Safety Cases And Risk Assessment For Onboard Hydride Storage

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydride Storage Safety Background and Objectives

Hydrogen storage technologies have evolved significantly over the past decades, with metal hydrides emerging as a promising solution for onboard hydrogen storage in various applications, particularly in the transportation sector. The development of hydride storage systems dates back to the 1970s when researchers began exploring alternatives to conventional compressed gas and cryogenic liquid hydrogen storage methods. Metal hydrides offer advantages in terms of volumetric hydrogen density and operational safety at moderate pressures, making them attractive for mobile applications.

The evolution of hydride storage technology has been driven by the global push toward decarbonization and the increasing interest in hydrogen as a clean energy carrier. Early metal hydride systems suffered from limitations including low gravimetric capacity, slow kinetics, and high costs. However, recent advancements in material science and engineering have led to significant improvements in these areas, with novel complex hydrides and nanostructured materials showing promising performance characteristics.

The primary technical objective in hydride storage safety research is to develop comprehensive safety protocols and risk assessment methodologies specifically tailored for onboard hydride storage systems. This includes identifying potential failure modes, understanding reaction mechanisms during normal and abnormal operating conditions, and establishing safety margins that account for the unique properties of different hydride materials. The goal is to ensure that hydride-based hydrogen storage systems can meet or exceed the safety standards established for conventional fuel systems.

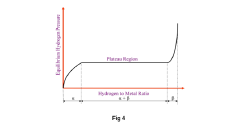

Another critical objective is to quantify and mitigate risks associated with thermal management during hydrogen absorption and desorption processes. Metal hydrides typically release significant heat during hydrogen absorption (exothermic reaction) and require heat input during desorption (endothermic reaction). Improper thermal management can lead to safety hazards including pressure buildup, material degradation, and in extreme cases, containment failure.

The research also aims to address safety concerns related to material stability over extended cycling, potential contamination effects, and behavior under extreme environmental conditions such as high temperatures, physical impact, or exposure to fire. Understanding these aspects is essential for developing robust safety cases that can satisfy regulatory requirements and build public confidence in hydrogen technologies.

Furthermore, the technical objectives include the development of advanced sensing and monitoring systems capable of detecting early signs of system malfunction or degradation, as well as establishing standardized testing protocols that can accurately assess the safety performance of different hydride storage systems under realistic operating scenarios. These efforts are crucial for facilitating the commercial deployment of hydride-based hydrogen storage technologies across various applications.

The evolution of hydride storage technology has been driven by the global push toward decarbonization and the increasing interest in hydrogen as a clean energy carrier. Early metal hydride systems suffered from limitations including low gravimetric capacity, slow kinetics, and high costs. However, recent advancements in material science and engineering have led to significant improvements in these areas, with novel complex hydrides and nanostructured materials showing promising performance characteristics.

The primary technical objective in hydride storage safety research is to develop comprehensive safety protocols and risk assessment methodologies specifically tailored for onboard hydride storage systems. This includes identifying potential failure modes, understanding reaction mechanisms during normal and abnormal operating conditions, and establishing safety margins that account for the unique properties of different hydride materials. The goal is to ensure that hydride-based hydrogen storage systems can meet or exceed the safety standards established for conventional fuel systems.

Another critical objective is to quantify and mitigate risks associated with thermal management during hydrogen absorption and desorption processes. Metal hydrides typically release significant heat during hydrogen absorption (exothermic reaction) and require heat input during desorption (endothermic reaction). Improper thermal management can lead to safety hazards including pressure buildup, material degradation, and in extreme cases, containment failure.

The research also aims to address safety concerns related to material stability over extended cycling, potential contamination effects, and behavior under extreme environmental conditions such as high temperatures, physical impact, or exposure to fire. Understanding these aspects is essential for developing robust safety cases that can satisfy regulatory requirements and build public confidence in hydrogen technologies.

Furthermore, the technical objectives include the development of advanced sensing and monitoring systems capable of detecting early signs of system malfunction or degradation, as well as establishing standardized testing protocols that can accurately assess the safety performance of different hydride storage systems under realistic operating scenarios. These efforts are crucial for facilitating the commercial deployment of hydride-based hydrogen storage technologies across various applications.

