Rapid Refueling Protocols And Heat Sink Design For Hydride Tanks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydride Tank Refueling Technology Evolution and Objectives

Hydrogen storage in metal hydride tanks has evolved significantly over the past decades, transitioning from experimental concepts to commercially viable solutions for clean energy applications. The journey began in the 1970s with fundamental research on metal hydride properties, primarily focusing on understanding absorption and desorption mechanisms. By the 1990s, the focus shifted toward practical applications, particularly for hydrogen-powered vehicles and stationary energy storage systems.

The early 2000s marked a pivotal moment with the introduction of first-generation commercial hydride tanks, which suffered from slow refueling rates and inefficient heat management during hydrogen absorption. These limitations stemmed from the exothermic nature of the hydrogen absorption process, which generates significant heat that must be efficiently removed to maintain optimal refueling speeds.

Between 2010 and 2015, second-generation systems emerged with improved heat exchange designs, reducing refueling times from several hours to under an hour. This progress was achieved through enhanced internal heat exchanger geometries and more thermally conductive materials. The development of multi-stage cooling systems further improved performance by addressing thermal gradients within the tanks.

Current state-of-the-art technology (2020 onwards) incorporates advanced heat sink designs with phase-change materials and microstructured heat exchangers, enabling refueling times approaching 20-30 minutes for passenger vehicle applications. These improvements represent significant progress but still fall short of the 5-10 minute refueling target considered necessary for broad consumer acceptance.

The technological trajectory clearly points toward increasingly sophisticated thermal management solutions integrated with optimized refueling protocols. Recent innovations include AI-controlled variable flow rate systems that adapt to real-time temperature conditions within the tank, maximizing absorption rates while preventing overheating.

The primary objective for next-generation hydride tank technology centers on achieving sub-10-minute refueling times while maintaining safety and system longevity. This requires solving the fundamental challenge of rapid heat dissipation during the hydrogen absorption process without compromising storage capacity or increasing system complexity and cost beyond practical limits.

Secondary objectives include improving energy efficiency of the refueling process, reducing system weight and volume, enhancing durability over thousands of refueling cycles, and developing standardized protocols that can be implemented across various tank designs and applications. These goals must be achieved while meeting stringent safety standards and cost targets to enable widespread commercial adoption.

The early 2000s marked a pivotal moment with the introduction of first-generation commercial hydride tanks, which suffered from slow refueling rates and inefficient heat management during hydrogen absorption. These limitations stemmed from the exothermic nature of the hydrogen absorption process, which generates significant heat that must be efficiently removed to maintain optimal refueling speeds.

Between 2010 and 2015, second-generation systems emerged with improved heat exchange designs, reducing refueling times from several hours to under an hour. This progress was achieved through enhanced internal heat exchanger geometries and more thermally conductive materials. The development of multi-stage cooling systems further improved performance by addressing thermal gradients within the tanks.

Current state-of-the-art technology (2020 onwards) incorporates advanced heat sink designs with phase-change materials and microstructured heat exchangers, enabling refueling times approaching 20-30 minutes for passenger vehicle applications. These improvements represent significant progress but still fall short of the 5-10 minute refueling target considered necessary for broad consumer acceptance.

The technological trajectory clearly points toward increasingly sophisticated thermal management solutions integrated with optimized refueling protocols. Recent innovations include AI-controlled variable flow rate systems that adapt to real-time temperature conditions within the tank, maximizing absorption rates while preventing overheating.

The primary objective for next-generation hydride tank technology centers on achieving sub-10-minute refueling times while maintaining safety and system longevity. This requires solving the fundamental challenge of rapid heat dissipation during the hydrogen absorption process without compromising storage capacity or increasing system complexity and cost beyond practical limits.

Secondary objectives include improving energy efficiency of the refueling process, reducing system weight and volume, enhancing durability over thousands of refueling cycles, and developing standardized protocols that can be implemented across various tank designs and applications. These goals must be achieved while meeting stringent safety standards and cost targets to enable widespread commercial adoption.

