Investigating Rail Gun Economic Sustainability in Defense Sectors

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Evolution and Objectives

The rail gun, a revolutionary electromagnetic projectile launcher, has undergone significant evolution since its inception in the early 20th century. Initially conceptualized by French inventor Louis Octave Fauchon-Villeplee in 1918, the technology remained largely theoretical for decades due to limitations in power supply and materials science.

The modern era of rail gun development began in the 1970s, with renewed interest from military and research institutions. This resurgence was driven by advancements in power electronics, capacitor technology, and high-strength materials. The U.S. Navy, in particular, spearheaded research efforts, recognizing the potential of rail guns to revolutionize naval warfare.

Throughout the 1980s and 1990s, progress in rail gun technology was marked by incremental improvements in projectile velocity, power efficiency, and barrel longevity. Key milestones included achieving muzzle velocities exceeding Mach 7 and developing more durable rail materials to withstand the extreme forces involved in electromagnetic acceleration.

The turn of the millennium saw a shift towards practical implementation, with the U.S. Navy's electromagnetic railgun (EMRG) program gaining momentum. This initiative aimed to develop a weapon system capable of launching projectiles at speeds of 5,600 mph (9,000 km/h) over distances exceeding 100 nautical miles (185 km).

In recent years, the focus has expanded beyond pure performance metrics to address critical challenges in economic sustainability and operational viability. Objectives now include reducing the cost per shot, enhancing power supply efficiency, and improving the durability of rail gun components to extend operational lifespans.

The current technological landscape sees rail guns poised at the intersection of cutting-edge physics and practical military application. Key objectives in the defense sector include integrating rail gun systems into existing naval platforms, developing compact power sources, and refining guidance systems for long-range projectiles.

Looking forward, the rail gun evolution trajectory aims to overcome persistent challenges such as thermal management, rail erosion, and power supply miniaturization. The ultimate goal is to create a economically viable, tactically flexible weapon system that can provide superior range, accuracy, and lethality compared to conventional artillery, while significantly reducing logistical burdens associated with explosive propellants and warheads.

The modern era of rail gun development began in the 1970s, with renewed interest from military and research institutions. This resurgence was driven by advancements in power electronics, capacitor technology, and high-strength materials. The U.S. Navy, in particular, spearheaded research efforts, recognizing the potential of rail guns to revolutionize naval warfare.

Throughout the 1980s and 1990s, progress in rail gun technology was marked by incremental improvements in projectile velocity, power efficiency, and barrel longevity. Key milestones included achieving muzzle velocities exceeding Mach 7 and developing more durable rail materials to withstand the extreme forces involved in electromagnetic acceleration.

The turn of the millennium saw a shift towards practical implementation, with the U.S. Navy's electromagnetic railgun (EMRG) program gaining momentum. This initiative aimed to develop a weapon system capable of launching projectiles at speeds of 5,600 mph (9,000 km/h) over distances exceeding 100 nautical miles (185 km).

In recent years, the focus has expanded beyond pure performance metrics to address critical challenges in economic sustainability and operational viability. Objectives now include reducing the cost per shot, enhancing power supply efficiency, and improving the durability of rail gun components to extend operational lifespans.

The current technological landscape sees rail guns poised at the intersection of cutting-edge physics and practical military application. Key objectives in the defense sector include integrating rail gun systems into existing naval platforms, developing compact power sources, and refining guidance systems for long-range projectiles.

Looking forward, the rail gun evolution trajectory aims to overcome persistent challenges such as thermal management, rail erosion, and power supply miniaturization. The ultimate goal is to create a economically viable, tactically flexible weapon system that can provide superior range, accuracy, and lethality compared to conventional artillery, while significantly reducing logistical burdens associated with explosive propellants and warheads.

Defense Market Demand Analysis

The defense market demand for rail gun technology has been steadily growing in recent years, driven by the need for advanced long-range precision strike capabilities. Military forces worldwide are seeking to enhance their artillery systems with increased range, accuracy, and lethality, making rail guns an attractive option for modernization efforts.

