How V12 Engines React to Varying Global Emission Standards

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Emission Goals

The V12 engine, renowned for its smooth power delivery and iconic sound, has been a symbol of automotive excellence for decades. However, its evolution has been significantly influenced by the ever-tightening global emission standards. The journey of V12 engines in response to these regulations showcases a fascinating interplay between performance engineering and environmental responsibility.

Initially developed for luxury and high-performance vehicles, V12 engines were prized for their ability to produce substantial power while maintaining exceptional refinement. As emission standards began to tighten in the 1970s and 1980s, manufacturers faced the challenge of maintaining the V12's performance characteristics while reducing harmful emissions.

The 1990s and early 2000s saw a shift towards more efficient V12 designs. Engine management systems became more sophisticated, allowing for precise control over fuel injection and ignition timing. Variable valve timing and lift systems were introduced, optimizing engine performance across a wider range of operating conditions while simultaneously improving fuel efficiency and reducing emissions.

As global emission standards continued to evolve, particularly with the introduction of Euro 5 and Euro 6 standards in Europe and similar regulations worldwide, V12 engine manufacturers had to employ increasingly advanced technologies. Direct fuel injection, improved turbocharging systems, and even mild hybridization were implemented to meet stringent emission targets without compromising the V12's legendary performance.

The current landscape of emission regulations presents both challenges and opportunities for V12 engines. Many regions are implementing stricter CO2 emission limits and real-world driving emission tests, pushing manufacturers to explore innovative solutions. Some have turned to full hybridization or even electrification to complement their V12 powertrains, allowing for zero-emission operation in urban areas while retaining the V12's character for high-performance driving scenarios.

Looking ahead, the goal for V12 engines is to achieve a delicate balance between preserving their unique attributes and meeting increasingly stringent emission standards. This may involve further advancements in materials science to reduce engine weight, the integration of advanced exhaust after-treatment systems, and the potential adoption of synthetic fuels or hydrogen combustion technologies. The ultimate aim is to ensure that the V12 engine can continue to exist in a world of tightening environmental regulations, maintaining its status as a pinnacle of automotive engineering while adapting to the demands of a more sustainable future.

Initially developed for luxury and high-performance vehicles, V12 engines were prized for their ability to produce substantial power while maintaining exceptional refinement. As emission standards began to tighten in the 1970s and 1980s, manufacturers faced the challenge of maintaining the V12's performance characteristics while reducing harmful emissions.

The 1990s and early 2000s saw a shift towards more efficient V12 designs. Engine management systems became more sophisticated, allowing for precise control over fuel injection and ignition timing. Variable valve timing and lift systems were introduced, optimizing engine performance across a wider range of operating conditions while simultaneously improving fuel efficiency and reducing emissions.

As global emission standards continued to evolve, particularly with the introduction of Euro 5 and Euro 6 standards in Europe and similar regulations worldwide, V12 engine manufacturers had to employ increasingly advanced technologies. Direct fuel injection, improved turbocharging systems, and even mild hybridization were implemented to meet stringent emission targets without compromising the V12's legendary performance.

The current landscape of emission regulations presents both challenges and opportunities for V12 engines. Many regions are implementing stricter CO2 emission limits and real-world driving emission tests, pushing manufacturers to explore innovative solutions. Some have turned to full hybridization or even electrification to complement their V12 powertrains, allowing for zero-emission operation in urban areas while retaining the V12's character for high-performance driving scenarios.

Looking ahead, the goal for V12 engines is to achieve a delicate balance between preserving their unique attributes and meeting increasingly stringent emission standards. This may involve further advancements in materials science to reduce engine weight, the integration of advanced exhaust after-treatment systems, and the potential adoption of synthetic fuels or hydrogen combustion technologies. The ultimate aim is to ensure that the V12 engine can continue to exist in a world of tightening environmental regulations, maintaining its status as a pinnacle of automotive engineering while adapting to the demands of a more sustainable future.

Market Demand Analysis for V12 Engines

The market demand for V12 engines has been undergoing significant shifts in recent years, primarily driven by evolving global emission standards and changing consumer preferences. Traditionally, V12 engines have been synonymous with luxury, performance, and prestige, finding their place in high-end sports cars, luxury sedans, and exclusive supercars. However, the landscape is rapidly changing due to increasing environmental concerns and stricter regulations worldwide.

