Thermal Management And Heat Exchanger Design In Hydride Tanks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydride Tank Thermal Management Background and Objectives

Hydrogen storage through metal hydrides represents a significant advancement in clean energy systems, offering a safer alternative to compressed gas storage. The evolution of this technology dates back to the 1970s when researchers first identified certain metal alloys capable of absorbing hydrogen at moderate pressures and temperatures. Over subsequent decades, the field has progressed from basic laboratory demonstrations to practical applications in various sectors including transportation, stationary power generation, and portable electronics.

The fundamental challenge in hydride tank thermal management stems from the thermodynamic nature of hydrogen absorption and desorption processes. Hydrogen absorption is exothermic, releasing substantial heat that must be efficiently removed to maintain optimal operating conditions. Conversely, desorption is endothermic, requiring heat input to sustain the reaction. This bidirectional thermal management requirement creates unique engineering challenges that conventional heat exchanger designs struggle to address effectively.

Recent technological trends indicate a shift toward more sophisticated thermal management systems that integrate multiple cooling and heating mechanisms. Advanced computational fluid dynamics modeling has enabled more precise prediction of heat transfer patterns within hydride beds, leading to optimized heat exchanger geometries. Additionally, the development of novel hydride materials with improved thermal conductivity has opened new possibilities for system design and efficiency improvements.

The primary technical objectives for hydride tank thermal management include achieving uniform temperature distribution throughout the hydride bed, minimizing thermal gradients that can lead to uneven hydrogen absorption/desorption, and reducing the overall thermal resistance between the hydride material and heat transfer fluid. Secondary objectives focus on system compactness, weight reduction, and cost-effectiveness to enhance commercial viability.

From an engineering perspective, the ideal thermal management system must balance contradictory requirements: it must provide sufficient thermal contact with the hydride material while allowing for volumetric expansion during hydrogen absorption, which can reach up to 25% in some materials. Furthermore, the system must maintain structural integrity under repeated thermal cycling and pressure variations.

The evolution of design approaches has progressed from simple external jacket cooling to complex internal heat exchanger networks, including finned tube designs, plate heat exchangers, and more recently, phase change material integration for passive thermal regulation. Each approach presents distinct advantages and limitations that must be evaluated within the context of specific application requirements.

The fundamental challenge in hydride tank thermal management stems from the thermodynamic nature of hydrogen absorption and desorption processes. Hydrogen absorption is exothermic, releasing substantial heat that must be efficiently removed to maintain optimal operating conditions. Conversely, desorption is endothermic, requiring heat input to sustain the reaction. This bidirectional thermal management requirement creates unique engineering challenges that conventional heat exchanger designs struggle to address effectively.

Recent technological trends indicate a shift toward more sophisticated thermal management systems that integrate multiple cooling and heating mechanisms. Advanced computational fluid dynamics modeling has enabled more precise prediction of heat transfer patterns within hydride beds, leading to optimized heat exchanger geometries. Additionally, the development of novel hydride materials with improved thermal conductivity has opened new possibilities for system design and efficiency improvements.

The primary technical objectives for hydride tank thermal management include achieving uniform temperature distribution throughout the hydride bed, minimizing thermal gradients that can lead to uneven hydrogen absorption/desorption, and reducing the overall thermal resistance between the hydride material and heat transfer fluid. Secondary objectives focus on system compactness, weight reduction, and cost-effectiveness to enhance commercial viability.

From an engineering perspective, the ideal thermal management system must balance contradictory requirements: it must provide sufficient thermal contact with the hydride material while allowing for volumetric expansion during hydrogen absorption, which can reach up to 25% in some materials. Furthermore, the system must maintain structural integrity under repeated thermal cycling and pressure variations.

The evolution of design approaches has progressed from simple external jacket cooling to complex internal heat exchanger networks, including finned tube designs, plate heat exchangers, and more recently, phase change material integration for passive thermal regulation. Each approach presents distinct advantages and limitations that must be evaluated within the context of specific application requirements.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by increasing focus on clean energy solutions and decarbonization efforts across industries. Current market valuations place the hydrogen storage sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 11-13% through 2030. Metal hydride storage systems, particularly those utilizing advanced thermal management techniques, represent a growing segment within this market.