The global defense market for advanced artillery systems, including rail guns, is projected to expand significantly over the next decade. This growth is fueled by increasing geopolitical tensions, the need to counter emerging threats, and the desire to maintain technological superiority in military capabilities.

Several key factors contribute to the rising demand for rail gun technology in the defense sector. First, the extended range of rail guns compared to conventional artillery offers strategic advantages in both offensive and defensive operations. This extended reach allows for engagement of targets beyond the capabilities of traditional systems, potentially changing the dynamics of battlefield engagements.

Second, the high velocity of projectiles fired from rail guns results in increased kinetic energy upon impact, enhancing destructive power without the need for explosive warheads. This characteristic is particularly valuable in scenarios where minimizing collateral damage is crucial, such as in urban warfare or precision strikes against hardened targets.

Third, the potential for reduced logistics footprint associated with rail gun systems is attractive to military planners. The absence of propellant charges and the use of inert projectiles simplify ammunition storage and handling, potentially leading to cost savings and improved operational flexibility.

However, the market demand for rail gun technology is not without challenges. The high power requirements and complex electromagnetic systems involved in rail gun operation present significant hurdles for practical deployment, particularly in mobile platforms. Additionally, the wear and tear on rail gun barrels due to extreme conditions during firing raise concerns about maintenance costs and operational readiness.

Despite these challenges, defense industry analysts predict a growing market for rail gun technology, particularly in naval applications where power generation capabilities are more readily available. Several major defense contractors are investing in rail gun research and development, indicating confidence in future market demand.

The economic sustainability of rail gun technology in the defense sector will largely depend on overcoming technical challenges and demonstrating clear operational advantages over existing systems. As research progresses and prototypes move closer to field deployment, the market demand is expected to crystallize, potentially leading to significant procurement programs by major military powers.

The global defense market for advanced artillery systems, including rail guns, is projected to expand significantly over the next decade. This growth is fueled by increasing geopolitical tensions, the need to counter emerging threats, and the desire to maintain technological superiority in military capabilities.

Several key factors contribute to the rising demand for rail gun technology in the defense sector. First, the extended range of rail guns compared to conventional artillery offers strategic advantages in both offensive and defensive operations. This extended reach allows for engagement of targets beyond the capabilities of traditional systems, potentially changing the dynamics of battlefield engagements.

Second, the high velocity of projectiles fired from rail guns results in increased kinetic energy upon impact, enhancing destructive power without the need for explosive warheads. This characteristic is particularly valuable in scenarios where minimizing collateral damage is crucial, such as in urban warfare or precision strikes against hardened targets.

Third, the potential for reduced logistics footprint associated with rail gun systems is attractive to military planners. The absence of propellant charges and the use of inert projectiles simplify ammunition storage and handling, potentially leading to cost savings and improved operational flexibility.

However, the market demand for rail gun technology is not without challenges. The high power requirements and complex electromagnetic systems involved in rail gun operation present significant hurdles for practical deployment, particularly in mobile platforms. Additionally, the wear and tear on rail gun barrels due to extreme conditions during firing raise concerns about maintenance costs and operational readiness.

Despite these challenges, defense industry analysts predict a growing market for rail gun technology, particularly in naval applications where power generation capabilities are more readily available. Several major defense contractors are investing in rail gun research and development, indicating confidence in future market demand.

The economic sustainability of rail gun technology in the defense sector will largely depend on overcoming technical challenges and demonstrating clear operational advantages over existing systems. As research progresses and prototypes move closer to field deployment, the market demand is expected to crystallize, potentially leading to significant procurement programs by major military powers.

Rail Gun Tech Challenges

Rail guns face several significant technical challenges that hinder their widespread adoption and economic sustainability in defense sectors. One of the primary issues is the immense power requirements needed to operate these electromagnetic weapons. The energy demand for a single shot can reach hundreds of megajoules, necessitating large and complex power storage and delivery systems. This not only increases the overall size and weight of the weapon but also limits its mobility and deployment options.

