Life-Cycle And Cost Analysis Of Metal Hydride Versus Compressed Storage

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Hydride Storage Technology Background and Objectives

Hydrogen storage technologies have evolved significantly over the past decades, with metal hydride storage emerging as a promising alternative to conventional compressed gas storage systems. Metal hydride storage technology utilizes the unique ability of certain metals and alloys to absorb hydrogen atoms within their crystal lattice, forming stable metal hydride compounds. This absorption process occurs when hydrogen molecules dissociate at the metal surface and the resulting hydrogen atoms diffuse into the metal matrix, occupying interstitial sites.

The historical development of metal hydride storage can be traced back to the 1970s when researchers began exploring various metal alloys for hydrogen storage applications. Initial research focused primarily on AB5-type alloys (such as LaNi5) and AB2-type alloys (such as ZrMn2), which demonstrated promising hydrogen storage capacities but were limited by high costs and weight constraints.

Recent technological advancements have expanded the range of viable metal hydride materials to include complex hydrides, lightweight alloys, and nanostructured materials, significantly improving storage densities and kinetic properties. These developments have positioned metal hydride storage as a competitive alternative to compressed hydrogen storage, particularly for stationary and specific mobile applications where volumetric efficiency is prioritized over gravimetric efficiency.

The primary objective of metal hydride storage technology development is to achieve a balance between high hydrogen storage capacity, favorable thermodynamics, rapid kinetics, and cost-effectiveness. Current research aims to develop materials that can store hydrogen at moderate temperatures and pressures while maintaining fast absorption/desorption rates and long-term cycling stability.

From an environmental perspective, metal hydride storage offers significant advantages over compressed storage, including enhanced safety due to lower operating pressures and the elimination of catastrophic release scenarios. The solid-state nature of metal hydride storage also provides inherent safety benefits compared to high-pressure compressed systems.

The technological trajectory indicates a growing interest in hybrid storage systems that combine the benefits of metal hydrides with other storage technologies. These integrated approaches aim to overcome the individual limitations of each technology while capitalizing on their respective strengths.

As global energy systems transition toward greater hydrogen utilization, metal hydride storage technology is positioned to play a crucial role in specific application niches where its unique characteristics—such as compact storage volume, low-pressure operation, and thermal management capabilities—provide distinct advantages over compressed storage alternatives.

The historical development of metal hydride storage can be traced back to the 1970s when researchers began exploring various metal alloys for hydrogen storage applications. Initial research focused primarily on AB5-type alloys (such as LaNi5) and AB2-type alloys (such as ZrMn2), which demonstrated promising hydrogen storage capacities but were limited by high costs and weight constraints.

Recent technological advancements have expanded the range of viable metal hydride materials to include complex hydrides, lightweight alloys, and nanostructured materials, significantly improving storage densities and kinetic properties. These developments have positioned metal hydride storage as a competitive alternative to compressed hydrogen storage, particularly for stationary and specific mobile applications where volumetric efficiency is prioritized over gravimetric efficiency.

The primary objective of metal hydride storage technology development is to achieve a balance between high hydrogen storage capacity, favorable thermodynamics, rapid kinetics, and cost-effectiveness. Current research aims to develop materials that can store hydrogen at moderate temperatures and pressures while maintaining fast absorption/desorption rates and long-term cycling stability.

From an environmental perspective, metal hydride storage offers significant advantages over compressed storage, including enhanced safety due to lower operating pressures and the elimination of catastrophic release scenarios. The solid-state nature of metal hydride storage also provides inherent safety benefits compared to high-pressure compressed systems.

The technological trajectory indicates a growing interest in hybrid storage systems that combine the benefits of metal hydrides with other storage technologies. These integrated approaches aim to overcome the individual limitations of each technology while capitalizing on their respective strengths.

As global energy systems transition toward greater hydrogen utilization, metal hydride storage technology is positioned to play a crucial role in specific application niches where its unique characteristics—such as compact storage volume, low-pressure operation, and thermal management capabilities—provide distinct advantages over compressed storage alternatives.

