Kaolinite vs Halloysite: Which Provides Better Rheology Control?

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clay Minerals Background and Research Objectives

Clay minerals have been integral components in various industrial applications for centuries, with their unique structural and chemical properties making them invaluable across sectors ranging from ceramics to pharmaceuticals. Among these minerals, kaolinite and halloysite represent two significant members of the kaolin group that have garnered substantial attention due to their rheological control capabilities. The evolution of clay mineral utilization has progressed from rudimentary pottery applications to sophisticated industrial processes, reflecting the growing understanding of their complex properties and behaviors.

Kaolinite, characterized by its 1:1 layered structure consisting of one tetrahedral silica sheet bonded to one octahedral alumina sheet, has been extensively studied since the early 20th century. Its relatively simple structure compared to other clay minerals has made it a model system for understanding clay-fluid interactions. Halloysite, while sharing the same chemical composition as kaolinite (Al₂Si₂O₅(OH)₄), distinguishes itself through its unique tubular morphology resulting from the rolling of its layers, often with interlayer water molecules.

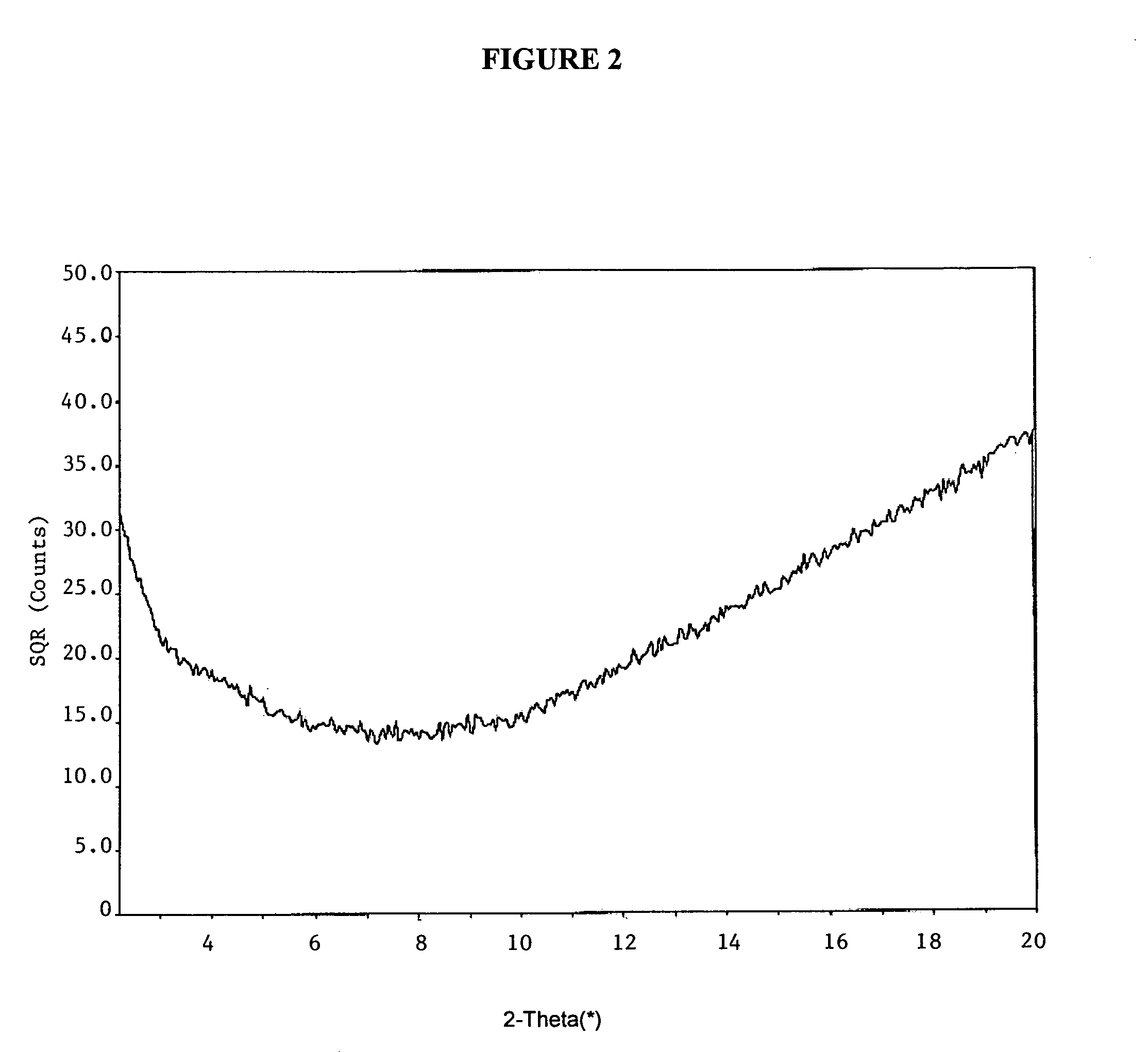

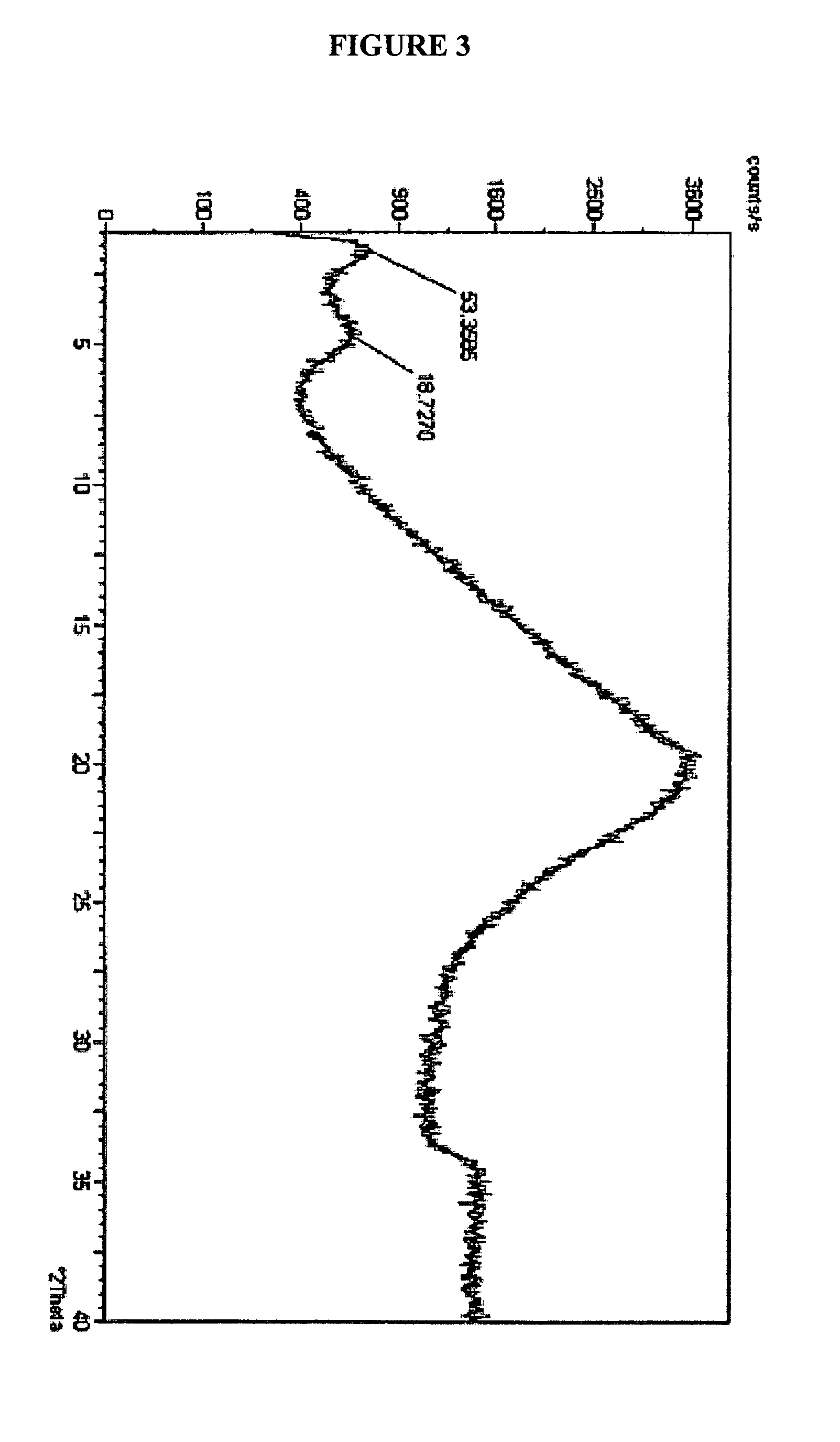

The technological trajectory in clay mineral research has witnessed significant advancements in analytical techniques, enabling more precise characterization of these minerals' structures and properties. Electron microscopy, X-ray diffraction, and spectroscopic methods have revolutionized our understanding of clay mineral behavior in various environments, particularly in colloidal suspensions where rheological properties become critical.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of kaolinite and halloysite in terms of their rheological control capabilities. Specifically, we aim to evaluate how the structural differences between these two minerals influence their performance in controlling viscosity, thixotropy, yield stress, and flow behavior in various formulations and under different conditions.

Additionally, this research seeks to identify the fundamental mechanisms underlying the rheological behavior of these clay minerals, including particle-particle interactions, surface chemistry effects, and the influence of environmental factors such as pH, ionic strength, and temperature. Understanding these mechanisms is crucial for optimizing formulations in applications ranging from drilling fluids to cosmetics and pharmaceuticals.

Furthermore, this investigation aims to establish quantitative relationships between the structural characteristics of kaolinite and halloysite and their rheological performance, potentially leading to predictive models that could guide formulation development. The research will also explore potential synergistic effects when these clay minerals are combined with other rheology modifiers, addressing a significant gap in current technical knowledge.

Through this comprehensive analysis, we anticipate providing valuable insights that will inform material selection decisions across industries where rheology control is paramount, ultimately contributing to more efficient processes and enhanced product performance.

