Identifying Weaknesses in Rail Gun Ballistic Projectiles

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution and Objectives

Rail guns have evolved significantly since their inception in the early 20th century. Initially conceived as a theoretical concept, these electromagnetic projectile launchers have progressed from laboratory experiments to potential military applications. The evolution of rail guns can be traced through several key stages, each marked by technological advancements and increased understanding of the underlying physics.

In the 1970s and 1980s, research into rail guns gained momentum, driven by the desire for high-velocity projectile launchers. Early prototypes demonstrated the feasibility of electromagnetic acceleration but were limited by power supply constraints and material limitations. The 1990s saw significant progress in power management and materials science, enabling the development of more robust and efficient rail gun systems.

The turn of the millennium marked a new era for rail gun technology. Advanced computer modeling and simulation techniques allowed for more precise designs, while improvements in capacitor technology and pulsed power systems addressed many of the previous energy storage and delivery challenges. This period also saw increased interest from military organizations, recognizing the potential of rail guns as long-range, high-velocity weapons.

Recent years have witnessed remarkable advancements in rail gun capabilities. Modern systems can accelerate projectiles to velocities exceeding Mach 7, with ranges potentially surpassing 100 nautical miles. These developments have been accompanied by progress in projectile design, focusing on aerodynamics and structural integrity to withstand the extreme forces involved.

The primary objectives of current rail gun research and development are multifaceted. Foremost is the goal of increasing muzzle velocity while maintaining or improving accuracy. This involves overcoming challenges related to rail erosion, projectile integrity, and power efficiency. Another critical objective is the miniaturization and ruggedization of rail gun systems, making them more suitable for field deployment on various platforms, including naval vessels and potentially land-based systems.

Enhancing the durability and lifespan of rail gun components remains a key focus. This includes developing more resilient rail materials and innovative cooling systems to manage the intense heat generated during firing. Additionally, there is a push to improve the rate of fire, aiming to make rail guns competitive with conventional artillery in terms of sustained engagement capabilities.

As rail gun technology continues to mature, the objectives extend beyond purely military applications. There is growing interest in exploring civilian uses, such as space launch systems or high-velocity impact testing for materials research. These diverse applications drive the need for more versatile and scalable rail gun designs, capable of adapting to various operational requirements and environmental conditions.

In the 1970s and 1980s, research into rail guns gained momentum, driven by the desire for high-velocity projectile launchers. Early prototypes demonstrated the feasibility of electromagnetic acceleration but were limited by power supply constraints and material limitations. The 1990s saw significant progress in power management and materials science, enabling the development of more robust and efficient rail gun systems.

The turn of the millennium marked a new era for rail gun technology. Advanced computer modeling and simulation techniques allowed for more precise designs, while improvements in capacitor technology and pulsed power systems addressed many of the previous energy storage and delivery challenges. This period also saw increased interest from military organizations, recognizing the potential of rail guns as long-range, high-velocity weapons.

Recent years have witnessed remarkable advancements in rail gun capabilities. Modern systems can accelerate projectiles to velocities exceeding Mach 7, with ranges potentially surpassing 100 nautical miles. These developments have been accompanied by progress in projectile design, focusing on aerodynamics and structural integrity to withstand the extreme forces involved.

The primary objectives of current rail gun research and development are multifaceted. Foremost is the goal of increasing muzzle velocity while maintaining or improving accuracy. This involves overcoming challenges related to rail erosion, projectile integrity, and power efficiency. Another critical objective is the miniaturization and ruggedization of rail gun systems, making them more suitable for field deployment on various platforms, including naval vessels and potentially land-based systems.

Enhancing the durability and lifespan of rail gun components remains a key focus. This includes developing more resilient rail materials and innovative cooling systems to manage the intense heat generated during firing. Additionally, there is a push to improve the rate of fire, aiming to make rail guns competitive with conventional artillery in terms of sustained engagement capabilities.

As rail gun technology continues to mature, the objectives extend beyond purely military applications. There is growing interest in exploring civilian uses, such as space launch systems or high-velocity impact testing for materials research. These diverse applications drive the need for more versatile and scalable rail gun designs, capable of adapting to various operational requirements and environmental conditions.