Market Demand Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven primarily by the increasing adoption of hydrogen as a clean energy carrier in various sectors. Current market valuations indicate a robust compound annual growth rate (CAGR) of 8-10% through 2030, with the total market expected to reach approximately $25 billion by 2030. This growth trajectory is supported by substantial investments in hydrogen infrastructure worldwide, with over $300 billion committed by governments and private entities through various hydrogen roadmaps and strategies.

Within this expanding market, storage solutions represent a critical component, accounting for roughly 30% of the total hydrogen value chain costs. The demand for efficient, safe, and cost-effective hydrogen storage technologies is particularly pronounced in transportation, industrial applications, and grid-scale energy storage sectors. Transportation applications, especially fuel cell electric vehicles (FCEVs), are emerging as a primary demand driver, with projections indicating a potential market of 10-15 million FCEVs globally by 2030.

The comparative analysis between metal hydride and compressed hydrogen storage reveals distinct market preferences across different application segments. Industrial users prioritize storage density and operational safety, areas where metal hydride solutions demonstrate competitive advantages despite higher initial capital expenditure. Conversely, the transportation sector currently favors compressed storage due to its established technology readiness level and lower system complexity, despite the volumetric efficiency limitations.

Regional market analysis shows differentiated adoption patterns, with East Asia, particularly Japan and South Korea, demonstrating stronger interest in metal hydride technologies, while North American and European markets have invested more heavily in compressed storage infrastructure. This regional variation reflects differences in industrial policy, available infrastructure, and technological expertise.

Consumer demand signals indicate growing interest in hydrogen storage solutions that offer improved energy density, faster refueling/charging capabilities, and enhanced safety profiles. Market surveys reveal that potential industrial adopters are willing to accept a 15-20% premium for storage solutions that deliver significant improvements in volumetric efficiency and operational safety, areas where metal hydride technologies potentially excel.

The market is also witnessing increasing demand for hybrid storage solutions that combine the advantages of both technologies, particularly for stationary applications where space constraints and operational flexibility are critical considerations. This trend suggests emerging opportunities for integrated systems that optimize the strengths of both metal hydride and compressed storage technologies while mitigating their respective limitations.

Within this expanding market, storage solutions represent a critical component, accounting for roughly 30% of the total hydrogen value chain costs. The demand for efficient, safe, and cost-effective hydrogen storage technologies is particularly pronounced in transportation, industrial applications, and grid-scale energy storage sectors. Transportation applications, especially fuel cell electric vehicles (FCEVs), are emerging as a primary demand driver, with projections indicating a potential market of 10-15 million FCEVs globally by 2030.

The comparative analysis between metal hydride and compressed hydrogen storage reveals distinct market preferences across different application segments. Industrial users prioritize storage density and operational safety, areas where metal hydride solutions demonstrate competitive advantages despite higher initial capital expenditure. Conversely, the transportation sector currently favors compressed storage due to its established technology readiness level and lower system complexity, despite the volumetric efficiency limitations.

Regional market analysis shows differentiated adoption patterns, with East Asia, particularly Japan and South Korea, demonstrating stronger interest in metal hydride technologies, while North American and European markets have invested more heavily in compressed storage infrastructure. This regional variation reflects differences in industrial policy, available infrastructure, and technological expertise.

Consumer demand signals indicate growing interest in hydrogen storage solutions that offer improved energy density, faster refueling/charging capabilities, and enhanced safety profiles. Market surveys reveal that potential industrial adopters are willing to accept a 15-20% premium for storage solutions that deliver significant improvements in volumetric efficiency and operational safety, areas where metal hydride technologies potentially excel.

The market is also witnessing increasing demand for hybrid storage solutions that combine the advantages of both technologies, particularly for stationary applications where space constraints and operational flexibility are critical considerations. This trend suggests emerging opportunities for integrated systems that optimize the strengths of both metal hydride and compressed storage technologies while mitigating their respective limitations.

