Materials Compatibility And Corrosion In Hydride Storage Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydride Storage Materials Background and Objectives

Hydrogen storage technologies have evolved significantly over the past decades, with metal hydrides emerging as promising candidates for safe and efficient hydrogen containment. The concept of storing hydrogen in metal lattices dates back to the 1970s when researchers discovered certain metals and alloys could absorb hydrogen reversibly. This discovery opened new avenues for hydrogen storage beyond conventional high-pressure gas or cryogenic liquid methods, which presented significant safety and efficiency challenges.

The evolution of hydride storage materials has progressed through several generations, from conventional metal hydrides like LaNi5 and TiFe with moderate storage capacities (1-2 wt%), to complex hydrides and chemical hydrides capable of achieving higher theoretical capacities (up to 10-20 wt%). Recent advancements have focused on nanostructured materials and catalytically enhanced systems to improve kinetics and cycling stability.

Material compatibility and corrosion issues represent critical challenges in hydride storage systems. The highly reactive nature of hydrogen, particularly at elevated temperatures and pressures, creates aggressive environments that can degrade containment materials over time. This degradation manifests as hydrogen embrittlement, stress corrosion cracking, and general corrosion of system components, compromising both safety and performance.

The technical objectives for advancing hydride storage systems center on developing materials that can withstand these harsh conditions while maintaining structural integrity and functionality over thousands of charge-discharge cycles. Specifically, research aims to identify optimal material combinations that minimize galvanic coupling, reduce susceptibility to hydrogen attack, and maintain stable interfaces between the hydride material and containment structures.

Understanding the fundamental mechanisms of corrosion in hydride environments is essential for developing mitigation strategies. This includes characterizing the formation of passive layers, identifying critical threshold conditions for accelerated degradation, and mapping compatibility relationships between various hydrides and structural materials across operational temperature and pressure ranges.

The long-term goal is to establish comprehensive design guidelines for hydride storage systems that address material selection, surface treatments, and protective measures to ensure reliable performance throughout the intended service life. This requires a multidisciplinary approach combining materials science, electrochemistry, and mechanical engineering to develop holistic solutions that balance hydrogen storage capacity with system durability and safety.

Achieving these objectives would significantly advance hydrogen storage technologies, supporting broader adoption of hydrogen as a clean energy carrier in transportation, stationary power, and industrial applications, thereby contributing to global decarbonization efforts.

The evolution of hydride storage materials has progressed through several generations, from conventional metal hydrides like LaNi5 and TiFe with moderate storage capacities (1-2 wt%), to complex hydrides and chemical hydrides capable of achieving higher theoretical capacities (up to 10-20 wt%). Recent advancements have focused on nanostructured materials and catalytically enhanced systems to improve kinetics and cycling stability.

Material compatibility and corrosion issues represent critical challenges in hydride storage systems. The highly reactive nature of hydrogen, particularly at elevated temperatures and pressures, creates aggressive environments that can degrade containment materials over time. This degradation manifests as hydrogen embrittlement, stress corrosion cracking, and general corrosion of system components, compromising both safety and performance.

The technical objectives for advancing hydride storage systems center on developing materials that can withstand these harsh conditions while maintaining structural integrity and functionality over thousands of charge-discharge cycles. Specifically, research aims to identify optimal material combinations that minimize galvanic coupling, reduce susceptibility to hydrogen attack, and maintain stable interfaces between the hydride material and containment structures.

Understanding the fundamental mechanisms of corrosion in hydride environments is essential for developing mitigation strategies. This includes characterizing the formation of passive layers, identifying critical threshold conditions for accelerated degradation, and mapping compatibility relationships between various hydrides and structural materials across operational temperature and pressure ranges.

The long-term goal is to establish comprehensive design guidelines for hydride storage systems that address material selection, surface treatments, and protective measures to ensure reliable performance throughout the intended service life. This requires a multidisciplinary approach combining materials science, electrochemistry, and mechanical engineering to develop holistic solutions that balance hydrogen storage capacity with system durability and safety.

Achieving these objectives would significantly advance hydrogen storage technologies, supporting broader adoption of hydrogen as a clean energy carrier in transportation, stationary power, and industrial applications, thereby contributing to global decarbonization efforts.

