Investigating Corrosion Resistance in Scramjet Engine Alloys

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Alloy Evolution

The evolution of alloys for scramjet engines has been a critical journey in aerospace engineering, marked by significant advancements in material science and manufacturing techniques. This progression has been driven by the extreme operational conditions faced by scramjet engines, including high temperatures, oxidative environments, and severe mechanical stresses.

In the early stages of scramjet development, conventional high-temperature alloys such as nickel-based superalloys were employed. These materials, while robust, had limitations in terms of their maximum operating temperatures and weight. As the demand for higher performance increased, researchers began exploring more advanced alloy compositions and manufacturing methods.

The 1980s and 1990s saw the introduction of intermetallic compounds, particularly those based on titanium aluminides. These materials offered improved high-temperature strength and reduced density compared to traditional superalloys. However, they faced challenges related to brittleness and complex processing requirements.

A significant breakthrough came with the development of refractory metal alloys, particularly those based on niobium and molybdenum. These materials demonstrated exceptional high-temperature strength and creep resistance, making them suitable for the most demanding sections of scramjet engines. The incorporation of silicon and other alloying elements helped to address oxidation issues, a critical factor in the corrosive environment of hypersonic flight.

The turn of the millennium brought about a renewed focus on composite materials, specifically ceramic matrix composites (CMCs). These materials offered an attractive combination of low density, high-temperature capability, and excellent oxidation resistance. The integration of CMCs into scramjet engine designs marked a paradigm shift in material selection strategies.

Recent years have seen the emergence of high-entropy alloys (HEAs) as potential candidates for scramjet applications. These multi-component alloys, characterized by their unique solid solution structures, have shown promising results in terms of high-temperature stability and corrosion resistance. Ongoing research is exploring tailored HEA compositions specifically designed for scramjet engine environments.

Parallel to these material developments, advancements in manufacturing technologies have played a crucial role. The advent of additive manufacturing techniques, such as selective laser melting and electron beam melting, has enabled the production of complex geometries and functionally graded materials. These methods have opened new possibilities for optimizing component designs and integrating cooling channels, further enhancing the performance and durability of scramjet engine components.

In the early stages of scramjet development, conventional high-temperature alloys such as nickel-based superalloys were employed. These materials, while robust, had limitations in terms of their maximum operating temperatures and weight. As the demand for higher performance increased, researchers began exploring more advanced alloy compositions and manufacturing methods.

The 1980s and 1990s saw the introduction of intermetallic compounds, particularly those based on titanium aluminides. These materials offered improved high-temperature strength and reduced density compared to traditional superalloys. However, they faced challenges related to brittleness and complex processing requirements.

A significant breakthrough came with the development of refractory metal alloys, particularly those based on niobium and molybdenum. These materials demonstrated exceptional high-temperature strength and creep resistance, making them suitable for the most demanding sections of scramjet engines. The incorporation of silicon and other alloying elements helped to address oxidation issues, a critical factor in the corrosive environment of hypersonic flight.

The turn of the millennium brought about a renewed focus on composite materials, specifically ceramic matrix composites (CMCs). These materials offered an attractive combination of low density, high-temperature capability, and excellent oxidation resistance. The integration of CMCs into scramjet engine designs marked a paradigm shift in material selection strategies.

Recent years have seen the emergence of high-entropy alloys (HEAs) as potential candidates for scramjet applications. These multi-component alloys, characterized by their unique solid solution structures, have shown promising results in terms of high-temperature stability and corrosion resistance. Ongoing research is exploring tailored HEA compositions specifically designed for scramjet engine environments.

Parallel to these material developments, advancements in manufacturing technologies have played a crucial role. The advent of additive manufacturing techniques, such as selective laser melting and electron beam melting, has enabled the production of complex geometries and functionally graded materials. These methods have opened new possibilities for optimizing component designs and integrating cooling channels, further enhancing the performance and durability of scramjet engine components.

Hypersonic Market Demand

The hypersonic market, particularly in relation to scramjet engine technology, is experiencing rapid growth and increasing demand. This surge is driven by both military and commercial interests, with a focus on developing faster and more efficient transportation systems. The global hypersonic technology market is projected to reach significant value in the coming years, with a compound annual growth rate (CAGR) exceeding 8% from 2021 to 2026.