Market Analysis for Rapid Hydrogen Refueling Solutions

The global market for rapid hydrogen refueling solutions is experiencing significant growth, driven primarily by the increasing adoption of hydrogen fuel cell vehicles (FCVs) and the expanding hydrogen infrastructure. Current market valuations indicate that the hydrogen refueling infrastructure market is projected to reach approximately 29 billion USD by 2027, with a compound annual growth rate exceeding 30% between 2022 and 2027.

The automotive sector represents the largest demand segment, with major manufacturers like Toyota, Hyundai, and Honda actively expanding their hydrogen vehicle offerings. Commercial fleet operators are emerging as key customers, particularly in logistics, public transportation, and heavy-duty applications where battery electric solutions face limitations regarding range and refueling time.

Regional market analysis reveals distinct development patterns. Asia-Pacific, led by Japan, South Korea, and China, currently dominates the market with extensive government support and infrastructure investments. Europe follows closely, with Germany, France, and the Nordic countries implementing ambitious hydrogen strategies. North America shows promising growth potential, particularly in California and the Northeast corridor.

Consumer demand is increasingly focused on refueling experiences comparable to conventional vehicles. Market research indicates that consumers expect refueling times under 5 minutes and range capabilities exceeding 300 miles per tank. This creates direct market pressure for innovations in rapid refueling protocols and heat management systems for hydride storage tanks.

The competitive landscape features diverse players across the value chain. Industrial gas companies like Air Liquide, Linde, and Air Products dominate infrastructure development, while specialized equipment manufacturers such as Nel Hydrogen, ITM Power, and McPhy focus on refueling station technology. Emerging startups are targeting niche innovations in heat sink design and thermal management systems.

Market barriers include high infrastructure costs, with current hydrogen refueling stations requiring investments between 1-2 million USD depending on capacity. Technical challenges related to heat management during rapid refueling represent significant market entry barriers, creating opportunities for innovative solutions in hydride tank design.

Regulatory frameworks are evolving favorably, with many jurisdictions implementing supportive policies. The European Union's Green Deal, Japan's hydrogen society roadmap, and California's zero-emission vehicle mandates all create market pull for advanced hydrogen refueling technologies. Industry standards for refueling protocols, such as SAE J2601, are maturing to ensure safety and interoperability across different vehicle platforms and refueling systems.

The automotive sector represents the largest demand segment, with major manufacturers like Toyota, Hyundai, and Honda actively expanding their hydrogen vehicle offerings. Commercial fleet operators are emerging as key customers, particularly in logistics, public transportation, and heavy-duty applications where battery electric solutions face limitations regarding range and refueling time.

Regional market analysis reveals distinct development patterns. Asia-Pacific, led by Japan, South Korea, and China, currently dominates the market with extensive government support and infrastructure investments. Europe follows closely, with Germany, France, and the Nordic countries implementing ambitious hydrogen strategies. North America shows promising growth potential, particularly in California and the Northeast corridor.

Consumer demand is increasingly focused on refueling experiences comparable to conventional vehicles. Market research indicates that consumers expect refueling times under 5 minutes and range capabilities exceeding 300 miles per tank. This creates direct market pressure for innovations in rapid refueling protocols and heat management systems for hydride storage tanks.

The competitive landscape features diverse players across the value chain. Industrial gas companies like Air Liquide, Linde, and Air Products dominate infrastructure development, while specialized equipment manufacturers such as Nel Hydrogen, ITM Power, and McPhy focus on refueling station technology. Emerging startups are targeting niche innovations in heat sink design and thermal management systems.

Market barriers include high infrastructure costs, with current hydrogen refueling stations requiring investments between 1-2 million USD depending on capacity. Technical challenges related to heat management during rapid refueling represent significant market entry barriers, creating opportunities for innovative solutions in hydride tank design.

Regulatory frameworks are evolving favorably, with many jurisdictions implementing supportive policies. The European Union's Green Deal, Japan's hydrogen society roadmap, and California's zero-emission vehicle mandates all create market pull for advanced hydrogen refueling technologies. Industry standards for refueling protocols, such as SAE J2601, are maturing to ensure safety and interoperability across different vehicle platforms and refueling systems.

