polymer engineering. The competitive landscape features established analytical instrument manufacturers like Waters Technology and Shimazu KK alongside specialized players such as Fluence Analytics, which has developed proprietary real-time polymer analysis solutions. Research institutions including Zhejiang University, Texas A&M, and Virginia Commonwealth University contribute significant innovations, while industrial giants like BASF, 3M, and SABIC leverage this technology for polymer development. The technology has reached moderate maturity but continues evolving, with companies like Yokogawa Fluence Analytics and Corning developing enhanced capabilities for analyzing polymers under stress conditions, indicating a trend toward more sophisticated in-situ measurement techniques.

Shimazu KK

Technical Solution: Shimadzu Corporation has developed specialized DLS instrumentation for polymer analysis under stress conditions, featuring their Multi-Sample Dynamic Light Scattering System. This technology incorporates temperature-controlled sample cells (range -10°C to 90°C) with programmable stress application mechanisms including variable shear rates and extensional flow capabilities. Their approach combines traditional DLS with rheological measurements, allowing simultaneous determination of viscoelastic properties and molecular dynamics of polymers under mechanical stress. The system utilizes fiber-optic probes that can be inserted directly into polymer processing equipment, enabling in-situ monitoring during actual manufacturing conditions. Shimadzu's proprietary analysis software employs advanced algorithms to deconvolute complex scattering patterns from polydisperse samples, providing detailed information about size distribution changes, aggregation behavior, and molecular weight shifts as polymers experience various stress conditions. The technology also incorporates multi-angle detection capabilities to enhance the accuracy of conformational analysis for non-spherical polymer structures under deformation.

Strengths: In-situ measurement capability provides real-world processing insights; combined rheological and DLS analysis offers comprehensive characterization; temperature control allows for thermal stress studies. Weaknesses: Fiber-optic probes may have limited durability in harsh processing environments; complex data interpretation requires specialized expertise; higher initial investment compared to conventional DLS systems.

Yokogawa Fluence Analytics, Inc.

