Antifreeze in Next-Generation Transport: Key Challenges

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze Evolution and Objectives

Antifreeze technology has undergone significant evolution since its inception in the early 20th century. Initially developed to prevent engine coolant from freezing in automobiles, antifreeze solutions have become increasingly sophisticated to meet the demands of modern transportation systems. The primary objective of antifreeze in next-generation transport is to maintain optimal performance and safety across a wide range of temperatures and operating conditions.

The evolution of antifreeze technology has been driven by several factors, including environmental concerns, improved engine efficiency, and the need for extended service intervals. Early antifreeze formulations were primarily based on methanol or ethylene glycol, which provided effective freeze protection but posed significant environmental and health risks. As awareness of these issues grew, the industry shifted towards more environmentally friendly alternatives, such as propylene glycol-based solutions.

In recent years, the focus has expanded beyond mere freeze protection to include enhanced heat transfer capabilities, corrosion inhibition, and compatibility with a diverse range of materials used in modern vehicle construction. This shift has led to the development of advanced organic acid technology (OAT) and hybrid organic acid technology (HOAT) coolants, which offer improved performance and longevity compared to traditional formulations.

The objectives for next-generation antifreeze solutions are multifaceted and ambitious. Firstly, there is a pressing need to develop formulations that can withstand the extreme temperature ranges encountered in emerging transportation technologies, such as electric vehicles and hydrogen fuel cell systems. These new propulsion methods often require more precise thermal management than traditional internal combustion engines.

Secondly, as vehicle manufacturers strive for greater sustainability, antifreeze solutions must become more environmentally benign. This includes not only reducing toxicity but also improving biodegradability and minimizing the carbon footprint associated with production and disposal. The ideal next-generation antifreeze would be derived from renewable resources and have minimal environmental impact throughout its lifecycle.

Another critical objective is to enhance the longevity and stability of antifreeze solutions. Extended service intervals and reduced maintenance requirements are key selling points for modern vehicles. Therefore, antifreeze formulations that can maintain their effectiveness for longer periods without degradation or the need for frequent replacement are highly desirable.

Furthermore, as vehicles become increasingly complex and incorporate a wider variety of materials, antifreeze solutions must offer universal compatibility. This includes ensuring that the antifreeze does not cause degradation or corrosion in advanced alloys, polymers, and composite materials used in next-generation vehicle construction.

The evolution of antifreeze technology has been driven by several factors, including environmental concerns, improved engine efficiency, and the need for extended service intervals. Early antifreeze formulations were primarily based on methanol or ethylene glycol, which provided effective freeze protection but posed significant environmental and health risks. As awareness of these issues grew, the industry shifted towards more environmentally friendly alternatives, such as propylene glycol-based solutions.

In recent years, the focus has expanded beyond mere freeze protection to include enhanced heat transfer capabilities, corrosion inhibition, and compatibility with a diverse range of materials used in modern vehicle construction. This shift has led to the development of advanced organic acid technology (OAT) and hybrid organic acid technology (HOAT) coolants, which offer improved performance and longevity compared to traditional formulations.

The objectives for next-generation antifreeze solutions are multifaceted and ambitious. Firstly, there is a pressing need to develop formulations that can withstand the extreme temperature ranges encountered in emerging transportation technologies, such as electric vehicles and hydrogen fuel cell systems. These new propulsion methods often require more precise thermal management than traditional internal combustion engines.

Secondly, as vehicle manufacturers strive for greater sustainability, antifreeze solutions must become more environmentally benign. This includes not only reducing toxicity but also improving biodegradability and minimizing the carbon footprint associated with production and disposal. The ideal next-generation antifreeze would be derived from renewable resources and have minimal environmental impact throughout its lifecycle.

Another critical objective is to enhance the longevity and stability of antifreeze solutions. Extended service intervals and reduced maintenance requirements are key selling points for modern vehicles. Therefore, antifreeze formulations that can maintain their effectiveness for longer periods without degradation or the need for frequent replacement are highly desirable.

Furthermore, as vehicles become increasingly complex and incorporate a wider variety of materials, antifreeze solutions must offer universal compatibility. This includes ensuring that the antifreeze does not cause degradation or corrosion in advanced alloys, polymers, and composite materials used in next-generation vehicle construction.