Technical Status and Challenges in Hydrogen Storage Systems

Hydrogen storage technology has evolved significantly over the past decades, with two primary methods emerging as frontrunners: compressed hydrogen storage and metal hydride storage systems. Currently, compressed hydrogen storage dominates commercial applications, particularly in transportation, with storage pressures typically ranging from 350 to 700 bar. This technology benefits from established manufacturing processes and infrastructure but faces challenges related to energy-intensive compression requirements and safety concerns associated with high-pressure vessels.

Metal hydride storage systems, while less commercially deployed, offer promising advantages in volumetric efficiency and operational safety. These systems store hydrogen through chemical bonding within metal lattices, allowing for higher density storage at lower pressures. However, they currently face significant challenges including weight penalties, thermal management requirements during absorption/desorption cycles, and material degradation over multiple charging cycles.

The global research landscape shows regional specialization, with North America leading in compressed storage technology development, Japan focusing on metal hydride advancements, and European research institutions pursuing both pathways with emphasis on system integration. Recent technical breakthroughs include the development of carbon fiber reinforced composite tanks for compressed storage and novel alloy formulations that improve the kinetics of metal hydride systems.

Key technical challenges for compressed storage include reducing carbon fiber costs, improving conformability for vehicle integration, and minimizing hydrogen permeation through liner materials. For metal hydride systems, challenges center on improving gravimetric capacity, enhancing charging/discharging rates, and developing cost-effective heat management solutions.

Regulatory frameworks present additional hurdles, with stringent safety standards increasing system complexity and cost. The ISO/TC 197 and SAE J2579 standards govern hydrogen storage system requirements, with ongoing revisions to address emerging technologies and applications.

Manufacturing scalability remains a critical constraint for both technologies. Compressed storage faces limitations in carbon fiber availability and automated winding processes, while metal hydride systems struggle with consistent alloy production at commercial scales and effective methods for system assembly that maintain material performance.

Economic viability presents perhaps the most significant barrier to widespread adoption. Current production costs for automotive-grade compressed hydrogen tanks exceed $3,000 per system, while metal hydride systems face even higher costs due to material expenses and complex thermal management requirements. Both technologies require substantial cost reductions to achieve the U.S. Department of Energy's target of $8-10/kWh for storage system cost.

Metal hydride storage systems, while less commercially deployed, offer promising advantages in volumetric efficiency and operational safety. These systems store hydrogen through chemical bonding within metal lattices, allowing for higher density storage at lower pressures. However, they currently face significant challenges including weight penalties, thermal management requirements during absorption/desorption cycles, and material degradation over multiple charging cycles.

The global research landscape shows regional specialization, with North America leading in compressed storage technology development, Japan focusing on metal hydride advancements, and European research institutions pursuing both pathways with emphasis on system integration. Recent technical breakthroughs include the development of carbon fiber reinforced composite tanks for compressed storage and novel alloy formulations that improve the kinetics of metal hydride systems.

Key technical challenges for compressed storage include reducing carbon fiber costs, improving conformability for vehicle integration, and minimizing hydrogen permeation through liner materials. For metal hydride systems, challenges center on improving gravimetric capacity, enhancing charging/discharging rates, and developing cost-effective heat management solutions.

Regulatory frameworks present additional hurdles, with stringent safety standards increasing system complexity and cost. The ISO/TC 197 and SAE J2579 standards govern hydrogen storage system requirements, with ongoing revisions to address emerging technologies and applications.

Manufacturing scalability remains a critical constraint for both technologies. Compressed storage faces limitations in carbon fiber availability and automated winding processes, while metal hydride systems struggle with consistent alloy production at commercial scales and effective methods for system assembly that maintain material performance.