Military applications remain the primary driver of hypersonic market demand. Nations such as the United States, China, and Russia are investing heavily in hypersonic weapons and defense systems, recognizing their potential to revolutionize warfare. These investments are spurring advancements in scramjet engine technology and materials science, including research into corrosion-resistant alloys for engine components.

In the commercial sector, there is growing interest in hypersonic passenger aircraft for long-distance travel. Companies like Boeing and Lockheed Martin are exploring concepts for hypersonic passenger planes that could dramatically reduce flight times for intercontinental journeys. This potential for faster global connectivity is attracting attention from airlines and investors, further fueling market demand.

The space industry is another significant contributor to hypersonic market growth. As private companies and government agencies aim to reduce the cost of space access, scramjet-powered vehicles are being considered for more efficient and reusable launch systems. This application requires materials capable of withstanding extreme temperatures and corrosive environments, driving demand for advanced alloys with superior corrosion resistance.

Emerging economies, particularly in Asia-Pacific, are showing increased interest in hypersonic technologies. Countries like India and Japan are investing in research and development programs, aiming to establish themselves as key players in this high-tech field. This regional expansion is creating new opportunities for collaborations and market growth.

The demand for hypersonic technologies is also influencing adjacent industries. Materials suppliers, propulsion system manufacturers, and thermal management solution providers are experiencing increased business opportunities. The need for specialized testing facilities and advanced simulation tools is growing, creating a ripple effect across the aerospace and defense supply chain.

However, the hypersonic market faces challenges that could impact demand. Technical hurdles in materials science, propulsion efficiency, and thermal management need to be overcome. Additionally, regulatory frameworks and international agreements regarding hypersonic technologies are still evolving, which could affect market growth and adoption rates in certain regions or applications.

Military applications remain the primary driver of hypersonic market demand. Nations such as the United States, China, and Russia are investing heavily in hypersonic weapons and defense systems, recognizing their potential to revolutionize warfare. These investments are spurring advancements in scramjet engine technology and materials science, including research into corrosion-resistant alloys for engine components.

In the commercial sector, there is growing interest in hypersonic passenger aircraft for long-distance travel. Companies like Boeing and Lockheed Martin are exploring concepts for hypersonic passenger planes that could dramatically reduce flight times for intercontinental journeys. This potential for faster global connectivity is attracting attention from airlines and investors, further fueling market demand.

The space industry is another significant contributor to hypersonic market growth. As private companies and government agencies aim to reduce the cost of space access, scramjet-powered vehicles are being considered for more efficient and reusable launch systems. This application requires materials capable of withstanding extreme temperatures and corrosive environments, driving demand for advanced alloys with superior corrosion resistance.

Emerging economies, particularly in Asia-Pacific, are showing increased interest in hypersonic technologies. Countries like India and Japan are investing in research and development programs, aiming to establish themselves as key players in this high-tech field. This regional expansion is creating new opportunities for collaborations and market growth.

The demand for hypersonic technologies is also influencing adjacent industries. Materials suppliers, propulsion system manufacturers, and thermal management solution providers are experiencing increased business opportunities. The need for specialized testing facilities and advanced simulation tools is growing, creating a ripple effect across the aerospace and defense supply chain.

However, the hypersonic market faces challenges that could impact demand. Technical hurdles in materials science, propulsion efficiency, and thermal management need to be overcome. Additionally, regulatory frameworks and international agreements regarding hypersonic technologies are still evolving, which could affect market growth and adoption rates in certain regions or applications.

Corrosion Challenges

Corrosion resistance presents a significant challenge in the development of scramjet engine alloys due to the extreme operating conditions these engines encounter. The high-speed airflow and elevated temperatures in scramjet engines create a highly oxidizing environment, which accelerates the corrosion process of engine components. This corrosive atmosphere is further exacerbated by the presence of combustion products and atmospheric contaminants.

One of the primary corrosion challenges in scramjet engines is hot corrosion, which occurs when molten salts deposit on metal surfaces at high temperatures. This type of corrosion can lead to rapid degradation of engine components, particularly in coastal or marine environments where salt concentrations are higher. The combination of high temperature and salt deposits can form low-melting eutectic compounds that dissolve protective oxide layers, exposing the underlying metal to further attack.