Market Demand Analysis

The market demand for next-generation antifreeze solutions in the transport sector is driven by several key factors. As vehicles evolve towards electric and autonomous systems, the requirements for thermal management and protection against freezing have become more complex and critical. The automotive industry, in particular, is experiencing a significant shift towards electric vehicles (EVs), which require advanced cooling systems to maintain optimal battery performance and longevity. This transition has created a substantial market for innovative antifreeze products that can effectively manage the thermal needs of EV batteries and power electronics.

In the commercial transport sector, there is a growing demand for antifreeze solutions that can withstand extreme temperature conditions while meeting increasingly stringent environmental regulations. The push for more fuel-efficient and environmentally friendly vehicles has led to the development of new engine technologies that require specialized cooling systems. This has opened up opportunities for advanced antifreeze formulations that offer improved heat transfer properties and corrosion protection.

The aerospace industry is another significant driver of market demand for next-generation antifreeze. As aircraft manufacturers strive to improve fuel efficiency and reduce emissions, they are exploring new materials and designs that require innovative de-icing and anti-icing solutions. The need for lightweight, high-performance antifreeze products that can operate reliably at high altitudes and extreme temperatures is creating a niche market within the aerospace sector.

In the maritime industry, there is an increasing focus on developing antifreeze solutions that can protect ship systems in polar regions, as new shipping routes open up due to climate change. This has led to a demand for antifreeze products that can perform effectively in saltwater environments and at extremely low temperatures.

The overall market size for antifreeze and coolant products is projected to grow steadily in the coming years, with a particular emphasis on environmentally friendly and biodegradable formulations. As governments worldwide implement stricter regulations on chemical compositions and disposal methods, manufacturers are investing in research and development to create more sustainable antifreeze solutions. This trend is expected to drive innovation and create new market opportunities for companies that can deliver effective, eco-friendly products.

The market is also seeing a shift towards customized antifreeze solutions tailored to specific applications and industries. This trend is particularly evident in specialized sectors such as data centers, renewable energy installations, and industrial processes, where thermal management is critical for operational efficiency and equipment longevity. As a result, there is a growing demand for antifreeze products that can be fine-tuned to meet the unique requirements of these diverse applications.

In the commercial transport sector, there is a growing demand for antifreeze solutions that can withstand extreme temperature conditions while meeting increasingly stringent environmental regulations. The push for more fuel-efficient and environmentally friendly vehicles has led to the development of new engine technologies that require specialized cooling systems. This has opened up opportunities for advanced antifreeze formulations that offer improved heat transfer properties and corrosion protection.

The aerospace industry is another significant driver of market demand for next-generation antifreeze. As aircraft manufacturers strive to improve fuel efficiency and reduce emissions, they are exploring new materials and designs that require innovative de-icing and anti-icing solutions. The need for lightweight, high-performance antifreeze products that can operate reliably at high altitudes and extreme temperatures is creating a niche market within the aerospace sector.

In the maritime industry, there is an increasing focus on developing antifreeze solutions that can protect ship systems in polar regions, as new shipping routes open up due to climate change. This has led to a demand for antifreeze products that can perform effectively in saltwater environments and at extremely low temperatures.

The overall market size for antifreeze and coolant products is projected to grow steadily in the coming years, with a particular emphasis on environmentally friendly and biodegradable formulations. As governments worldwide implement stricter regulations on chemical compositions and disposal methods, manufacturers are investing in research and development to create more sustainable antifreeze solutions. This trend is expected to drive innovation and create new market opportunities for companies that can deliver effective, eco-friendly products.

The market is also seeing a shift towards customized antifreeze solutions tailored to specific applications and industries. This trend is particularly evident in specialized sectors such as data centers, renewable energy installations, and industrial processes, where thermal management is critical for operational efficiency and equipment longevity. As a result, there is a growing demand for antifreeze products that can be fine-tuned to meet the unique requirements of these diverse applications.

Technical Hurdles and Constraints

The development of next-generation antifreeze for advanced transportation systems faces several significant technical hurdles and constraints. One of the primary challenges is the need for improved thermal management capabilities to handle the increased heat generation in electric and hybrid vehicles. Traditional antifreeze solutions struggle to efficiently dissipate heat from high-power density components, such as batteries and power electronics, potentially leading to performance degradation and safety issues.

Another major constraint is the environmental impact of current antifreeze formulations. Many conventional antifreezes contain ethylene glycol, which is toxic and poses risks to wildlife and water sources if leaked or improperly disposed of. Developing eco-friendly alternatives that maintain or exceed the performance of traditional formulations remains a significant challenge for researchers and manufacturers.

