How Variable Valve Timing Enhances V12 Engine Efficiency

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 VVT Evolution

The evolution of Variable Valve Timing (VVT) in V12 engines represents a significant milestone in automotive engineering, marking a shift towards enhanced efficiency and performance. This technological progression can be traced through several key stages, each contributing to the refinement of V12 engine capabilities.

In the early stages of V12 engine development, fixed valve timing was the norm. This approach, while reliable, limited the engine's ability to optimize performance across different operating conditions. The introduction of basic VVT systems in the 1980s marked the first step towards more flexible engine management. These early systems typically allowed for adjustment of either intake or exhaust valve timing, but not both simultaneously.

The 1990s saw a leap forward with the implementation of more advanced VVT systems in high-performance V12 engines. Luxury and sports car manufacturers began incorporating dual VVT systems, capable of adjusting both intake and exhaust valve timing independently. This development significantly improved engine breathing, allowing for better low-end torque and high-end power.

As environmental concerns grew in the 2000s, VVT technology in V12 engines evolved to focus on efficiency alongside performance. Continuous Variable Valve Timing (CVVT) systems emerged, offering seamless adjustment of valve timing across the entire operating range. This innovation led to notable improvements in fuel economy and emissions reduction, without compromising the power output that V12 engines are renowned for.

The latest phase in V12 VVT evolution has seen the integration of more sophisticated electronic control systems and the advent of variable valve lift technology. These advancements allow for even finer control over engine breathing, optimizing combustion efficiency across a broader range of operating conditions. Some cutting-edge systems now incorporate camless valve actuation, using electromagnetic or hydraulic actuators to control valve movement with unprecedented precision.

Throughout this evolution, the primary goals have remained consistent: to enhance engine efficiency, improve power delivery, and reduce emissions. The progression of VVT technology in V12 engines has not only met these objectives but has also played a crucial role in keeping these high-performance powerplants relevant in an increasingly efficiency-focused automotive landscape.

In the early stages of V12 engine development, fixed valve timing was the norm. This approach, while reliable, limited the engine's ability to optimize performance across different operating conditions. The introduction of basic VVT systems in the 1980s marked the first step towards more flexible engine management. These early systems typically allowed for adjustment of either intake or exhaust valve timing, but not both simultaneously.

The 1990s saw a leap forward with the implementation of more advanced VVT systems in high-performance V12 engines. Luxury and sports car manufacturers began incorporating dual VVT systems, capable of adjusting both intake and exhaust valve timing independently. This development significantly improved engine breathing, allowing for better low-end torque and high-end power.

As environmental concerns grew in the 2000s, VVT technology in V12 engines evolved to focus on efficiency alongside performance. Continuous Variable Valve Timing (CVVT) systems emerged, offering seamless adjustment of valve timing across the entire operating range. This innovation led to notable improvements in fuel economy and emissions reduction, without compromising the power output that V12 engines are renowned for.

The latest phase in V12 VVT evolution has seen the integration of more sophisticated electronic control systems and the advent of variable valve lift technology. These advancements allow for even finer control over engine breathing, optimizing combustion efficiency across a broader range of operating conditions. Some cutting-edge systems now incorporate camless valve actuation, using electromagnetic or hydraulic actuators to control valve movement with unprecedented precision.

Throughout this evolution, the primary goals have remained consistent: to enhance engine efficiency, improve power delivery, and reduce emissions. The progression of VVT technology in V12 engines has not only met these objectives but has also played a crucial role in keeping these high-performance powerplants relevant in an increasingly efficiency-focused automotive landscape.

Market Demand Analysis

The market demand for variable valve timing (VVT) technology in V12 engines has been steadily increasing, driven by the automotive industry's pursuit of enhanced efficiency and performance. Luxury car manufacturers and high-performance vehicle producers are particularly interested in VVT systems for their V12 engines, as these powerplants are often the flagship offerings in their lineups.