Kaolinite, characterized by its 1:1 layered structure consisting of one tetrahedral silica sheet bonded to one octahedral alumina sheet, has been extensively studied since the early 20th century. Its relatively simple structure compared to other clay minerals has made it a model system for understanding clay-fluid interactions. Halloysite, while sharing the same chemical composition as kaolinite (Al₂Si₂O₅(OH)₄), distinguishes itself through its unique tubular morphology resulting from the rolling of its layers, often with interlayer water molecules.

The technological trajectory in clay mineral research has witnessed significant advancements in analytical techniques, enabling more precise characterization of these minerals' structures and properties. Electron microscopy, X-ray diffraction, and spectroscopic methods have revolutionized our understanding of clay mineral behavior in various environments, particularly in colloidal suspensions where rheological properties become critical.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of kaolinite and halloysite in terms of their rheological control capabilities. Specifically, we aim to evaluate how the structural differences between these two minerals influence their performance in controlling viscosity, thixotropy, yield stress, and flow behavior in various formulations and under different conditions.

Additionally, this research seeks to identify the fundamental mechanisms underlying the rheological behavior of these clay minerals, including particle-particle interactions, surface chemistry effects, and the influence of environmental factors such as pH, ionic strength, and temperature. Understanding these mechanisms is crucial for optimizing formulations in applications ranging from drilling fluids to cosmetics and pharmaceuticals.

Furthermore, this investigation aims to establish quantitative relationships between the structural characteristics of kaolinite and halloysite and their rheological performance, potentially leading to predictive models that could guide formulation development. The research will also explore potential synergistic effects when these clay minerals are combined with other rheology modifiers, addressing a significant gap in current technical knowledge.

Through this comprehensive analysis, we anticipate providing valuable insights that will inform material selection decisions across industries where rheology control is paramount, ultimately contributing to more efficient processes and enhanced product performance.

Market Applications and Demand Analysis

The global market for rheology modifiers is experiencing significant growth, driven by expanding applications in paints, coatings, adhesives, personal care products, and pharmaceuticals. Within this market, clay-based rheology modifiers, particularly kaolinite and halloysite, have established distinct market segments based on their unique performance characteristics.

The paint and coating industry represents the largest application sector for rheology control agents, accounting for approximately 35% of the total market. In this segment, kaolinite has traditionally dominated due to its cost-effectiveness and reliable performance in water-based formulations. However, halloysite is gaining traction in premium coating applications where superior suspension stability and anti-sagging properties justify its higher price point.

In the personal care and cosmetics industry, the demand for natural rheology modifiers has surged as consumers increasingly prefer "clean" and sustainable products. Halloysite has found particular success in this sector due to its tubular structure that provides excellent thixotropic properties without the opacity issues sometimes associated with kaolinite. This allows formulators to create transparent gels and creams with precise flow characteristics.

The pharmaceutical and healthcare sectors present rapidly growing markets for both clay types. Kaolinite continues to be widely used in oral medications and topical formulations, while halloysite's unique tubular structure has created new opportunities in controlled drug delivery systems. The ability to load active ingredients into halloysite nanotubes has sparked significant research interest and commercial development activities.

Regional market analysis reveals interesting patterns in adoption. North American and European markets show increasing preference for halloysite in premium applications, while kaolinite maintains strong positions in developing markets where cost considerations often outweigh performance advantages. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for both clay types, driven by rapid industrialization and expanding manufacturing sectors.

Market forecasts indicate that the global demand for specialized rheology modifiers will continue to grow at a compound annual rate of 5-6% through 2028. Within this growth, halloysite is expected to gain market share at a faster rate than kaolinite, particularly in high-value applications where its superior rheological control justifies the price premium.

Customer feedback analysis reveals that formulators increasingly make selection decisions based on specific performance attributes rather than traditional material categories. This trend favors halloysite in applications requiring precise rheology control, while kaolinite maintains advantages in cost-sensitive mass-market applications where "good enough" performance is acceptable.

The paint and coating industry represents the largest application sector for rheology control agents, accounting for approximately 35% of the total market. In this segment, kaolinite has traditionally dominated due to its cost-effectiveness and reliable performance in water-based formulations. However, halloysite is gaining traction in premium coating applications where superior suspension stability and anti-sagging properties justify its higher price point.

In the personal care and cosmetics industry, the demand for natural rheology modifiers has surged as consumers increasingly prefer "clean" and sustainable products. Halloysite has found particular success in this sector due to its tubular structure that provides excellent thixotropic properties without the opacity issues sometimes associated with kaolinite. This allows formulators to create transparent gels and creams with precise flow characteristics.

The pharmaceutical and healthcare sectors present rapidly growing markets for both clay types. Kaolinite continues to be widely used in oral medications and topical formulations, while halloysite's unique tubular structure has created new opportunities in controlled drug delivery systems. The ability to load active ingredients into halloysite nanotubes has sparked significant research interest and commercial development activities.

Regional market analysis reveals interesting patterns in adoption. North American and European markets show increasing preference for halloysite in premium applications, while kaolinite maintains strong positions in developing markets where cost considerations often outweigh performance advantages. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for both clay types, driven by rapid industrialization and expanding manufacturing sectors.

Market forecasts indicate that the global demand for specialized rheology modifiers will continue to grow at a compound annual rate of 5-6% through 2028. Within this growth, halloysite is expected to gain market share at a faster rate than kaolinite, particularly in high-value applications where its superior rheological control justifies the price premium.