In the luxury car segment, which has been a stronghold for V12 engines, there's a noticeable trend towards downsizing and electrification. Many luxury automakers are gradually phasing out their V12 offerings in favor of smaller, turbocharged engines or hybrid powertrains. This shift is partly in response to tightening emission standards in key markets such as Europe, China, and the United States.

Despite these challenges, there remains a niche but passionate market for V12-powered vehicles. Enthusiasts and collectors continue to value the unique characteristics of V12 engines, including their smooth power delivery and distinctive sound. This demand is particularly evident in limited-edition supercars and bespoke luxury vehicles, where exclusivity and performance are paramount.

The racing and motorsport sector also contributes to the ongoing demand for V12 engines, albeit in a limited capacity. Some racing series still utilize V12 engines, maintaining a market for high-performance, race-spec V12 units. However, even in motorsports, there's a gradual shift towards more efficient and environmentally friendly powertrains.

Geographically, the demand for V12 engines varies significantly. In regions with less stringent emission regulations, such as parts of the Middle East and certain Asian markets, the appetite for V12-powered vehicles remains relatively strong. Conversely, in markets with stricter environmental policies, like Western Europe and California, the demand is declining more rapidly.

The aviation and marine industries represent another segment where V12 engines still find application, particularly in high-performance boats and small aircraft. These sectors, while niche, contribute to the overall market demand for V12 engines, especially those optimized for these specific applications.

Looking ahead, the market for V12 engines is expected to become increasingly specialized. As mainstream automotive manufacturers move away from V12 engines, boutique manufacturers and high-end customization shops may become the primary purveyors of V12-powered vehicles. This shift could lead to a scenario where V12 engines become even more exclusive, potentially increasing their appeal among collectors and enthusiasts.

In the luxury car segment, which has been a stronghold for V12 engines, there's a noticeable trend towards downsizing and electrification. Many luxury automakers are gradually phasing out their V12 offerings in favor of smaller, turbocharged engines or hybrid powertrains. This shift is partly in response to tightening emission standards in key markets such as Europe, China, and the United States.

Despite these challenges, there remains a niche but passionate market for V12-powered vehicles. Enthusiasts and collectors continue to value the unique characteristics of V12 engines, including their smooth power delivery and distinctive sound. This demand is particularly evident in limited-edition supercars and bespoke luxury vehicles, where exclusivity and performance are paramount.

The racing and motorsport sector also contributes to the ongoing demand for V12 engines, albeit in a limited capacity. Some racing series still utilize V12 engines, maintaining a market for high-performance, race-spec V12 units. However, even in motorsports, there's a gradual shift towards more efficient and environmentally friendly powertrains.

Geographically, the demand for V12 engines varies significantly. In regions with less stringent emission regulations, such as parts of the Middle East and certain Asian markets, the appetite for V12-powered vehicles remains relatively strong. Conversely, in markets with stricter environmental policies, like Western Europe and California, the demand is declining more rapidly.

The aviation and marine industries represent another segment where V12 engines still find application, particularly in high-performance boats and small aircraft. These sectors, while niche, contribute to the overall market demand for V12 engines, especially those optimized for these specific applications.

Looking ahead, the market for V12 engines is expected to become increasingly specialized. As mainstream automotive manufacturers move away from V12 engines, boutique manufacturers and high-end customization shops may become the primary purveyors of V12-powered vehicles. This shift could lead to a scenario where V12 engines become even more exclusive, potentially increasing their appeal among collectors and enthusiasts.

Global Emission Standards and V12 Challenges

Global emission standards have become increasingly stringent over the past few decades, posing significant challenges for high-performance engines, particularly V12 configurations. These standards vary across different regions, with Europe, North America, and Asia implementing their own specific regulations. The European Union's Euro 6 standards, the United States' EPA Tier 3 regulations, and China's China 6 standards are among the most stringent globally.

V12 engines, known for their power, smoothness, and prestige, face unique challenges in meeting these diverse emission requirements. Their large displacement and high fuel consumption inherently result in greater emissions compared to smaller engine configurations. The primary pollutants targeted by these standards include carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

To comply with varying global emission standards, V12 engine manufacturers have had to implement a range of technological solutions. Advanced fuel injection systems, such as direct injection and high-pressure common rail systems, have been adopted to improve fuel efficiency and reduce emissions. Variable valve timing and lift technologies have also been incorporated to optimize engine performance across different operating conditions.