Oxidation is another critical corrosion challenge faced by scramjet engine alloys. The extreme temperatures experienced during hypersonic flight can cause rapid oxidation of metal surfaces, leading to the formation of oxide scales. While some oxide layers can provide temporary protection, they often become unstable or spall off at the high temperatures and velocities encountered in scramjet engines, exposing fresh metal to further oxidation.

The presence of hydrogen in the combustion environment poses an additional corrosion challenge. Hydrogen embrittlement can occur when atomic hydrogen diffuses into the metal structure, leading to a reduction in ductility and tensile strength. This phenomenon is particularly concerning for high-strength alloys used in critical engine components, as it can result in unexpected failures under stress.

Erosion-corrosion is yet another issue that scramjet engine alloys must contend with. The high-velocity airflow, combined with particulate matter and combustion products, can cause mechanical erosion of surfaces while simultaneously promoting corrosive reactions. This synergistic effect can lead to accelerated material loss and degradation of engine performance over time.

The development of corrosion-resistant alloys for scramjet engines is further complicated by the need to balance corrosion resistance with other critical properties such as high-temperature strength, thermal stability, and manufacturability. Alloys that exhibit excellent corrosion resistance may not necessarily possess the mechanical properties required to withstand the extreme stresses and temperatures of scramjet operation.

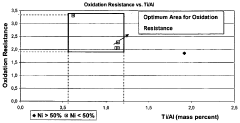

Addressing these corrosion challenges requires a multifaceted approach, including the development of advanced alloy compositions, protective coatings, and surface treatments. Researchers are exploring various strategies, such as the incorporation of corrosion-resistant elements like chromium, aluminum, and silicon into alloy compositions, as well as the application of thermal barrier coatings and environmental barrier coatings to protect underlying materials.

One of the primary corrosion challenges in scramjet engines is hot corrosion, which occurs when molten salts deposit on metal surfaces at high temperatures. This type of corrosion can lead to rapid degradation of engine components, particularly in coastal or marine environments where salt concentrations are higher. The combination of high temperature and salt deposits can form low-melting eutectic compounds that dissolve protective oxide layers, exposing the underlying metal to further attack.

Oxidation is another critical corrosion challenge faced by scramjet engine alloys. The extreme temperatures experienced during hypersonic flight can cause rapid oxidation of metal surfaces, leading to the formation of oxide scales. While some oxide layers can provide temporary protection, they often become unstable or spall off at the high temperatures and velocities encountered in scramjet engines, exposing fresh metal to further oxidation.

The presence of hydrogen in the combustion environment poses an additional corrosion challenge. Hydrogen embrittlement can occur when atomic hydrogen diffuses into the metal structure, leading to a reduction in ductility and tensile strength. This phenomenon is particularly concerning for high-strength alloys used in critical engine components, as it can result in unexpected failures under stress.

Erosion-corrosion is yet another issue that scramjet engine alloys must contend with. The high-velocity airflow, combined with particulate matter and combustion products, can cause mechanical erosion of surfaces while simultaneously promoting corrosive reactions. This synergistic effect can lead to accelerated material loss and degradation of engine performance over time.

The development of corrosion-resistant alloys for scramjet engines is further complicated by the need to balance corrosion resistance with other critical properties such as high-temperature strength, thermal stability, and manufacturability. Alloys that exhibit excellent corrosion resistance may not necessarily possess the mechanical properties required to withstand the extreme stresses and temperatures of scramjet operation.

Addressing these corrosion challenges requires a multifaceted approach, including the development of advanced alloy compositions, protective coatings, and surface treatments. Researchers are exploring various strategies, such as the incorporation of corrosion-resistant elements like chromium, aluminum, and silicon into alloy compositions, as well as the application of thermal barrier coatings and environmental barrier coatings to protect underlying materials.

Current Anti-Corrosion

01 High-temperature resistant alloys for scramjet engines

Development of alloys that can withstand the extreme temperatures encountered in scramjet engines. These alloys are designed to maintain their structural integrity and corrosion resistance under high-temperature conditions, which is crucial for the engine's performance and longevity.- High-temperature resistant alloys for scramjet engines: Development of alloys capable of withstanding extreme temperatures in scramjet engines. These materials are designed to maintain structural integrity and resist corrosion under the high-temperature, high-speed conditions typical of scramjet operation.