Customer feedback analysis reveals that formulators increasingly make selection decisions based on specific performance attributes rather than traditional material categories. This trend favors halloysite in applications requiring precise rheology control, while kaolinite maintains advantages in cost-sensitive mass-market applications where "good enough" performance is acceptable.

Current Rheological Control Challenges

Rheological control in industrial applications presents significant challenges that impact product performance, manufacturing efficiency, and cost-effectiveness. The current landscape of rheology control faces several critical issues that demand innovative solutions, particularly when comparing clay minerals like kaolinite and halloysite as rheological modifiers.

One of the primary challenges is achieving consistent rheological properties across varying temperature and pH conditions. Many industrial processes experience fluctuations in these parameters, causing unpredictable changes in viscosity, yield stress, and thixotropic behavior. This inconsistency leads to quality control issues and increased production costs due to the need for constant reformulation and adjustment.

Formulation complexity represents another significant hurdle. Rheological modifiers often interact unpredictably with other components in complex formulations, creating compatibility issues that can destabilize the entire system. These interactions may lead to phase separation, sedimentation, or unexpected changes in flow behavior that compromise product integrity and shelf life.

Processing limitations also constrain rheological control options. High-shear processing environments can degrade certain rheological modifiers, while others may require specific incorporation techniques that add complexity to manufacturing processes. This creates a trade-off between desired rheological properties and practical implementation in production environments.

Environmental and regulatory pressures have intensified the search for sustainable rheological control agents. Traditional synthetic modifiers face increasing scrutiny due to environmental persistence and potential toxicity concerns. This has accelerated interest in naturally derived alternatives like kaolinite and halloysite, though questions remain about their performance consistency and modification requirements.

Cost-effectiveness presents an ongoing challenge, particularly for high-volume applications. Premium rheological modifiers may deliver superior performance but at prohibitive costs that impact overall product economics. This drives the need for solutions that balance performance with economic viability across different market segments.

Application-specific requirements further complicate rheological control strategies. Different industries—from paints and coatings to personal care products—demand tailored rheological profiles that may be difficult to achieve with a single modifier type. This necessitates specialized approaches and often complex blends of multiple rheology control agents.

The technical gap between laboratory performance and real-world application represents perhaps the most persistent challenge. Rheological modifiers that perform well in controlled laboratory conditions may fail to deliver consistent results in actual production environments, creating a significant barrier to commercial implementation and technology transfer.

One of the primary challenges is achieving consistent rheological properties across varying temperature and pH conditions. Many industrial processes experience fluctuations in these parameters, causing unpredictable changes in viscosity, yield stress, and thixotropic behavior. This inconsistency leads to quality control issues and increased production costs due to the need for constant reformulation and adjustment.

Formulation complexity represents another significant hurdle. Rheological modifiers often interact unpredictably with other components in complex formulations, creating compatibility issues that can destabilize the entire system. These interactions may lead to phase separation, sedimentation, or unexpected changes in flow behavior that compromise product integrity and shelf life.

Processing limitations also constrain rheological control options. High-shear processing environments can degrade certain rheological modifiers, while others may require specific incorporation techniques that add complexity to manufacturing processes. This creates a trade-off between desired rheological properties and practical implementation in production environments.

Environmental and regulatory pressures have intensified the search for sustainable rheological control agents. Traditional synthetic modifiers face increasing scrutiny due to environmental persistence and potential toxicity concerns. This has accelerated interest in naturally derived alternatives like kaolinite and halloysite, though questions remain about their performance consistency and modification requirements.

Cost-effectiveness presents an ongoing challenge, particularly for high-volume applications. Premium rheological modifiers may deliver superior performance but at prohibitive costs that impact overall product economics. This drives the need for solutions that balance performance with economic viability across different market segments.

Application-specific requirements further complicate rheological control strategies. Different industries—from paints and coatings to personal care products—demand tailored rheological profiles that may be difficult to achieve with a single modifier type. This necessitates specialized approaches and often complex blends of multiple rheology control agents.

The technical gap between laboratory performance and real-world application represents perhaps the most persistent challenge. Rheological modifiers that perform well in controlled laboratory conditions may fail to deliver consistent results in actual production environments, creating a significant barrier to commercial implementation and technology transfer.

Comparative Analysis of Kaolinite and Halloysite Solutions

01 Rheological modifiers for clay-based systems

Kaolinite and halloysite can be combined with specific rheological modifiers to control flow properties in various applications. These modifiers interact with the clay particles to create stable suspensions with predictable viscosity profiles. The addition of polymeric additives, such as polyacrylamides or cellulose derivatives, can enhance the thixotropic behavior of kaolinite and halloysite suspensions, allowing for better control of rheological properties in industrial formulations.- Rheological modifiers for clay-based systems: Kaolinite and halloysite can be combined with specific rheological modifiers to control flow properties in various applications. These modifiers interact with the clay particles to create stable suspensions with controlled viscosity and thixotropic behavior. The addition of polymeric additives, such as polyacrylamides or cellulose derivatives, can enhance the rheological properties of kaolinite and halloysite suspensions, making them suitable for applications requiring precise flow control.