Material wear and tear pose another critical challenge. The intense electromagnetic forces and extreme temperatures generated during firing cause rapid degradation of the rail gun's components, particularly the rails themselves. This results in a limited operational lifespan and high maintenance costs, as parts need frequent replacement. The development of more durable materials capable of withstanding these extreme conditions remains an ongoing research focus.

Projectile design presents additional hurdles. The high-velocity projectiles used in rail guns must be engineered to withstand the enormous acceleration forces and maintain stability during flight. Achieving the right balance between mass, aerodynamics, and structural integrity is crucial for accuracy and effectiveness. Furthermore, the projectiles must be designed to carry payloads or incorporate guidance systems without compromising their performance under extreme conditions.

Heat management is another significant technical obstacle. The rapid discharge of electrical energy generates substantial heat, which can affect the weapon's performance and reliability. Developing efficient cooling systems that can rapidly dissipate heat without adding excessive weight or complexity to the rail gun system is essential for sustained operation.

Precision and accuracy at long ranges remain challenging due to the effects of atmospheric drag and the Earth's rotation on ultra-high-velocity projectiles. Compensating for these factors requires advanced fire control systems and potentially guided projectiles, adding further complexity and cost to the overall system.

Electromagnetic interference (EMI) is a concern both for the rail gun's own electronic systems and for nearby equipment. The intense electromagnetic fields generated during firing can disrupt sensitive electronics, necessitating robust shielding and EMI mitigation strategies.

Lastly, the integration of rail guns into existing naval platforms or land-based systems presents significant engineering challenges. The weapon's size, power requirements, and unique operational characteristics often require substantial modifications to the host platform, potentially limiting its adoption in retrofitting scenarios.

Addressing these technical challenges is crucial for improving the economic sustainability of rail guns in defense sectors. Ongoing research and development efforts focus on enhancing power efficiency, developing more durable materials, improving projectile design, and refining heat management and fire control systems. Overcoming these hurdles will be key to realizing the full potential of rail gun technology in military applications.

Material wear and tear pose another critical challenge. The intense electromagnetic forces and extreme temperatures generated during firing cause rapid degradation of the rail gun's components, particularly the rails themselves. This results in a limited operational lifespan and high maintenance costs, as parts need frequent replacement. The development of more durable materials capable of withstanding these extreme conditions remains an ongoing research focus.

Projectile design presents additional hurdles. The high-velocity projectiles used in rail guns must be engineered to withstand the enormous acceleration forces and maintain stability during flight. Achieving the right balance between mass, aerodynamics, and structural integrity is crucial for accuracy and effectiveness. Furthermore, the projectiles must be designed to carry payloads or incorporate guidance systems without compromising their performance under extreme conditions.

Heat management is another significant technical obstacle. The rapid discharge of electrical energy generates substantial heat, which can affect the weapon's performance and reliability. Developing efficient cooling systems that can rapidly dissipate heat without adding excessive weight or complexity to the rail gun system is essential for sustained operation.

Precision and accuracy at long ranges remain challenging due to the effects of atmospheric drag and the Earth's rotation on ultra-high-velocity projectiles. Compensating for these factors requires advanced fire control systems and potentially guided projectiles, adding further complexity and cost to the overall system.

Electromagnetic interference (EMI) is a concern both for the rail gun's own electronic systems and for nearby equipment. The intense electromagnetic fields generated during firing can disrupt sensitive electronics, necessitating robust shielding and EMI mitigation strategies.

Lastly, the integration of rail guns into existing naval platforms or land-based systems presents significant engineering challenges. The weapon's size, power requirements, and unique operational characteristics often require substantial modifications to the host platform, potentially limiting its adoption in retrofitting scenarios.