Military Demand Analysis

The military demand for rail gun ballistic projectiles has been steadily increasing in recent years, driven by the need for advanced long-range precision strike capabilities. Armed forces worldwide are seeking to enhance their artillery systems with electromagnetic rail gun technology, which offers significant advantages over traditional chemical propellant-based weapons.

Rail guns provide superior muzzle velocities, extended range, and reduced logistics burden compared to conventional artillery. The U.S. Navy, in particular, has shown keen interest in developing rail gun systems for naval applications, aiming to achieve ranges of 100 nautical miles or more. This demand is fueled by the desire to engage targets from safer standoff distances and potentially intercept incoming threats such as anti-ship missiles.

The market for rail gun technology is expected to grow as more nations invest in research and development. Countries like China and Russia are also pursuing rail gun programs, indicating a global trend towards this advanced weaponry. The demand is not limited to naval applications; ground-based and vehicle-mounted rail gun systems are also being explored for land warfare scenarios.

One of the key drivers for military demand is the potential cost-effectiveness of rail gun projectiles. Unlike guided missiles, these projectiles are relatively inexpensive to produce, allowing for a higher volume of fire at a fraction of the cost. This aspect is particularly attractive for military planners looking to optimize budget allocations while maintaining strategic capabilities.

However, the demand for rail gun technology also highlights the need for addressing weaknesses in ballistic projectiles. As these projectiles travel at hypersonic speeds, they face extreme conditions that can affect their performance and accuracy. Military requirements emphasize the need for projectiles that can withstand the intense electromagnetic forces, extreme temperatures, and aerodynamic stresses encountered during launch and flight.

The ability to identify and mitigate weaknesses in rail gun ballistic projectiles is crucial for meeting military expectations. Armed forces require projectiles that maintain structural integrity throughout their flight path, ensuring consistent performance and accuracy at extended ranges. This demand drives research into advanced materials, innovative projectile designs, and sophisticated modeling techniques to predict and overcome potential failure modes.

Furthermore, there is a growing interest in developing "smart" rail gun projectiles with limited guidance capabilities. While not as complex as guided missiles, these projectiles could potentially adjust their trajectory in flight, further enhancing accuracy and effectiveness. This represents an evolving aspect of military demand, pushing the boundaries of what rail gun technology can achieve.

Rail guns provide superior muzzle velocities, extended range, and reduced logistics burden compared to conventional artillery. The U.S. Navy, in particular, has shown keen interest in developing rail gun systems for naval applications, aiming to achieve ranges of 100 nautical miles or more. This demand is fueled by the desire to engage targets from safer standoff distances and potentially intercept incoming threats such as anti-ship missiles.

The market for rail gun technology is expected to grow as more nations invest in research and development. Countries like China and Russia are also pursuing rail gun programs, indicating a global trend towards this advanced weaponry. The demand is not limited to naval applications; ground-based and vehicle-mounted rail gun systems are also being explored for land warfare scenarios.

One of the key drivers for military demand is the potential cost-effectiveness of rail gun projectiles. Unlike guided missiles, these projectiles are relatively inexpensive to produce, allowing for a higher volume of fire at a fraction of the cost. This aspect is particularly attractive for military planners looking to optimize budget allocations while maintaining strategic capabilities.

However, the demand for rail gun technology also highlights the need for addressing weaknesses in ballistic projectiles. As these projectiles travel at hypersonic speeds, they face extreme conditions that can affect their performance and accuracy. Military requirements emphasize the need for projectiles that can withstand the intense electromagnetic forces, extreme temperatures, and aerodynamic stresses encountered during launch and flight.

The ability to identify and mitigate weaknesses in rail gun ballistic projectiles is crucial for meeting military expectations. Armed forces require projectiles that maintain structural integrity throughout their flight path, ensuring consistent performance and accuracy at extended ranges. This demand drives research into advanced materials, innovative projectile designs, and sophisticated modeling techniques to predict and overcome potential failure modes.

Furthermore, there is a growing interest in developing "smart" rail gun projectiles with limited guidance capabilities. While not as complex as guided missiles, these projectiles could potentially adjust their trajectory in flight, further enhancing accuracy and effectiveness. This represents an evolving aspect of military demand, pushing the boundaries of what rail gun technology can achieve.