Current Challenges in Hydride Tank Refueling Systems

Hydride tanks face significant challenges in achieving rapid refueling capabilities while maintaining safety and efficiency. The primary obstacle lies in the exothermic nature of hydrogen absorption, which generates substantial heat during refueling. Current systems struggle to dissipate this heat effectively, resulting in extended refueling times that can range from several hours to days, making them impractical for commercial applications.

Temperature management represents the most critical challenge, as hydride materials typically operate optimally within narrow temperature ranges. When temperatures exceed these thresholds during rapid refueling, absorption kinetics deteriorate dramatically, reducing storage capacity and extending refueling duration. Conventional cooling methods often prove inadequate for handling the thermal loads generated during accelerated hydrogen uptake.

Heat transfer limitations within the tank structure further complicate refueling operations. The low thermal conductivity of hydride powders (typically 0.1-1 W/m·K) creates significant thermal gradients throughout the storage medium. These gradients lead to uneven hydrogen absorption, with outer regions becoming saturated while inner regions remain underutilized, resulting in inefficient storage capacity utilization and prolonged refueling times.

Pressure management during refueling presents another substantial challenge. Optimal absorption rates require maintaining specific pressure profiles throughout the refueling process. Current systems struggle to implement dynamic pressure control protocols that adapt to changing absorption rates and temperature conditions. Without precise pressure management, refueling efficiency decreases substantially, particularly as the tank approaches full capacity.

Material degradation accelerates under rapid refueling conditions. The thermal and mechanical stresses induced during fast hydrogen uptake can cause hydride particle decrepitation, reducing cycle life and storage capacity over time. This degradation is particularly pronounced in systems designed for high gravimetric and volumetric storage densities, creating a challenging trade-off between refueling speed and system longevity.

Scale-up issues persist when transitioning from laboratory-scale demonstrations to commercial-sized systems. Heat dissipation challenges increase exponentially with tank size due to the unfavorable surface-area-to-volume ratio in larger systems. Engineering solutions that work effectively for small tanks often fail to scale proportionally, necessitating fundamentally different approaches for commercial applications.

Safety concerns also intensify during rapid refueling. The combination of high pressure, elevated temperatures, and potential material instability creates risk scenarios that must be mitigated through robust engineering controls. Current safety systems often impose operational constraints that limit refueling rates below theoretically achievable levels.

Temperature management represents the most critical challenge, as hydride materials typically operate optimally within narrow temperature ranges. When temperatures exceed these thresholds during rapid refueling, absorption kinetics deteriorate dramatically, reducing storage capacity and extending refueling duration. Conventional cooling methods often prove inadequate for handling the thermal loads generated during accelerated hydrogen uptake.

Heat transfer limitations within the tank structure further complicate refueling operations. The low thermal conductivity of hydride powders (typically 0.1-1 W/m·K) creates significant thermal gradients throughout the storage medium. These gradients lead to uneven hydrogen absorption, with outer regions becoming saturated while inner regions remain underutilized, resulting in inefficient storage capacity utilization and prolonged refueling times.

Pressure management during refueling presents another substantial challenge. Optimal absorption rates require maintaining specific pressure profiles throughout the refueling process. Current systems struggle to implement dynamic pressure control protocols that adapt to changing absorption rates and temperature conditions. Without precise pressure management, refueling efficiency decreases substantially, particularly as the tank approaches full capacity.

Material degradation accelerates under rapid refueling conditions. The thermal and mechanical stresses induced during fast hydrogen uptake can cause hydride particle decrepitation, reducing cycle life and storage capacity over time. This degradation is particularly pronounced in systems designed for high gravimetric and volumetric storage densities, creating a challenging trade-off between refueling speed and system longevity.

Scale-up issues persist when transitioning from laboratory-scale demonstrations to commercial-sized systems. Heat dissipation challenges increase exponentially with tank size due to the unfavorable surface-area-to-volume ratio in larger systems. Engineering solutions that work effectively for small tanks often fail to scale proportionally, necessitating fundamentally different approaches for commercial applications.