Addressing these technical challenges is crucial for improving the economic sustainability of rail guns in defense sectors. Ongoing research and development efforts focus on enhancing power efficiency, developing more durable materials, improving projectile design, and refining heat management and fire control systems. Overcoming these hurdles will be key to realizing the full potential of rail gun technology in military applications.

Current Rail Gun Solutions

01 Cost-effective manufacturing and maintenance

Developing economically sustainable rail gun systems involves optimizing manufacturing processes and materials to reduce production costs. This includes designing components for easier maintenance and replacement, as well as implementing efficient supply chain management to ensure long-term viability.- Cost-effective manufacturing and maintenance: Developing economically sustainable rail gun systems involves optimizing manufacturing processes and materials to reduce production costs. This includes designing components for easier maintenance and longer lifespan, minimizing the need for frequent replacements. Implementing advanced manufacturing techniques and using durable, cost-effective materials can significantly improve the economic viability of rail gun technology.

- Energy efficiency and power management: Improving the energy efficiency of rail gun systems is crucial for economic sustainability. This involves developing advanced power management systems, energy recovery mechanisms, and more efficient energy storage solutions. Optimizing the power supply and distribution can reduce operational costs and increase the feasibility of rail gun technology for various applications.

- Multi-purpose and adaptable design: Creating rail gun systems with versatile designs that can be adapted for multiple purposes enhances their economic viability. This includes developing modular components and scalable architectures that allow for easy customization and application in various fields such as defense, space launch, and industrial uses. A flexible design approach can expand the market potential and justify investment in the technology.

- Integration with existing infrastructure: Ensuring that rail gun systems can be integrated with existing infrastructure and supply chains is essential for economic sustainability. This involves designing systems that are compatible with current power grids, transportation networks, and manufacturing facilities. Seamless integration can reduce implementation costs and increase the likelihood of widespread adoption.

- Lifecycle cost analysis and optimization: Conducting comprehensive lifecycle cost analyses of rail gun systems is crucial for improving their economic sustainability. This includes evaluating all aspects of the technology from research and development through to decommissioning. By identifying cost drivers and opportunities for optimization throughout the lifecycle, strategies can be developed to enhance long-term economic viability and return on investment.

02 Energy efficiency and power management

Improving the energy efficiency of rail gun systems is crucial for economic sustainability. This involves developing advanced power management systems, energy storage solutions, and optimizing the electromagnetic propulsion mechanism to reduce energy consumption while maintaining performance.Expand Specific Solutions03 Integration with existing infrastructure

Ensuring rail gun systems can be integrated with existing military and naval infrastructure is essential for economic viability. This includes developing adaptable designs that can be retrofitted to current platforms and creating standardized interfaces for seamless integration with existing power and control systems.Expand Specific Solutions04 Multi-purpose applications

Expanding the potential applications of rail gun technology beyond military use can improve economic sustainability. This involves exploring civilian and commercial applications, such as space launch systems or high-speed transportation, to increase market potential and justify research and development costs.Expand Specific Solutions05 Lifecycle cost analysis and optimization

Conducting comprehensive lifecycle cost analysis for rail gun systems is crucial for long-term economic sustainability. This includes evaluating operational costs, maintenance requirements, and potential upgrades over the system's lifespan, as well as implementing strategies to optimize these factors for improved cost-effectiveness.Expand Specific Solutions

Key Defense Industry Players

The rail gun technology sector is currently in an early development stage, characterized by significant research and development efforts but limited commercial applications. The market size remains relatively small, primarily driven by defense sector investments. Technological maturity is still evolving, with key players like Raytheon Co., Boeing Co., and Naval Research Laboratory leading advancements. These organizations are focusing on improving power efficiency, projectile design, and system integration. Other companies such as BAE Systems and General Atomics are also contributing to the field. The economic sustainability of rail guns in defense sectors depends on overcoming challenges related to power requirements, barrel longevity, and cost-effectiveness compared to traditional weapon systems.

Raytheon Co.