Current Challenges in Rail Gun Technology

Rail gun technology, while promising in its potential for high-velocity projectile launches, faces several significant challenges that hinder its widespread adoption and practical implementation. One of the primary obstacles is the immense power requirements needed to generate the electromagnetic fields necessary for projectile acceleration. Current power systems struggle to provide the massive bursts of energy required for effective rail gun operation, limiting their deployment to large platforms with substantial power generation capabilities.

The extreme wear and tear on rail gun components present another major hurdle. The high-speed projectile launch process subjects the rails to intense electromagnetic forces, causing rapid erosion and deformation. This wear significantly reduces the operational lifespan of rail guns and necessitates frequent maintenance and replacement of critical components, impacting their reliability and cost-effectiveness in real-world applications.

Thermal management poses a considerable challenge in rail gun technology. The intense electrical currents and friction generated during projectile acceleration produce enormous amounts of heat. Without effective cooling systems, this heat buildup can lead to material degradation, reduced performance, and potential system failures. Developing efficient heat dissipation mechanisms that can operate under the extreme conditions of rail gun firing remains a critical area of research.

The design and materials used in rail gun projectiles also present ongoing challenges. Projectiles must withstand the extreme accelerations and electromagnetic forces experienced during launch while maintaining their structural integrity and aerodynamic properties. Finding the right balance between durability, mass, and aerodynamic efficiency is crucial for maximizing range and accuracy.

Additionally, the precision and control of rail gun projectiles remain areas of concern. Unlike conventional gun systems, rail guns lack the stabilizing effects of rifling, making it more challenging to ensure consistent and accurate projectile trajectories. Developing guidance systems that can function under the intense launch conditions and provide in-flight course corrections is an active area of research aimed at improving rail gun accuracy and effectiveness.

Scaling rail gun technology for different applications presents its own set of challenges. While large-scale systems have shown promise in naval applications, miniaturizing the technology for use in smaller platforms or portable systems has proven difficult due to power, size, and weight constraints. Overcoming these limitations is essential for expanding the potential applications of rail gun technology across various military and civilian domains.

The extreme wear and tear on rail gun components present another major hurdle. The high-speed projectile launch process subjects the rails to intense electromagnetic forces, causing rapid erosion and deformation. This wear significantly reduces the operational lifespan of rail guns and necessitates frequent maintenance and replacement of critical components, impacting their reliability and cost-effectiveness in real-world applications.

Thermal management poses a considerable challenge in rail gun technology. The intense electrical currents and friction generated during projectile acceleration produce enormous amounts of heat. Without effective cooling systems, this heat buildup can lead to material degradation, reduced performance, and potential system failures. Developing efficient heat dissipation mechanisms that can operate under the extreme conditions of rail gun firing remains a critical area of research.

The design and materials used in rail gun projectiles also present ongoing challenges. Projectiles must withstand the extreme accelerations and electromagnetic forces experienced during launch while maintaining their structural integrity and aerodynamic properties. Finding the right balance between durability, mass, and aerodynamic efficiency is crucial for maximizing range and accuracy.

Additionally, the precision and control of rail gun projectiles remain areas of concern. Unlike conventional gun systems, rail guns lack the stabilizing effects of rifling, making it more challenging to ensure consistent and accurate projectile trajectories. Developing guidance systems that can function under the intense launch conditions and provide in-flight course corrections is an active area of research aimed at improving rail gun accuracy and effectiveness.

Scaling rail gun technology for different applications presents its own set of challenges. While large-scale systems have shown promise in naval applications, miniaturizing the technology for use in smaller platforms or portable systems has proven difficult due to power, size, and weight constraints. Overcoming these limitations is essential for expanding the potential applications of rail gun technology across various military and civilian domains.

Existing Rail Gun Projectile Designs

01 Electromagnetic interference vulnerability

Rail gun ballistic projectiles are susceptible to electromagnetic interference, which can disrupt their guidance systems and affect accuracy. This weakness stems from the reliance on electromagnetic forces for propulsion and potentially for guidance, making them vulnerable to countermeasures that exploit this dependency.- Electromagnetic interference vulnerability: Rail gun ballistic projectiles are susceptible to electromagnetic interference, which can disrupt their guidance systems and affect accuracy. This vulnerability stems from the high-energy electromagnetic fields generated during launch and can be exploited by countermeasures.

- Thermal management challenges: The extreme temperatures generated during rail gun firing can lead to projectile deformation and reduced performance. Inadequate thermal management can result in decreased accuracy, range, and overall effectiveness of the projectile.