Safety concerns also intensify during rapid refueling. The combination of high pressure, elevated temperatures, and potential material instability creates risk scenarios that must be mitigated through robust engineering controls. Current safety systems often impose operational constraints that limit refueling rates below theoretically achievable levels.

State-of-the-Art Heat Management Solutions for Hydride Tanks

01 Heat sink designs for hydride tanks

Heat sink designs are crucial for managing temperature during hydrogen absorption and desorption in metal hydride tanks. These designs incorporate various cooling mechanisms such as fins, channels, or embedded cooling tubes to efficiently remove or add heat. Advanced heat sink configurations help maintain optimal operating temperatures, prevent overheating during rapid refueling, and ensure consistent hydrogen flow rates. Effective thermal management systems can significantly improve the overall efficiency and safety of hydride storage systems.- Heat sink designs for hydride tanks: Heat sink designs are crucial for managing temperature during hydrogen absorption and desorption in metal hydride tanks. These designs incorporate various cooling mechanisms such as fins, channels, or embedded cooling tubes to efficiently dissipate heat generated during hydrogen charging. Effective heat sink integration helps maintain optimal operating temperatures, preventing performance degradation and ensuring safe operation of the storage system.

- Rapid refueling technologies for hydride storage systems: Rapid refueling technologies for metal hydride tanks focus on accelerating the hydrogen absorption process. These innovations include optimized flow distribution systems, enhanced heat exchange mechanisms, and pressure management techniques that allow for faster charging cycles. By addressing the thermal management challenges during rapid hydrogen uptake, these technologies significantly reduce refueling times while maintaining storage capacity and system integrity.

- Integrated cooling systems for temperature management: Integrated cooling systems are designed specifically for temperature management during hydrogen storage and release operations. These systems combine active and passive cooling methods, including liquid cooling circuits, thermoelectric elements, and phase change materials. The integration of these cooling mechanisms with the hydride tank structure enables precise temperature control, which is essential for optimizing hydrogen storage density and ensuring consistent performance during rapid refueling cycles.

- Advanced hydride materials for improved heat transfer: Advanced hydride materials are being developed with enhanced thermal conductivity properties to address heat transfer challenges. These materials incorporate metal matrices, composite structures, or additives that improve heat dissipation throughout the hydride bed. By optimizing the material composition and structure, these innovations reduce thermal resistance within the storage medium, allowing for more efficient heat transfer during hydrogen charging and discharging processes.

- Modular tank designs with enhanced thermal management: Modular tank designs feature segmented hydride containers with dedicated thermal management systems for each module. This approach distributes heat generation and dissipation more evenly throughout the storage system. The modular architecture allows for scalable hydrogen storage capacity while maintaining efficient heat transfer characteristics. These designs often incorporate specialized heat exchange interfaces between modules to optimize overall system performance during rapid refueling operations.

02 Rapid refueling technologies for hydride storage systems

Rapid refueling technologies for hydride tanks focus on accelerating the hydrogen absorption process while managing the associated heat generation. These technologies include optimized flow distribution systems, pressure management techniques, and specialized refueling protocols. By addressing the thermal and kinetic limitations of hydrogen uptake, these innovations enable faster filling times while maintaining the structural integrity of the storage system. Advanced refueling approaches also consider the balance between speed and safety to prevent damage to the metal hydride material.Expand Specific Solutions03 Thermal management systems for hydride tanks

Thermal management systems for hydride tanks integrate cooling and heating elements to control the temperature during hydrogen absorption and release. These systems utilize various heat transfer mechanisms including liquid cooling circuits, phase change materials, and thermoelectric devices. Efficient thermal management enables consistent hydrogen storage capacity, extends the lifespan of the hydride material, and improves overall system performance. Advanced designs focus on uniform temperature distribution throughout the tank to prevent hotspots and ensure reliable operation under various conditions.Expand Specific Solutions04 Structural designs for enhanced heat transfer in hydride tanks