Technical Solution: Raytheon has been at the forefront of railgun technology development for defense applications. Their approach focuses on creating a compact, lightweight railgun system suitable for naval vessels and land-based platforms. Raytheon's design incorporates advanced power management systems to handle the high energy requirements of railguns, utilizing capacitor banks and pulse-forming networks to deliver the necessary electrical current[1]. They have also developed specialized projectiles capable of withstanding the extreme forces involved in railgun launches, with reported muzzle velocities exceeding Mach 7[2]. Raytheon's railgun system integrates sophisticated targeting and fire control systems, leveraging their expertise in radar and sensor technologies to enhance accuracy and range[3].

Strengths: Advanced power management, specialized projectile design, and integrated targeting systems. Weaknesses: High development costs and potential reliability issues due to the system's complexity.

The Boeing Co.

Technical Solution: Boeing's approach to railgun technology focuses on integrating these advanced weapon systems into existing and future military platforms. Their design emphasizes modularity and scalability, allowing for adaptation to various naval vessels and land-based systems. Boeing's railgun concept incorporates advanced materials science, using novel composites and alloys to address rail erosion and structural integrity issues[7]. They have also developed sophisticated power management systems to handle the high energy demands of railguns, exploring the use of advanced energy storage technologies such as supercapacitors[8]. Boeing's research extends to projectile design, focusing on creating rounds that can maintain stability and accuracy over extended ranges while carrying various payloads for different mission profiles.

Strengths: Modular and scalable design, advanced materials research, and integration expertise. Weaknesses: Less public demonstration of operational prototypes compared to some competitors.

Core Rail Gun Innovations

Railgun system

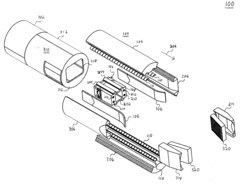

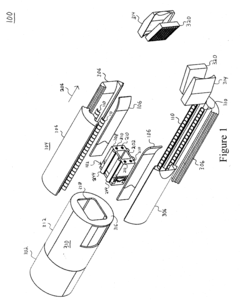

PatentInactiveUS20100194212A1

Innovation

- A railgun system that uses liquid metal, preferably aluminum or aluminum alloys, introduced into a gap between the armature and electrically conductive rails to reduce contact resistance and enhance acceleration, with features like a chamber for containing the liquid metal, a port for directing it into the gap, and a backing to conduct current and maintain the gap, optimizing the Lorentz force for speed.

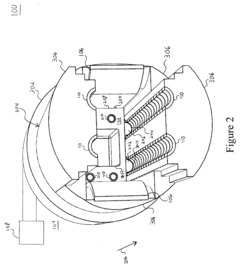

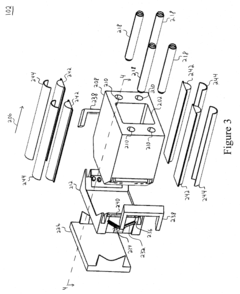

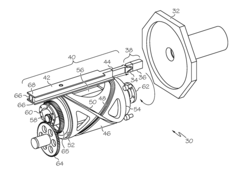

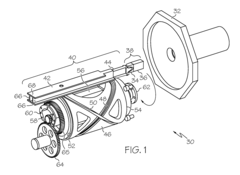

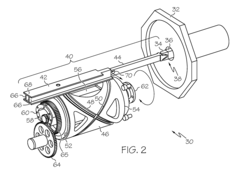

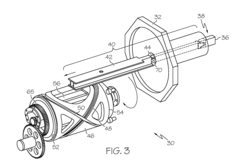

Loading machine for feeding a receiver

PatentActiveUS20120167701A1

Innovation

- A loading machine featuring a drum cam with intersecting cam paths that engage a telescoping rammer subassembly, allowing for longitudinal movement between home and deployed positions, enabling continuous payload delivery and compactness by internal motor mounting.