Demand for efficient hydrogen storage solutions spans multiple sectors. The transportation industry, especially heavy-duty vehicles and material handling equipment, shows strong interest in hydride-based storage due to its volumetric efficiency advantages over compressed gas systems. Industrial applications, including power backup systems and grid stabilization, constitute another significant market segment, valued at roughly 3.5 billion USD annually.

Regional market analysis reveals Asia-Pacific as the fastest-growing market for hydrogen storage technologies, with Japan, South Korea, and China leading investments in hydride tank research and commercialization. Europe follows closely, with Germany, France, and the UK establishing ambitious hydrogen infrastructure plans that specifically address thermal management challenges in storage systems.

Market segmentation by technology shows that while compressed and liquid hydrogen storage currently dominate with approximately 70% market share, metal hydride storage systems are gaining traction due to safety advantages and improving energy density metrics. The specific sub-segment focusing on thermal management and heat exchanger design in hydride tanks is experiencing accelerated growth at 15-17% annually, outpacing the broader hydrogen storage market.

Customer requirements analysis indicates shifting priorities toward systems that can manage the exothermic absorption and endothermic desorption processes efficiently. End-users increasingly demand storage solutions with faster refueling capabilities, which directly correlates to heat exchanger efficiency in hydride tanks. Survey data from industrial customers shows that 65% rank thermal management capabilities as a "critical" or "very important" factor in purchasing decisions.

Competitive landscape assessment reveals specialized players focusing on thermal management innovations, including companies like McPhy Energy, Pragma Industries, and HydrogenPro, alongside research divisions of major industrial gas companies. Market concentration remains moderate, with the top five players controlling approximately 40% of the hydride tank segment, suggesting opportunities for new entrants with innovative thermal management solutions.

Price sensitivity analysis indicates customers are willing to pay a 15-20% premium for hydride storage systems that demonstrate superior thermal management capabilities, particularly when these improvements translate to faster refueling times and extended operational cycles.

Demand for efficient hydrogen storage solutions spans multiple sectors. The transportation industry, especially heavy-duty vehicles and material handling equipment, shows strong interest in hydride-based storage due to its volumetric efficiency advantages over compressed gas systems. Industrial applications, including power backup systems and grid stabilization, constitute another significant market segment, valued at roughly 3.5 billion USD annually.

Regional market analysis reveals Asia-Pacific as the fastest-growing market for hydrogen storage technologies, with Japan, South Korea, and China leading investments in hydride tank research and commercialization. Europe follows closely, with Germany, France, and the UK establishing ambitious hydrogen infrastructure plans that specifically address thermal management challenges in storage systems.

Market segmentation by technology shows that while compressed and liquid hydrogen storage currently dominate with approximately 70% market share, metal hydride storage systems are gaining traction due to safety advantages and improving energy density metrics. The specific sub-segment focusing on thermal management and heat exchanger design in hydride tanks is experiencing accelerated growth at 15-17% annually, outpacing the broader hydrogen storage market.

Customer requirements analysis indicates shifting priorities toward systems that can manage the exothermic absorption and endothermic desorption processes efficiently. End-users increasingly demand storage solutions with faster refueling capabilities, which directly correlates to heat exchanger efficiency in hydride tanks. Survey data from industrial customers shows that 65% rank thermal management capabilities as a "critical" or "very important" factor in purchasing decisions.

Competitive landscape assessment reveals specialized players focusing on thermal management innovations, including companies like McPhy Energy, Pragma Industries, and HydrogenPro, alongside research divisions of major industrial gas companies. Market concentration remains moderate, with the top five players controlling approximately 40% of the hydride tank segment, suggesting opportunities for new entrants with innovative thermal management solutions.

Price sensitivity analysis indicates customers are willing to pay a 15-20% premium for hydride storage systems that demonstrate superior thermal management capabilities, particularly when these improvements translate to faster refueling times and extended operational cycles.

Current Challenges in Hydride Tank Heat Exchange Technology

The thermal management of hydride tanks presents significant engineering challenges that continue to impede the widespread adoption of hydrogen storage systems. One of the primary challenges is the inherent thermodynamics of hydrogen absorption and desorption processes. The absorption of hydrogen into metal hydrides is exothermic, releasing substantial heat that must be efficiently removed to maintain optimal absorption rates. Conversely, desorption is endothermic, requiring heat input to release hydrogen at practical rates. This bidirectional thermal management requirement creates complex design constraints for heat exchanger systems.