Exhaust gas recirculation (EGR) systems have been refined to reduce NOx emissions, while particulate filters and selective catalytic reduction (SCR) systems have been employed to tackle PM and NOx respectively. These aftertreatment systems have become increasingly sophisticated to meet the stringent limits set by various regulatory bodies.

The challenge for V12 engines lies not only in meeting the current standards but also in anticipating future regulations. Manufacturers must invest heavily in research and development to ensure their engines remain compliant while maintaining the performance characteristics that define the V12 experience. This has led to the exploration of hybrid and electrification technologies to supplement V12 powertrains, allowing for reduced emissions during urban driving while preserving the engine's full potential for high-performance scenarios.

The varying nature of global emission standards adds another layer of complexity. Engines must be adaptable to different markets, often requiring region-specific calibrations and hardware configurations. This increases development costs and complicates production logistics for manufacturers.

As a result of these challenges, the future of V12 engines in the global automotive landscape remains uncertain. While they continue to represent the pinnacle of internal combustion engine technology, their long-term viability will depend on the industry's ability to innovate and adapt to an ever-evolving regulatory environment.

V12 engines, known for their power, smoothness, and prestige, face unique challenges in meeting these diverse emission requirements. Their large displacement and high fuel consumption inherently result in greater emissions compared to smaller engine configurations. The primary pollutants targeted by these standards include carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

To comply with varying global emission standards, V12 engine manufacturers have had to implement a range of technological solutions. Advanced fuel injection systems, such as direct injection and high-pressure common rail systems, have been adopted to improve fuel efficiency and reduce emissions. Variable valve timing and lift technologies have also been incorporated to optimize engine performance across different operating conditions.

Exhaust gas recirculation (EGR) systems have been refined to reduce NOx emissions, while particulate filters and selective catalytic reduction (SCR) systems have been employed to tackle PM and NOx respectively. These aftertreatment systems have become increasingly sophisticated to meet the stringent limits set by various regulatory bodies.

The challenge for V12 engines lies not only in meeting the current standards but also in anticipating future regulations. Manufacturers must invest heavily in research and development to ensure their engines remain compliant while maintaining the performance characteristics that define the V12 experience. This has led to the exploration of hybrid and electrification technologies to supplement V12 powertrains, allowing for reduced emissions during urban driving while preserving the engine's full potential for high-performance scenarios.

The varying nature of global emission standards adds another layer of complexity. Engines must be adaptable to different markets, often requiring region-specific calibrations and hardware configurations. This increases development costs and complicates production logistics for manufacturers.

As a result of these challenges, the future of V12 engines in the global automotive landscape remains uncertain. While they continue to represent the pinnacle of internal combustion engine technology, their long-term viability will depend on the industry's ability to innovate and adapt to an ever-evolving regulatory environment.

Current V12 Emission Reduction Solutions

01 Emission control systems for V12 engines

Various emission control systems are designed specifically for V12 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies to optimize combustion and minimize pollutants.- Emission control systems for V12 engines: Various emission control systems are designed specifically for V12 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies to optimize combustion and minimize pollutants.

- Engine management systems for V12 engines: Sophisticated engine management systems are developed to control and optimize the performance of V12 engines while minimizing emissions. These systems may incorporate advanced sensors, electronic control units, and software algorithms to monitor and adjust engine parameters in real-time.

- Fuel efficiency improvements for V12 engines: Innovations in V12 engine design focus on improving fuel efficiency to reduce overall emissions. This may include technologies such as variable valve timing, cylinder deactivation, and advanced materials to reduce weight and friction, resulting in lower fuel consumption and emissions.

- Alternative fuel systems for V12 engines: Research and development efforts explore the use of alternative fuels in V12 engines to reduce emissions. This may include adapting V12 engines to run on biofuels, hydrogen, or other low-emission fuel sources, as well as developing hybrid powertrains that combine V12 engines with electric motors.

- Exhaust aftertreatment technologies for V12 engines: Advanced exhaust aftertreatment technologies are developed specifically for V12 engines to further reduce emissions. These may include selective catalytic reduction (SCR) systems, particulate filters, and advanced oxidation catalysts designed to effectively treat the high exhaust volumes produced by V12 engines.