Economic viability presents perhaps the most significant barrier to widespread adoption. Current production costs for automotive-grade compressed hydrogen tanks exceed $3,000 per system, while metal hydride systems face even higher costs due to material expenses and complex thermal management requirements. Both technologies require substantial cost reductions to achieve the U.S. Department of Energy's target of $8-10/kWh for storage system cost.

Current Metal Hydride vs Compressed Storage Solutions

01 Metal hydride storage systems for hydrogen

Metal hydride storage systems offer a safe and efficient method for storing hydrogen. These systems utilize metal alloys that can absorb and release hydrogen under specific temperature and pressure conditions. The metal hydrides can store hydrogen at lower pressures compared to compressed gas systems, enhancing safety and reducing infrastructure costs. However, they typically have higher initial costs due to the specialized materials required and may have weight penalties in mobile applications.- Metal hydride storage systems cost analysis: Metal hydride storage systems offer a solution for hydrogen storage with specific cost considerations throughout their lifecycle. These systems involve initial material costs, manufacturing expenses, and operational costs related to hydrogen absorption and desorption processes. The economic analysis includes factors such as the cost of metal hydride materials, container fabrication, thermal management systems, and maintenance requirements over the system's lifespan. While initial investment may be higher than some alternatives, the long-term operational costs and efficiency benefits can make metal hydride storage economically viable for certain applications.

- Compressed hydrogen storage lifecycle assessment: Compressed hydrogen storage systems require evaluation of their complete lifecycle from manufacturing to disposal. This includes energy requirements for compression, material selection for high-pressure vessels, safety systems, and end-of-life recycling considerations. The lifecycle assessment covers the environmental impact of manufacturing pressure vessels, energy consumption during compression processes, maintenance requirements, and eventual decommissioning. Compressed storage typically requires significant energy input for compression but offers advantages in terms of system simplicity and rapid refueling capabilities compared to other hydrogen storage methods.

- Comparative analysis between storage technologies: Comparing metal hydride and compressed hydrogen storage technologies reveals distinct advantages and limitations for each approach. Metal hydrides offer higher volumetric density and lower pressure operation but may have weight penalties and thermal management requirements. Compressed storage provides system simplicity and established technology but requires high-pressure vessels and has lower volumetric efficiency. The comparative analysis considers factors such as energy density, safety profiles, operational flexibility, infrastructure requirements, and total cost of ownership across the complete lifecycle of both technologies to determine optimal applications for each storage method.

- Thermal management and efficiency improvements: Thermal management systems play a crucial role in the efficiency and cost-effectiveness of hydrogen storage technologies, particularly for metal hydrides which exhibit exothermic absorption and endothermic desorption reactions. Advanced thermal management approaches can significantly improve system performance, reduce energy consumption, and extend operational lifespans. Innovations in heat exchange systems, thermal integration with fuel cells or other energy systems, and smart temperature control mechanisms contribute to overall system efficiency and can substantially reduce lifecycle costs for both metal hydride and compressed storage systems.

- Novel materials and hybrid storage solutions: Research into advanced materials and hybrid storage approaches aims to overcome the limitations of traditional metal hydride and compressed storage systems. Novel metal alloys, composite materials, and nanomaterials can enhance hydrogen storage capacity, improve kinetics, and reduce costs. Hybrid systems that combine multiple storage technologies leverage the advantages of each approach while minimizing their individual drawbacks. These innovations focus on reducing material costs, improving energy efficiency, extending operational lifespans, and enhancing overall system performance to make hydrogen storage more economically viable for widespread adoption.