The global luxury car market, where V12 engines are most prevalent, is projected to grow significantly in the coming years. This growth is fueled by rising disposable incomes in emerging markets and a continued demand for premium vehicles in established markets. As environmental regulations become more stringent worldwide, there is an increasing pressure on manufacturers to improve fuel efficiency and reduce emissions, even in their most powerful engines.

VVT technology offers a solution to this challenge by optimizing engine performance across various operating conditions. It allows for better fuel economy during low-load situations while maintaining the high-performance characteristics that V12 engine buyers expect. This dual benefit has created a strong market pull for VVT systems in V12 engines.

The automotive industry's shift towards electrification has not diminished the demand for advanced internal combustion engine technologies. Instead, it has intensified the need for innovations that can extend the viability of traditional powertrains. VVT systems are seen as a critical component in this strategy, helping manufacturers meet emissions standards while preserving the unique characteristics of V12 engines that enthusiasts value.

Market analysis indicates that the adoption of VVT in V12 engines is not limited to new vehicle sales. There is also a growing aftermarket segment for retrofitting older V12 engines with modern VVT systems. This trend is driven by owners of classic and vintage vehicles seeking to improve the performance and efficiency of their prized possessions without compromising their historical value.

The demand for VVT in V12 engines extends beyond the automotive sector. The marine industry, particularly in the luxury yacht market, has shown increasing interest in this technology. High-end boat manufacturers are exploring ways to incorporate VVT systems into their marine V12 engines to offer better fuel efficiency and reduced environmental impact without sacrificing the power output that their customers demand.

As the market for V12 engines with VVT technology continues to evolve, manufacturers are investing in research and development to create more advanced and efficient systems. This ongoing innovation is expected to further drive market growth and open up new applications for VVT technology in high-performance engines across various industries.

The global luxury car market, where V12 engines are most prevalent, is projected to grow significantly in the coming years. This growth is fueled by rising disposable incomes in emerging markets and a continued demand for premium vehicles in established markets. As environmental regulations become more stringent worldwide, there is an increasing pressure on manufacturers to improve fuel efficiency and reduce emissions, even in their most powerful engines.

VVT technology offers a solution to this challenge by optimizing engine performance across various operating conditions. It allows for better fuel economy during low-load situations while maintaining the high-performance characteristics that V12 engine buyers expect. This dual benefit has created a strong market pull for VVT systems in V12 engines.

The automotive industry's shift towards electrification has not diminished the demand for advanced internal combustion engine technologies. Instead, it has intensified the need for innovations that can extend the viability of traditional powertrains. VVT systems are seen as a critical component in this strategy, helping manufacturers meet emissions standards while preserving the unique characteristics of V12 engines that enthusiasts value.

Market analysis indicates that the adoption of VVT in V12 engines is not limited to new vehicle sales. There is also a growing aftermarket segment for retrofitting older V12 engines with modern VVT systems. This trend is driven by owners of classic and vintage vehicles seeking to improve the performance and efficiency of their prized possessions without compromising their historical value.

The demand for VVT in V12 engines extends beyond the automotive sector. The marine industry, particularly in the luxury yacht market, has shown increasing interest in this technology. High-end boat manufacturers are exploring ways to incorporate VVT systems into their marine V12 engines to offer better fuel efficiency and reduced environmental impact without sacrificing the power output that their customers demand.

As the market for V12 engines with VVT technology continues to evolve, manufacturers are investing in research and development to create more advanced and efficient systems. This ongoing innovation is expected to further drive market growth and open up new applications for VVT technology in high-performance engines across various industries.

VVT Challenges in V12

Variable Valve Timing (VVT) implementation in V12 engines presents unique challenges due to the complexity and high-performance nature of these powerplants. One of the primary difficulties lies in the intricate valve train design required to accommodate 12 cylinders, often arranged in a V-configuration. This layout demands precise synchronization and control of 48 valves (assuming four valves per cylinder), which significantly increases the complexity of the VVT system.