02 Engine management systems for V12 engines

Sophisticated engine management systems are developed to control and optimize the performance of V12 engines while minimizing emissions. These systems may incorporate advanced sensors, electronic control units, and software algorithms to monitor and adjust engine parameters in real-time.Expand Specific Solutions03 Fuel efficiency improvements for V12 engines

Innovations in V12 engine design focus on improving fuel efficiency to reduce overall emissions. These improvements may include advanced materials, optimized combustion chamber designs, and variable valve timing systems to enhance engine performance and reduce fuel consumption.Expand Specific Solutions04 Exhaust aftertreatment technologies for V12 engines

Specialized exhaust aftertreatment technologies are developed for V12 engines to further reduce emissions. These may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and advanced oxidation catalysts designed to target specific pollutants in the exhaust stream.Expand Specific Solutions05 Alternative fuel systems for V12 engines

Research and development efforts explore alternative fuel systems for V12 engines to reduce emissions. These may include hybrid powertrains, hydrogen fuel cells, or biofuel compatibility to provide cleaner energy sources and lower overall environmental impact.Expand Specific Solutions

Key Players in V12 Engine Manufacturing

The global V12 engine market is in a mature phase, with a relatively stable but limited market size due to stringent emission standards worldwide. The technology's maturity is high, with companies like Cummins, Inc. and Renault SA leading in engine development and emissions control. However, the industry faces challenges as it adapts to varying global emission standards, pushing manufacturers to innovate in areas such as fuel efficiency and exhaust aftertreatment. Companies like Johnson Matthey Plc and BASF Mobile Emissions Catalysts LLC are at the forefront of developing catalytic technologies to meet these evolving requirements. The competitive landscape is characterized by a mix of established automotive giants and specialized component manufacturers, all working to balance performance with environmental compliance.

Cummins, Inc.

Technical Solution: Cummins has developed advanced aftertreatment systems for V12 engines to meet varying global emission standards. Their technology includes a combination of Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) systems. The SCR system uses Diesel Exhaust Fluid (DEF) to convert NOx emissions into harmless nitrogen and water, while the DPF captures and eliminates particulate matter. Cummins has also implemented advanced engine control modules that can adapt to different emission requirements in real-time, allowing for optimal performance across various regions[1][3]. Their V12 engines utilize high-pressure common rail fuel systems and variable geometry turbochargers to enhance fuel efficiency and reduce emissions without compromising power output[2].

Strengths: Adaptability to various emission standards, high performance while maintaining compliance. Weaknesses: Complexity of systems may lead to higher maintenance costs, reliance on DEF availability in different markets.

Renault SA

Technical Solution: Renault has focused on developing hybrid technologies for their V12 engines to meet stringent emission standards. Their approach combines a V12 internal combustion engine with electric motors, creating a hybrid powertrain that significantly reduces emissions. The system incorporates regenerative braking to capture and store energy, which is then used to assist the V12 engine during acceleration, reducing fuel consumption and emissions. Renault has also implemented advanced catalytic converters and particulate filters specifically designed for V12 engines[4]. Their engine management systems use predictive algorithms to optimize the balance between the V12 engine and electric motors based on driving conditions and local emission requirements[5].

Strengths: Innovative hybrid technology reduces emissions while maintaining V12 performance. Weaknesses: Added complexity and weight from hybrid systems, potentially higher production costs.