- Structural integrity issues: Rail gun projectiles experience extreme acceleration forces during launch, which can compromise their structural integrity. This weakness can lead to projectile fragmentation or deformation in flight, reducing effectiveness and accuracy.

- Limited range and velocity degradation: Despite initial high velocities, rail gun projectiles can experience significant velocity degradation over long distances due to atmospheric drag. This limitation affects their effective range and impact energy at the target.

- Countermeasure susceptibility: Rail gun projectiles may be vulnerable to various countermeasures, including advanced armor systems, active protection systems, and electronic warfare techniques. These countermeasures can potentially deflect, destroy, or disrupt the projectile before it reaches its target.

02 Structural integrity issues

The extreme acceleration and high velocities experienced by rail gun projectiles can lead to structural integrity problems. The intense forces involved may cause deformation or disintegration of the projectile during launch or flight, reducing effectiveness and range.Expand Specific Solutions03 Power supply limitations

Rail guns require massive amounts of electrical power to operate effectively, which can be a significant weakness in mobile or field applications. The need for large, specialized power sources limits their deployment options and makes them vulnerable to power disruptions.Expand Specific Solutions04 Barrel wear and maintenance

The high-energy launch process in rail guns causes significant wear on the barrel, requiring frequent maintenance and replacement. This weakness impacts the weapon's reliability, operational readiness, and cost-effectiveness in prolonged use scenarios.Expand Specific Solutions05 Atmospheric interaction effects

Rail gun projectiles, due to their extremely high velocities, are subject to intense atmospheric interactions. This can lead to issues such as ablation, plasma formation, and trajectory instability, potentially reducing accuracy and effectiveness at long ranges or in varying atmospheric conditions.Expand Specific Solutions

Key Players in Rail Gun Industry

The field of rail gun ballistic projectiles is in a relatively early stage of development, with ongoing research and innovation. The market size is growing but still limited, primarily driven by military and defense applications. Technological maturity varies, with companies like Raytheon Co. and General Dynamics leading in advanced research and development. Other players such as JFE Steel Corp. and NIPPON STEEL CORP. contribute specialized materials expertise. Academic institutions like Beijing Institute of Technology and Nanjing University of Science & Technology are also actively involved in research, indicating a collaborative ecosystem between industry and academia. The competitive landscape is characterized by a mix of established defense contractors and specialized materials companies, with potential for further innovation and market expansion.

Raytheon Co.

Technical Solution: Raytheon has developed advanced rail gun projectiles with improved aerodynamics and materials. Their projectiles utilize a composite sabot design that reduces parasitic mass and improves muzzle velocity[1]. The company has also implemented novel thermal management techniques to mitigate heat-related issues during launch. Raytheon's projectiles incorporate smart guidance systems for increased accuracy over long distances[2]. Additionally, they have developed specialized coatings to reduce in-bore wear and extend barrel life[3].

Strengths: Advanced materials and aerodynamics, smart guidance systems, thermal management. Weaknesses: High cost, complexity of systems, potential electromagnetic interference issues.

The Boeing Co.

Technical Solution: Boeing has focused on developing lightweight, high-strength projectiles for rail gun systems. Their approach utilizes advanced composite materials and innovative structural designs to maximize kinetic energy delivery while minimizing projectile mass[4]. Boeing's projectiles incorporate a modular design allowing for various payload options. They have also developed specialized fin stabilization systems for improved in-flight stability and accuracy[5]. Additionally, Boeing has implemented advanced telemetry systems in their projectiles for real-time performance monitoring and data collection during flight[6].

Strengths: Lightweight design, modular payload options, advanced telemetry. Weaknesses: Potential durability issues with composite materials, higher production costs, limited testing data in real-world conditions.

Critical Innovations in Projectile Materials

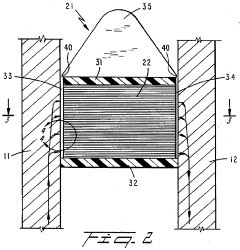

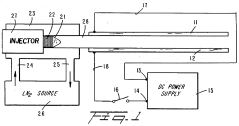

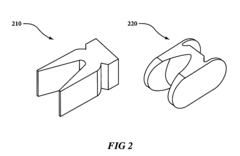

Superconducting projectile for a rail gun and the combination of a rail gun with a superconducting projectile

PatentInactiveUS4901621A

Innovation

- A rail gun projectile with a superconducting armature using high-temperature Type II superconductors arranged perpendicularly to the rail direction, coupled with metal and dielectric regions to distribute current uniformly and minimize heating, and thin metallic layers to enhance current distribution and mechanical stability.