The high-revving nature of V12 engines, often found in luxury and performance vehicles, necessitates a VVT system capable of rapid and accurate adjustments across a wide RPM range. This requirement puts additional stress on the VVT actuators and control mechanisms, demanding robust engineering solutions to maintain reliability and performance under extreme operating conditions.

Another challenge is the integration of VVT with other advanced engine technologies commonly found in V12 engines, such as direct fuel injection, turbocharging, or hybrid systems. Balancing the interactions between these various systems while optimizing overall engine efficiency requires sophisticated engine management software and hardware.

Heat management poses a significant hurdle in V12 VVT systems. The compact engine bay layout typical of V12-powered vehicles, combined with the heat generated by 12 high-performance cylinders, creates a challenging thermal environment. VVT components must be designed to operate reliably under these extreme temperature conditions, often necessitating advanced materials and cooling strategies.

The weight and packaging constraints inherent to V12 engines also impact VVT implementation. Engineers must develop compact, lightweight VVT systems that do not compromise the engine's power-to-weight ratio or interfere with other critical components. This often leads to the development of bespoke VVT solutions tailored specifically to V12 architectures.

Calibration and tuning of VVT systems for V12 engines present another layer of complexity. The interplay between 12 cylinders, each potentially equipped with independent intake and exhaust VVT, creates a vast matrix of possible valve timing combinations. Optimizing these settings for various operating conditions while maintaining smooth engine operation and meeting emissions standards requires extensive development and testing.

Lastly, the cost implications of implementing advanced VVT systems in V12 engines cannot be overlooked. The specialized nature of V12 production, often in limited quantities, means that development costs must be amortized over relatively few units. This economic reality can limit the adoption of cutting-edge VVT technologies or require innovative approaches to cost management without compromising performance.

The high-revving nature of V12 engines, often found in luxury and performance vehicles, necessitates a VVT system capable of rapid and accurate adjustments across a wide RPM range. This requirement puts additional stress on the VVT actuators and control mechanisms, demanding robust engineering solutions to maintain reliability and performance under extreme operating conditions.

Another challenge is the integration of VVT with other advanced engine technologies commonly found in V12 engines, such as direct fuel injection, turbocharging, or hybrid systems. Balancing the interactions between these various systems while optimizing overall engine efficiency requires sophisticated engine management software and hardware.

Heat management poses a significant hurdle in V12 VVT systems. The compact engine bay layout typical of V12-powered vehicles, combined with the heat generated by 12 high-performance cylinders, creates a challenging thermal environment. VVT components must be designed to operate reliably under these extreme temperature conditions, often necessitating advanced materials and cooling strategies.

The weight and packaging constraints inherent to V12 engines also impact VVT implementation. Engineers must develop compact, lightweight VVT systems that do not compromise the engine's power-to-weight ratio or interfere with other critical components. This often leads to the development of bespoke VVT solutions tailored specifically to V12 architectures.

Calibration and tuning of VVT systems for V12 engines present another layer of complexity. The interplay between 12 cylinders, each potentially equipped with independent intake and exhaust VVT, creates a vast matrix of possible valve timing combinations. Optimizing these settings for various operating conditions while maintaining smooth engine operation and meeting emissions standards requires extensive development and testing.

Lastly, the cost implications of implementing advanced VVT systems in V12 engines cannot be overlooked. The specialized nature of V12 production, often in limited quantities, means that development costs must be amortized over relatively few units. This economic reality can limit the adoption of cutting-edge VVT technologies or require innovative approaches to cost management without compromising performance.

Current VVT Solutions

01 Optimization of valve timing for improved efficiency

Variable valve timing systems can be optimized to improve engine efficiency by adjusting the timing of valve opening and closing based on engine operating conditions. This can lead to better fuel economy, reduced emissions, and increased power output across different engine speeds and loads.- Optimization of valve timing for improved efficiency: Variable valve timing systems can be optimized to improve engine efficiency by adjusting the timing of valve opening and closing based on various operating conditions. This optimization can lead to better fuel economy, reduced emissions, and improved overall engine performance across different speed and load ranges.