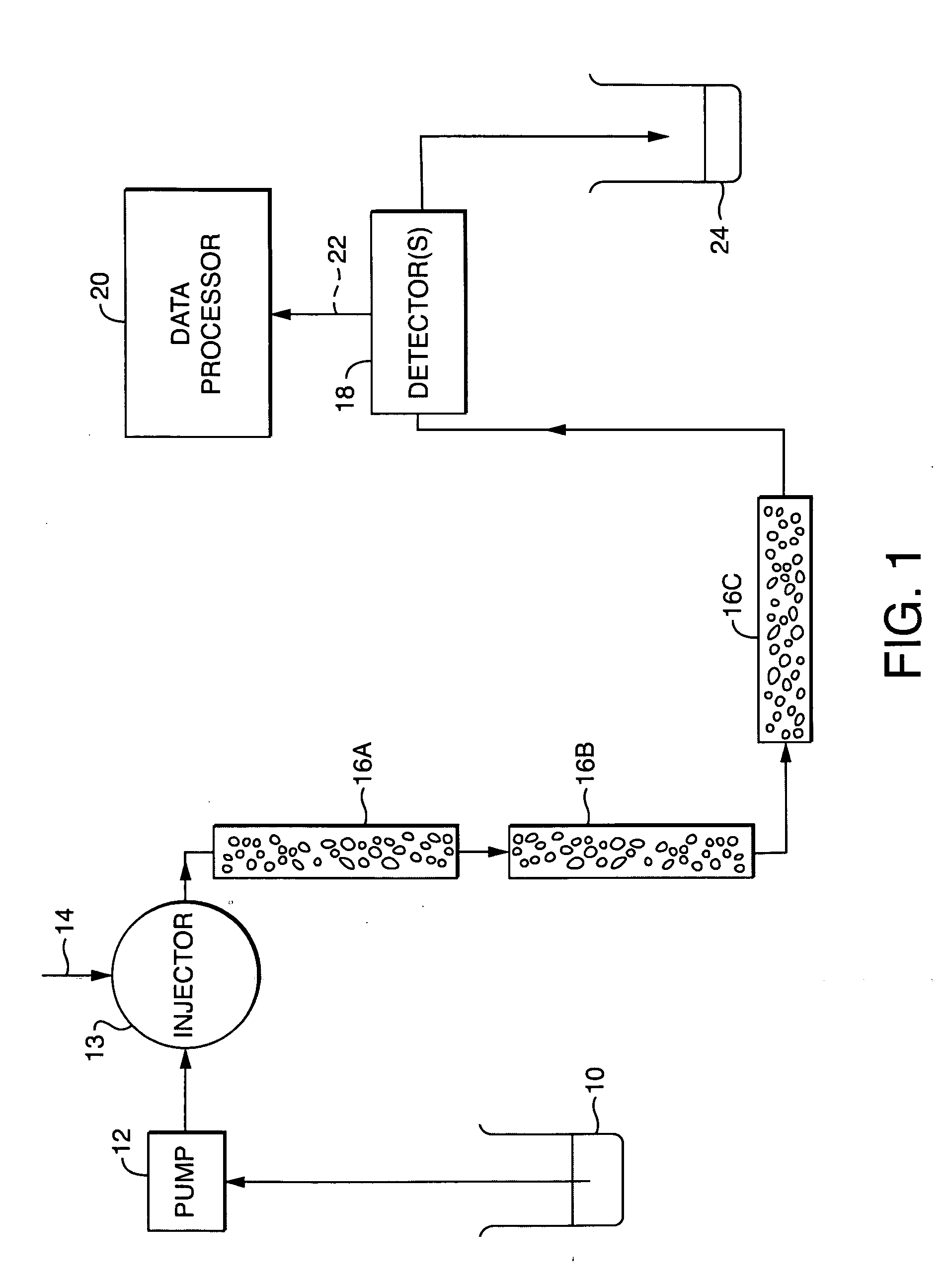

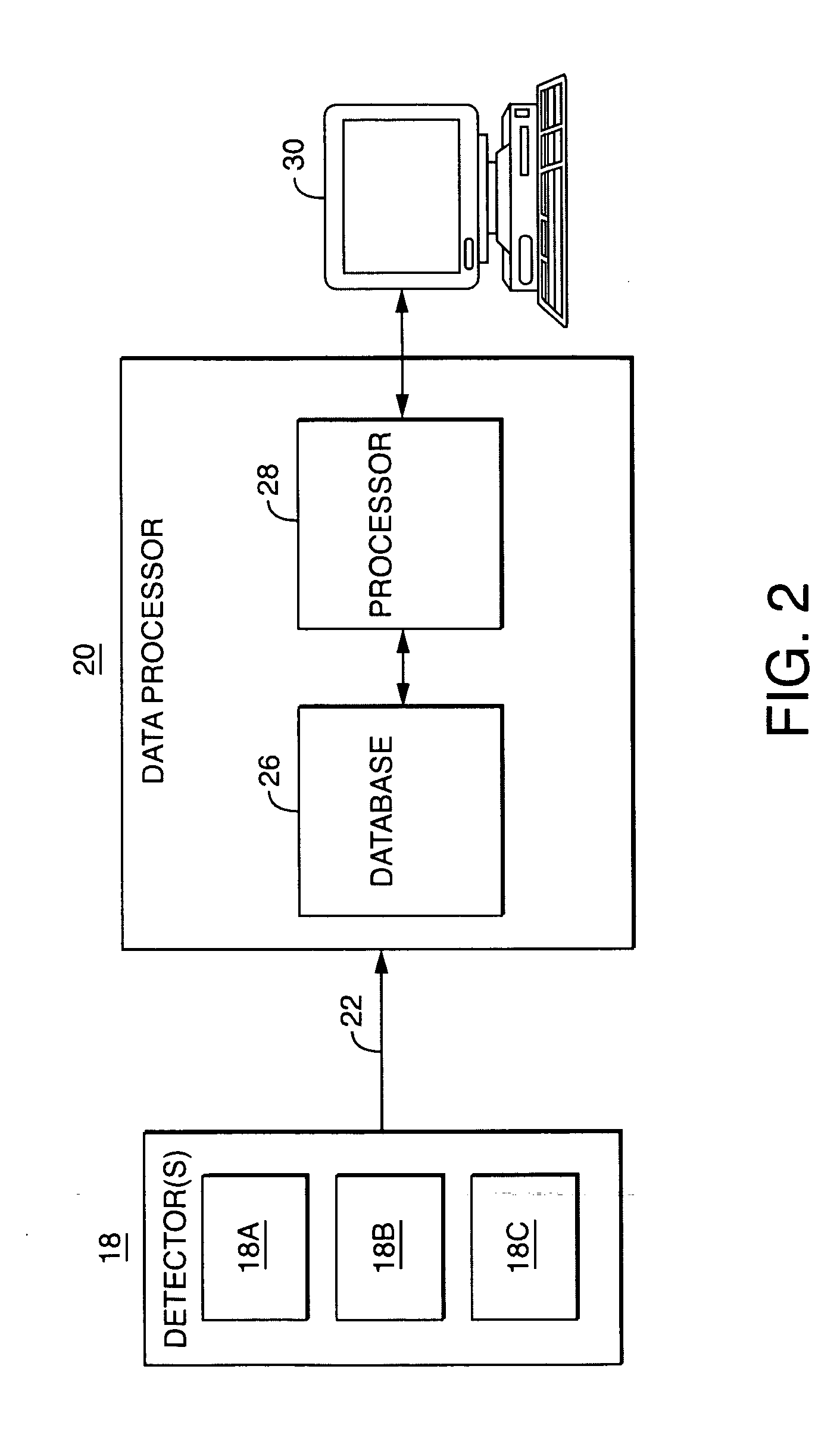

Technical Solution: Yokogawa Fluence Analytics has developed ACOMP (Automatic Continuous Online Monitoring of Polymerization), an innovative system that utilizes dynamic light scattering (DLS) to analyze polymers under stress in real-time. The technology continuously extracts polymer samples from reactors, dilutes them to appropriate concentrations, and subjects them to multi-detector analysis including DLS. This allows for monitoring of critical polymer properties such as molecular weight, intrinsic viscosity, and particle size distribution while the polymer is experiencing various stress conditions. The system incorporates specialized flow cells designed to apply controlled shear stress during measurement, enabling researchers to observe how polymer structures respond to mechanical forces during synthesis or processing. Their proprietary algorithms process the autocorrelation functions from DLS to extract meaningful data about polymer relaxation times and conformational changes under different stress conditions.

Strengths: Real-time continuous monitoring capability allows for immediate process adjustments; integrated multi-detector approach provides comprehensive polymer characterization; automated sampling reduces human error. Weaknesses: Complex system requires significant initial investment; may require customization for specific polymer types; sensitivity to flow conditions can affect measurement accuracy in high-stress environments.

Key Innovations in Polymer Stress Measurement

System and method for determining radius of gyration, molecular weight, and intrinsic viscosity of a polymeric distribution using gel permeation chromatography and light scattering detection

PatentInactiveUS20050240385A1

Innovation

- The method employs a GPC chromatograph system with multi-angle laser light-scattering, refractive index, and viscometer detectors, using novel algorithms to compute the radius of gyration for each slice, which involves fitting parameterized models simultaneously to all data collected at each slice, reducing the impact of detector noise and providing more stable estimates.