- Corrosion-resistant coatings for engine components: Application of specialized coatings to protect scramjet engine components from corrosion. These coatings are formulated to withstand the harsh operating environment and provide a barrier against oxidation and other forms of corrosion.

- Advanced manufacturing techniques for scramjet alloys: Innovative manufacturing processes to produce alloys with enhanced corrosion resistance for scramjet engines. These techniques may include precision casting, additive manufacturing, or advanced heat treatment methods to optimize material properties.

- Composite materials for improved corrosion resistance: Development of composite materials that combine the strength of metal alloys with the corrosion resistance of ceramics or other materials. These composites are designed to provide superior performance in the extreme conditions of scramjet engines.

- Surface treatment methods for enhancing corrosion resistance: Application of various surface treatment techniques to improve the corrosion resistance of scramjet engine alloys. These methods may include nitriding, carburizing, or other processes that modify the surface properties of the alloys to enhance their durability in corrosive environments.

02 Corrosion-resistant coatings for scramjet engine components

Application of specialized coatings to protect scramjet engine components from corrosion. These coatings are formulated to withstand the harsh operating environment, including exposure to high-temperature gases and potential chemical reactions.Expand Specific Solutions03 Advanced manufacturing techniques for corrosion-resistant alloys

Utilization of innovative manufacturing processes to produce corrosion-resistant alloys for scramjet engines. These techniques may include powder metallurgy, additive manufacturing, or other advanced methods that enhance the material's properties and performance.Expand Specific Solutions04 Composite materials for improved corrosion resistance

Development of composite materials that combine the benefits of different alloys or incorporate non-metallic components to enhance corrosion resistance in scramjet engines. These composites aim to provide superior performance compared to traditional single-alloy materials.Expand Specific Solutions05 Surface treatment methods for enhancing corrosion resistance

Application of various surface treatment techniques to improve the corrosion resistance of scramjet engine alloys. These methods may include heat treatments, chemical processes, or mechanical treatments that modify the surface properties of the alloys to enhance their resistance to corrosion.Expand Specific Solutions

Key Industry Players

The investigation of corrosion resistance in scramjet engine alloys is currently in a nascent stage, with the market poised for significant growth as hypersonic technology advances. The global market for scramjet engines is expanding, driven by increasing investments in defense and aerospace sectors. Technologically, the field is still evolving, with companies like QuesTek Innovations LLC and Kobe Steel, Ltd. leading in materials development. AVIC Shenyang Liming Aero-Engine and Aerojet Rocketdyne, Inc. are making strides in engine manufacturing, while research institutions such as Instituto Superior Técnico de Lisboa contribute to fundamental advancements. The collaboration between materials science experts and aerospace manufacturers is crucial for overcoming the extreme environmental challenges faced by scramjet engines.

QuesTek Innovations LLC

Technical Solution: QuesTek specializes in computational materials design and has applied this approach to develop corrosion-resistant alloys for scramjet engines. Using their Integrated Computational Materials Engineering (ICME) platform, they have created a series of high-entropy alloys (HEAs) that exhibit exceptional corrosion resistance in extreme environments [7]. These HEAs, composed of five or more principal elements in near-equiatomic proportions, form stable single-phase solid solutions with high configurational entropy. This unique structure provides superior resistance to oxidation, sulfidation, and other forms of high-temperature corrosion. QuesTek has also developed a machine learning algorithm to predict and optimize the formation of protective oxide scales on these alloys, further enhancing their corrosion resistance [8].

Strengths: Cutting-edge computational design approach, potential for rapid alloy development and optimization. Weaknesses: Limited real-world testing data for novel alloys, potential challenges in scaling up production.

General Electric Technology GmbH

Technical Solution: GE has focused on developing advanced thermal and environmental barrier coating (T/EBC) systems for scramjet engine components. Their latest T/EBC system consists of a multi-layer structure, including a bond coat, a thermally grown oxide layer, and a top coat made of rare earth zirconates [9]. This system provides excellent resistance to both oxidation and calcium-magnesium-alumino-silicate (CMAS) infiltration, a common issue in scramjet engines. GE has also pioneered the use of vapor phase aluminizing and platinum aluminide coatings to enhance the corrosion resistance of nickel-based superalloys used in engine hot sections. Additionally, they have developed a novel process for applying nanostructured coatings that offer improved adherence and durability under extreme thermal cycling conditions [10].