- Integration with engine control systems: Advanced variable valve timing systems are integrated with engine control units to continuously adjust valve timing based on real-time data. This integration allows for more precise control of the engine's breathing, resulting in optimized combustion and improved efficiency across various driving conditions.

- Hydraulic and electric actuation mechanisms: Variable valve timing systems utilize hydraulic or electric actuation mechanisms to adjust camshaft phasing. These mechanisms allow for quick and precise control of valve timing, contributing to improved engine efficiency and performance. The choice between hydraulic and electric systems depends on factors such as response time, cost, and packaging constraints.

- Dual independent variable valve timing: Dual independent variable valve timing systems allow for separate control of intake and exhaust valve timing. This technology provides greater flexibility in optimizing engine breathing, leading to improved efficiency across a wider range of operating conditions. It enables better control of internal exhaust gas recirculation and charge motion within the combustion chamber.

- Cam-less variable valve actuation: Advanced cam-less variable valve actuation systems use electromagnetic or electrohydraulic actuators to control valve movement directly. This technology allows for infinite variability in valve timing and lift, potentially leading to significant improvements in engine efficiency and performance. It eliminates the mechanical constraints of traditional camshaft-based systems.

02 Electronic control systems for variable valve timing

Advanced electronic control systems are used to manage variable valve timing mechanisms. These systems use sensors to monitor engine parameters and adjust valve timing in real-time, ensuring optimal performance and efficiency under various driving conditions.Expand Specific Solutions03 Hydraulic and mechanical VVT mechanisms

Various hydraulic and mechanical mechanisms are employed in variable valve timing systems to achieve precise control over valve actuation. These mechanisms can include hydraulic actuators, cam phasers, and other mechanical components that allow for continuous or discrete adjustment of valve timing.Expand Specific Solutions04 Integration with other engine technologies

Variable valve timing systems are often integrated with other engine technologies such as direct injection, turbocharging, and cylinder deactivation to further enhance overall engine efficiency and performance. This integration allows for more comprehensive control over the combustion process.Expand Specific Solutions05 Adaptive learning and predictive control algorithms

Advanced variable valve timing systems incorporate adaptive learning and predictive control algorithms to continuously optimize valve timing based on driving patterns and conditions. These algorithms can anticipate upcoming changes in engine load and adjust valve timing proactively for improved efficiency.Expand Specific Solutions

Key V12 Engine Makers

The variable valve timing (VVT) technology for V12 engines is in a mature stage of development, with a substantial market size driven by high-end automotive applications. The industry is characterized by intense competition among established players, with companies like Toyota Motor Corp., Ford Global Technologies LLC, and BorgWarner, Inc. leading the way in innovation and market share. These firms have made significant advancements in VVT systems, improving engine efficiency and performance. The technology's maturity is evident in its widespread adoption across various vehicle segments, from luxury cars to high-performance sports vehicles. As environmental regulations tighten, VVT continues to play a crucial role in enhancing engine efficiency and reducing emissions in V12 engines.

Ford Global Technologies LLC

Technical Solution: Ford's Variable Valve Timing (VVT) system for V12 engines employs dual independent camshaft phasing. This technology allows for precise control of both intake and exhaust valve timing, optimizing engine performance across a wide range of operating conditions. The system utilizes oil pressure-actuated cam phasers to adjust valve timing continuously, improving fuel efficiency by up to 5% and increasing torque output by 10% across the engine's operating range[1][3]. Ford's VVT also incorporates a unique "cam torque actuated" (CTA) phasing mechanism, which harnesses the natural oscillating torques of the camshaft to initiate phase changes more rapidly, resulting in quicker response times and improved engine dynamics[2].