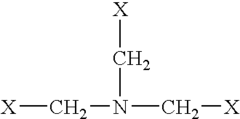

- Surface modification of clay nanotubes: Surface modification techniques can be applied to kaolinite and halloysite nanotubes to control their rheological properties. By treating the clay surfaces with silanes, quaternary ammonium compounds, or other surface-active agents, the interaction between particles can be manipulated. This modification affects the dispersion stability, viscosity, and flow behavior of the clay suspensions, allowing for tailored rheological profiles suitable for specific industrial applications.

- pH-dependent rheology control: The rheological properties of kaolinite and halloysite suspensions are highly dependent on pH conditions. By adjusting the pH, the surface charge of clay particles can be modified, affecting their interaction and aggregation behavior. This pH-dependent control allows for the development of responsive systems where viscosity and flow properties can be tuned by simple acid or base addition, providing versatility in applications ranging from drilling fluids to cosmetic formulations.

- Composite formulations with enhanced rheological properties: Kaolinite and halloysite can be incorporated into composite formulations with other materials to achieve enhanced rheological properties. These composites may include combinations with polymers, other clay minerals, or nanoparticles to create systems with synergistic effects. The resulting materials exhibit improved stability, controlled thixotropy, and predictable flow behavior, making them valuable in applications such as coatings, adhesives, and pharmaceutical formulations.

- Temperature-responsive rheology systems: Temperature-responsive rheology systems can be developed using kaolinite and halloysite as key components. These systems exhibit controlled changes in viscosity and flow properties in response to temperature variations. By combining the clay minerals with temperature-sensitive polymers or additives, formulations can be created that undergo predictable rheological transitions at specific temperature thresholds, providing advantages in applications such as oil recovery, controlled release systems, and thermal management materials.

02 Surface modification of clay nanotubes

Surface treatment of kaolinite and halloysite nanotubes can significantly alter their rheological properties. By modifying the surface chemistry through functionalization or coating with organic compounds, the interaction between clay particles and the surrounding medium can be controlled. This enables precise adjustment of viscosity, yield stress, and flow behavior in various applications including cosmetics, pharmaceuticals, and advanced materials. Surface-modified clay nanotubes can provide enhanced dispersion stability and improved rheological control.Expand Specific Solutions03 Clay-polymer composite systems for viscosity control

Combining kaolinite and halloysite with specific polymers creates composite systems with enhanced rheological properties. These clay-polymer composites exhibit synergistic effects that allow for precise control of flow behavior under various conditions. The intercalation of polymers between clay layers or around nanotubes can create networks that respond to external stimuli such as temperature, pH, or shear force. This approach enables the development of smart materials with adaptive rheological properties for specialized applications.Expand Specific Solutions04 Halloysite nanotube dispersion techniques

Specialized dispersion techniques for halloysite nanotubes can significantly improve rheological control in various formulations. Methods such as ultrasonication, high-shear mixing, and the use of dispersing agents help achieve uniform distribution of halloysite in the matrix material. Properly dispersed halloysite nanotubes can form structured networks that provide predictable and controllable rheological properties, including shear-thinning behavior and yield stress characteristics that are valuable in coatings, adhesives, and other applications.Expand Specific Solutions05 Temperature and pH-responsive clay rheology systems

Kaolinite and halloysite can be formulated into systems that exhibit responsive rheological behavior to environmental changes such as temperature and pH. By incorporating specific additives or through surface modification, these clay minerals can form networks that undergo controlled gelation, thickening, or thinning in response to external stimuli. This responsive behavior is particularly valuable in applications requiring on-demand rheology changes, such as in enhanced oil recovery, drug delivery systems, and smart coatings where flow properties need to adapt to changing conditions.Expand Specific Solutions

Leading Industry Players and Research Institutions

The rheology control market for kaolinite versus halloysite is currently in a growth phase, with increasing applications in pharmaceuticals, cosmetics, and advanced materials. The global market for these clay minerals is expanding, driven by their unique structural properties and versatility. Technologically, kaolinite has reached maturity with established players like China Kaolin Co., Ltd. and Yunnan Tianhong Gaoling Mining Co., Ltd. dominating traditional applications, while halloysite is emerging as an innovative alternative with research support from institutions like China University of Geosciences and Rensselaer Polytechnic Institute. Companies like Pfizer, Henkel, and Sinopec are exploring both minerals for specialized rheological applications, with halloysite gaining traction for its tubular structure and superior suspension properties in high-performance formulations.

Centro de Investigación en Química Aplicada

Technical Solution: Centro de Investigación en Química Aplicada (CIQA) has conducted extensive research comparing kaolinite and halloysite for rheology control in polymer composites and coating applications. Their approach involves comprehensive characterization of clay mineral structures and their impact on rheological properties in various media. CIQA's research has demonstrated that kaolinite, with its plate-like structure (typical aspect ratio 10-15:1), provides effective viscosity control through edge-to-face interactions that create three-dimensional networks in suspension. Their studies show kaolinite typically achieves yield stress values of 8-12 Pa at 25% solid content in water-based systems. For halloysite, CIQA has documented the unique rheological benefits of its tubular structure (typical dimensions 50-70 nm diameter, 1-3 μm length), which creates different flow dynamics compared to platy kaolinite. Their comparative analysis reveals halloysite can achieve similar rheological effects at 30-40% lower concentrations than kaolinite in many applications. CIQA has also developed novel surface modification techniques using silane coupling agents to enhance the compatibility and rheological performance of both clay types in non-aqueous systems.