Strengths: Comprehensive coating solutions, strong integration with engine design and manufacturing. Weaknesses: High costs associated with rare earth elements, potential environmental concerns with some coating processes.

Innovative Alloy Patents

Alloys with high corrosion resistance for engine valve applications

PatentInactiveCA2688507C

Innovation

- A Ni-Fe-Cr precipitation-hardened superalloy with higher niobium, aluminum, and chromium content, forming intermetallic phases that enhance corrosion and heat resistance, and a balanced composition to minimize interface energy, thereby reducing nickel content and production costs.

Corrosion-resistant alloy

PatentActiveTW202219289A

Innovation

- Novel composition of chromium, germanium, and at least one of cobalt, iron, and nickel in specific ratios for enhanced corrosion resistance.

- Inclusion of germanium in a relatively high content range (4-25 at%) to improve corrosion resistance.

- Flexibility in the first component selection (Co, Fe, Ni) allows for tailoring the alloy properties for specific applications.

Material Testing Methods

Material testing methods play a crucial role in investigating corrosion resistance in scramjet engine alloys. These methods are designed to simulate the harsh operating conditions of scramjet engines and evaluate the performance of various alloy compositions under extreme temperatures, pressures, and corrosive environments.

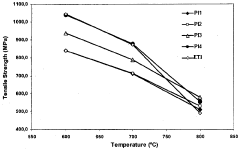

One of the primary testing methods employed is high-temperature oxidation testing. This involves exposing alloy samples to elevated temperatures, typically ranging from 800°C to 1200°C, in an oxygen-rich atmosphere. The samples are subjected to cyclic heating and cooling to mimic the thermal stresses experienced during engine operation. Weight change measurements and surface analysis techniques are used to assess the extent of oxidation and the formation of protective oxide scales.

Hot corrosion testing is another essential method for evaluating the corrosion resistance of scramjet engine alloys. This test simulates the effects of molten salt deposits on the alloy surface, which can accelerate corrosion rates. Samples are coated with a mixture of sulfates and chlorides and exposed to high temperatures. The resulting corrosion products are analyzed using microscopy and spectroscopic techniques to determine the extent and mechanisms of corrosion.

Erosion-corrosion testing is conducted to assess the combined effects of mechanical wear and chemical attack on alloy surfaces. This is particularly relevant for scramjet engines, where high-velocity gas flows can cause erosion of protective oxide layers. Samples are subjected to a high-temperature gas stream containing abrasive particles, and the resulting surface degradation is quantified using profilometry and electron microscopy.

Electrochemical testing methods, such as potentiodynamic polarization and electrochemical impedance spectroscopy, are employed to evaluate the corrosion behavior of alloys in various electrolytes. These techniques provide insights into the corrosion kinetics and mechanisms, allowing researchers to compare the performance of different alloy compositions under controlled conditions.

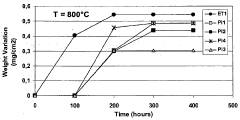

Long-term exposure tests are conducted to assess the durability of alloys over extended periods. Samples are exposed to simulated scramjet engine environments for hundreds or thousands of hours, with periodic analysis of weight change, microstructure, and mechanical properties. These tests are crucial for predicting the service life of engine components and identifying potential failure modes.

Advanced characterization techniques, including X-ray diffraction, transmission electron microscopy, and atom probe tomography, are used to analyze the microstructural changes and elemental distribution in alloys after corrosion testing. These methods provide valuable insights into the formation of protective scales, interdiffusion processes, and the role of alloying elements in enhancing corrosion resistance.

One of the primary testing methods employed is high-temperature oxidation testing. This involves exposing alloy samples to elevated temperatures, typically ranging from 800°C to 1200°C, in an oxygen-rich atmosphere. The samples are subjected to cyclic heating and cooling to mimic the thermal stresses experienced during engine operation. Weight change measurements and surface analysis techniques are used to assess the extent of oxidation and the formation of protective oxide scales.

Hot corrosion testing is another essential method for evaluating the corrosion resistance of scramjet engine alloys. This test simulates the effects of molten salt deposits on the alloy surface, which can accelerate corrosion rates. Samples are coated with a mixture of sulfates and chlorides and exposed to high temperatures. The resulting corrosion products are analyzed using microscopy and spectroscopic techniques to determine the extent and mechanisms of corrosion.