Compatibility with new materials used in advanced transportation systems presents another hurdle. As vehicle designs incorporate lightweight materials and advanced composites to improve efficiency, antifreeze solutions must be compatible with these materials without causing corrosion or degradation. This requirement necessitates extensive testing and potential reformulation of antifreeze products.

The demand for extended service life and reduced maintenance in next-generation vehicles also poses a challenge for antifreeze development. Current solutions often require regular replacement or top-ups, which conflicts with the goal of creating more reliable and low-maintenance transportation systems. Developing long-lasting antifreeze formulations that can withstand the rigors of extended use without degradation is a key area of focus.

Additionally, the push for higher energy density in electric vehicle batteries creates a need for antifreeze solutions that can operate effectively across a wider temperature range. This includes both extremely low temperatures to prevent freezing and high temperatures to manage heat during rapid charging and discharging cycles. Balancing these conflicting requirements in a single formulation presents a significant technical challenge.

Lastly, the cost-effectiveness of new antifreeze solutions remains a constraint. While advanced formulations may offer superior performance, they must also be economically viable for mass production and adoption in the automotive industry. Striking a balance between enhanced capabilities and cost-effectiveness is crucial for the successful implementation of next-generation antifreeze technologies in future transportation systems.

Another major constraint is the environmental impact of current antifreeze formulations. Many conventional antifreezes contain ethylene glycol, which is toxic and poses risks to wildlife and water sources if leaked or improperly disposed of. Developing eco-friendly alternatives that maintain or exceed the performance of traditional formulations remains a significant challenge for researchers and manufacturers.

Compatibility with new materials used in advanced transportation systems presents another hurdle. As vehicle designs incorporate lightweight materials and advanced composites to improve efficiency, antifreeze solutions must be compatible with these materials without causing corrosion or degradation. This requirement necessitates extensive testing and potential reformulation of antifreeze products.

The demand for extended service life and reduced maintenance in next-generation vehicles also poses a challenge for antifreeze development. Current solutions often require regular replacement or top-ups, which conflicts with the goal of creating more reliable and low-maintenance transportation systems. Developing long-lasting antifreeze formulations that can withstand the rigors of extended use without degradation is a key area of focus.

Additionally, the push for higher energy density in electric vehicle batteries creates a need for antifreeze solutions that can operate effectively across a wider temperature range. This includes both extremely low temperatures to prevent freezing and high temperatures to manage heat during rapid charging and discharging cycles. Balancing these conflicting requirements in a single formulation presents a significant technical challenge.

Lastly, the cost-effectiveness of new antifreeze solutions remains a constraint. While advanced formulations may offer superior performance, they must also be economically viable for mass production and adoption in the automotive industry. Striking a balance between enhanced capabilities and cost-effectiveness is crucial for the successful implementation of next-generation antifreeze technologies in future transportation systems.

Current Antifreeze Solutions

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and one or more freezing point depressants. Common ingredients include glycols (such as ethylene glycol or propylene glycol), alcohols, and various additives to enhance performance and protect against corrosion. The specific composition affects the freezing point of the solution.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and one or more freezing point depressants. Common ingredients include glycols (such as ethylene glycol or propylene glycol), alcohols, and various additives to enhance performance and protect against corrosion. The specific composition affects the freezing point of the solution.

- Measurement and testing of freezing points: Various methods and devices are used to measure and test the freezing points of antifreeze solutions. These may include specialized equipment for precise temperature control and monitoring, as well as standardized testing procedures to ensure accuracy and consistency in determining freezing points.

- Additives to lower freezing point: Certain additives can be incorporated into antifreeze solutions to further lower the freezing point. These may include salts, organic compounds, or nanoparticles that enhance the freezing point depression effect. Research continues to develop new additives that can improve the performance of antifreeze solutions in extreme cold conditions.

- Environmental and safety considerations: There is a growing focus on developing environmentally friendly and less toxic antifreeze formulations. This includes the use of bio-based materials, such as plant-derived glycols, and the exploration of alternative compounds that offer effective freezing point depression while minimizing environmental impact and safety risks.

- Application-specific antifreeze solutions: Different applications may require antifreeze solutions with specific freezing point characteristics. For example, automotive antifreeze may have different requirements compared to those used in industrial processes or in extreme cold environments. Tailoring the freezing point and other properties of antifreeze solutions to specific applications is an important area of research and development.