Strengths: Comprehensive scientific understanding of structure-property relationships; ability to predict rheological behavior based on clay mineral characteristics; expertise in surface modification techniques. Weaknesses: Research-focused approach may lack large-scale industrial implementation experience; limited commercial product portfolio compared to industrial manufacturers.

China Kaolin Co., Ltd

Technical Solution: China Kaolin Co., Ltd has developed advanced rheology control solutions based on their high-purity kaolinite products. Their technology involves precise particle size distribution control (0.5-2μm) and surface modification techniques to enhance kaolinite's rheological properties. The company employs a proprietary beneficiation process that removes impurities while preserving the plate-like structure of kaolinite particles, which is crucial for rheology control. Their research has demonstrated that kaolinite-based suspensions exhibit pseudoplastic behavior with yield stress values typically ranging from 5-15 Pa at 30% solid content, making them effective thickening agents. China Kaolin has also developed specialized surface treatments using polyelectrolytes to modify the surface charge of kaolinite particles, enhancing their dispersion stability and rheological performance in various industrial applications.

Strengths: Superior stability in high-temperature and high-shear environments; consistent quality control; cost-effective compared to synthetic alternatives. Weaknesses: Limited performance in highly acidic environments; requires higher loading levels than some halloysite formulations to achieve equivalent rheological effects.

Key Patents and Scientific Literature Review

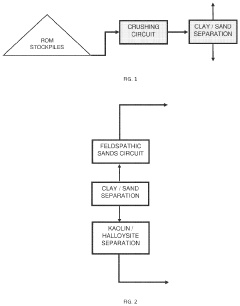

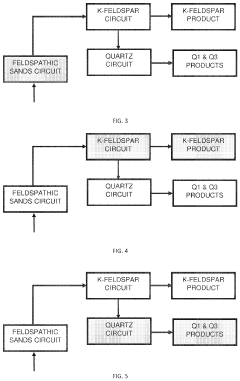

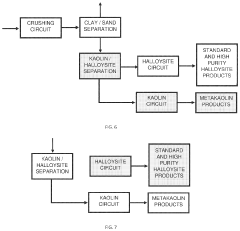

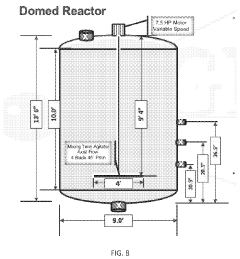

Liberation, separation, and concentration of halloysite from a composite natural or synthetic mineral resource

PatentPendingUS20240009681A1

Innovation

- A wet processing system, known as the Halloysite Kaolin Separation (HKS) system, that optimizes buoyancy forces of halloysite using chemical and thermal treatments, and employs mechanical and hydraulic reactors with optimized operating parameters to separate and concentrate halloysite from other minerals, achieving high purity and quality.