Economic Viability Assessment

The economic viability assessment of rail gun technology in defense sectors is a critical aspect of its potential adoption and long-term sustainability. This analysis encompasses various factors that contribute to the overall cost-effectiveness and financial feasibility of implementing rail gun systems.

Initial investment costs for rail gun technology are substantial, primarily due to the extensive research and development required, as well as the sophisticated manufacturing processes involved. These costs include the development of advanced materials capable of withstanding extreme electromagnetic forces, high-capacity power storage systems, and precision control mechanisms. Additionally, the infrastructure needed to support rail gun operations, such as specialized launch platforms and power generation facilities, further increases the upfront expenditure.

Operational costs must also be carefully considered. While rail guns offer the advantage of using electromagnetic energy rather than chemical propellants, the energy requirements for firing are significant. This necessitates robust and efficient power generation and storage solutions, which may incur ongoing operational expenses. Maintenance costs are another crucial factor, as the intense forces involved in rail gun operation can lead to rapid wear of components, potentially requiring frequent replacements and specialized maintenance procedures.

However, these costs must be weighed against the potential long-term savings and strategic advantages. Rail guns offer the prospect of reduced ammunition costs compared to traditional explosive projectiles, as they utilize relatively inexpensive metal projectiles. The extended range and increased accuracy of rail guns may also lead to improved mission effectiveness, potentially reducing the number of engagements required and, consequently, overall operational costs.

The economic assessment must also consider the potential for dual-use applications and technology transfer. Advancements in materials science, power systems, and electromagnetic technologies driven by rail gun development could have valuable applications in other sectors, potentially offsetting some of the research and development costs through commercial spin-offs.

Scalability and economies of scale are important considerations in the economic viability of rail gun technology. As production volumes increase and manufacturing processes are optimized, unit costs are likely to decrease, improving the overall economic proposition. Additionally, the potential for modular designs that can be adapted to various platforms and mission profiles could enhance the technology's versatility and cost-effectiveness across different defense applications.

In conclusion, while the initial investment and operational costs of rail gun technology are significant, the potential for long-term cost savings, improved operational effectiveness, and technological spillovers presents a compelling case for its economic viability in defense sectors. Careful analysis of these factors, along with ongoing technological advancements, will be crucial in determining the ultimate sustainability and adoption of rail gun systems in military applications.

Initial investment costs for rail gun technology are substantial, primarily due to the extensive research and development required, as well as the sophisticated manufacturing processes involved. These costs include the development of advanced materials capable of withstanding extreme electromagnetic forces, high-capacity power storage systems, and precision control mechanisms. Additionally, the infrastructure needed to support rail gun operations, such as specialized launch platforms and power generation facilities, further increases the upfront expenditure.

Operational costs must also be carefully considered. While rail guns offer the advantage of using electromagnetic energy rather than chemical propellants, the energy requirements for firing are significant. This necessitates robust and efficient power generation and storage solutions, which may incur ongoing operational expenses. Maintenance costs are another crucial factor, as the intense forces involved in rail gun operation can lead to rapid wear of components, potentially requiring frequent replacements and specialized maintenance procedures.

However, these costs must be weighed against the potential long-term savings and strategic advantages. Rail guns offer the prospect of reduced ammunition costs compared to traditional explosive projectiles, as they utilize relatively inexpensive metal projectiles. The extended range and increased accuracy of rail guns may also lead to improved mission effectiveness, potentially reducing the number of engagements required and, consequently, overall operational costs.

The economic assessment must also consider the potential for dual-use applications and technology transfer. Advancements in materials science, power systems, and electromagnetic technologies driven by rail gun development could have valuable applications in other sectors, potentially offsetting some of the research and development costs through commercial spin-offs.

Scalability and economies of scale are important considerations in the economic viability of rail gun technology. As production volumes increase and manufacturing processes are optimized, unit costs are likely to decrease, improving the overall economic proposition. Additionally, the potential for modular designs that can be adapted to various platforms and mission profiles could enhance the technology's versatility and cost-effectiveness across different defense applications.