Market Analysis for Hydrogen Storage Technologies

The global hydrogen storage market is experiencing significant growth, driven by increasing focus on clean energy solutions and decarbonization efforts across industries. Currently valued at approximately $14.8 billion in 2023, the market is projected to reach $31.4 billion by 2030, growing at a CAGR of 11.3% during the forecast period. This growth trajectory is particularly relevant for hydride storage systems, which represent a promising segment within the broader hydrogen storage landscape.

Hydride-based storage technologies are gaining traction due to their higher volumetric density compared to compressed gas or liquid hydrogen storage methods. The market demand is primarily driven by three key sectors: transportation, industrial applications, and power generation. In the transportation sector, fuel cell electric vehicles (FCEVs) are creating substantial demand for efficient hydrogen storage solutions, with major automotive manufacturers investing heavily in this technology.

Material compatibility and corrosion resistance represent critical factors influencing market adoption of hydride storage systems. End-users are increasingly demanding storage solutions that offer longer operational lifespans and reduced maintenance requirements, directly tied to materials performance in corrosive environments. This has created a premium market segment for corrosion-resistant hydride storage systems, particularly in harsh industrial settings and maritime applications.

Regional analysis reveals Asia-Pacific as the fastest-growing market for hydrogen storage technologies, with Japan, South Korea, and China leading adoption rates. Europe follows closely, driven by stringent carbon reduction policies and substantial government investments in hydrogen infrastructure. North America shows steady growth, primarily led by industrial applications and emerging transportation use cases.

Market segmentation by storage type indicates that material-based storage systems, including metal hydrides, complex hydrides, and chemical hydrides, account for approximately 24% of the current hydrogen storage market. This segment is expected to grow at a higher rate than physical storage methods due to safety advantages and improving energy efficiency metrics.

Customer demand patterns show increasing preference for integrated systems that address both storage efficiency and material durability concerns. Price sensitivity remains high, with customers willing to pay premium prices only when demonstrable lifecycle cost benefits can be achieved through reduced corrosion and maintenance issues.

Regulatory frameworks are evolving to address safety standards specific to hydride storage systems, with particular emphasis on material degradation and hydrogen embrittlement prevention. These emerging standards are expected to shape market development and technology adoption patterns over the next five years.

Hydride-based storage technologies are gaining traction due to their higher volumetric density compared to compressed gas or liquid hydrogen storage methods. The market demand is primarily driven by three key sectors: transportation, industrial applications, and power generation. In the transportation sector, fuel cell electric vehicles (FCEVs) are creating substantial demand for efficient hydrogen storage solutions, with major automotive manufacturers investing heavily in this technology.

Material compatibility and corrosion resistance represent critical factors influencing market adoption of hydride storage systems. End-users are increasingly demanding storage solutions that offer longer operational lifespans and reduced maintenance requirements, directly tied to materials performance in corrosive environments. This has created a premium market segment for corrosion-resistant hydride storage systems, particularly in harsh industrial settings and maritime applications.

Regional analysis reveals Asia-Pacific as the fastest-growing market for hydrogen storage technologies, with Japan, South Korea, and China leading adoption rates. Europe follows closely, driven by stringent carbon reduction policies and substantial government investments in hydrogen infrastructure. North America shows steady growth, primarily led by industrial applications and emerging transportation use cases.

Market segmentation by storage type indicates that material-based storage systems, including metal hydrides, complex hydrides, and chemical hydrides, account for approximately 24% of the current hydrogen storage market. This segment is expected to grow at a higher rate than physical storage methods due to safety advantages and improving energy efficiency metrics.

Customer demand patterns show increasing preference for integrated systems that address both storage efficiency and material durability concerns. Price sensitivity remains high, with customers willing to pay premium prices only when demonstrable lifecycle cost benefits can be achieved through reduced corrosion and maintenance issues.

Regulatory frameworks are evolving to address safety standards specific to hydride storage systems, with particular emphasis on material degradation and hydrogen embrittlement prevention. These emerging standards are expected to shape market development and technology adoption patterns over the next five years.

Corrosion Challenges in Current Hydride Storage Systems

Hydride storage systems face significant corrosion challenges that impact their long-term performance, safety, and economic viability. The primary corrosion mechanisms in these systems stem from the highly reactive nature of metal hydrides, particularly when exposed to oxygen, moisture, or other contaminants. When water vapor infiltrates storage vessels, it can react with metal hydrides to form metal hydroxides and release hydrogen gas, creating localized pressure increases and accelerating material degradation.