Polyfunctional dispersants for controlling viscosity of phyllosilicates

PatentInactiveUS7081483B2

Innovation

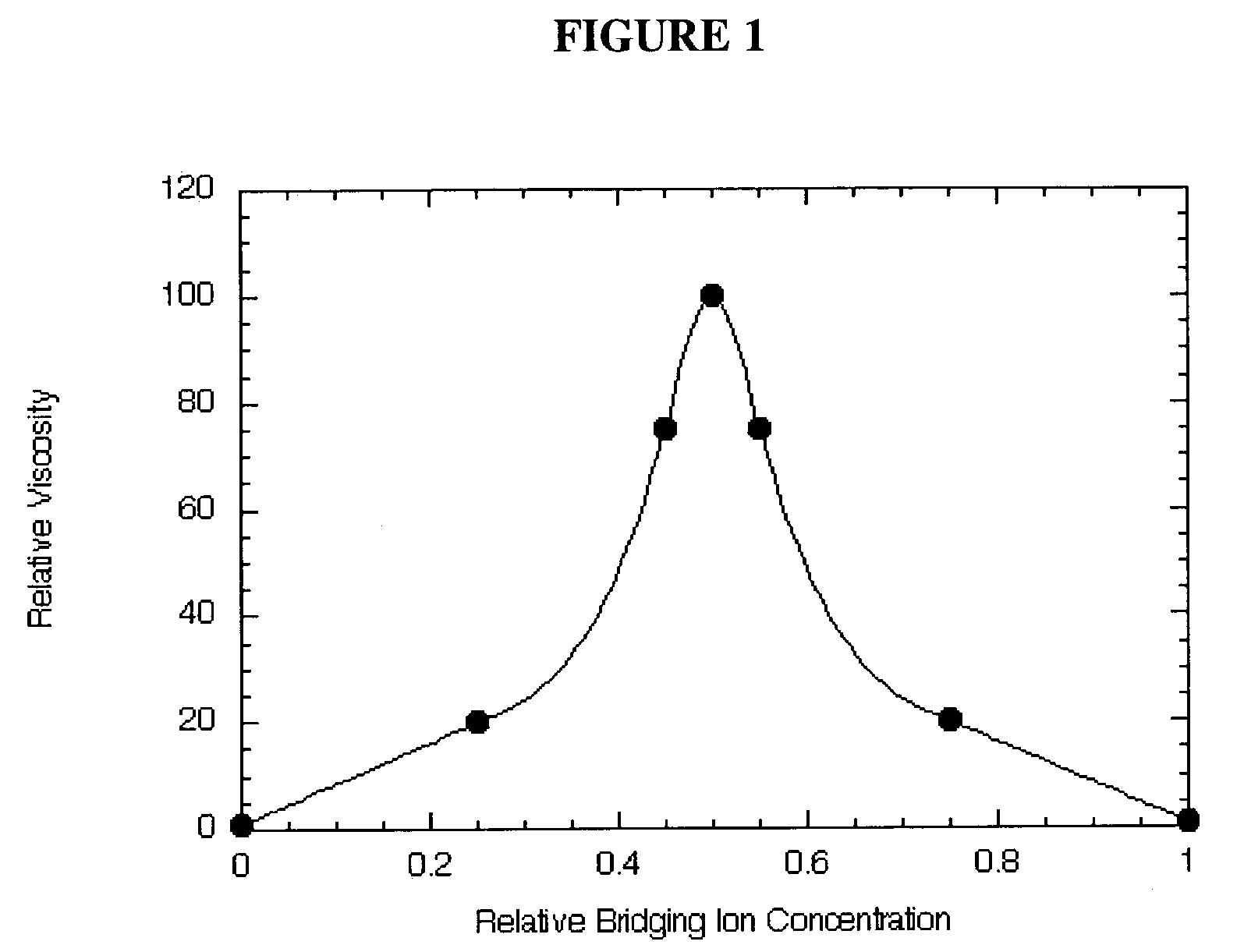

- The use of polyfunctional dispersants in combination with phyllosilicates allows for the formation of high concentration slurries with manageable viscosity, and the addition of multivalent cations or cationic low molecular weight polymers can substantially increase or decrease viscosity, while also imparting corrosion inhibiting properties and improving dispersability and exfoliation in polymer matrices.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of clay minerals like kaolinite and halloysite are increasingly important factors in their industrial applications, particularly in rheology control. When comparing these two minerals from an environmental perspective, several key aspects must be considered.

Mining practices for both kaolinite and halloysite have significant environmental implications. Kaolinite deposits are typically more abundant and accessible, often requiring less intensive extraction methods compared to halloysite. This generally results in a smaller carbon footprint per unit of kaolinite produced. Halloysite mining, being more specialized due to its rarer occurrence, may involve more resource-intensive extraction processes, potentially leading to greater habitat disruption and energy consumption.

Processing requirements also differ substantially between these clay minerals. Kaolinite often requires more extensive chemical treatments to achieve desired rheological properties, which can generate more waste and chemical byproducts. Conversely, halloysite's natural tubular structure provides inherent rheological advantages with less processing, potentially reducing chemical usage and associated environmental impacts.

Water consumption represents another critical environmental consideration. Rheological applications typically involve aqueous systems, and the efficiency with which these clays interact with water affects overall resource utilization. Halloysite generally demonstrates superior water efficiency in achieving comparable rheological control, potentially reducing water requirements in formulations.

Biodegradability and end-of-life considerations favor both minerals as natural materials, but with important distinctions. Kaolinite, being more chemically modified in many applications, may contain additives that reduce its environmental compatibility. Halloysite, often used in more pristine forms, typically presents fewer concerns regarding environmental persistence.

Carbon footprint calculations across the lifecycle reveal that transportation impacts can be significant. Since kaolinite deposits are more globally distributed, local sourcing options may reduce transportation emissions. Halloysite's more limited geographical availability often necessitates longer transportation routes, potentially offsetting some of its processing advantages.

Regulatory frameworks increasingly emphasize sustainable material sourcing. Both minerals face evolving compliance requirements, though halloysite's natural functionality may position it advantageously as regulations tighten around chemical additives commonly used with kaolinite.

Recent sustainability innovations include beneficiation techniques that improve the efficiency of both minerals, reducing waste and energy requirements. Additionally, research into hybrid systems combining these clays with bio-based materials shows promise for developing more environmentally responsible rheology control solutions that maintain performance while reducing environmental impact.

Mining practices for both kaolinite and halloysite have significant environmental implications. Kaolinite deposits are typically more abundant and accessible, often requiring less intensive extraction methods compared to halloysite. This generally results in a smaller carbon footprint per unit of kaolinite produced. Halloysite mining, being more specialized due to its rarer occurrence, may involve more resource-intensive extraction processes, potentially leading to greater habitat disruption and energy consumption.

Processing requirements also differ substantially between these clay minerals. Kaolinite often requires more extensive chemical treatments to achieve desired rheological properties, which can generate more waste and chemical byproducts. Conversely, halloysite's natural tubular structure provides inherent rheological advantages with less processing, potentially reducing chemical usage and associated environmental impacts.

Water consumption represents another critical environmental consideration. Rheological applications typically involve aqueous systems, and the efficiency with which these clays interact with water affects overall resource utilization. Halloysite generally demonstrates superior water efficiency in achieving comparable rheological control, potentially reducing water requirements in formulations.