Heat transfer efficiency within hydride beds represents another critical challenge. Metal hydride powders typically exhibit poor thermal conductivity (0.1-1.5 W/m·K), creating significant thermal gradients within the storage medium. These gradients lead to non-uniform reaction rates, reduced storage capacity, and extended fueling/defueling times. Current heat exchanger designs struggle to achieve uniform temperature distribution throughout the hydride bed, particularly in scaled-up systems where heat transfer distances increase.

Material compatibility issues further complicate heat exchanger design. The corrosive nature of many hydride materials, coupled with high operating pressures (often exceeding 350 bar) and cyclic temperature variations (typically between -40°C and 120°C), severely limits material selection. Traditional heat exchanger materials like copper and aluminum may experience degradation through hydrogen embrittlement or chemical reactions with the hydride material, compromising system integrity and performance over time.

Scale-up challenges present additional barriers to commercial implementation. Laboratory-scale heat exchanger designs that perform adequately often encounter significant efficiency losses when scaled to practical storage capacities. The surface area-to-volume ratio decreases with increasing tank size, reducing heat transfer rates and exacerbating thermal management issues. This scaling problem has proven particularly difficult to overcome in automotive and stationary storage applications.

Weight and volume constraints impose further limitations, especially in mobile applications. Effective heat exchangers typically require substantial mass and volume, directly competing with the primary goal of maximizing gravimetric and volumetric hydrogen storage density. Current designs struggle to balance thermal management requirements with the need for compact, lightweight storage systems that can meet DOE targets (5.5 wt% system-level storage and 40 g/L).

Energy efficiency concerns also persist in current systems. External heating/cooling circuits require parasitic power that reduces overall system efficiency. In automotive applications, this parasitic load can consume 10-15% of the stored hydrogen's energy content, significantly impacting vehicle range and performance. Developing passive or low-energy thermal management solutions remains an elusive goal for researchers and engineers in this field.

Heat transfer efficiency within hydride beds represents another critical challenge. Metal hydride powders typically exhibit poor thermal conductivity (0.1-1.5 W/m·K), creating significant thermal gradients within the storage medium. These gradients lead to non-uniform reaction rates, reduced storage capacity, and extended fueling/defueling times. Current heat exchanger designs struggle to achieve uniform temperature distribution throughout the hydride bed, particularly in scaled-up systems where heat transfer distances increase.

Material compatibility issues further complicate heat exchanger design. The corrosive nature of many hydride materials, coupled with high operating pressures (often exceeding 350 bar) and cyclic temperature variations (typically between -40°C and 120°C), severely limits material selection. Traditional heat exchanger materials like copper and aluminum may experience degradation through hydrogen embrittlement or chemical reactions with the hydride material, compromising system integrity and performance over time.

Scale-up challenges present additional barriers to commercial implementation. Laboratory-scale heat exchanger designs that perform adequately often encounter significant efficiency losses when scaled to practical storage capacities. The surface area-to-volume ratio decreases with increasing tank size, reducing heat transfer rates and exacerbating thermal management issues. This scaling problem has proven particularly difficult to overcome in automotive and stationary storage applications.

Weight and volume constraints impose further limitations, especially in mobile applications. Effective heat exchangers typically require substantial mass and volume, directly competing with the primary goal of maximizing gravimetric and volumetric hydrogen storage density. Current designs struggle to balance thermal management requirements with the need for compact, lightweight storage systems that can meet DOE targets (5.5 wt% system-level storage and 40 g/L).

Energy efficiency concerns also persist in current systems. External heating/cooling circuits require parasitic power that reduces overall system efficiency. In automotive applications, this parasitic load can consume 10-15% of the stored hydrogen's energy content, significantly impacting vehicle range and performance. Developing passive or low-energy thermal management solutions remains an elusive goal for researchers and engineers in this field.