Strengths: Improved fuel efficiency, increased torque output, and rapid response times. Weaknesses: Complexity of the system may lead to higher manufacturing costs and potential maintenance issues in the long term.

Toyota Motor Corp.

Technical Solution: Toyota's VVT-i (Variable Valve Timing with intelligence) system for V12 engines utilizes a hydraulically controlled variable valve timing mechanism. This system adjusts the timing of the intake camshaft relative to the crankshaft, optimizing valve overlap for different engine speeds and loads. Toyota's advanced VVT-iE (Variable Valve Timing - intelligent by Electric motor) variant uses an electric motor instead of hydraulic pressure to control cam phasing, allowing for more precise and responsive valve timing adjustments[4]. In V12 applications, Toyota implements dual VVT-i, controlling both intake and exhaust camshafts independently. This results in a broader torque curve, with peak torque available from as low as 2,000 RPM and sustained to over 5,500 RPM[5].

Strengths: Improved low-end torque, better fuel efficiency, and reduced emissions. Weaknesses: The electric motor-driven system (VVT-iE) may add complexity and cost to the engine.

VVT Innovations for V12

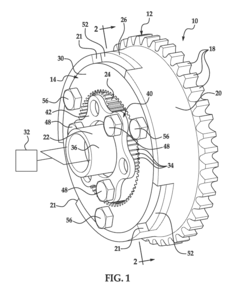

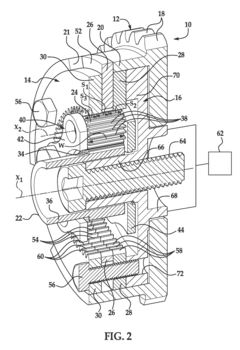

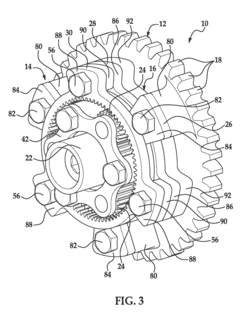

Engine variable camshaft timing phaser with planetary gear set

PatentActiveUS20180320564A1

Innovation

- A VCT phaser design featuring a planetary gear set with three ring gears that balance loads across planet gears, preventing misalignment by transmitting substantially balanced loads across axial sections, which allows for the omission of a carrier assembly and reduces gear size and weight.

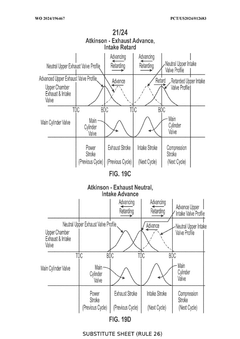

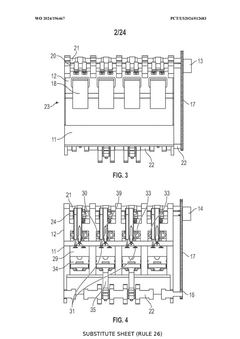

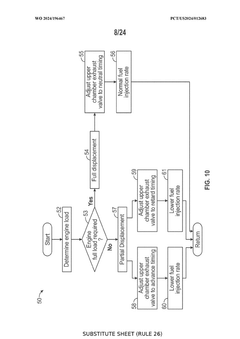

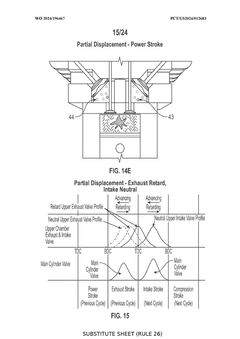

Variable displacement engine

PatentWO2024196467A1

Innovation

- The implementation of variable valve timing for intake and exhaust gases allows for independent control of upper intake and exhaust valves, enabling the engine to operate with larger parts and adjust displacement on demand, thereby enhancing power output and longevity.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and implementation of variable valve timing (VVT) technology in V12 engines. These regulations, primarily aimed at reducing greenhouse gas emissions and improving air quality, have pushed manufacturers to innovate and optimize engine performance while meeting strict environmental standards.