The cyclic loading and unloading of hydrogen in storage systems introduces additional stress factors. Temperature fluctuations during absorption (exothermic) and desorption (endothermic) processes create thermal cycling that can weaken material interfaces and accelerate corrosion rates. These thermal cycles, combined with volumetric changes in the hydride materials, contribute to mechanical fatigue and potential failure points in containment vessels.

Material selection presents another critical challenge. Traditional stainless steels, while resistant to many forms of corrosion, can experience hydrogen embrittlement when exposed to high-pressure hydrogen environments. This phenomenon reduces the mechanical strength of the material and increases susceptibility to crack formation and propagation. Specialized alloys developed for hydrogen service often come with significant cost premiums, creating economic barriers to widespread adoption.

Internal surface treatments and coatings offer partial solutions but introduce their own complications. Coating delamination can occur during thermal cycling, creating potential contamination issues within the storage system. Additionally, many coating materials that resist hydrogen permeation may not withstand the mechanical stresses associated with hydride expansion and contraction cycles.

Impurity management represents another significant corrosion challenge. Even trace amounts of sulfur compounds, ammonia, or carbon monoxide can poison catalyst surfaces and accelerate corrosion processes. These impurities can originate from hydrogen production processes or gradually accumulate through multiple refilling cycles, necessitating robust purification systems that add complexity and cost.

The interface between hydride materials and container walls presents particular vulnerability to crevice corrosion and galvanic effects. When dissimilar metals are used in construction, electrochemical potential differences can accelerate corrosion at contact points. This issue becomes more pronounced in systems designed for high-temperature operation, where reaction kinetics accelerate and protective oxide layers may become unstable.

Current mitigation strategies often involve trade-offs between corrosion resistance, cost, weight, and thermal conductivity. For example, aluminum alloys offer weight advantages but may require specialized surface treatments to prevent hydrogen-induced degradation. These engineering compromises highlight the need for innovative material solutions specifically designed for the unique challenges of hydride storage environments.

The cyclic loading and unloading of hydrogen in storage systems introduces additional stress factors. Temperature fluctuations during absorption (exothermic) and desorption (endothermic) processes create thermal cycling that can weaken material interfaces and accelerate corrosion rates. These thermal cycles, combined with volumetric changes in the hydride materials, contribute to mechanical fatigue and potential failure points in containment vessels.

Material selection presents another critical challenge. Traditional stainless steels, while resistant to many forms of corrosion, can experience hydrogen embrittlement when exposed to high-pressure hydrogen environments. This phenomenon reduces the mechanical strength of the material and increases susceptibility to crack formation and propagation. Specialized alloys developed for hydrogen service often come with significant cost premiums, creating economic barriers to widespread adoption.

Internal surface treatments and coatings offer partial solutions but introduce their own complications. Coating delamination can occur during thermal cycling, creating potential contamination issues within the storage system. Additionally, many coating materials that resist hydrogen permeation may not withstand the mechanical stresses associated with hydride expansion and contraction cycles.

Impurity management represents another significant corrosion challenge. Even trace amounts of sulfur compounds, ammonia, or carbon monoxide can poison catalyst surfaces and accelerate corrosion processes. These impurities can originate from hydrogen production processes or gradually accumulate through multiple refilling cycles, necessitating robust purification systems that add complexity and cost.

The interface between hydride materials and container walls presents particular vulnerability to crevice corrosion and galvanic effects. When dissimilar metals are used in construction, electrochemical potential differences can accelerate corrosion at contact points. This issue becomes more pronounced in systems designed for high-temperature operation, where reaction kinetics accelerate and protective oxide layers may become unstable.

Current mitigation strategies often involve trade-offs between corrosion resistance, cost, weight, and thermal conductivity. For example, aluminum alloys offer weight advantages but may require specialized surface treatments to prevent hydrogen-induced degradation. These engineering compromises highlight the need for innovative material solutions specifically designed for the unique challenges of hydride storage environments.