Market Analysis for Onboard Hydrogen Storage Systems

The global market for onboard hydrogen storage systems is experiencing significant growth, driven by the increasing adoption of hydrogen fuel cell vehicles and the global push towards decarbonization. Current market valuations indicate that the onboard hydrogen storage market reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 9.8% through 2030, potentially reaching 2.5 billion USD by the end of the decade.

The automotive sector represents the largest application segment, accounting for roughly 65% of the total market share. This dominance is expected to continue as major automotive manufacturers including Toyota, Hyundai, and Honda expand their hydrogen fuel cell vehicle offerings. Commercial vehicles, particularly heavy-duty trucks and buses, are emerging as the fastest-growing segment due to their operational advantages with hydrogen fuel cells compared to battery electric alternatives.

Regionally, Asia-Pacific currently leads the market with approximately 45% share, primarily due to strong government support in Japan, South Korea, and increasingly China. Europe follows with 30% market share, driven by ambitious hydrogen strategies in countries like Germany, France, and the UK. North America accounts for about 20% of the market, with California leading hydrogen infrastructure development in the United States.

Metal hydride storage systems specifically represent about 18% of the current onboard hydrogen storage market, competing with compressed gas (70%) and liquid hydrogen (12%) technologies. However, hydride-based solutions are projected to grow at a faster rate of 12% annually due to their inherent safety advantages and improving volumetric efficiency.

Consumer demand patterns indicate increasing preference for vehicles with longer range capabilities, with surveys showing that 75% of potential fuel cell vehicle buyers consider range anxiety a primary concern. This creates significant market pull for advanced hydride storage systems that can offer improved gravimetric and volumetric hydrogen densities.

Market barriers include high system costs, with current metal hydride storage systems costing approximately 3-4 times more than conventional compressed hydrogen tanks on a per-kilogram basis. Limited hydrogen refueling infrastructure also remains a significant constraint, with fewer than 700 hydrogen refueling stations operational globally as of 2023.

The competitive landscape features specialized material technology companies like McPhy Energy and Pragma Industries developing proprietary metal hydride formulations, alongside larger industrial gas companies such as Air Liquide and Linde that are investing in comprehensive hydrogen mobility solutions.

The automotive sector represents the largest application segment, accounting for roughly 65% of the total market share. This dominance is expected to continue as major automotive manufacturers including Toyota, Hyundai, and Honda expand their hydrogen fuel cell vehicle offerings. Commercial vehicles, particularly heavy-duty trucks and buses, are emerging as the fastest-growing segment due to their operational advantages with hydrogen fuel cells compared to battery electric alternatives.

Regionally, Asia-Pacific currently leads the market with approximately 45% share, primarily due to strong government support in Japan, South Korea, and increasingly China. Europe follows with 30% market share, driven by ambitious hydrogen strategies in countries like Germany, France, and the UK. North America accounts for about 20% of the market, with California leading hydrogen infrastructure development in the United States.

Metal hydride storage systems specifically represent about 18% of the current onboard hydrogen storage market, competing with compressed gas (70%) and liquid hydrogen (12%) technologies. However, hydride-based solutions are projected to grow at a faster rate of 12% annually due to their inherent safety advantages and improving volumetric efficiency.

Consumer demand patterns indicate increasing preference for vehicles with longer range capabilities, with surveys showing that 75% of potential fuel cell vehicle buyers consider range anxiety a primary concern. This creates significant market pull for advanced hydride storage systems that can offer improved gravimetric and volumetric hydrogen densities.

Market barriers include high system costs, with current metal hydride storage systems costing approximately 3-4 times more than conventional compressed hydrogen tanks on a per-kilogram basis. Limited hydrogen refueling infrastructure also remains a significant constraint, with fewer than 700 hydrogen refueling stations operational globally as of 2023.

The competitive landscape features specialized material technology companies like McPhy Energy and Pragma Industries developing proprietary metal hydride formulations, alongside larger industrial gas companies such as Air Liquide and Linde that are investing in comprehensive hydrogen mobility solutions.

Technical Challenges in Hydride Storage Safety

The development of onboard hydride storage systems faces significant technical challenges related to safety and risk management. The complex nature of metal hydrides, which store hydrogen through chemical bonding, introduces unique safety concerns that differ substantially from conventional compressed gas or liquid hydrogen storage methods.