Biodegradability and end-of-life considerations favor both minerals as natural materials, but with important distinctions. Kaolinite, being more chemically modified in many applications, may contain additives that reduce its environmental compatibility. Halloysite, often used in more pristine forms, typically presents fewer concerns regarding environmental persistence.

Carbon footprint calculations across the lifecycle reveal that transportation impacts can be significant. Since kaolinite deposits are more globally distributed, local sourcing options may reduce transportation emissions. Halloysite's more limited geographical availability often necessitates longer transportation routes, potentially offsetting some of its processing advantages.

Regulatory frameworks increasingly emphasize sustainable material sourcing. Both minerals face evolving compliance requirements, though halloysite's natural functionality may position it advantageously as regulations tighten around chemical additives commonly used with kaolinite.

Recent sustainability innovations include beneficiation techniques that improve the efficiency of both minerals, reducing waste and energy requirements. Additionally, research into hybrid systems combining these clays with bio-based materials shows promise for developing more environmentally responsible rheology control solutions that maintain performance while reducing environmental impact.

Performance Testing Methodologies and Standards

To effectively evaluate the rheological performance of kaolinite and halloysite clay minerals, standardized testing methodologies are essential for generating reliable and comparable data. The rheological behavior assessment typically begins with sample preparation protocols that specify precise solid content percentages, dispersion methods, and aging times to ensure consistency across experiments.

Viscosity measurements form the cornerstone of rheological testing, with rotational viscometers being the industry standard. ASTM D2196 and ISO 3219 provide guidelines for measuring viscosity of non-Newtonian fluids, applicable to clay suspensions. These tests typically employ controlled shear rates ranging from 0.1 to 1000 s⁻¹ to generate comprehensive flow curves that reveal thixotropic behavior and yield stress characteristics.

Yield stress determination represents another critical parameter, commonly measured through stress ramp tests or oscillatory measurements. The Herschel-Bulkley model is frequently applied to characterize the yield stress of clay suspensions, with ASTM D4648 offering standardized procedures for determining this parameter in clay-based systems.

Thixotropy assessment, particularly relevant for comparing kaolinite and halloysite, typically employs hysteresis loop tests where shear rate is increased and then decreased while measuring viscosity. The area between the resulting curves quantifies thixotropic behavior, with larger areas indicating greater structural recovery potential.

Oscillatory testing provides insights into viscoelastic properties through amplitude and frequency sweeps. These tests measure storage modulus (G') and loss modulus (G"), revealing the elastic and viscous components of the clay suspensions. ISO 6721 provides guidelines for dynamic mechanical analysis applicable to these measurements.

Temperature stability testing evaluates rheological performance across varying thermal conditions (typically 5-80°C), critical for applications where temperature fluctuations occur. ASTM D2983 offers standardized procedures for low-temperature viscosity measurements.

Sedimentation stability tests, including those outlined in ASTM D1401, assess the suspension stability over time through visual observation or analytical centrifugation techniques. These tests typically run for 24-72 hours to evaluate long-term stability characteristics.

pH sensitivity testing examines rheological behavior across pH ranges (typically 4-10), as clay mineral surface charges—and consequently their rheological properties—are significantly influenced by pH. This testing is particularly important when comparing kaolinite and halloysite due to their different surface chemistry and charge distribution.

Viscosity measurements form the cornerstone of rheological testing, with rotational viscometers being the industry standard. ASTM D2196 and ISO 3219 provide guidelines for measuring viscosity of non-Newtonian fluids, applicable to clay suspensions. These tests typically employ controlled shear rates ranging from 0.1 to 1000 s⁻¹ to generate comprehensive flow curves that reveal thixotropic behavior and yield stress characteristics.

Yield stress determination represents another critical parameter, commonly measured through stress ramp tests or oscillatory measurements. The Herschel-Bulkley model is frequently applied to characterize the yield stress of clay suspensions, with ASTM D4648 offering standardized procedures for determining this parameter in clay-based systems.

Thixotropy assessment, particularly relevant for comparing kaolinite and halloysite, typically employs hysteresis loop tests where shear rate is increased and then decreased while measuring viscosity. The area between the resulting curves quantifies thixotropic behavior, with larger areas indicating greater structural recovery potential.

Oscillatory testing provides insights into viscoelastic properties through amplitude and frequency sweeps. These tests measure storage modulus (G') and loss modulus (G"), revealing the elastic and viscous components of the clay suspensions. ISO 6721 provides guidelines for dynamic mechanical analysis applicable to these measurements.

Temperature stability testing evaluates rheological performance across varying thermal conditions (typically 5-80°C), critical for applications where temperature fluctuations occur. ASTM D2983 offers standardized procedures for low-temperature viscosity measurements.

Sedimentation stability tests, including those outlined in ASTM D1401, assess the suspension stability over time through visual observation or analytical centrifugation techniques. These tests typically run for 24-72 hours to evaluate long-term stability characteristics.

pH sensitivity testing examines rheological behavior across pH ranges (typically 4-10), as clay mineral surface charges—and consequently their rheological properties—are significantly influenced by pH. This testing is particularly important when comparing kaolinite and halloysite due to their different surface chemistry and charge distribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!