Core Innovations in V12 Engine Design

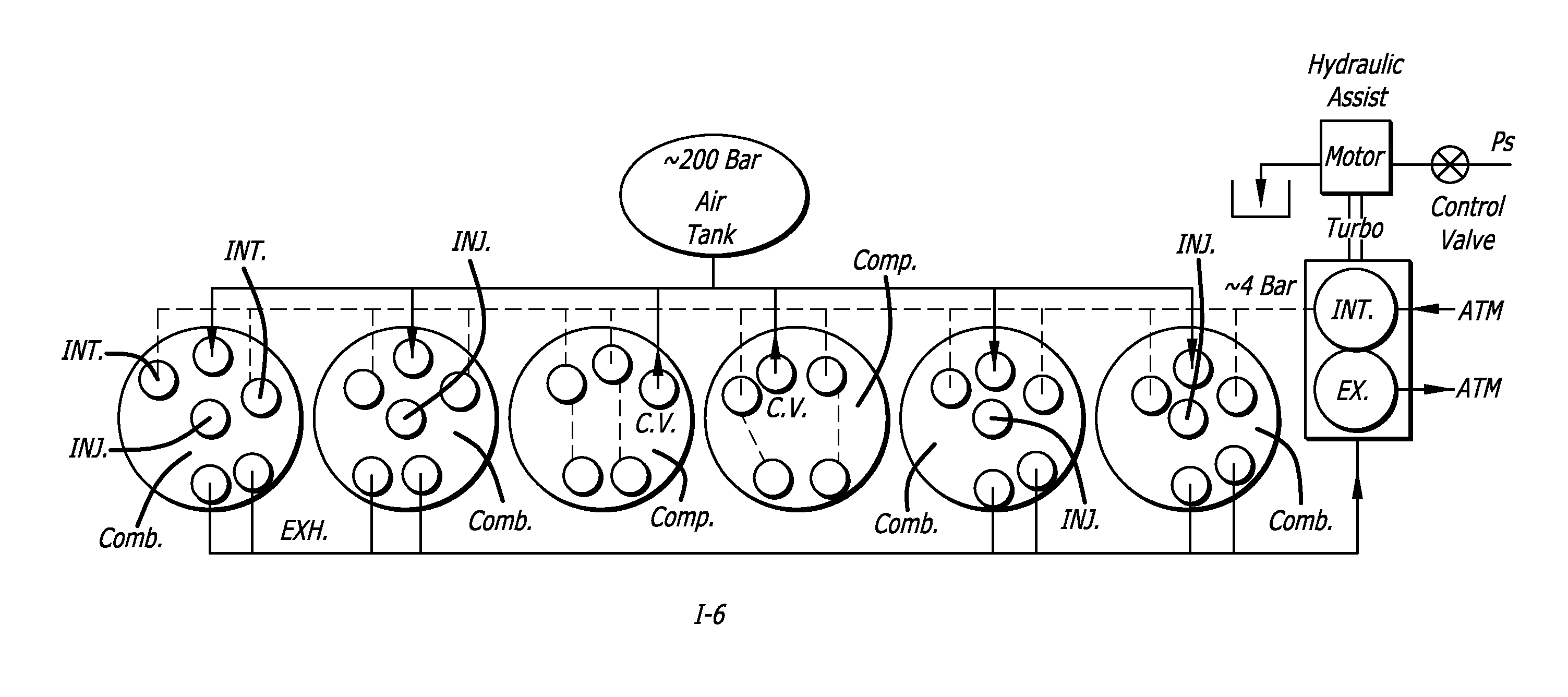

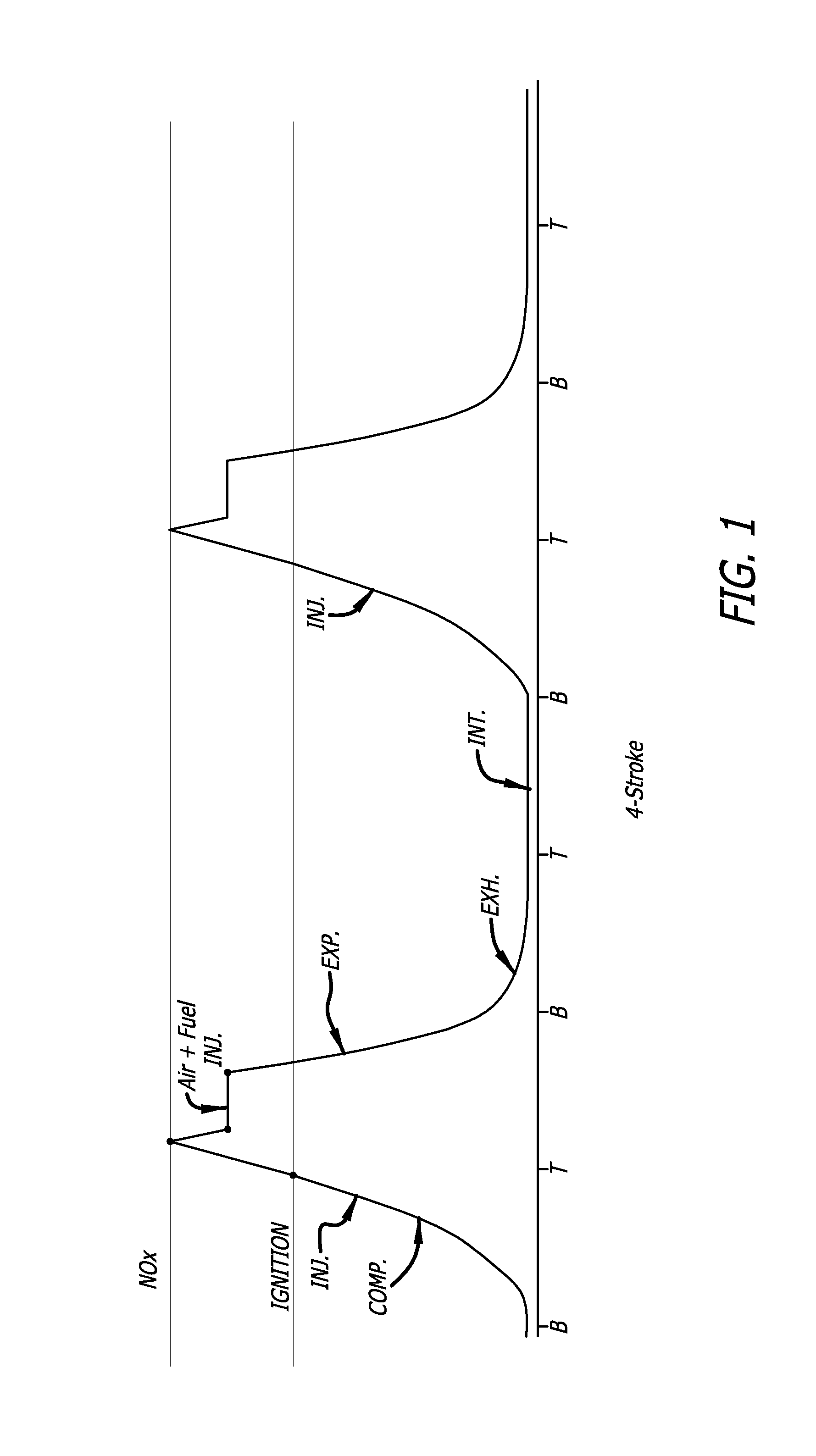

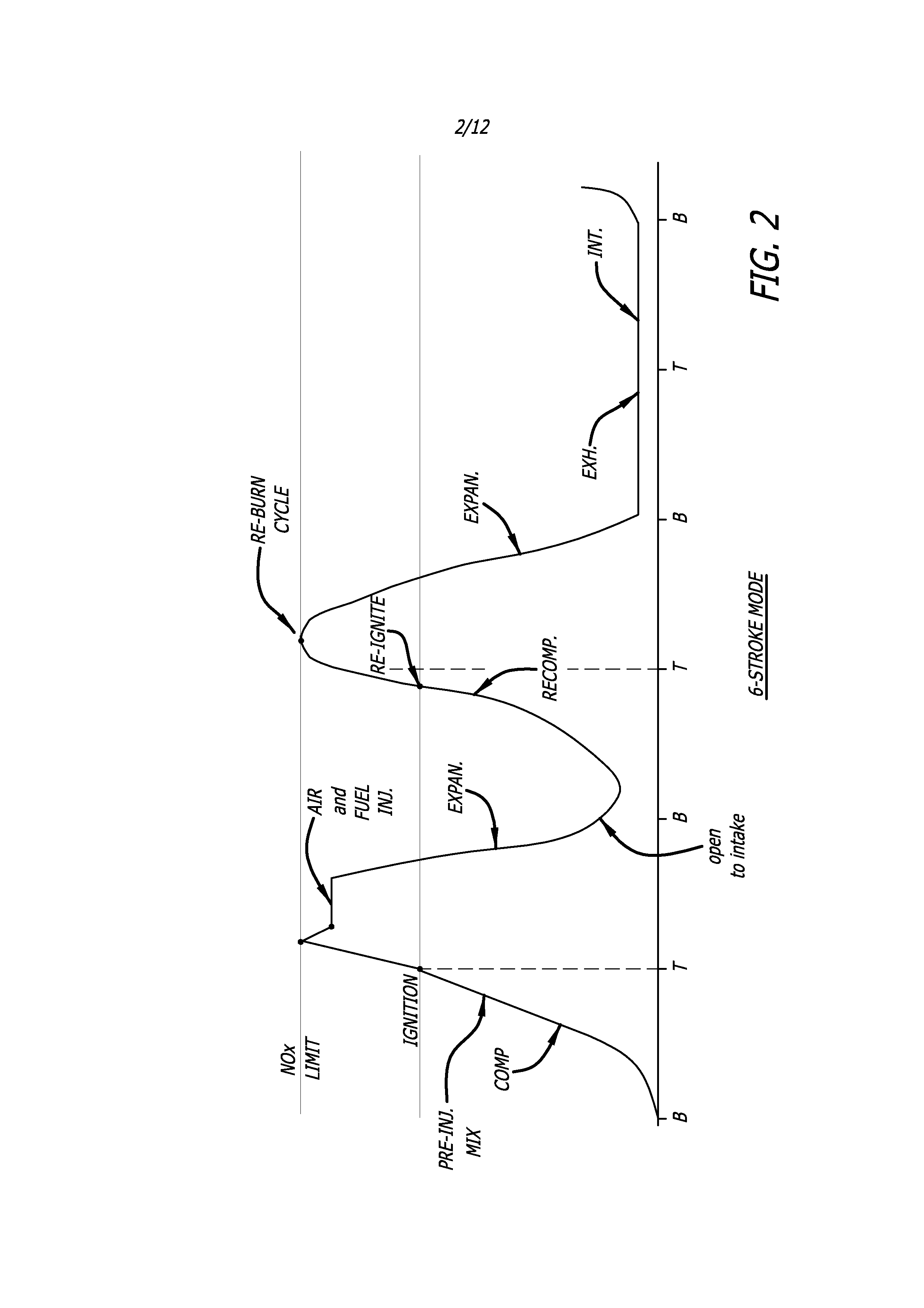

High performance, low emission engines, multiple cylinder engines and operating methods

PatentInactiveUS7954472B1

Innovation

- Implementing a controllable engine valve actuation system that injects both fuel and air during the main injection phase, with pre-injection occurring before the ignition temperature, and using a pressure sensor to manage combustion temperatures below the NOX formation limit, allowing for more complete combustion and increased energy output.

Environmental Impact Assessment

The environmental impact of V12 engines in relation to varying global emission standards is a critical consideration for both manufacturers and policymakers. These powerful engines, known for their high performance and luxurious applications, face increasing scrutiny due to their typically higher fuel consumption and emissions output compared to smaller engine configurations.

Globally, emission standards have become increasingly stringent, with different regions implementing varied regulations. The European Union's Euro 6 standards, California's CARB regulations, and China's National 6 standards represent some of the world's most stringent emissions controls. These standards typically focus on reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon (HC) emissions.