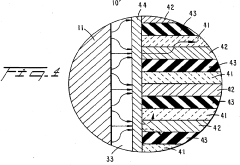

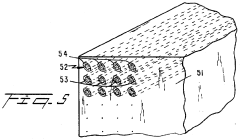

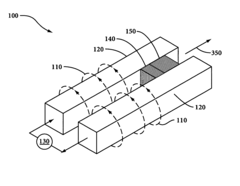

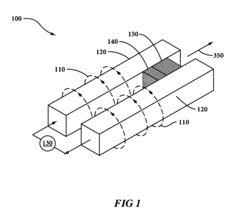

ILP rail-gun armature and rails

PatentActiveUS8132562B1

Innovation

- The use of carbon-carbon composite materials for both armatures and rails, fabricated through a process of carbonization, infusion with a carbon matrix, and graphitization, along with reinforcement and additional refractory metals, to create a durable and conductive structure that minimizes damage during high-velocity projectile launches.

Environmental Impact Assessment

The environmental impact assessment of rail gun ballistic projectiles is a critical aspect of their development and deployment. These advanced weapons systems, while offering significant military advantages, also pose potential risks to the environment that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with rail gun projectiles is the acoustic impact. The high-velocity launch of these projectiles generates intense sound waves that can propagate over long distances. This noise pollution may have adverse effects on local wildlife, particularly in sensitive ecosystems. Marine environments near coastal testing or deployment sites could be especially vulnerable, with potential disruptions to marine mammal communication and navigation.

Another significant environmental consideration is the impact of projectile materials on soil and water systems. Rail gun projectiles are typically composed of dense, high-strength materials that may contain heavy metals or other potentially toxic substances. When these projectiles impact their targets or land in the environment, they can fragment and disperse these materials. This dispersion may lead to soil contamination and potential leaching into groundwater systems, affecting both terrestrial and aquatic ecosystems.

The high-energy nature of rail gun launches also raises concerns about atmospheric effects. The intense electromagnetic fields generated during launch, coupled with the extreme velocities of the projectiles, may interact with the atmosphere in ways that could potentially affect local weather patterns or contribute to the creation of ionized plasma. While the scale of these effects may be limited, cumulative impacts from repeated launches should be considered in long-term environmental assessments.

Habitat destruction is another potential consequence of rail gun testing and deployment. The construction of testing facilities and the impact areas required for these weapons can lead to the loss or fragmentation of natural habitats. This is particularly concerning in ecologically sensitive areas or regions with high biodiversity. The long-range capabilities of rail guns may also extend the potential impact zone far beyond traditional artillery ranges, necessitating a broader scope for environmental impact studies.

Lastly, the environmental assessment must consider the lifecycle impact of rail gun projectiles, from manufacturing to disposal. The production of these advanced projectiles may involve energy-intensive processes and the use of rare or toxic materials. Proper disposal protocols must be developed to handle spent or damaged projectiles, ensuring that hazardous materials are not released into the environment.

One of the primary environmental concerns associated with rail gun projectiles is the acoustic impact. The high-velocity launch of these projectiles generates intense sound waves that can propagate over long distances. This noise pollution may have adverse effects on local wildlife, particularly in sensitive ecosystems. Marine environments near coastal testing or deployment sites could be especially vulnerable, with potential disruptions to marine mammal communication and navigation.

Another significant environmental consideration is the impact of projectile materials on soil and water systems. Rail gun projectiles are typically composed of dense, high-strength materials that may contain heavy metals or other potentially toxic substances. When these projectiles impact their targets or land in the environment, they can fragment and disperse these materials. This dispersion may lead to soil contamination and potential leaching into groundwater systems, affecting both terrestrial and aquatic ecosystems.

The high-energy nature of rail gun launches also raises concerns about atmospheric effects. The intense electromagnetic fields generated during launch, coupled with the extreme velocities of the projectiles, may interact with the atmosphere in ways that could potentially affect local weather patterns or contribute to the creation of ionized plasma. While the scale of these effects may be limited, cumulative impacts from repeated launches should be considered in long-term environmental assessments.