Data Processing Algorithms for Stressed Polymer Analysis

The evolution of data processing algorithms for stressed polymer analysis using Dynamic Light Scattering (DLS) has significantly enhanced our understanding of polymer behavior under mechanical stress. Traditional DLS data processing methods, primarily designed for equilibrium systems, often fail to accurately capture the complex dynamics of polymers under stress conditions. This necessitated the development of specialized algorithms capable of handling non-equilibrium states and stress-induced anisotropy.

Early algorithms focused on autocorrelation function analysis, employing simple exponential fitting models. However, these proved inadequate for stressed polymers due to their inability to account for non-Gaussian distributions and multiple relaxation processes occurring simultaneously. The introduction of CONTIN analysis in the 1990s marked a significant advancement, allowing for the resolution of multiple relaxation modes through Laplace inversion of the correlation function.

More sophisticated approaches emerged with the development of maximum entropy methods (MEM) and regularization techniques, which provided more robust solutions to the ill-posed inversion problem inherent in DLS data processing. These algorithms effectively balance fitting accuracy with physical constraints, reducing artifacts in the derived relaxation time distributions.

Recent computational advances have enabled the implementation of machine learning algorithms for DLS data processing. Neural networks and support vector machines have demonstrated remarkable capabilities in pattern recognition within noisy DLS data from stressed polymers. These approaches can identify subtle changes in scattering patterns that traditional algorithms might miss, particularly in systems with complex morphological transitions under stress.

Time-resolved DLS algorithms represent another critical development, allowing for the tracking of rapid structural changes during stress application and relaxation. These algorithms employ sliding window analysis or wavelet transforms to capture temporal evolution of polymer dynamics with millisecond resolution.