V12 engines, due to their larger displacement and higher fuel consumption, often struggle to meet these tightening regulations without significant technological interventions. Manufacturers have responded by implementing various technologies to reduce emissions, including advanced catalytic converters, exhaust gas recirculation (EGR) systems, and particulate filters. Some have also explored hybridization to offset the environmental impact of these large engines.

The carbon dioxide (CO2) emissions from V12 engines are particularly problematic in the context of global climate change mitigation efforts. Many countries have implemented CO2-based taxation systems and fleet average emissions targets, which put pressure on manufacturers to reduce the carbon footprint of their high-performance vehicles. This has led to a trend of downsizing and turbocharging in the luxury and sports car segments, with some manufacturers phasing out V12 engines in favor of smaller, more efficient powertrains.

The varying nature of global emission standards presents a challenge for V12 engine manufacturers, as they must design engines that can comply with the most stringent regulations while maintaining performance characteristics. This often results in different engine tunes or configurations for different markets, increasing complexity and cost for manufacturers.

Despite these challenges, some manufacturers have managed to keep V12 engines compliant with current standards through extensive research and development. However, the long-term viability of V12 engines in a world of increasingly strict emissions regulations remains uncertain. The environmental impact assessment of these engines must consider not only their direct emissions but also the lifecycle emissions associated with their production and the vehicles they power.

Globally, emission standards have become increasingly stringent, with different regions implementing varied regulations. The European Union's Euro 6 standards, California's CARB regulations, and China's National 6 standards represent some of the world's most stringent emissions controls. These standards typically focus on reducing nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbon (HC) emissions.

V12 engines, due to their larger displacement and higher fuel consumption, often struggle to meet these tightening regulations without significant technological interventions. Manufacturers have responded by implementing various technologies to reduce emissions, including advanced catalytic converters, exhaust gas recirculation (EGR) systems, and particulate filters. Some have also explored hybridization to offset the environmental impact of these large engines.

The carbon dioxide (CO2) emissions from V12 engines are particularly problematic in the context of global climate change mitigation efforts. Many countries have implemented CO2-based taxation systems and fleet average emissions targets, which put pressure on manufacturers to reduce the carbon footprint of their high-performance vehicles. This has led to a trend of downsizing and turbocharging in the luxury and sports car segments, with some manufacturers phasing out V12 engines in favor of smaller, more efficient powertrains.