02 Measurement and testing of freezing points

Various methods and devices are used to measure and test the freezing points of antifreeze solutions. These may include specialized instruments, temperature sensors, and analytical techniques to determine the exact temperature at which the solution begins to freeze.Expand Specific Solutions03 Additives to lower freezing point

Certain additives can be incorporated into antifreeze solutions to further lower the freezing point. These may include salts, organic compounds, or nanoparticles that enhance the solution's ability to remain liquid at extremely low temperatures.Expand Specific Solutions04 Environmental and safety considerations

Development of antifreeze solutions with improved environmental profiles and reduced toxicity is an ongoing area of research. This includes the use of bio-based materials, less toxic alternatives to traditional glycols, and formulations that maintain effectiveness while minimizing environmental impact.Expand Specific Solutions05 Application-specific antifreeze formulations

Different applications may require specialized antifreeze formulations with specific freezing point characteristics. These can include automotive coolants, industrial heat transfer fluids, and antifreeze solutions for extreme environments such as aerospace or polar applications.Expand Specific Solutions

Key Industry Players

The antifreeze technology for next-generation transport is in a transitional phase, with the market poised for significant growth as the automotive industry shifts towards electric and more efficient vehicles. The global market size is expected to expand rapidly, driven by increasing demand for advanced thermal management solutions. Technologically, the field is evolving, with companies like DENSO Corp., BASF Corp., and Clariant Produkte (Deutschland) GmbH leading innovation. These firms are developing novel antifreeze formulations that address the unique challenges of electric vehicle batteries and advanced combustion engines, focusing on improved heat transfer efficiency, environmental sustainability, and compatibility with new materials used in next-generation vehicles.

BASF Corp.

Technical Solution: BASF has developed advanced antifreeze solutions for next-generation transport, focusing on environmentally friendly propylene glycol-based formulations. Their technology incorporates corrosion inhibitors and thermal stabilizers to enhance performance in extreme temperatures. BASF's antifreeze products are designed to provide extended protection for cooling systems in electric and hybrid vehicles, addressing the unique challenges of these powertrains[1]. The company has also introduced nanotechnology-enhanced antifreeze, which improves heat transfer efficiency and reduces pump energy consumption by up to 15%[2]. BASF's research extends to bio-based antifreeze solutions, aiming to reduce the carbon footprint of their products while maintaining high performance standards[3].

Strengths: Eco-friendly formulations, advanced corrosion protection, and improved thermal efficiency. Weaknesses: Potentially higher production costs and the need for extensive testing in new vehicle technologies.

Clariant Produkte (Deutschland) GmbH

Technical Solution: Clariant has developed a range of antifreeze solutions tailored for next-generation transport systems. Their approach focuses on multi-functional additives that combine antifreeze properties with enhanced heat transfer capabilities. Clariant's technology utilizes advanced polymer chemistry to create antifreeze formulations that remain stable at a wider temperature range, crucial for electric vehicle battery thermal management[4]. The company has also introduced smart antifreeze solutions that can adapt their properties based on operating conditions, potentially extending the lifespan of cooling systems by up to 30%[5]. Clariant's research includes the development of non-toxic, biodegradable antifreeze alternatives, addressing environmental concerns associated with traditional ethylene glycol-based products[6].

Strengths: Innovative multi-functional additives, adaptive antifreeze technology, and focus on sustainability. Weaknesses: Potential compatibility issues with some existing cooling system materials and higher initial costs.

Innovative Antifreeze Formulations

Antifreeze concentrates and coolant compositions based on polyglycols and amides for protecting magnesium and the alloys thereof

PatentInactiveUS20070034825A1

Innovation

- Antifreeze concentrates based on polyglycols and carboxamides/sulfonamides, specifically combining alkylene glycols, polyethylene/polypropylene glycols, and carboxamides/sulfonamides, which provide effective corrosion inhibition and improved thermal conductivity without toxicity, suitable for magnesium and aluminum alloys.