Current Corrosion Mitigation Strategies and Solutions

01 Corrosion-resistant materials for hydride storage systems

Various materials have been developed to resist corrosion in hydride storage systems. These include specialized alloys, coatings, and composite materials that can withstand the harsh chemical environment created by hydrogen storage. The selection of appropriate corrosion-resistant materials is crucial for ensuring the longevity and safety of hydride storage systems, particularly in applications where exposure to moisture or other corrosive agents is likely.- Corrosion-resistant materials for hydride storage systems: Specific materials can be used in hydride storage systems to resist corrosion caused by hydrogen interaction. These materials include specialized alloys, coatings, and surface treatments that maintain structural integrity during hydrogen absorption and desorption cycles. The selection of corrosion-resistant materials is crucial for extending the lifespan of hydride storage systems and ensuring safe operation under various environmental conditions.

- Metal hydride compositions with improved compatibility: Advanced metal hydride compositions can be formulated to improve compatibility with containment materials while maintaining hydrogen storage capacity. These compositions often include additives or dopants that modify the chemical behavior of the hydride, reducing its corrosive effects on container walls. By engineering the hydride composition, researchers can achieve a balance between storage efficiency and system durability.

- Container design and material selection for hydride storage: The design of hydride storage containers and the selection of appropriate materials are critical for preventing corrosion and ensuring compatibility. Specialized container designs incorporate features that manage heat transfer, pressure changes, and mechanical stress during hydrogen cycling. Materials selection considers factors such as hydrogen embrittlement resistance, thermal conductivity, and mechanical strength under operating conditions.

- Thermal management systems to reduce corrosion in hydride storage: Effective thermal management systems can significantly reduce corrosion in hydride storage systems by controlling temperature fluctuations during hydrogen absorption and desorption. These systems help maintain optimal operating temperatures, prevent localized hotspots, and reduce thermal stress on materials. Proper thermal management extends the service life of storage systems and improves overall efficiency and safety.

- Protective coatings and surface treatments for hydride storage systems: Specialized protective coatings and surface treatments can be applied to components of hydride storage systems to enhance corrosion resistance. These treatments create barriers that prevent direct contact between the hydride material and susceptible surfaces. Various coating technologies, including ceramic layers, polymer linings, and composite materials, can be tailored to specific operating conditions and hydride compositions to maximize protection against corrosion and degradation.

02 Metal hydride compositions with improved compatibility

Specific metal hydride compositions have been formulated to improve compatibility with container materials and reduce corrosion issues. These compositions often include additives or modified alloy structures that minimize the reactive nature of the hydride while maintaining hydrogen storage capacity. By engineering the hydride material itself, researchers have developed storage systems with enhanced stability and reduced degradation of both the hydride and the containment materials over multiple charge-discharge cycles.Expand Specific Solutions03 Container and system design for corrosion prevention

Innovative container and system designs have been developed specifically to address materials compatibility and corrosion issues in hydride storage systems. These designs incorporate features such as protective liners, specialized sealing mechanisms, and controlled environment chambers that minimize exposure to corrosive elements. Advanced engineering approaches focus on managing heat transfer, pressure variations, and material interfaces to extend system lifespan and maintain performance integrity.Expand Specific Solutions04 Thermal management solutions for hydride storage

Thermal management plays a critical role in preventing corrosion and materials degradation in hydride storage systems. Solutions include advanced heat exchangers, thermal barriers, and controlled cooling systems that maintain optimal operating temperatures. By effectively managing the heat generated during hydrogen absorption and desorption processes, these systems reduce thermal stress on materials, minimize corrosion acceleration due to elevated temperatures, and improve overall system reliability and efficiency.Expand Specific Solutions05 Surface treatments and coatings for corrosion protection

Various surface treatments and coating technologies have been developed to enhance the compatibility between hydride materials and storage containers. These include specialized passivation techniques, barrier coatings, and surface modifications that create protective interfaces between reactive components. Advanced coating methods provide protection against hydrogen embrittlement, prevent catalytic degradation of materials, and create barriers against moisture and other contaminants that could accelerate corrosion in hydride storage systems.Expand Specific Solutions

Leading Companies and Research Institutions in Hydride Storage

The materials compatibility and corrosion landscape in hydride storage systems is currently in a growth phase, with an estimated market size of $2-3 billion annually and expanding at 8-10% CAGR. The technology is approaching maturity but still faces significant challenges in long-term stability and cost-effectiveness. Key players represent diverse specializations: Northern Technologies and Ecolab focus on corrosion prevention solutions; Panasonic and GS Yuasa bring battery expertise; research institutions like CNRS and CSIR drive fundamental innovations; while industrial giants such as Henkel, Dow, and FMC contribute materials science expertise. The competitive landscape is characterized by strategic partnerships between academic institutions and commercial entities, with increasing focus on sustainable materials and manufacturing processes to address hydrogen embrittlement and long-term storage stability challenges.