State-of-the-Art Heat Exchanger Designs for Hydride Tanks

01 Cooling systems for hydride tanks

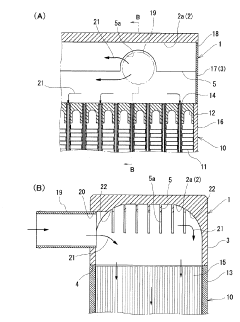

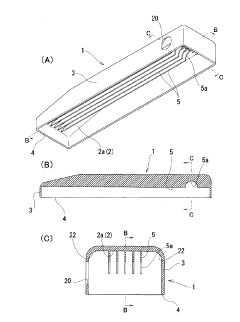

Cooling systems are essential for managing the thermal conditions of hydride tanks during hydrogen absorption, which is an exothermic process. These systems typically include heat exchangers, cooling channels, or cooling jackets that surround the hydride material to remove excess heat. Efficient cooling prevents overheating and maintains optimal operating temperatures, which is crucial for the safety and performance of hydrogen storage systems.- Cooling systems for hydride tanks: Cooling systems are essential for managing the thermal conditions of hydride tanks during hydrogen absorption, which is an exothermic process. These systems typically include heat exchangers, cooling channels, or cooling jackets that surround the hydride material to remove excess heat. Efficient cooling prevents overheating and maintains optimal operating temperatures, which is crucial for the safety and performance of hydrogen storage systems.

- Heating mechanisms for hydrogen desorption: Heating mechanisms are implemented in hydride tanks to facilitate hydrogen desorption, which is an endothermic process requiring heat input. These systems may include electric heaters, thermal fluid circulation systems, or waste heat recovery from fuel cells or engines. Controlled heating ensures efficient hydrogen release rates while maintaining appropriate pressure levels within the storage system.

- Integrated thermal management systems: Integrated thermal management systems combine heating and cooling functionalities to regulate the temperature of hydride tanks during both absorption and desorption cycles. These systems often incorporate temperature sensors, control units, and heat transfer networks that can adapt to changing operational conditions. The integration optimizes energy efficiency by balancing thermal requirements across different operating modes.

- Phase change materials for thermal buffering: Phase change materials (PCMs) are utilized in hydride tank thermal management to provide thermal buffering capabilities. These materials absorb or release heat during phase transitions, helping to stabilize temperature fluctuations during hydrogen absorption and desorption processes. PCMs can improve system efficiency by reducing the need for active cooling or heating in certain operational scenarios.

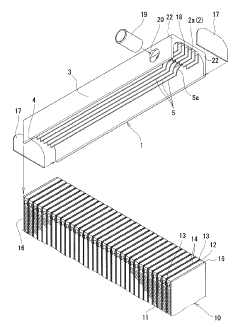

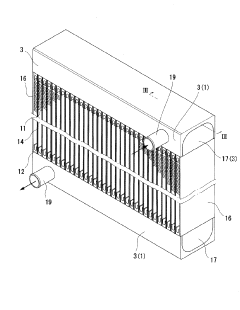

- Advanced heat exchanger designs: Advanced heat exchanger designs are developed specifically for hydride tank applications to enhance thermal conductivity and heat transfer efficiency. These designs may include finned structures, micro-channel configurations, or novel materials with high thermal conductivity. Improved heat exchanger performance allows for faster refueling times, more efficient hydrogen release, and better overall system thermal management.

02 Heating mechanisms for hydrogen release

Heating mechanisms are implemented in hydride tanks to facilitate hydrogen desorption, which is an endothermic process requiring heat input. These systems may include electric heaters, heat exchangers utilizing waste heat from fuel cells or engines, or thermal integration with other vehicle systems. Controlled heating ensures efficient hydrogen release rates to meet power demands while maintaining system stability.Expand Specific Solutions03 Integrated thermal management systems

Integrated thermal management systems for hydride tanks combine heating and cooling functionalities within a single design. These systems often feature fluid circulation channels that can carry either hot or cold fluid depending on whether hydrogen absorption or desorption is needed. The integration optimizes space utilization, reduces system complexity, and improves overall energy efficiency by enabling heat recovery between processes.Expand Specific Solutions04 Temperature monitoring and control systems

Advanced temperature monitoring and control systems are implemented to maintain optimal thermal conditions in hydride tanks. These systems utilize temperature sensors distributed throughout the tank, coupled with electronic control units that regulate cooling or heating based on real-time measurements. Precise temperature control ensures safe operation, prevents thermal runaway, and optimizes hydrogen storage capacity and release rates under varying operating conditions.Expand Specific Solutions05 Phase change materials for thermal buffering

Phase change materials (PCMs) are incorporated into hydride tank designs to provide thermal buffering capabilities. These materials absorb or release heat during phase transitions, helping to stabilize temperatures during rapid hydrogen absorption or desorption events. PCMs can reduce the size requirements for active cooling systems, improve thermal response times, and enhance overall system efficiency by storing and releasing thermal energy as needed.Expand Specific Solutions