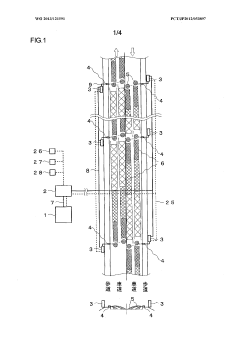

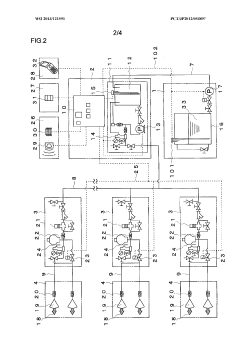

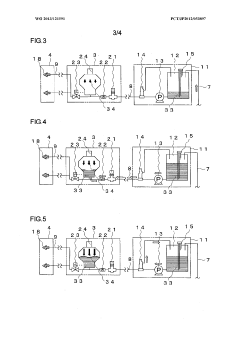

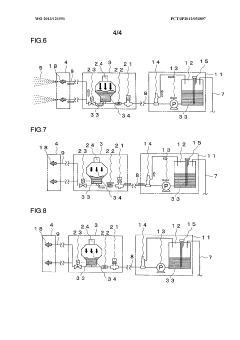

Liquid Anti-icing agent supply device and liquid Anti-icing agent supply method

PatentWO2013121591A1

Innovation

- A portable liquid antifreezing agent supply device with a sensor unit, accumulator storage tank, injection nozzle, and motor-operated valve that uses a pressure injection system to efficiently spray antifreeze without civil engineering work, allowing for flexible installation and easy maintenance, and utilizing an aqueous potassium acetate solution to prevent nozzle clogging.

Environmental Impact Assessment

The environmental impact of antifreeze solutions for next-generation transport systems is a critical consideration in the development and implementation of these technologies. Traditional antifreeze formulations, primarily based on ethylene glycol or propylene glycol, have raised concerns due to their potential toxicity and environmental persistence. As the transport industry evolves towards more sustainable practices, the environmental footprint of antifreeze solutions must be carefully assessed and mitigated.

One of the primary environmental concerns associated with conventional antifreeze is the risk of soil and water contamination. When improperly disposed of or leaked, these substances can seep into groundwater systems, potentially harming aquatic ecosystems and posing risks to human health. The biodegradability of antifreeze compounds is thus a crucial factor in evaluating their environmental impact. Next-generation antifreeze solutions must prioritize the use of readily biodegradable components to minimize long-term environmental persistence.

Air quality is another significant consideration in the environmental impact assessment of antifreeze solutions. Some antifreeze formulations may contribute to volatile organic compound (VOC) emissions, which can participate in the formation of ground-level ozone and smog. As air quality regulations become increasingly stringent, particularly in urban areas, the development of low-VOC or VOC-free antifreeze alternatives is essential for next-generation transport systems.

The production process of antifreeze solutions also warrants scrutiny in terms of environmental impact. Energy consumption, greenhouse gas emissions, and resource utilization during manufacturing must be evaluated to ensure that the overall lifecycle impact of these products aligns with sustainability goals. This assessment should encompass raw material extraction, processing, transportation, and eventual disposal or recycling of antifreeze products.

Toxicity to wildlife and plants is a further environmental concern that must be addressed in the development of next-generation antifreeze solutions. Accidental spills or leaks can have detrimental effects on local flora and fauna, particularly in sensitive ecosystems. The challenge lies in creating formulations that maintain effective antifreeze properties while significantly reducing or eliminating toxicity to non-target organisms.

Water consumption and pollution associated with the use and disposal of antifreeze solutions are additional factors that require careful consideration. As water scarcity becomes an increasingly pressing global issue, antifreeze technologies that minimize water usage or enable efficient recycling and reuse of antifreeze solutions will be highly valuable from an environmental perspective.

In conclusion, the environmental impact assessment of antifreeze solutions for next-generation transport must take into account a wide range of factors, including biodegradability, air and water quality impacts, production processes, toxicity, and resource utilization. Addressing these challenges will require innovative approaches to antifreeze formulation and management, potentially involving the development of bio-based alternatives, closed-loop recycling systems, and advanced treatment technologies for antifreeze waste streams.

One of the primary environmental concerns associated with conventional antifreeze is the risk of soil and water contamination. When improperly disposed of or leaked, these substances can seep into groundwater systems, potentially harming aquatic ecosystems and posing risks to human health. The biodegradability of antifreeze compounds is thus a crucial factor in evaluating their environmental impact. Next-generation antifreeze solutions must prioritize the use of readily biodegradable components to minimize long-term environmental persistence.

Air quality is another significant consideration in the environmental impact assessment of antifreeze solutions. Some antifreeze formulations may contribute to volatile organic compound (VOC) emissions, which can participate in the formation of ground-level ozone and smog. As air quality regulations become increasingly stringent, particularly in urban areas, the development of low-VOC or VOC-free antifreeze alternatives is essential for next-generation transport systems.