In conclusion, while the initial investment and operational costs of rail gun technology are significant, the potential for long-term cost savings, improved operational effectiveness, and technological spillovers presents a compelling case for its economic viability in defense sectors. Careful analysis of these factors, along with ongoing technological advancements, will be crucial in determining the ultimate sustainability and adoption of rail gun systems in military applications.

Environmental Impact Analysis

The environmental impact of rail gun technology in defense sectors is a critical consideration for assessing its economic sustainability. Rail guns, while offering potential advantages in terms of range and projectile velocity, also present unique environmental challenges that must be carefully evaluated.

One of the primary environmental concerns associated with rail gun technology is the significant electromagnetic emissions generated during operation. These emissions can potentially interfere with local ecosystems, affecting wildlife behavior and migration patterns. Additionally, the intense electromagnetic fields may have unforeseen long-term effects on plant life and soil composition in the vicinity of rail gun installations.

The high-energy nature of rail gun operations also raises questions about noise pollution. The acoustic impact of rail gun firing can be substantial, potentially disturbing both human populations and wildlife in surrounding areas. This aspect necessitates careful site selection and the implementation of noise mitigation strategies to minimize ecological disruption.

Material degradation is another environmental factor to consider. The extreme conditions experienced by rail gun components during firing can lead to accelerated wear and the release of particulate matter. This may result in localized air and soil contamination, requiring stringent monitoring and containment measures to prevent environmental degradation.

Energy consumption is a significant environmental consideration for rail gun systems. The power requirements for operating these weapons are substantial, potentially leading to increased carbon emissions if non-renewable energy sources are utilized. Integrating renewable energy solutions into rail gun power systems could mitigate this impact but presents its own set of technical challenges.

The production and disposal of specialized ammunition for rail guns also warrant environmental scrutiny. The manufacturing processes for these projectiles may involve hazardous materials, and their eventual disposal must be managed to prevent soil and water contamination. Developing eco-friendly ammunition and implementing robust recycling programs could help address these concerns.

Lastly, the potential for accidental discharge or misfires must be considered from an environmental perspective. Such incidents could result in unintended damage to natural habitats or protected areas, necessitating comprehensive safety protocols and environmental risk assessments for rail gun deployment and testing sites.

One of the primary environmental concerns associated with rail gun technology is the significant electromagnetic emissions generated during operation. These emissions can potentially interfere with local ecosystems, affecting wildlife behavior and migration patterns. Additionally, the intense electromagnetic fields may have unforeseen long-term effects on plant life and soil composition in the vicinity of rail gun installations.

The high-energy nature of rail gun operations also raises questions about noise pollution. The acoustic impact of rail gun firing can be substantial, potentially disturbing both human populations and wildlife in surrounding areas. This aspect necessitates careful site selection and the implementation of noise mitigation strategies to minimize ecological disruption.

Material degradation is another environmental factor to consider. The extreme conditions experienced by rail gun components during firing can lead to accelerated wear and the release of particulate matter. This may result in localized air and soil contamination, requiring stringent monitoring and containment measures to prevent environmental degradation.

Energy consumption is a significant environmental consideration for rail gun systems. The power requirements for operating these weapons are substantial, potentially leading to increased carbon emissions if non-renewable energy sources are utilized. Integrating renewable energy solutions into rail gun power systems could mitigate this impact but presents its own set of technical challenges.

The production and disposal of specialized ammunition for rail guns also warrant environmental scrutiny. The manufacturing processes for these projectiles may involve hazardous materials, and their eventual disposal must be managed to prevent soil and water contamination. Developing eco-friendly ammunition and implementing robust recycling programs could help address these concerns.

Lastly, the potential for accidental discharge or misfires must be considered from an environmental perspective. Such incidents could result in unintended damage to natural habitats or protected areas, necessitating comprehensive safety protocols and environmental risk assessments for rail gun deployment and testing sites.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!