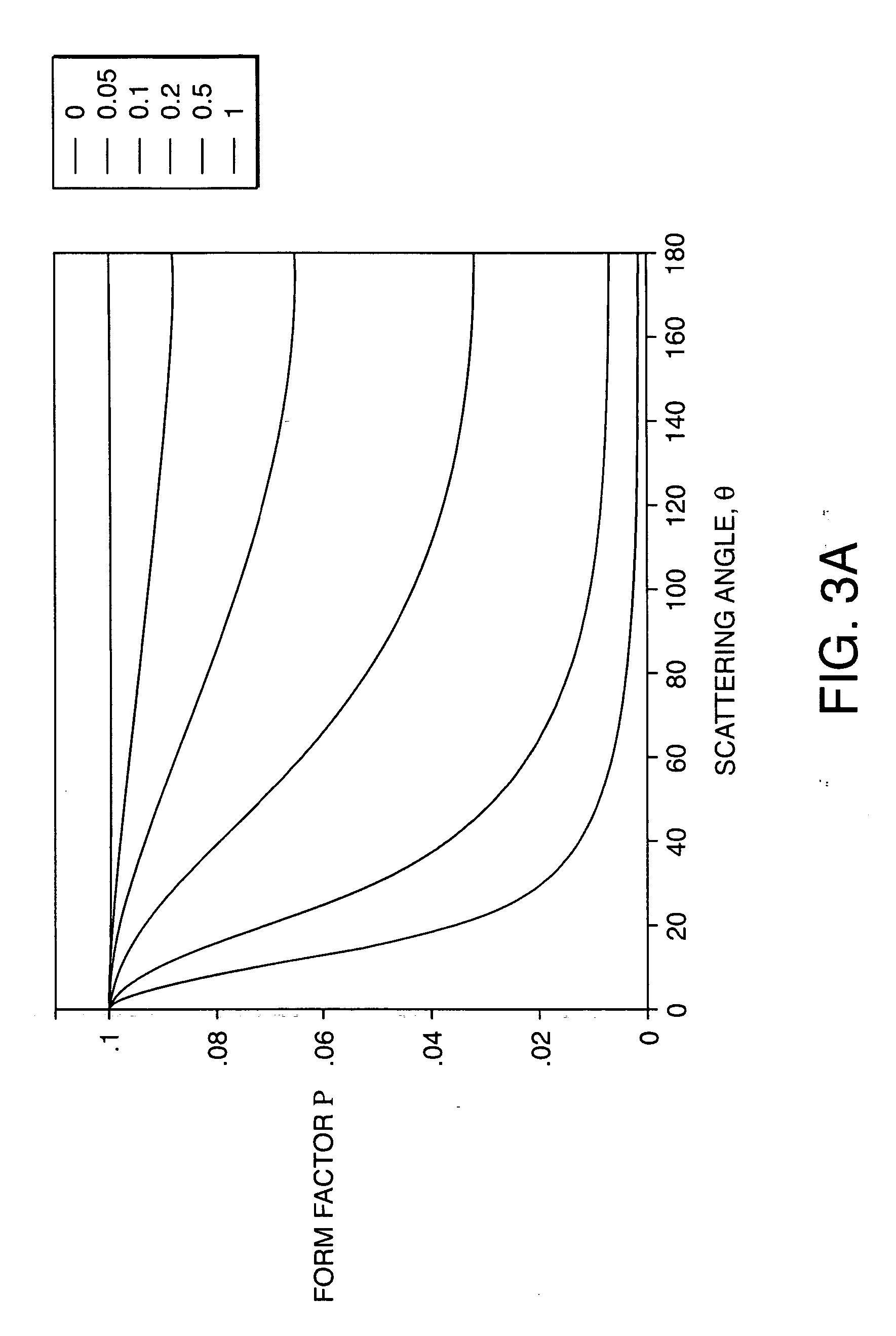

Multi-angle DLS data processing algorithms have become increasingly important for stressed polymer analysis, as they can resolve anisotropic scattering patterns resulting from alignment or deformation. These algorithms combine data from multiple scattering angles to reconstruct three-dimensional information about polymer conformation and orientation under stress.

The integration of rheological models with DLS data processing has created powerful hybrid algorithms that correlate scattering data directly with mechanical properties. These approaches enable researchers to establish quantitative relationships between molecular-level dynamics and macroscopic mechanical behavior, bridging the gap between structure and function in stressed polymer systems.

Early algorithms focused on autocorrelation function analysis, employing simple exponential fitting models. However, these proved inadequate for stressed polymers due to their inability to account for non-Gaussian distributions and multiple relaxation processes occurring simultaneously. The introduction of CONTIN analysis in the 1990s marked a significant advancement, allowing for the resolution of multiple relaxation modes through Laplace inversion of the correlation function.

More sophisticated approaches emerged with the development of maximum entropy methods (MEM) and regularization techniques, which provided more robust solutions to the ill-posed inversion problem inherent in DLS data processing. These algorithms effectively balance fitting accuracy with physical constraints, reducing artifacts in the derived relaxation time distributions.

Recent computational advances have enabled the implementation of machine learning algorithms for DLS data processing. Neural networks and support vector machines have demonstrated remarkable capabilities in pattern recognition within noisy DLS data from stressed polymers. These approaches can identify subtle changes in scattering patterns that traditional algorithms might miss, particularly in systems with complex morphological transitions under stress.

Time-resolved DLS algorithms represent another critical development, allowing for the tracking of rapid structural changes during stress application and relaxation. These algorithms employ sliding window analysis or wavelet transforms to capture temporal evolution of polymer dynamics with millisecond resolution.

Multi-angle DLS data processing algorithms have become increasingly important for stressed polymer analysis, as they can resolve anisotropic scattering patterns resulting from alignment or deformation. These algorithms combine data from multiple scattering angles to reconstruct three-dimensional information about polymer conformation and orientation under stress.

The integration of rheological models with DLS data processing has created powerful hybrid algorithms that correlate scattering data directly with mechanical properties. These approaches enable researchers to establish quantitative relationships between molecular-level dynamics and macroscopic mechanical behavior, bridging the gap between structure and function in stressed polymer systems.