Erosion-corrosion testing is conducted to assess the combined effects of mechanical wear and chemical attack on alloy surfaces. This is particularly relevant for scramjet engines, where high-velocity gas flows can cause erosion of protective oxide layers. Samples are subjected to a high-temperature gas stream containing abrasive particles, and the resulting surface degradation is quantified using profilometry and electron microscopy.

Electrochemical testing methods, such as potentiodynamic polarization and electrochemical impedance spectroscopy, are employed to evaluate the corrosion behavior of alloys in various electrolytes. These techniques provide insights into the corrosion kinetics and mechanisms, allowing researchers to compare the performance of different alloy compositions under controlled conditions.

Long-term exposure tests are conducted to assess the durability of alloys over extended periods. Samples are exposed to simulated scramjet engine environments for hundreds or thousands of hours, with periodic analysis of weight change, microstructure, and mechanical properties. These tests are crucial for predicting the service life of engine components and identifying potential failure modes.

Advanced characterization techniques, including X-ray diffraction, transmission electron microscopy, and atom probe tomography, are used to analyze the microstructural changes and elemental distribution in alloys after corrosion testing. These methods provide valuable insights into the formation of protective scales, interdiffusion processes, and the role of alloying elements in enhancing corrosion resistance.

Environmental Impact

The environmental impact of scramjet engine alloys and their corrosion resistance is a critical consideration in the development and deployment of hypersonic technologies. The materials used in scramjet engines must not only withstand extreme temperatures and pressures but also minimize their ecological footprint throughout their lifecycle.

Corrosion-resistant alloys in scramjet engines contribute to reduced environmental impact by extending the operational lifespan of these components. This longevity translates to fewer replacements, thereby decreasing the overall resource consumption and waste generation associated with manufacturing and disposal processes. Additionally, improved corrosion resistance can lead to more efficient fuel combustion, potentially reducing emissions during flight operations.

However, the production of these specialized alloys often involves energy-intensive processes and the use of rare earth elements. The mining and refining of these materials can have significant environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions. Balancing the environmental costs of production against the benefits of improved engine performance and longevity is a key challenge for researchers and engineers in this field.

The use of corrosion-resistant alloys may also impact the recyclability of scramjet engine components at the end of their service life. While some alloys may be more easily recycled, others might require specialized processes that could have additional environmental implications. Developing alloys that maintain high performance while also being environmentally friendly in their production and disposal is an ongoing area of research.

Furthermore, the potential for these alloys to release particulate matter or other pollutants during high-speed flight must be carefully evaluated. Even minute amounts of material loss due to corrosion or erosion at hypersonic speeds could have cumulative effects on atmospheric composition, particularly in the upper atmosphere where scramjets operate.

As environmental regulations become more stringent globally, the development of scramjet engine alloys must also consider compliance with current and future environmental standards. This includes not only the direct emissions from the engines but also the entire supply chain and lifecycle of the materials used in their construction.

Corrosion-resistant alloys in scramjet engines contribute to reduced environmental impact by extending the operational lifespan of these components. This longevity translates to fewer replacements, thereby decreasing the overall resource consumption and waste generation associated with manufacturing and disposal processes. Additionally, improved corrosion resistance can lead to more efficient fuel combustion, potentially reducing emissions during flight operations.

However, the production of these specialized alloys often involves energy-intensive processes and the use of rare earth elements. The mining and refining of these materials can have significant environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions. Balancing the environmental costs of production against the benefits of improved engine performance and longevity is a key challenge for researchers and engineers in this field.

The use of corrosion-resistant alloys may also impact the recyclability of scramjet engine components at the end of their service life. While some alloys may be more easily recycled, others might require specialized processes that could have additional environmental implications. Developing alloys that maintain high performance while also being environmentally friendly in their production and disposal is an ongoing area of research.

Furthermore, the potential for these alloys to release particulate matter or other pollutants during high-speed flight must be carefully evaluated. Even minute amounts of material loss due to corrosion or erosion at hypersonic speeds could have cumulative effects on atmospheric composition, particularly in the upper atmosphere where scramjets operate.

As environmental regulations become more stringent globally, the development of scramjet engine alloys must also consider compliance with current and future environmental standards. This includes not only the direct emissions from the engines but also the entire supply chain and lifecycle of the materials used in their construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!