Leading Companies in Hydride Storage Technology

The thermal management and heat exchanger design in hydride tanks market is currently in a growth phase, with increasing focus on hydrogen storage solutions for clean energy applications. The global market size is expanding rapidly, driven by hydrogen economy initiatives and decarbonization efforts. Technical maturity varies significantly among key players, with research institutions like Commissariat à l'énergie atomique, CNRS, and Helmholtz-Zentrum Hereon leading fundamental research, while industrial players such as Air Liquide, McPhy Energy, and GKN Hydrogen focus on commercialization. Major automotive companies including Honda, DENSO, and LG Energy Solution are advancing integration of these systems into vehicles. Chinese entities like Shandong University and China Petroleum & Chemical Corp are making significant investments to close the technology gap with Western counterparts.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed advanced thermal management systems for hydride tanks utilizing multi-scale heat exchanger designs. Their approach incorporates embedded heat exchangers with optimized fin structures that maximize surface contact with metal hydride materials while minimizing thermal resistance. The system employs a network of cooling channels with variable cross-sections to address non-uniform heat generation during hydrogen absorption. CEA's design includes phase-change materials integrated into the tank walls to provide passive thermal regulation during peak loading conditions. Their thermal management solution also features adaptive control systems that modulate coolant flow rates based on real-time temperature monitoring across multiple tank zones, ensuring optimal operating conditions throughout the hydrogen storage and release cycles.

Strengths: Superior thermal conductivity across the hydride bed, reducing hotspots and enabling faster refueling times. Advanced simulation capabilities for predicting thermal behavior under various operating conditions. Weaknesses: Higher manufacturing complexity and cost compared to simpler designs. Requires sophisticated control systems that add to overall system complexity.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered an innovative thermal management system for hydride tanks specifically designed for automotive applications. Their approach features a dual-circuit cooling system that separates the high-temperature absorption phase from the lower-temperature desorption phase, optimizing efficiency in both processes. The heat exchanger design incorporates aluminum microchannels with proprietary surface treatments to enhance thermal conductivity while reducing weight. Honda's system utilizes waste heat from the vehicle's powertrain during hydrogen release, while employing dedicated cooling circuits during refueling to manage the exothermic reaction heat. The design includes strategically placed temperature sensors and a sophisticated control algorithm that adjusts coolant flow based on hydrogen demand, ambient conditions, and vehicle operating state, ensuring consistent performance across varying driving scenarios.

Strengths: Lightweight design optimized for vehicle integration, excellent power density, and efficient use of existing vehicle thermal systems. Weaknesses: Performance may be limited in extreme ambient temperature conditions, and the system requires integration with vehicle cooling architecture, limiting standalone applications.

Critical Patents in Hydride Thermal Management Systems

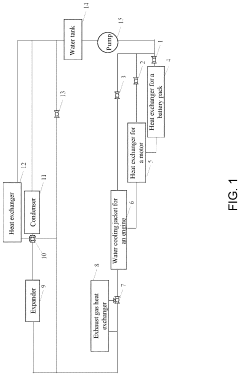

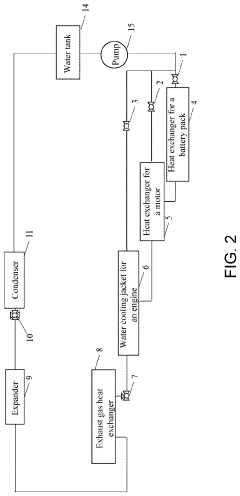

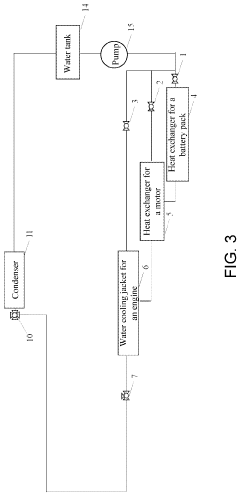

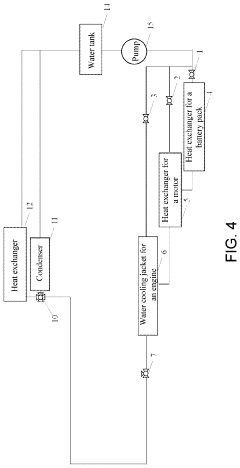

Thermal management system and method for hybrid vehicle

PatentActiveUS11319864B2

Innovation

- A thermal management system that integrates an expander, four-way valve, heat exchangers, check valves, and an air conditioner/heat pump system to manage heat across multiple components, allowing for seven operating modes to optimize heat dissipation and waste heat recovery, and includes a configuration that adjusts valve openings to control coolant flux and meet varying driving conditions.