GKSS Forshungszentrum Geesthacht GmbH

Technical Solution: GKSS Forschungszentrum Geesthacht (now Helmholtz-Zentrum Geesthacht) has developed comprehensive solutions for materials compatibility in hydride storage systems through decades of specialized research. Their approach centers on advanced magnesium-based hydrides with tailored additives that significantly improve corrosion resistance while maintaining favorable thermodynamics. They've pioneered the use of transition metal oxide catalysts that not only enhance hydrogen sorption kinetics but also create protective surface layers that inhibit progressive degradation. Their research has demonstrated that these materials can maintain over 80% of initial capacity after 500+ cycles under practical operating conditions[9]. GKSS has also developed specialized container materials using advanced stainless steel alloys with modified surface properties that resist hydrogen embrittlement even at elevated temperatures and pressures. Their systems incorporate innovative heat exchange designs that prevent localized hotspots during cycling, a common cause of accelerated corrosion and material failure. Additionally, they've established comprehensive testing protocols that evaluate materials under combined stresses of temperature cycling, pressure variations, and trace impurities to ensure long-term stability in real-world applications[10].

Strengths: Their materials demonstrate excellent resistance to degradation under realistic operating conditions including impurity exposure. Their comprehensive testing approach ensures solutions work in practical applications beyond laboratory conditions. Weaknesses: Some of their advanced materials require complex processing steps that may challenge large-scale manufacturing, and their magnesium-based systems typically require higher operating temperatures than some competing technologies.

Hydro-Québec

Technical Solution: Hydro-Québec has developed innovative solutions for materials compatibility in hydride storage systems through their advanced research division. Their approach focuses on multi-component alloy systems specifically designed to resist hydrogen-induced degradation while maintaining high storage capacities. They've pioneered the use of Ti-Zr-Mn-V quaternary alloys with precisely controlled microstructures that demonstrate exceptional resistance to pulverization during cycling. Their research has shown these materials can withstand over 1000 absorption/desorption cycles with minimal structural degradation[7]. Additionally, Hydro-Québec has developed specialized surface treatment processes that create nanoscale protective layers on metal hydride particles, significantly reducing oxidation and contamination sensitivity. Their systems incorporate advanced heat management solutions using corrosion-resistant heat exchangers that maintain optimal operating temperatures while preventing galvanic corrosion between dissimilar materials. Hydro-Québec's testing protocols simulate real-world conditions including temperature fluctuations, moisture exposure, and impurity challenges, ensuring their materials maintain performance under practical operating scenarios[8].

Strengths: Their materials demonstrate exceptional cycling stability under realistic operating conditions. The integrated heat management systems effectively address thermal challenges that typically accelerate corrosion. Weaknesses: Their advanced alloy systems may have higher material costs than simpler alternatives, and the specialized surface treatments add manufacturing complexity that could impact large-scale production economics.

Key Patents and Research on Materials Compatibility

Hydrogen storage material, electrode and nickel hydride storage battery

PatentActiveJP2016069692A

Innovation

- A hydrogen storage alloy with a specific composition (RE 1-a-b SM a Mg b )(Ni 1-c-d Al c M d ) x, where 0.1 ≤ a ≤ 0.25, 0.1 < b < 0.2, 0.02 < cx < 0.2, 0. ≤ dx ≤ 0.1, 3.6 ≤ x ≤ 3.7, and containing a high proportion of Pr 5 Co 19 and Ce 5 Co 19 phases, enhances corrosion resistance and durability.