Material stability represents a primary challenge, as many metal hydrides exhibit pyrophoric properties when exposed to air or moisture. This reactivity can lead to spontaneous ignition, particularly during system failures or accidents that compromise containment integrity. The exothermic nature of hydrogen absorption processes further complicates safety management, as inadequate thermal management can trigger uncontrolled temperature increases and potential thermal runaway scenarios.

Pressure management presents another critical challenge. While hydride systems typically operate at lower pressures than compressed hydrogen tanks, they can still generate significant internal pressures during hydrogen desorption, especially under elevated temperatures. Engineering reliable pressure relief systems that function effectively under various operational and emergency conditions remains technically demanding.

Contamination sensitivity constitutes a persistent concern, as even trace impurities in hydrogen gas can progressively degrade storage capacity and kinetics of metal hydrides. This degradation may lead to unpredictable behavior during charging and discharging cycles, potentially creating hazardous conditions that are difficult to detect through conventional monitoring systems.

The integration of hydride storage systems into vehicles introduces additional complexities related to vibration, shock resistance, and crash safety. The mechanical integrity of hydride beds must be maintained under diverse driving conditions and potential accident scenarios, requiring advanced structural design and robust containment strategies that can withstand significant physical impacts.

Thermal management systems for hydride storage face particular challenges in balancing efficient hydrogen release with safe operating temperatures. The design must prevent localized hotspots during rapid hydrogen charging or discharging, while simultaneously ensuring sufficient heat transfer for practical hydrogen release rates during normal operation.

Detection and monitoring technologies for hydride-based systems remain underdeveloped compared to conventional hydrogen storage methods. Current sensor technologies struggle to provide reliable, real-time data on the state of hydride materials, hydrogen content, and early warning of potential failure modes, creating significant gaps in safety monitoring capabilities.

Standardized testing protocols specifically designed for hydride storage systems are largely absent from regulatory frameworks, complicating safety certification processes. The development of appropriate accelerated aging tests, failure mode analyses, and performance degradation assessments represents a substantial technical challenge that must be addressed to enable widespread adoption of this technology.

Material stability represents a primary challenge, as many metal hydrides exhibit pyrophoric properties when exposed to air or moisture. This reactivity can lead to spontaneous ignition, particularly during system failures or accidents that compromise containment integrity. The exothermic nature of hydrogen absorption processes further complicates safety management, as inadequate thermal management can trigger uncontrolled temperature increases and potential thermal runaway scenarios.

Pressure management presents another critical challenge. While hydride systems typically operate at lower pressures than compressed hydrogen tanks, they can still generate significant internal pressures during hydrogen desorption, especially under elevated temperatures. Engineering reliable pressure relief systems that function effectively under various operational and emergency conditions remains technically demanding.

Contamination sensitivity constitutes a persistent concern, as even trace impurities in hydrogen gas can progressively degrade storage capacity and kinetics of metal hydrides. This degradation may lead to unpredictable behavior during charging and discharging cycles, potentially creating hazardous conditions that are difficult to detect through conventional monitoring systems.

The integration of hydride storage systems into vehicles introduces additional complexities related to vibration, shock resistance, and crash safety. The mechanical integrity of hydride beds must be maintained under diverse driving conditions and potential accident scenarios, requiring advanced structural design and robust containment strategies that can withstand significant physical impacts.

Thermal management systems for hydride storage face particular challenges in balancing efficient hydrogen release with safe operating temperatures. The design must prevent localized hotspots during rapid hydrogen charging or discharging, while simultaneously ensuring sufficient heat transfer for practical hydrogen release rates during normal operation.

Detection and monitoring technologies for hydride-based systems remain underdeveloped compared to conventional hydrogen storage methods. Current sensor technologies struggle to provide reliable, real-time data on the state of hydride materials, hydrogen content, and early warning of potential failure modes, creating significant gaps in safety monitoring capabilities.

Standardized testing protocols specifically designed for hydride storage systems are largely absent from regulatory frameworks, complicating safety certification processes. The development of appropriate accelerated aging tests, failure mode analyses, and performance degradation assessments represents a substantial technical challenge that must be addressed to enable widespread adoption of this technology.