Tank for heat exchanger and heat exchanger including the tank

PatentActiveJP2021143782A

Innovation

- The heat exchanger tank design incorporates projections or protrusions on the thick portions of the tank body to promote heat transfer and reduce temperature differences, thereby minimizing thermal stress and warping.

Safety Standards and Regulations for Hydrogen Storage Systems

The regulatory landscape for hydrogen storage systems, particularly those utilizing hydride tanks with thermal management systems, is governed by a comprehensive framework of international and regional standards. ISO 16111 serves as the cornerstone standard for transportable gas storage devices using hydrogen absorbed in reversible metal hydrides, detailing specific requirements for thermal management systems to prevent overheating during charging and discharging processes.

In the United States, the Department of Energy's Technical Targets for Onboard Hydrogen Storage Systems establishes stringent safety parameters for thermal management in hydride tanks, including maximum allowable temperature gradients and heat dissipation rates. These are complemented by NFPA 2 (Hydrogen Technologies Code), which provides detailed safety provisions for hydrogen storage systems, with specific sections addressing thermal runaway prevention and heat exchanger integrity.

European regulations, primarily through the EU Regulation 79/2009 and the UN ECE R134, mandate rigorous testing protocols for hydrogen storage systems, including thermal cycling tests and heat dissipation capacity evaluations. These standards specifically address the unique challenges of metal hydride storage systems, where thermal management is critical for both safety and performance.

The International Fire Code (IFC) and International Building Code (IBC) contain provisions for hydrogen storage facilities, with requirements for thermal isolation, ventilation systems, and emergency heat dissipation capabilities. These codes are particularly relevant for stationary hydride tank installations where heat exchanger design must account for both normal operation and emergency scenarios.

Japan's High Pressure Gas Safety Act and its associated technical standards (KHKS) provide detailed requirements for thermal management systems in hydrogen storage, reflecting the country's advanced position in hydrogen technology deployment. These standards emphasize redundancy in cooling systems and robust heat exchanger designs to prevent thermal-related failures.

Classification societies such as DNV GL have developed specialized standards for maritime applications of hydrogen storage systems, addressing the unique thermal management challenges in marine environments where ambient conditions can vary dramatically and cooling water availability fluctuates.

Emerging standards from organizations like SAE International (J2579) are increasingly focusing on the integration of advanced thermal management techniques, including phase change materials and advanced heat exchanger designs, reflecting the evolving technology landscape in hydride-based hydrogen storage systems.

In the United States, the Department of Energy's Technical Targets for Onboard Hydrogen Storage Systems establishes stringent safety parameters for thermal management in hydride tanks, including maximum allowable temperature gradients and heat dissipation rates. These are complemented by NFPA 2 (Hydrogen Technologies Code), which provides detailed safety provisions for hydrogen storage systems, with specific sections addressing thermal runaway prevention and heat exchanger integrity.

European regulations, primarily through the EU Regulation 79/2009 and the UN ECE R134, mandate rigorous testing protocols for hydrogen storage systems, including thermal cycling tests and heat dissipation capacity evaluations. These standards specifically address the unique challenges of metal hydride storage systems, where thermal management is critical for both safety and performance.

The International Fire Code (IFC) and International Building Code (IBC) contain provisions for hydrogen storage facilities, with requirements for thermal isolation, ventilation systems, and emergency heat dissipation capabilities. These codes are particularly relevant for stationary hydride tank installations where heat exchanger design must account for both normal operation and emergency scenarios.

Japan's High Pressure Gas Safety Act and its associated technical standards (KHKS) provide detailed requirements for thermal management systems in hydrogen storage, reflecting the country's advanced position in hydrogen technology deployment. These standards emphasize redundancy in cooling systems and robust heat exchanger designs to prevent thermal-related failures.

Classification societies such as DNV GL have developed specialized standards for maritime applications of hydrogen storage systems, addressing the unique thermal management challenges in marine environments where ambient conditions can vary dramatically and cooling water availability fluctuates.

Emerging standards from organizations like SAE International (J2579) are increasingly focusing on the integration of advanced thermal management techniques, including phase change materials and advanced heat exchanger designs, reflecting the evolving technology landscape in hydride-based hydrogen storage systems.