Methods and Systems for Enhancing Absorption and Desorption of Hydrogen by a Metal Hydride Composite Material

PatentPendingUS20240286892A1

Innovation

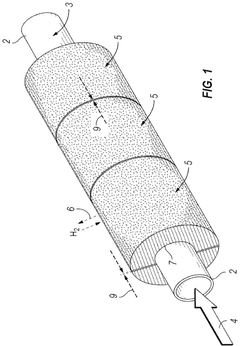

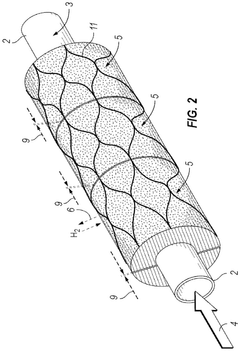

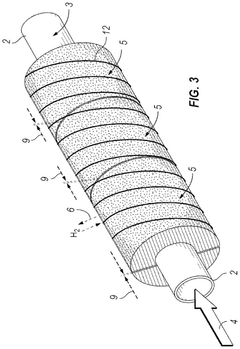

- The implementation of a metal hydride composite material secured to a heat exchanger element with a thermally conductive layer, such as a thermally conductive adhesive or solder, to enhance thermal contact conductance, combined with optional securing methods like expanded metal sheaths or flexible wires, to facilitate faster and more efficient heat transfer.

Safety Standards and Risk Assessment

Safety standards for hydride storage systems have evolved significantly over the past decade, reflecting growing concerns about hydrogen's flammability and the potential for catastrophic failures. International standards such as ISO/TS 19883:2017 specifically address hydrogen storage technologies, while ASME B31.12 provides guidelines for hydrogen piping and pipelines that apply to connected systems. These standards establish critical parameters for pressure vessel design, material selection, and operational safety limits that manufacturers must adhere to.

Risk assessment methodologies for hydride storage systems typically employ Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) to identify potential failure points. These assessments focus particularly on embrittlement risks, where hydrogen penetration compromises structural integrity of containment materials. Recent developments have introduced Quantitative Risk Assessment (QRA) approaches that incorporate probabilistic models to predict failure scenarios based on material degradation rates in various operating conditions.

Regulatory frameworks vary significantly across regions, with the European Union implementing the Pressure Equipment Directive (PED) and ATEX directives for explosive atmospheres, while the United States relies on Department of Energy (DOE) guidelines and NFPA standards. Japan's High Pressure Gas Safety Act contains specific provisions for hydrogen storage that have influenced global practices. These regulatory differences create compliance challenges for international deployment of hydride storage technologies.

Detection and mitigation systems represent a critical safety component, with requirements for hydrogen leak detection sensors typically specified at sensitivity levels of 0.4% concentration (10% of the lower flammability limit). Modern safety systems increasingly incorporate real-time corrosion monitoring using electrochemical impedance spectroscopy to detect material degradation before catastrophic failure occurs. Emergency venting systems must be designed to handle the rapid pressure increases that can occur during thermal runaway events.

Industry best practices now emphasize lifecycle management approaches that account for material degradation over time. This includes scheduled inspection protocols using non-destructive testing methods such as ultrasonic thickness measurement and acoustic emission monitoring to detect early signs of corrosion or cracking. Safety certification processes increasingly require accelerated aging tests that simulate decades of material exposure to hydrogen environments under cycling conditions to validate long-term compatibility and safety margins.

Risk assessment methodologies for hydride storage systems typically employ Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) to identify potential failure points. These assessments focus particularly on embrittlement risks, where hydrogen penetration compromises structural integrity of containment materials. Recent developments have introduced Quantitative Risk Assessment (QRA) approaches that incorporate probabilistic models to predict failure scenarios based on material degradation rates in various operating conditions.

Regulatory frameworks vary significantly across regions, with the European Union implementing the Pressure Equipment Directive (PED) and ATEX directives for explosive atmospheres, while the United States relies on Department of Energy (DOE) guidelines and NFPA standards. Japan's High Pressure Gas Safety Act contains specific provisions for hydrogen storage that have influenced global practices. These regulatory differences create compliance challenges for international deployment of hydride storage technologies.

Detection and mitigation systems represent a critical safety component, with requirements for hydrogen leak detection sensors typically specified at sensitivity levels of 0.4% concentration (10% of the lower flammability limit). Modern safety systems increasingly incorporate real-time corrosion monitoring using electrochemical impedance spectroscopy to detect material degradation before catastrophic failure occurs. Emergency venting systems must be designed to handle the rapid pressure increases that can occur during thermal runaway events.