Industrial Standards and Calibration Methods

The standardization of Dynamic Light Scattering (DLS) techniques for analyzing polymers under stress has evolved significantly over the past two decades. ASTM International has established several key standards, including ASTM E2490 for particle size analysis by DLS and ASTM D7296 specifically addressing polymer characterization. These standards provide detailed protocols for sample preparation, instrument calibration, and data interpretation, ensuring consistency across different laboratories and research institutions.

ISO has complemented these efforts with ISO 22412:2017, which outlines comprehensive guidelines for DLS measurements of particles, emulsions, and micelles in various environments, including those under mechanical stress. This standard is particularly valuable for polymer analysis as it addresses the unique challenges of measuring dynamic properties in non-equilibrium conditions.

Calibration methods for DLS instruments when analyzing stressed polymers require specialized approaches beyond standard particle size calibration. NIST-traceable polystyrene latex standards remain the primary reference materials, but their application must be modified when studying polymers under stress. The calibration process typically involves a multi-step procedure: initial calibration with standard spherical particles under static conditions, followed by verification using well-characterized polymer samples under controlled stress conditions.

The European Materials Characterisation Council has developed supplementary guidelines specifically addressing the calibration of DLS instruments for viscoelastic materials under deformation. These guidelines recommend regular verification using certified reference materials with known responses to applied stress, ensuring measurement accuracy across different stress regimes.

Temperature calibration deserves special attention in stress-related polymer studies, as even minor temperature fluctuations can significantly alter polymer chain dynamics. The recommended practice involves using at least three temperature points spanning the experimental range, with verification using materials that exhibit well-documented temperature-dependent behavior.

Data quality standards have also been established for polymer stress analysis, with specific metrics for signal-to-noise ratios, correlation function quality, and minimum count rates. The International Union of Pure and Applied Chemistry (IUPAC) recommends that correlation functions should maintain a minimum intercept value of 0.8 and demonstrate clear exponential decay characteristics even under high stress conditions to ensure reliable data interpretation.

Cross-validation with complementary techniques such as rheology or small-angle neutron scattering has become an industry standard practice, particularly for novel polymer systems or extreme stress conditions where established calibration methods may reach their limitations.

ISO has complemented these efforts with ISO 22412:2017, which outlines comprehensive guidelines for DLS measurements of particles, emulsions, and micelles in various environments, including those under mechanical stress. This standard is particularly valuable for polymer analysis as it addresses the unique challenges of measuring dynamic properties in non-equilibrium conditions.

Calibration methods for DLS instruments when analyzing stressed polymers require specialized approaches beyond standard particle size calibration. NIST-traceable polystyrene latex standards remain the primary reference materials, but their application must be modified when studying polymers under stress. The calibration process typically involves a multi-step procedure: initial calibration with standard spherical particles under static conditions, followed by verification using well-characterized polymer samples under controlled stress conditions.

The European Materials Characterisation Council has developed supplementary guidelines specifically addressing the calibration of DLS instruments for viscoelastic materials under deformation. These guidelines recommend regular verification using certified reference materials with known responses to applied stress, ensuring measurement accuracy across different stress regimes.

Temperature calibration deserves special attention in stress-related polymer studies, as even minor temperature fluctuations can significantly alter polymer chain dynamics. The recommended practice involves using at least three temperature points spanning the experimental range, with verification using materials that exhibit well-documented temperature-dependent behavior.

Data quality standards have also been established for polymer stress analysis, with specific metrics for signal-to-noise ratios, correlation function quality, and minimum count rates. The International Union of Pure and Applied Chemistry (IUPAC) recommends that correlation functions should maintain a minimum intercept value of 0.8 and demonstrate clear exponential decay characteristics even under high stress conditions to ensure reliable data interpretation.

Cross-validation with complementary techniques such as rheology or small-angle neutron scattering has become an industry standard practice, particularly for novel polymer systems or extreme stress conditions where established calibration methods may reach their limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!