Current Risk Assessment Methodologies for Hydride Systems

01 Safety systems for onboard hydride storage

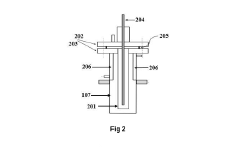

Various safety systems are designed to protect onboard hydride storage systems from hazards. These include monitoring systems that detect leaks, pressure changes, or temperature fluctuations, and automatically trigger safety protocols. Advanced sensors and control mechanisms can isolate storage compartments in case of emergency, preventing cascading failures. These safety systems are crucial for vehicles and vessels using hydrogen as fuel, ensuring that the highly flammable nature of hydrogen is properly managed.- Safety systems for onboard metal hydride storage: Metal hydride storage systems for vehicles require specialized safety mechanisms to prevent hazards during operation. These systems include pressure relief devices, temperature monitoring, and containment structures designed to withstand impact and prevent hydrogen leakage. Advanced sensors continuously monitor storage conditions to detect anomalies before they become dangerous, while isolation systems can quickly seal off hydrogen storage in emergency situations.

- Thermal management for hydride storage safety: Effective thermal management is critical for safe onboard hydride storage as hydrogen absorption and desorption processes generate significant heat. Cooling systems prevent overheating during charging, while heating systems maintain optimal operating temperatures during discharge. These thermal control mechanisms include liquid cooling circuits, heat exchangers, and insulation materials that protect against external temperature fluctuations and prevent thermal runaway scenarios.

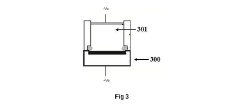

- Structural integrity and crash protection: Hydride storage vessels require robust structural design to maintain integrity during vehicle collisions or accidents. Reinforced containers with impact-absorbing materials protect the hydride material from physical damage. Specialized mounting systems isolate the storage units from vibration and shock while providing secure attachment to the vehicle frame. These protective measures prevent hydrogen release during crash scenarios and maintain system integrity under extreme conditions.

- Monitoring and control systems for hydride safety: Advanced electronic monitoring systems are essential for maintaining safe operation of onboard hydride storage. These systems include hydrogen sensors that detect leaks, pressure transducers that monitor storage conditions, and integrated control units that manage the entire hydrogen storage system. Real-time data analysis allows for predictive maintenance and automatic safety responses, while user interfaces provide operators with system status information and safety alerts.

- Material improvements for safer hydride storage: Research into advanced hydride materials focuses on improving safety characteristics while maintaining hydrogen storage capacity. These materials feature enhanced thermal stability, reduced pyrophoricity, and improved resistance to contamination. Composite hydride materials incorporate stabilizers and catalysts that improve hydrogen release characteristics under controlled conditions while reducing reactivity during abnormal conditions. Nanostructured hydrides offer improved kinetics and safety through controlled hydrogen binding energies.

02 Thermal management for hydride storage

Effective thermal management is essential for safe onboard hydride storage. Metal hydrides release heat during hydrogen absorption and require heat during desorption. Systems include cooling mechanisms to prevent overheating during charging and heating elements to facilitate hydrogen release. Temperature control systems maintain optimal operating conditions and prevent thermal runaway scenarios. Proper insulation and heat exchange systems are incorporated to manage the exothermic and endothermic reactions associated with hydrogen storage in metal hydrides.Expand Specific Solutions03 Structural integrity and containment solutions

Specialized containment vessels and structural designs ensure the physical integrity of hydride storage systems under various conditions. These include reinforced tanks that can withstand impacts, pressure variations, and vibrations encountered during vehicle operation. Compartmentalization strategies isolate hydride materials to prevent catastrophic failures. Materials selected for containment vessels offer resistance to hydrogen embrittlement and maintain structural integrity over the system's operational lifetime, even under extreme conditions such as accidents or collisions.Expand Specific Solutions04 Integration with fuel cell systems

Safe integration of hydride storage with fuel cell systems involves specialized interfaces and control mechanisms. These systems manage hydrogen flow between storage and fuel cells, ensuring consistent supply while maintaining safety parameters. Pressure regulation systems prevent dangerous buildup or sudden releases of hydrogen. Emergency shutdown capabilities can quickly isolate the hydride storage from the fuel cell in case of system failures. The integration design considers the entire hydrogen pathway from storage to consumption to prevent leaks or uncontrolled reactions.Expand Specific Solutions05 Advanced hydride materials for safer storage