Industry best practices now emphasize lifecycle management approaches that account for material degradation over time. This includes scheduled inspection protocols using non-destructive testing methods such as ultrasonic thickness measurement and acoustic emission monitoring to detect early signs of corrosion or cracking. Safety certification processes increasingly require accelerated aging tests that simulate decades of material exposure to hydrogen environments under cycling conditions to validate long-term compatibility and safety margins.

Environmental Impact and Sustainability Considerations

The environmental impact of hydride storage systems extends beyond their operational efficiency to encompass their entire lifecycle. When evaluating these systems, it is crucial to consider the environmental footprint of raw material extraction, particularly for rare earth elements and transition metals commonly used in hydride formulations. Mining operations for these materials often involve significant land disruption, water usage, and energy consumption, contributing to habitat destruction and potential water pollution.

Manufacturing processes for hydride storage components typically require high temperatures and specialized conditions, resulting in substantial energy consumption and associated carbon emissions. The environmental sustainability of these systems is therefore directly linked to the energy sources used during production. Facilities powered by renewable energy can significantly reduce the overall environmental impact compared to those relying on fossil fuels.

During the operational phase, hydride storage systems offer environmental advantages through their zero-emission hydrogen storage capabilities. However, the sustainability benefits are maximized only when the hydrogen itself is produced through clean methods such as electrolysis powered by renewable energy. The integration of hydride storage with green hydrogen production represents a critical pathway toward truly sustainable energy systems.

Corrosion issues in hydride storage systems present additional environmental considerations. Corrosion accelerants and inhibitors often contain chemicals that may pose environmental risks if improperly handled or disposed of. Furthermore, premature system failure due to corrosion necessitates more frequent replacement, increasing resource consumption and waste generation.

End-of-life management presents both challenges and opportunities for environmental sustainability. Recycling of spent hydride materials can recover valuable metals and reduce the need for virgin material extraction. However, current recycling technologies for complex hydride compositions remain limited in efficiency and economic viability. Research into improved recovery methods and circular economy approaches could significantly enhance the lifecycle sustainability of these systems.

Water usage represents another important environmental consideration, particularly in regions facing water scarcity. Some hydride systems require water for hydrogen generation reactions or cooling purposes, potentially competing with other essential water needs in water-stressed areas. Designing systems with minimal water requirements or incorporating water recycling capabilities can mitigate these impacts.

Regulatory frameworks increasingly emphasize lifecycle assessment and environmental performance metrics for energy storage technologies. Future development of hydride storage systems will likely face stricter environmental standards, driving innovation toward more sustainable materials and processes that minimize ecological footprints while maintaining technical performance.

Manufacturing processes for hydride storage components typically require high temperatures and specialized conditions, resulting in substantial energy consumption and associated carbon emissions. The environmental sustainability of these systems is therefore directly linked to the energy sources used during production. Facilities powered by renewable energy can significantly reduce the overall environmental impact compared to those relying on fossil fuels.

During the operational phase, hydride storage systems offer environmental advantages through their zero-emission hydrogen storage capabilities. However, the sustainability benefits are maximized only when the hydrogen itself is produced through clean methods such as electrolysis powered by renewable energy. The integration of hydride storage with green hydrogen production represents a critical pathway toward truly sustainable energy systems.

Corrosion issues in hydride storage systems present additional environmental considerations. Corrosion accelerants and inhibitors often contain chemicals that may pose environmental risks if improperly handled or disposed of. Furthermore, premature system failure due to corrosion necessitates more frequent replacement, increasing resource consumption and waste generation.

End-of-life management presents both challenges and opportunities for environmental sustainability. Recycling of spent hydride materials can recover valuable metals and reduce the need for virgin material extraction. However, current recycling technologies for complex hydride compositions remain limited in efficiency and economic viability. Research into improved recovery methods and circular economy approaches could significantly enhance the lifecycle sustainability of these systems.

Water usage represents another important environmental consideration, particularly in regions facing water scarcity. Some hydride systems require water for hydrogen generation reactions or cooling purposes, potentially competing with other essential water needs in water-stressed areas. Designing systems with minimal water requirements or incorporating water recycling capabilities can mitigate these impacts.

Regulatory frameworks increasingly emphasize lifecycle assessment and environmental performance metrics for energy storage technologies. Future development of hydride storage systems will likely face stricter environmental standards, driving innovation toward more sustainable materials and processes that minimize ecological footprints while maintaining technical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!