The production process of antifreeze solutions also warrants scrutiny in terms of environmental impact. Energy consumption, greenhouse gas emissions, and resource utilization during manufacturing must be evaluated to ensure that the overall lifecycle impact of these products aligns with sustainability goals. This assessment should encompass raw material extraction, processing, transportation, and eventual disposal or recycling of antifreeze products.

Toxicity to wildlife and plants is a further environmental concern that must be addressed in the development of next-generation antifreeze solutions. Accidental spills or leaks can have detrimental effects on local flora and fauna, particularly in sensitive ecosystems. The challenge lies in creating formulations that maintain effective antifreeze properties while significantly reducing or eliminating toxicity to non-target organisms.

Water consumption and pollution associated with the use and disposal of antifreeze solutions are additional factors that require careful consideration. As water scarcity becomes an increasingly pressing global issue, antifreeze technologies that minimize water usage or enable efficient recycling and reuse of antifreeze solutions will be highly valuable from an environmental perspective.

In conclusion, the environmental impact assessment of antifreeze solutions for next-generation transport must take into account a wide range of factors, including biodegradability, air and water quality impacts, production processes, toxicity, and resource utilization. Addressing these challenges will require innovative approaches to antifreeze formulation and management, potentially involving the development of bio-based alternatives, closed-loop recycling systems, and advanced treatment technologies for antifreeze waste streams.

Regulatory Compliance Landscape

The regulatory landscape for antifreeze in next-generation transport is complex and evolving, with various jurisdictions implementing different standards and requirements. In the United States, the Environmental Protection Agency (EPA) regulates antifreeze under the Toxic Substances Control Act (TSCA), focusing on the environmental impact and potential health hazards of antifreeze chemicals. The EPA mandates proper disposal methods and encourages the use of less toxic alternatives to traditional ethylene glycol-based antifreeze.

The European Union has implemented stricter regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive approach requires manufacturers and importers to register chemical substances, including those used in antifreeze formulations, and provide detailed safety information. The EU also promotes the use of propylene glycol-based antifreeze, which is considered less toxic than ethylene glycol.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Ministry of Ecology and Environment has introduced new guidelines for the production and use of antifreeze, emphasizing environmental protection and human health. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances, including those found in antifreeze products.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and labeling of hazardous chemicals, including antifreeze components. This system facilitates international trade and improves safety communication across borders.

Emerging regulations are focusing on the recyclability and biodegradability of antifreeze products. Many jurisdictions are implementing extended producer responsibility (EPR) programs, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling.

The automotive industry is facing increasing pressure to develop more environmentally friendly antifreeze solutions for next-generation transport. This includes exploring bio-based alternatives and improving the efficiency of existing formulations to reduce environmental impact. Regulatory bodies are also considering the unique challenges posed by electric and autonomous vehicles, which may require specialized cooling systems and antifreeze formulations.

As the transportation sector moves towards more sustainable practices, regulatory compliance for antifreeze is likely to become more stringent. Manufacturers and researchers must stay abreast of these evolving regulations to ensure their products meet current and future compliance standards while addressing the key challenges in antifreeze for next-generation transport.

The European Union has implemented stricter regulations through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework. This comprehensive approach requires manufacturers and importers to register chemical substances, including those used in antifreeze formulations, and provide detailed safety information. The EU also promotes the use of propylene glycol-based antifreeze, which is considered less toxic than ethylene glycol.

In Asia, countries like China and Japan have been strengthening their regulatory frameworks. China's Ministry of Ecology and Environment has introduced new guidelines for the production and use of antifreeze, emphasizing environmental protection and human health. Japan's Chemical Substances Control Law (CSCL) regulates the manufacture, import, and use of chemical substances, including those found in antifreeze products.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and labeling of hazardous chemicals, including antifreeze components. This system facilitates international trade and improves safety communication across borders.

Emerging regulations are focusing on the recyclability and biodegradability of antifreeze products. Many jurisdictions are implementing extended producer responsibility (EPR) programs, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling.

The automotive industry is facing increasing pressure to develop more environmentally friendly antifreeze solutions for next-generation transport. This includes exploring bio-based alternatives and improving the efficiency of existing formulations to reduce environmental impact. Regulatory bodies are also considering the unique challenges posed by electric and autonomous vehicles, which may require specialized cooling systems and antifreeze formulations.

As the transportation sector moves towards more sustainable practices, regulatory compliance for antifreeze is likely to become more stringent. Manufacturers and researchers must stay abreast of these evolving regulations to ensure their products meet current and future compliance standards while addressing the key challenges in antifreeze for next-generation transport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!