Development of advanced hydride materials focuses on improving safety characteristics while maintaining or enhancing storage capacity. These materials feature reduced pyrophoricity, improved stability under varying conditions, and optimized hydrogen release rates. Complex hydrides and nanostructured materials offer improved safety profiles compared to traditional metal hydrides. Research includes creating composite materials that combine high storage capacity with inherent safety features such as reduced reactivity with air and moisture, making them more suitable for onboard applications in various transportation modes.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Solutions

The onboard hydride storage safety and risk assessment landscape is evolving rapidly, with the market currently in a growth phase as hydrogen gains traction as a clean energy carrier. The global market is expanding, driven by automotive and maritime applications, with companies like Toyota Motor Corporation leading technological advancement through extensive R&D investments. The technology maturity varies across sectors, with automotive applications more developed than maritime implementations. Key players demonstrate different maturity levels: Toyota and Commissariat à l'énergie atomique show advanced capabilities in hydride storage systems, while shipbuilding companies like Hudong-Zhonghua and Jiangnan Shipyard are integrating these technologies into marine applications. Research institutions including Battelle Memorial Institute and Savannah River Nuclear Solutions are advancing fundamental safety protocols, creating a competitive ecosystem balancing commercial deployment with ongoing safety innovation.

Battelle Memorial Institute

Technical Solution: Battelle has pioneered comprehensive safety assessment methodologies specifically for hydride-based hydrogen storage systems. Their approach integrates probabilistic risk assessment (PRA) with experimental validation to quantify failure modes and consequences. Battelle's safety case framework addresses the unique characteristics of metal hydrides, including thermal management during absorption/desorption cycles, potential for pyrophoric reactions with air if containment is breached, and material degradation over time. Their risk assessment methodology incorporates fault tree analysis, event tree analysis, and failure mode and effects analysis (FMEA) to identify critical safety scenarios. Battelle has developed specialized testing protocols that simulate extreme conditions such as external fire, mechanical impact, and over-pressurization to validate safety systems. Their approach includes quantitative risk metrics that allow for comparison between different hydride materials and system designs, enabling risk-informed decision making. Battelle's safety cases also address operational aspects including fueling procedures, maintenance protocols, and end-of-life disposal considerations for hydride materials.

Strengths: Battelle's methodology provides a comprehensive, quantitative approach to risk assessment that enables direct comparison between different storage technologies. Their extensive testing capabilities allow for validation of theoretical models with experimental data. Weaknesses: Their approach requires extensive data collection and analysis, making it resource-intensive for implementation, particularly for novel hydride materials with limited operational history.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced metal hydride storage systems for hydrogen, focusing on safety and risk mitigation. Their technology utilizes specialized alloys (typically Ti-Cr-V based) that can absorb and release hydrogen under controlled conditions. Toyota's approach includes multi-layered safety systems with thermal management controls that prevent overheating during hydrogen absorption (an exothermic process). Their safety cases incorporate fail-safe designs with pressure relief devices, temperature sensors, and isolation systems that activate during abnormal conditions. Toyota has implemented comprehensive risk assessment methodologies that address both normal operations and accident scenarios, including collision, fire, and extreme environmental conditions. Their hydride storage systems undergo rigorous testing including drop tests, penetration tests, and thermal exposure tests to validate safety performance. Toyota's risk assessment framework specifically addresses the unique properties of metal hydrides, including potential for dust explosions during maintenance and the thermal management challenges during rapid charging.

Strengths: Toyota's extensive automotive safety experience translates well to hydrogen storage systems, with proven implementation in commercial vehicles. Their integrated approach to thermal management effectively addresses one of the key safety challenges of hydride storage. Weaknesses: The systems add significant weight compared to high-pressure storage options, and the thermal management requirements increase system complexity and cost.