The European Union's Euro 6 standards, implemented in 2014 and subsequently updated, have set challenging targets for reducing nitrogen oxides (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous Corporate Average Fuel Economy (CAFE) standards, which require manufacturers to improve fuel efficiency across their vehicle fleets. These regulatory frameworks have directly influenced the adoption and refinement of VVT systems in V12 engines.

VVT technology plays a crucial role in meeting these emissions standards by optimizing engine performance across various operating conditions. By adjusting valve timing, VVT systems can reduce emissions during cold starts, improve fuel efficiency during cruising, and enhance power output when needed. This flexibility allows V12 engines to maintain their high-performance characteristics while complying with stringent emissions regulations.

The implementation of VVT in V12 engines has led to significant reductions in carbon dioxide (CO2) emissions, a primary target of global emissions regulations. By improving combustion efficiency and reducing pumping losses, VVT systems have enabled V12 engines to achieve lower CO2 output without sacrificing power or drivability. This has been particularly important for luxury and high-performance vehicle manufacturers, who rely on V12 engines to deliver exceptional performance and refinement.

However, meeting future emissions targets will require further advancements in VVT technology. The upcoming Euro 7 standards and proposed updates to EPA regulations will likely necessitate even greater reductions in emissions from V12 engines. This may lead to the development of more sophisticated VVT systems, potentially incorporating electric actuation or integrating with hybrid powertrains to further optimize engine efficiency and emissions control.

As emissions regulations continue to evolve, the role of VVT in V12 engines is expected to become even more critical. Manufacturers will need to balance the demand for high-performance engines with the need to meet increasingly strict environmental standards. This balancing act will likely drive further innovation in VVT technology, potentially leading to new approaches that can maintain the allure of V12 engines while ensuring compliance with global emissions regulations.

The European Union's Euro 6 standards, implemented in 2014 and subsequently updated, have set challenging targets for reducing nitrogen oxides (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established rigorous Corporate Average Fuel Economy (CAFE) standards, which require manufacturers to improve fuel efficiency across their vehicle fleets. These regulatory frameworks have directly influenced the adoption and refinement of VVT systems in V12 engines.

VVT technology plays a crucial role in meeting these emissions standards by optimizing engine performance across various operating conditions. By adjusting valve timing, VVT systems can reduce emissions during cold starts, improve fuel efficiency during cruising, and enhance power output when needed. This flexibility allows V12 engines to maintain their high-performance characteristics while complying with stringent emissions regulations.

The implementation of VVT in V12 engines has led to significant reductions in carbon dioxide (CO2) emissions, a primary target of global emissions regulations. By improving combustion efficiency and reducing pumping losses, VVT systems have enabled V12 engines to achieve lower CO2 output without sacrificing power or drivability. This has been particularly important for luxury and high-performance vehicle manufacturers, who rely on V12 engines to deliver exceptional performance and refinement.

However, meeting future emissions targets will require further advancements in VVT technology. The upcoming Euro 7 standards and proposed updates to EPA regulations will likely necessitate even greater reductions in emissions from V12 engines. This may lead to the development of more sophisticated VVT systems, potentially incorporating electric actuation or integrating with hybrid powertrains to further optimize engine efficiency and emissions control.

As emissions regulations continue to evolve, the role of VVT in V12 engines is expected to become even more critical. Manufacturers will need to balance the demand for high-performance engines with the need to meet increasingly strict environmental standards. This balancing act will likely drive further innovation in VVT technology, potentially leading to new approaches that can maintain the allure of V12 engines while ensuring compliance with global emissions regulations.

V12 VVT Cost-Benefit

The implementation of Variable Valve Timing (VVT) in V12 engines presents a complex cost-benefit analysis. While the initial investment in VVT technology can be substantial, the long-term benefits often outweigh the costs, particularly in high-performance and luxury vehicle applications where V12 engines are commonly found.