Efficiency Metrics and Performance Evaluation Methods

Evaluating the efficiency and performance of thermal management systems in hydride tanks requires comprehensive metrics and standardized testing methodologies. The hydrogen storage industry has developed several key performance indicators that serve as benchmarks for comparing different heat exchanger designs and thermal management approaches.

The primary efficiency metric for hydride tank thermal management is the effective thermal conductivity (ETC), which measures how efficiently heat transfers through the metal hydride bed. Higher ETC values indicate superior heat transfer capabilities, directly impacting hydrogen absorption and desorption rates. Industry standards typically require ETC values between 2-15 W/m·K depending on the specific application requirements.

Heat transfer coefficient (HTC) represents another critical parameter, quantifying the rate of heat exchange between the cooling/heating fluid and the hydride material. Advanced heat exchanger designs aim to maximize this coefficient, with current high-performance systems achieving HTCs of 500-2000 W/m²·K under optimal conditions.

Temperature uniformity index (TUI) has emerged as an essential metric that evaluates the homogeneity of temperature distribution throughout the hydride bed. Lower temperature gradients (high TUI values) prevent localized overheating and ensure consistent reaction kinetics across the entire storage medium.

Performance evaluation methods typically involve both experimental testing and computational validation. Standardized testing protocols include temperature response tests, where temperature sensors positioned throughout the hydride bed monitor thermal response during hydrogen charging and discharging cycles. Pressure decay measurements provide insights into absorption kinetics as a function of heat exchanger efficiency.

Computational fluid dynamics (CFD) simulations have become indispensable tools for predicting thermal behavior before physical prototyping. These models incorporate coupled heat and mass transfer equations to simulate real-world operating conditions. The accuracy of CFD predictions is typically validated against experimental data with acceptable deviation thresholds of ±5-10%.

Energy efficiency ratio (EER) calculations quantify the relationship between hydrogen storage capacity and thermal energy input requirements. This metric is particularly valuable for comparing different heat exchanger designs under identical operating conditions. Leading systems currently achieve EER values of 0.8-0.9, approaching the theoretical maximum of 1.0.

Cycle life testing evaluates long-term performance stability, with industry standards requiring minimal degradation in thermal management efficiency over 1,000+ absorption/desorption cycles. Accelerated aging tests expose systems to extreme temperature fluctuations to predict lifetime performance under various operating scenarios.

The primary efficiency metric for hydride tank thermal management is the effective thermal conductivity (ETC), which measures how efficiently heat transfers through the metal hydride bed. Higher ETC values indicate superior heat transfer capabilities, directly impacting hydrogen absorption and desorption rates. Industry standards typically require ETC values between 2-15 W/m·K depending on the specific application requirements.

Heat transfer coefficient (HTC) represents another critical parameter, quantifying the rate of heat exchange between the cooling/heating fluid and the hydride material. Advanced heat exchanger designs aim to maximize this coefficient, with current high-performance systems achieving HTCs of 500-2000 W/m²·K under optimal conditions.

Temperature uniformity index (TUI) has emerged as an essential metric that evaluates the homogeneity of temperature distribution throughout the hydride bed. Lower temperature gradients (high TUI values) prevent localized overheating and ensure consistent reaction kinetics across the entire storage medium.

Performance evaluation methods typically involve both experimental testing and computational validation. Standardized testing protocols include temperature response tests, where temperature sensors positioned throughout the hydride bed monitor thermal response during hydrogen charging and discharging cycles. Pressure decay measurements provide insights into absorption kinetics as a function of heat exchanger efficiency.

Computational fluid dynamics (CFD) simulations have become indispensable tools for predicting thermal behavior before physical prototyping. These models incorporate coupled heat and mass transfer equations to simulate real-world operating conditions. The accuracy of CFD predictions is typically validated against experimental data with acceptable deviation thresholds of ±5-10%.

Energy efficiency ratio (EER) calculations quantify the relationship between hydrogen storage capacity and thermal energy input requirements. This metric is particularly valuable for comparing different heat exchanger designs under identical operating conditions. Leading systems currently achieve EER values of 0.8-0.9, approaching the theoretical maximum of 1.0.

Cycle life testing evaluates long-term performance stability, with industry standards requiring minimal degradation in thermal management efficiency over 1,000+ absorption/desorption cycles. Accelerated aging tests expose systems to extreme temperature fluctuations to predict lifetime performance under various operating scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!