Critical Safety Case Studies and Technical Standards

Method of hydrogen storage and generation by thermal decomposition of magnesium using silicon nanoparticles

PatentActiveIN202421035874A

Innovation

- A method involving a mixture of Magnesium and Silicon nanoparticles for hydrogen storage and generation through thermal decomposition, where Silicon nanoparticles act as catalysts to enhance hydrogen adsorption and desorption, using ball milling to produce nanoparticles and a Sievert's type apparatus for kinetic studies.

Regulatory Framework for Hydrogen Vehicle Safety

The regulatory landscape for hydrogen vehicles represents a complex framework of international, national, and regional standards designed to ensure the safe deployment of hydrogen technology in transportation. The United Nations Economic Commission for Europe (UNECE) has established Global Technical Regulation No. 13 (GTR 13), which specifically addresses hydrogen and fuel cell vehicle safety requirements, including onboard storage systems utilizing metal hydrides. This regulation mandates rigorous testing protocols for pressure vessels, including bonfire tests, drop tests, and permeation assessments to verify containment integrity under various conditions.

In the United States, the Department of Transportation's National Highway Traffic Safety Administration (NHTSA) has incorporated elements of these international standards into Federal Motor Vehicle Safety Standards (FMVSS), while the Department of Energy has published technical reference guides for hydrogen storage systems. The Society of Automotive Engineers (SAE) has developed complementary standards, particularly SAE J2579, which outlines performance-based requirements for hydrogen fuel systems in light-duty vehicles.

The European Union has implemented Regulation (EC) No. 79/2009 and its implementing regulation (EU) No. 406/2010, which establish type-approval requirements for hydrogen-powered vehicles. These regulations specifically address metal hydride storage systems, requiring manufacturers to demonstrate compliance with safety parameters including thermal management during charging/discharging cycles, structural integrity, and hydrogen release mechanisms.

Japan's High Pressure Gas Safety Act and the associated technical standards from JARI (Japan Automobile Research Institute) provide another significant regulatory framework, with particular attention to the unique characteristics of hydride storage systems, including thermal management during hydrogen absorption and desorption processes.

China has recently strengthened its regulatory approach through GB/T standards that address hydrogen storage safety, with specific provisions for metal hydride systems that acknowledge their different risk profile compared to compressed gas storage. These standards emphasize cycle life testing and material degradation assessment.

Certification processes across these jurisdictions typically require extensive documentation of risk assessments, including Failure Mode and Effects Analysis (FMEA), Hazard and Operability Studies (HAZOP), and quantitative risk assessments that model potential release scenarios. These assessments must demonstrate that risks have been reduced to As Low As Reasonably Practicable (ALARP) levels.

Regulatory harmonization efforts are ongoing through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to standardize safety requirements globally while accommodating the unique characteristics of different hydrogen storage technologies, including the thermal management challenges specific to metal hydride systems.

In the United States, the Department of Transportation's National Highway Traffic Safety Administration (NHTSA) has incorporated elements of these international standards into Federal Motor Vehicle Safety Standards (FMVSS), while the Department of Energy has published technical reference guides for hydrogen storage systems. The Society of Automotive Engineers (SAE) has developed complementary standards, particularly SAE J2579, which outlines performance-based requirements for hydrogen fuel systems in light-duty vehicles.

The European Union has implemented Regulation (EC) No. 79/2009 and its implementing regulation (EU) No. 406/2010, which establish type-approval requirements for hydrogen-powered vehicles. These regulations specifically address metal hydride storage systems, requiring manufacturers to demonstrate compliance with safety parameters including thermal management during charging/discharging cycles, structural integrity, and hydrogen release mechanisms.

Japan's High Pressure Gas Safety Act and the associated technical standards from JARI (Japan Automobile Research Institute) provide another significant regulatory framework, with particular attention to the unique characteristics of hydride storage systems, including thermal management during hydrogen absorption and desorption processes.

China has recently strengthened its regulatory approach through GB/T standards that address hydrogen storage safety, with specific provisions for metal hydride systems that acknowledge their different risk profile compared to compressed gas storage. These standards emphasize cycle life testing and material degradation assessment.

Certification processes across these jurisdictions typically require extensive documentation of risk assessments, including Failure Mode and Effects Analysis (FMEA), Hazard and Operability Studies (HAZOP), and quantitative risk assessments that model potential release scenarios. These assessments must demonstrate that risks have been reduced to As Low As Reasonably Practicable (ALARP) levels.