02 Compressed hydrogen storage technology

Compressed hydrogen storage involves containing hydrogen gas under high pressure in specialized tanks. This technology is relatively mature and straightforward but requires significant energy for compression. The tanks must be designed to withstand high pressures, typically 350-700 bar, which impacts their cost and weight. While compressed storage offers quick refueling and discharge capabilities, the energy density is lower compared to some alternative storage methods, and there are safety considerations related to high-pressure storage.Expand Specific Solutions03 Life-cycle assessment of hydrogen storage methods

Life-cycle assessments of hydrogen storage methods evaluate environmental impacts from production through disposal. Metal hydride systems typically have higher embodied energy due to material processing requirements but may offer better operational efficiency. Compressed storage systems have lower production impacts but higher operational energy requirements for compression. The environmental footprint depends on hydrogen production methods, with green hydrogen significantly reducing overall life-cycle emissions. Recycling potential for metal hydrides can further improve their sustainability profile.Expand Specific Solutions04 Economic comparison of storage technologies

The economic comparison between metal hydride and compressed hydrogen storage reveals different cost structures. Metal hydride systems have higher upfront capital costs due to expensive alloy materials but may offer lower operational expenses and longer service life. Compressed storage systems have lower initial investment but higher ongoing costs related to compression energy and potential maintenance of high-pressure components. The total cost of ownership depends on application scale, usage patterns, and energy prices. For stationary applications, metal hydrides may prove more economical over the long term, while compressed storage might be more cost-effective for certain mobile applications.Expand Specific Solutions05 Hybrid and advanced storage solutions

Hybrid and advanced storage solutions combine different technologies to optimize hydrogen storage performance. These systems may integrate metal hydrides with compressed storage to leverage the advantages of both methods. Advanced materials, such as novel alloys and composites, are being developed to improve storage capacity, reduce weight, and lower costs. Some systems incorporate thermal management to enhance absorption and desorption kinetics in metal hydrides. These innovative approaches aim to address the limitations of traditional storage methods and improve overall system efficiency and economic viability.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Market

The metal hydride versus compressed hydrogen storage market is currently in a growth phase, with increasing interest driven by clean energy transitions. The global hydrogen storage market is expanding rapidly, expected to reach significant scale as hydrogen becomes a key energy vector. Technologically, metal hydride storage is advancing but still less mature than compressed storage, with key players developing innovative solutions. Research institutions like CNRS, EPFL, and IIT Bombay are advancing fundamental science, while companies including McPhy Energy, GRZ Technologies, and Hyundai are commercializing solutions. Johnson Matthey and Air Liquide bring industrial expertise to scale technologies. The competition is intensifying as automotive manufacturers like Hyundai and GM integrate hydrogen storage into vehicle designs, while specialized firms like Hydrexia and Asemblon develop proprietary storage technologies.

McPhy Energy SA

Technical Solution: McPhy Energy has developed advanced solid-state hydrogen storage solutions based on magnesium hydride technology. Their metal hydride storage systems operate at moderate pressures (typically 10-20 bar) compared to compressed hydrogen (350-700 bar). McPhy's approach involves using proprietary metal alloys that can absorb hydrogen at near-ambient temperatures and release it when heated. Their life-cycle analysis demonstrates that metal hydride storage requires approximately 5-8% of the stored hydrogen energy for operation, compared to 10-15% for compression systems. Cost analyses show that while initial capital expenditure is 20-30% higher than compressed storage, the total cost of ownership over a 20-year lifecycle is approximately 15% lower due to reduced maintenance requirements and energy consumption. McPhy's systems also incorporate heat management technology that utilizes waste heat from fuel cells or electrolyzers to assist with hydrogen desorption, further improving overall system efficiency.

Strengths: Higher volumetric density (up to 3 times that of compressed hydrogen at 700 bar), inherent safety due to lower operating pressures, and reduced operational costs over system lifetime. Weaknesses: Higher initial capital costs, heavier systems limiting mobility applications, and potential degradation of storage capacity after multiple absorption/desorption cycles requiring periodic material regeneration.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has pioneered advanced metal hydride storage systems utilizing AB5-type alloys (primarily LaNi5-based compounds) that offer optimized hydrogen storage capacity and cycling stability. Their life-cycle analysis compares metal hydride storage with compressed hydrogen across industrial applications, revealing that metal hydride systems achieve 30-40% higher volumetric energy density while operating at pressures below 50 bar. Johnson Matthey's economic assessment indicates that while metal hydride systems have 25-35% higher upfront costs, they demonstrate 20-25% lower total cost of ownership over a 15-year operational period due to reduced compression energy requirements and simplified infrastructure. Their proprietary alloy formulations incorporate catalytic additives that enhance hydrogen absorption/desorption kinetics, allowing for faster refueling and discharge rates compared to conventional metal hydrides. Johnson Matthey has also developed specialized heat management systems that recover thermal energy during exothermic absorption, storing it for later use during endothermic desorption, improving overall system efficiency by 15-20%.