Habitat destruction is another potential consequence of rail gun testing and deployment. The construction of testing facilities and the impact areas required for these weapons can lead to the loss or fragmentation of natural habitats. This is particularly concerning in ecologically sensitive areas or regions with high biodiversity. The long-range capabilities of rail guns may also extend the potential impact zone far beyond traditional artillery ranges, necessitating a broader scope for environmental impact studies.

Lastly, the environmental assessment must consider the lifecycle impact of rail gun projectiles, from manufacturing to disposal. The production of these advanced projectiles may involve energy-intensive processes and the use of rare or toxic materials. Proper disposal protocols must be developed to handle spent or damaged projectiles, ensuring that hazardous materials are not released into the environment.

International Regulations on Rail Gun Technology

The international regulations on rail gun technology are complex and evolving, reflecting the dual-use nature of this advanced weaponry. Currently, there is no comprehensive global treaty specifically governing rail guns. However, several existing frameworks and agreements indirectly impact their development and proliferation.

The Wassenaar Arrangement, established in 1996, aims to control the export of conventional arms and dual-use technologies. While it does not explicitly mention rail guns, the technology falls under its purview due to its potential military applications. Participating states are expected to exercise caution in transferring related technologies that could contribute to rail gun development.

The Missile Technology Control Regime (MTCR), although primarily focused on missile systems, has implications for rail gun technology. The MTCR guidelines cover technologies that could be used in delivery systems for weapons of mass destruction, potentially encompassing certain aspects of rail gun development.

The United Nations Register of Conventional Arms, while not legally binding, encourages transparency in arms transfers. As rail guns become more prevalent, they may be included in future reporting categories, promoting international oversight.

National export control regulations play a crucial role in governing rail gun technology transfers. The United States, for instance, includes rail gun-related items on its Commerce Control List, requiring export licenses for certain components and technologies. Similarly, the European Union's dual-use export control regime covers technologies that could contribute to rail gun development.

Research collaborations involving rail gun technology are subject to scrutiny under various international agreements. The Budapest Convention on Cybercrime, for example, may be relevant in cases where digital information related to rail gun design is shared across borders.

As rail gun technology advances, there is growing discussion among policymakers about the need for more specific international regulations. Concerns about potential destabilizing effects and the risk of proliferation are driving efforts to establish clearer guidelines. Some experts advocate for expanding existing arms control treaties to explicitly address rail guns and similar emerging technologies.

The lack of a unified international approach to rail gun regulation presents challenges for researchers and developers. Navigating the complex landscape of national and international regulations requires careful consideration of potential dual-use applications and export compliance requirements.

The Wassenaar Arrangement, established in 1996, aims to control the export of conventional arms and dual-use technologies. While it does not explicitly mention rail guns, the technology falls under its purview due to its potential military applications. Participating states are expected to exercise caution in transferring related technologies that could contribute to rail gun development.

The Missile Technology Control Regime (MTCR), although primarily focused on missile systems, has implications for rail gun technology. The MTCR guidelines cover technologies that could be used in delivery systems for weapons of mass destruction, potentially encompassing certain aspects of rail gun development.

The United Nations Register of Conventional Arms, while not legally binding, encourages transparency in arms transfers. As rail guns become more prevalent, they may be included in future reporting categories, promoting international oversight.

National export control regulations play a crucial role in governing rail gun technology transfers. The United States, for instance, includes rail gun-related items on its Commerce Control List, requiring export licenses for certain components and technologies. Similarly, the European Union's dual-use export control regime covers technologies that could contribute to rail gun development.

Research collaborations involving rail gun technology are subject to scrutiny under various international agreements. The Budapest Convention on Cybercrime, for example, may be relevant in cases where digital information related to rail gun design is shared across borders.

As rail gun technology advances, there is growing discussion among policymakers about the need for more specific international regulations. Concerns about potential destabilizing effects and the risk of proliferation are driving efforts to establish clearer guidelines. Some experts advocate for expanding existing arms control treaties to explicitly address rail guns and similar emerging technologies.

The lack of a unified international approach to rail gun regulation presents challenges for researchers and developers. Navigating the complex landscape of national and international regulations requires careful consideration of potential dual-use applications and export compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!