Regulatory harmonization efforts are ongoing through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which aims to standardize safety requirements globally while accommodating the unique characteristics of different hydrogen storage technologies, including the thermal management challenges specific to metal hydride systems.

Environmental Impact Assessment of Hydride Storage Systems

The environmental impact assessment of hydride storage systems reveals both significant advantages and potential concerns. Hydrogen storage using metal hydrides offers substantial environmental benefits compared to conventional fossil fuel systems, primarily through zero-emission operation during use phase. When hydrogen is produced from renewable energy sources, the entire lifecycle can approach carbon neutrality, representing a critical pathway toward decarbonizing transportation and energy sectors.

Metal hydride storage systems demonstrate minimal direct environmental impacts during normal operation, with no toxic emissions or greenhouse gases released. This characteristic positions them favorably against traditional fuel storage systems that may leak volatile organic compounds or contribute to air pollution. The closed-loop nature of hydride storage systems effectively contains hydrogen, preventing environmental contamination under standard operating conditions.

However, the environmental footprint of hydride storage systems extends beyond operational phases. The production of specialized metal alloys for hydrides often involves energy-intensive mining and refining processes. Rare earth elements and specialized metals commonly used in advanced hydride formulations present particular concerns regarding resource depletion and mining impacts. Life cycle assessments indicate that the environmental burden is heavily weighted toward the manufacturing phase rather than the use phase.

Water consumption represents another environmental consideration, particularly for systems requiring cooling during hydrogen absorption processes. While water requirements are generally modest compared to many industrial processes, deployment in water-stressed regions may necessitate additional sustainability measures. Recycling potential offers a mitigating factor, as most metal hydride materials can be recovered and reprocessed at end-of-life, reducing the need for virgin material extraction.

Safety incidents involving hydride storage systems could potentially result in localized environmental impacts. Although hydrogen itself dissipates rapidly in open environments with minimal ecological effects, thermal events during system failure might release metal particulates or cause secondary environmental damage. Proper containment design and emergency response protocols are essential to minimize these risks.

From a comparative perspective, hydride storage systems generally present lower environmental risks than compressed hydrogen, cryogenic liquid hydrogen, or fossil fuel alternatives. The solid-state nature of the storage medium eliminates concerns about large-scale hydrogen or fuel leakage events. When integrated into comprehensive environmental management systems, hydride storage technologies can contribute significantly to sustainable transportation and energy solutions while minimizing ecological footprints.

Metal hydride storage systems demonstrate minimal direct environmental impacts during normal operation, with no toxic emissions or greenhouse gases released. This characteristic positions them favorably against traditional fuel storage systems that may leak volatile organic compounds or contribute to air pollution. The closed-loop nature of hydride storage systems effectively contains hydrogen, preventing environmental contamination under standard operating conditions.

However, the environmental footprint of hydride storage systems extends beyond operational phases. The production of specialized metal alloys for hydrides often involves energy-intensive mining and refining processes. Rare earth elements and specialized metals commonly used in advanced hydride formulations present particular concerns regarding resource depletion and mining impacts. Life cycle assessments indicate that the environmental burden is heavily weighted toward the manufacturing phase rather than the use phase.

Water consumption represents another environmental consideration, particularly for systems requiring cooling during hydrogen absorption processes. While water requirements are generally modest compared to many industrial processes, deployment in water-stressed regions may necessitate additional sustainability measures. Recycling potential offers a mitigating factor, as most metal hydride materials can be recovered and reprocessed at end-of-life, reducing the need for virgin material extraction.

Safety incidents involving hydride storage systems could potentially result in localized environmental impacts. Although hydrogen itself dissipates rapidly in open environments with minimal ecological effects, thermal events during system failure might release metal particulates or cause secondary environmental damage. Proper containment design and emergency response protocols are essential to minimize these risks.

From a comparative perspective, hydride storage systems generally present lower environmental risks than compressed hydrogen, cryogenic liquid hydrogen, or fossil fuel alternatives. The solid-state nature of the storage medium eliminates concerns about large-scale hydrogen or fuel leakage events. When integrated into comprehensive environmental management systems, hydride storage technologies can contribute significantly to sustainable transportation and energy solutions while minimizing ecological footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!