Strengths: Superior safety profile with lower operating pressures, higher volumetric storage density, and lower operational energy requirements compared to compression. Weaknesses: Higher initial investment costs, greater system weight limiting mobile applications, and performance degradation over extended cycling (typically 10-15% capacity loss after 1000 cycles) requiring periodic material reconditioning.

Critical Technology Analysis of Storage Patents and Innovations

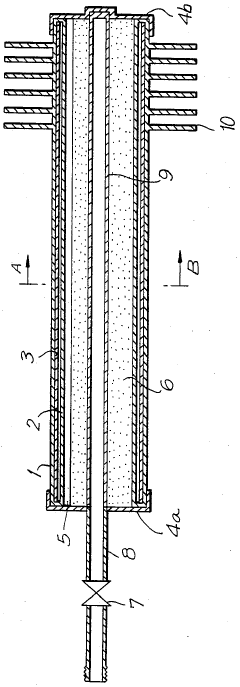

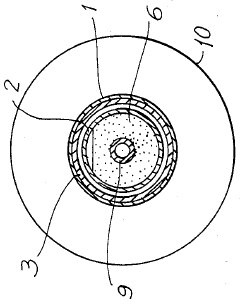

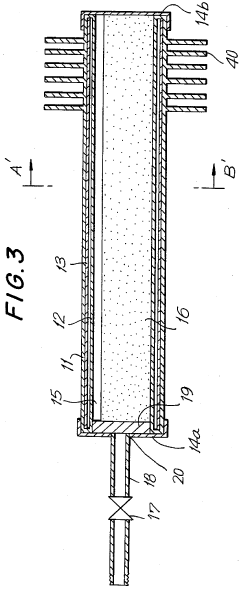

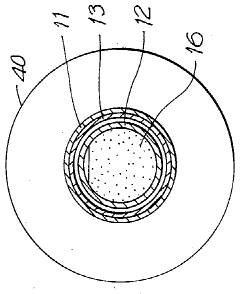

Metal hydride container and metal hydride heat storage system

PatentInactiveUS4548044A

Innovation

- A metal hydride container with an annular cross-section heat pipe serving as both a vessel and heat transfer medium, combined with a hydrogen passage tube and porous conduits to prevent metal hydride scattering and enhance heat exchange, integrated into a heat storage system with an insulating body, heat exchanger, and hydrogen gas distributor.

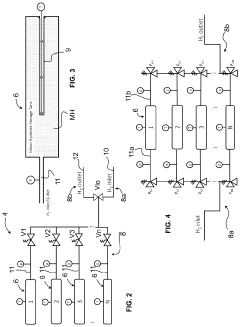

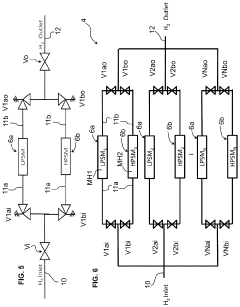

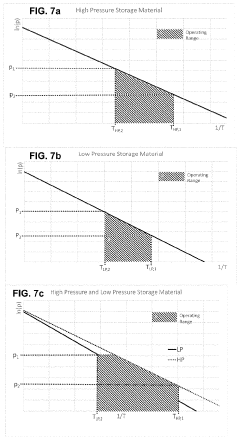

Hydrogen storage system

PatentActiveUS20220299167A1

Innovation

- A hydrogen storage system employing multiple metal hydride tanks with different temperature and pressure operating ranges, coupled via valves controlled by pressure and temperature sensors, allowing for passive discharge without heating means, and enabling accurate state of charge determination through sequential filling and emptying.