The varying nature of global emission standards presents a challenge for V12 engine manufacturers, as they must design engines that can comply with the most stringent regulations while maintaining performance characteristics. This often results in different engine tunes or configurations for different markets, increasing complexity and cost for manufacturers.

Despite these challenges, some manufacturers have managed to keep V12 engines compliant with current standards through extensive research and development. However, the long-term viability of V12 engines in a world of increasingly strict emissions regulations remains uncertain. The environmental impact assessment of these engines must consider not only their direct emissions but also the lifecycle emissions associated with their production and the vehicles they power.

Economic Viability of V12 Engines

The economic viability of V12 engines in the face of varying global emission standards presents a complex challenge for manufacturers and consumers alike. As emission regulations tighten worldwide, the cost-benefit analysis of producing and maintaining these high-performance engines becomes increasingly critical.

V12 engines, known for their smooth operation and impressive power output, have long been a symbol of luxury and performance in the automotive industry. However, their fuel consumption and emissions output are significantly higher than smaller, more efficient engine configurations. This disparity has led to increased scrutiny and regulatory pressure on V12 engines in many markets.

The cost of developing and producing V12 engines that comply with stringent emission standards has risen substantially. Manufacturers must invest heavily in research and development to implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations aim to improve fuel efficiency and reduce emissions, but they also drive up production costs.

Additionally, the implementation of exhaust after-treatment systems, such as particulate filters and selective catalytic reduction (SCR) systems, further increases the complexity and cost of V12 engines. These systems require regular maintenance and consume additional resources, impacting the overall operating costs for vehicle owners.

The market for V12 engines is primarily limited to high-end luxury vehicles and supercars, where price sensitivity is lower. However, even in this segment, the economic pressures are mounting. Manufacturers must balance the prestige and performance associated with V12 engines against the increasing costs of compliance and potential market restrictions.

In some regions, punitive taxes on high-emission vehicles further erode the economic viability of V12 engines. These taxes can significantly increase the total cost of ownership, potentially deterring buyers and reducing demand. As a result, some manufacturers are exploring alternative technologies, such as high-output turbocharged V8 engines or hybrid powertrains, to deliver comparable performance with improved efficiency.

Despite these challenges, there remains a niche market for V12 engines, particularly in regions with less stringent emission standards or where luxury and performance take precedence over environmental concerns. However, the long-term economic sustainability of V12 engines in a global context is increasingly uncertain, as manufacturers must weigh the costs of continued development against shrinking market opportunities and potential regulatory obsolescence.

V12 engines, known for their smooth operation and impressive power output, have long been a symbol of luxury and performance in the automotive industry. However, their fuel consumption and emissions output are significantly higher than smaller, more efficient engine configurations. This disparity has led to increased scrutiny and regulatory pressure on V12 engines in many markets.

The cost of developing and producing V12 engines that comply with stringent emission standards has risen substantially. Manufacturers must invest heavily in research and development to implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations aim to improve fuel efficiency and reduce emissions, but they also drive up production costs.

Additionally, the implementation of exhaust after-treatment systems, such as particulate filters and selective catalytic reduction (SCR) systems, further increases the complexity and cost of V12 engines. These systems require regular maintenance and consume additional resources, impacting the overall operating costs for vehicle owners.

The market for V12 engines is primarily limited to high-end luxury vehicles and supercars, where price sensitivity is lower. However, even in this segment, the economic pressures are mounting. Manufacturers must balance the prestige and performance associated with V12 engines against the increasing costs of compliance and potential market restrictions.

In some regions, punitive taxes on high-emission vehicles further erode the economic viability of V12 engines. These taxes can significantly increase the total cost of ownership, potentially deterring buyers and reducing demand. As a result, some manufacturers are exploring alternative technologies, such as high-output turbocharged V8 engines or hybrid powertrains, to deliver comparable performance with improved efficiency.

Despite these challenges, there remains a niche market for V12 engines, particularly in regions with less stringent emission standards or where luxury and performance take precedence over environmental concerns. However, the long-term economic sustainability of V12 engines in a global context is increasingly uncertain, as manufacturers must weigh the costs of continued development against shrinking market opportunities and potential regulatory obsolescence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!