From a cost perspective, integrating VVT into a V12 engine requires significant upfront expenditure. The system's complexity, with its additional components such as cam phasers, oil control valves, and advanced engine control units, increases the overall production cost. Moreover, the development and testing phases for VVT systems tailored to V12 engines demand considerable time and resources, further adding to the initial investment.

However, the benefits of VVT in V12 engines are numerous and impactful. Firstly, VVT significantly enhances fuel efficiency by optimizing valve timing across various engine speeds and loads. This improvement can lead to substantial fuel savings over the lifetime of the vehicle, offsetting the initial cost increase. In the context of increasingly stringent emissions regulations, the reduced fuel consumption also translates to lower CO2 emissions, helping manufacturers meet environmental standards and avoid potential fines.

Performance gains are another crucial benefit of VVT in V12 engines. The technology allows for improved torque across a broader RPM range, enhancing drivability and responsiveness. This is particularly valuable in luxury and high-performance vehicles, where smooth power delivery and instant acceleration are key selling points. The improved performance can justify higher price points, contributing to the overall value proposition of the vehicle.

Maintenance costs present a mixed picture. While VVT systems introduce additional complexity that may require specialized servicing, they can also contribute to reduced wear on engine components by optimizing combustion processes. This potential for extended engine life and reduced long-term maintenance costs should be factored into the overall cost-benefit analysis.

From a market perspective, the inclusion of VVT in V12 engines can be a significant differentiator. In the premium and luxury segments where V12 engines are prevalent, advanced technologies like VVT are often expected by consumers and can influence purchasing decisions. The perceived value added by VVT can support higher profit margins, helping to recoup the initial investment more quickly.

In conclusion, while the implementation of VVT in V12 engines involves substantial upfront costs, the long-term benefits in terms of efficiency, performance, and market positioning generally justify the investment. As technology advances and production scales increase, the cost-benefit ratio is likely to improve further, solidifying VVT as a standard feature in high-end V12 engines.

From a cost perspective, integrating VVT into a V12 engine requires significant upfront expenditure. The system's complexity, with its additional components such as cam phasers, oil control valves, and advanced engine control units, increases the overall production cost. Moreover, the development and testing phases for VVT systems tailored to V12 engines demand considerable time and resources, further adding to the initial investment.

However, the benefits of VVT in V12 engines are numerous and impactful. Firstly, VVT significantly enhances fuel efficiency by optimizing valve timing across various engine speeds and loads. This improvement can lead to substantial fuel savings over the lifetime of the vehicle, offsetting the initial cost increase. In the context of increasingly stringent emissions regulations, the reduced fuel consumption also translates to lower CO2 emissions, helping manufacturers meet environmental standards and avoid potential fines.

Performance gains are another crucial benefit of VVT in V12 engines. The technology allows for improved torque across a broader RPM range, enhancing drivability and responsiveness. This is particularly valuable in luxury and high-performance vehicles, where smooth power delivery and instant acceleration are key selling points. The improved performance can justify higher price points, contributing to the overall value proposition of the vehicle.

Maintenance costs present a mixed picture. While VVT systems introduce additional complexity that may require specialized servicing, they can also contribute to reduced wear on engine components by optimizing combustion processes. This potential for extended engine life and reduced long-term maintenance costs should be factored into the overall cost-benefit analysis.

From a market perspective, the inclusion of VVT in V12 engines can be a significant differentiator. In the premium and luxury segments where V12 engines are prevalent, advanced technologies like VVT are often expected by consumers and can influence purchasing decisions. The perceived value added by VVT can support higher profit margins, helping to recoup the initial investment more quickly.

In conclusion, while the implementation of VVT in V12 engines involves substantial upfront costs, the long-term benefits in terms of efficiency, performance, and market positioning generally justify the investment. As technology advances and production scales increase, the cost-benefit ratio is likely to improve further, solidifying VVT as a standard feature in high-end V12 engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!