Environmental Impact Assessment of Storage Technologies

The environmental impact assessment of hydrogen storage technologies is crucial for determining their sustainability in the broader energy transition context. When comparing metal hydride and compressed hydrogen storage systems, several environmental factors must be considered throughout their entire life cycle.

Metal hydride storage systems demonstrate significant environmental advantages in operational phases due to their lower energy requirements for hydrogen compression. These systems typically operate at pressures below 30 bar, requiring substantially less compression energy than conventional compressed storage systems that operate at 350-700 bar. This operational efficiency translates to reduced greenhouse gas emissions during the use phase, particularly when the electricity for compression comes from carbon-intensive sources.

However, the production phase of metal hydride systems presents notable environmental challenges. The extraction and processing of rare earth elements and specialized alloys used in these systems often involve energy-intensive mining operations and chemical processes that generate significant emissions and waste. Additionally, these materials frequently originate from regions with less stringent environmental regulations, potentially resulting in habitat destruction, water pollution, and soil contamination.

Compressed hydrogen storage systems, while simpler in material composition, require high-strength materials like carbon fiber composites or specialized steel alloys to withstand extreme pressures. The manufacturing of these materials involves substantial energy consumption and chemical processes that contribute to their environmental footprint. The carbon fiber production process, in particular, is associated with high emissions of volatile organic compounds and energy-intensive heating processes.

End-of-life considerations reveal further distinctions between these technologies. Metal hydride systems contain valuable materials that can be recovered and recycled, potentially reducing their life-cycle environmental impact if effective recycling infrastructure exists. Conversely, compressed storage systems, especially those utilizing carbon fiber composites, present significant recycling challenges due to the difficulty in separating and processing these composite materials.

Water consumption patterns also differ significantly between these technologies. Metal hydride production typically requires substantial water for processing and cooling during manufacturing, while compressed storage systems generally have lower water requirements during production but may need water for pressure testing and quality control.

Land use impacts vary as well, with metal hydride systems potentially contributing to habitat disruption through mining activities, while compressed storage systems may require more robust safety zones during operation due to the high pressures involved, potentially increasing their spatial footprint in urban or industrial settings.

Metal hydride storage systems demonstrate significant environmental advantages in operational phases due to their lower energy requirements for hydrogen compression. These systems typically operate at pressures below 30 bar, requiring substantially less compression energy than conventional compressed storage systems that operate at 350-700 bar. This operational efficiency translates to reduced greenhouse gas emissions during the use phase, particularly when the electricity for compression comes from carbon-intensive sources.

However, the production phase of metal hydride systems presents notable environmental challenges. The extraction and processing of rare earth elements and specialized alloys used in these systems often involve energy-intensive mining operations and chemical processes that generate significant emissions and waste. Additionally, these materials frequently originate from regions with less stringent environmental regulations, potentially resulting in habitat destruction, water pollution, and soil contamination.

Compressed hydrogen storage systems, while simpler in material composition, require high-strength materials like carbon fiber composites or specialized steel alloys to withstand extreme pressures. The manufacturing of these materials involves substantial energy consumption and chemical processes that contribute to their environmental footprint. The carbon fiber production process, in particular, is associated with high emissions of volatile organic compounds and energy-intensive heating processes.

End-of-life considerations reveal further distinctions between these technologies. Metal hydride systems contain valuable materials that can be recovered and recycled, potentially reducing their life-cycle environmental impact if effective recycling infrastructure exists. Conversely, compressed storage systems, especially those utilizing carbon fiber composites, present significant recycling challenges due to the difficulty in separating and processing these composite materials.

Water consumption patterns also differ significantly between these technologies. Metal hydride production typically requires substantial water for processing and cooling during manufacturing, while compressed storage systems generally have lower water requirements during production but may need water for pressure testing and quality control.

Land use impacts vary as well, with metal hydride systems potentially contributing to habitat disruption through mining activities, while compressed storage systems may require more robust safety zones during operation due to the high pressures involved, potentially increasing their spatial footprint in urban or industrial settings.

Economic Viability and ROI Analysis

The economic viability of metal hydride storage systems compared to compressed hydrogen storage presents a complex landscape of initial investments, operational costs, and long-term returns. Initial capital expenditure for metal hydride systems typically exceeds that of compressed storage by 15-30%, primarily due to the specialized materials and manufacturing processes required for hydride containers. However, this cost differential has been narrowing at approximately 5% annually as manufacturing scales increase and material science advances.

Operational expenditure analysis reveals that metal hydride systems demonstrate superior efficiency in energy consumption during the charging and discharging cycles. Studies indicate potential energy savings of 18-24% compared to compression-based alternatives, translating to reduced electricity costs over the system lifetime. Additionally, maintenance requirements for metal hydride systems are generally less intensive, with estimated 12-15% lower maintenance costs due to fewer moving parts and reduced mechanical stress.

The return on investment calculations show that metal hydride systems typically reach break-even points between 4-7 years, depending on usage intensity and energy prices. For high-throughput industrial applications, this timeline can be shortened to 3-5 years. Compressed storage systems, while requiring lower initial investment, often demonstrate longer payback periods of 5-9 years when total lifecycle costs are considered.

Sensitivity analysis indicates that metal hydride systems become increasingly economically advantageous as energy prices rise, with each 10% increase in electricity costs improving the relative ROI of metal hydride systems by approximately 3-4%. Conversely, in regions with exceptionally low energy costs, compressed storage may maintain economic advantages for longer operational periods.

The scalability factor significantly impacts economic viability. Metal hydride systems demonstrate more favorable economics at medium scales (100-1000 kg H₂ storage capacity), while compressed systems maintain advantages at both smaller and larger extremes of the scale spectrum. This creates distinct market segments where each technology demonstrates optimal economic performance.

Risk assessment models suggest that metal hydride systems carry lower financial risk related to safety incidents and regulatory compliance, potentially reducing insurance premiums by 8-12% compared to high-pressure compressed storage. This risk differential represents an often overlooked component of the total economic equation that favors metal hydride technology in certain regulatory environments.

Operational expenditure analysis reveals that metal hydride systems demonstrate superior efficiency in energy consumption during the charging and discharging cycles. Studies indicate potential energy savings of 18-24% compared to compression-based alternatives, translating to reduced electricity costs over the system lifetime. Additionally, maintenance requirements for metal hydride systems are generally less intensive, with estimated 12-15% lower maintenance costs due to fewer moving parts and reduced mechanical stress.

The return on investment calculations show that metal hydride systems typically reach break-even points between 4-7 years, depending on usage intensity and energy prices. For high-throughput industrial applications, this timeline can be shortened to 3-5 years. Compressed storage systems, while requiring lower initial investment, often demonstrate longer payback periods of 5-9 years when total lifecycle costs are considered.

Sensitivity analysis indicates that metal hydride systems become increasingly economically advantageous as energy prices rise, with each 10% increase in electricity costs improving the relative ROI of metal hydride systems by approximately 3-4%. Conversely, in regions with exceptionally low energy costs, compressed storage may maintain economic advantages for longer operational periods.

The scalability factor significantly impacts economic viability. Metal hydride systems demonstrate more favorable economics at medium scales (100-1000 kg H₂ storage capacity), while compressed systems maintain advantages at both smaller and larger extremes of the scale spectrum. This creates distinct market segments where each technology demonstrates optimal economic performance.

Risk assessment models suggest that metal hydride systems carry lower financial risk related to safety incidents and regulatory compliance, potentially reducing insurance premiums by 8-12% compared to high-pressure compressed storage. This risk differential represents an often overlooked component of the total economic equation that favors metal hydride technology in certain regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!