Innovative structural designs for hydride tanks focus on maximizing heat transfer efficiency through optimized internal geometries. These designs incorporate features such as internal fins, honeycomb structures, metal foams, or heat pipes embedded within the hydride bed. By increasing the effective surface area for heat exchange and reducing thermal resistance, these structural enhancements facilitate faster hydrogen absorption and desorption rates. Advanced materials with high thermal conductivity are also integrated into the tank design to further improve heat transfer capabilities.Expand Specific Solutions05 Integration of hydride tanks with vehicle cooling systems

Integration of hydride storage tanks with vehicle cooling systems allows for efficient thermal management by utilizing existing heat exchange infrastructure. These integrated designs connect the hydride tank's thermal management system with the vehicle's cooling circuit, enabling heat recovery during refueling and operation. The shared cooling architecture reduces system complexity, weight, and cost while improving overall energy efficiency. Advanced integration approaches include intelligent thermal management controls that optimize the heat exchange between the hydride tank and other vehicle systems based on operating conditions.Expand Specific Solutions

Leading Companies in Hydride Tank Technology

The hydrogen storage market for rapid refueling applications is currently in a growth phase, with increasing demand driven by clean energy transitions. The market size is expanding significantly as hydrogen mobility applications gain traction, particularly in transportation sectors. Technologically, hydride tank refueling protocols and heat sink designs are advancing toward commercial maturity, with research institutions like Shandong University and CNRS providing fundamental research while companies demonstrate varying levels of technological readiness. McPhy Energy, BASF, and LG Energy Solution lead in commercial applications, while Hyundai Motor and Magna Steyr are integrating these technologies into vehicle platforms. The Commissariat à l'énergie atomique and Shanghai Hyfun Energy are developing innovative heat management solutions critical for rapid refueling, with thermal management remaining the primary technical challenge for widespread adoption.

McPhy Energy SA

Technical Solution: McPhy Energy has pioneered a solid-state hydrogen storage solution using magnesium hydride materials with enhanced thermal conductivity properties specifically designed for rapid refueling applications. Their HYMAG technology platform incorporates a patented heat sink architecture featuring a three-dimensional aluminum foam structure that penetrates throughout the hydride material, creating extensive thermal pathways for efficient heat dissipation during hydrogen absorption. The system utilizes a pressurized oil cooling circuit that surrounds the hydride container, providing uniform temperature control across the entire tank volume. McPhy's refueling protocol implements a staged pressure ramp-up sequence that optimizes the balance between refueling speed and heat generation, achieving complete refills in approximately 8-10 minutes for their commercial-scale systems[2]. Their latest generation systems incorporate phase-change materials within the heat sink design to absorb thermal energy spikes during rapid refueling events.

Strengths: High volumetric hydrogen storage density compared to compressed gas; excellent safety profile due to low-pressure storage; modular design allows scaling for different applications. Weaknesses: Higher system complexity requiring sophisticated thermal management; relatively higher cost compared to conventional storage methods; performance degradation after multiple refueling cycles requires periodic maintenance.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed an innovative hydride tank system featuring a multi-layered heat sink architecture optimized for rapid hydrogen refueling. Their design incorporates a network of embedded heat exchangers with variable density distribution matched to the thermal gradient patterns that emerge during refueling. The system utilizes a composite metal hydride material with dopants specifically selected to enhance thermal conductivity while maintaining hydrogen storage capacity. CEA's refueling protocol employs an adaptive control algorithm that continuously adjusts hydrogen flow rates based on real-time temperature and pressure measurements throughout the tank, enabling refueling times of 6-7 minutes for their demonstration systems[3]. A distinctive feature is their patented "thermal wave management" approach that strategically directs cooling capacity to different tank regions as the absorption reaction front progresses through the hydride material, preventing thermal bottlenecks that would otherwise limit refueling speeds.

Strengths: Advanced thermal management system with precise control of temperature gradients; sophisticated modeling capabilities that optimize tank design for specific applications; excellent safety features with multiple redundant systems. Weaknesses: Complex control systems require specialized expertise for maintenance; higher initial cost compared to conventional storage solutions; technology still primarily at demonstration scale rather than full commercial deployment.

Critical Patents in Rapid Refueling Heat Sink Design

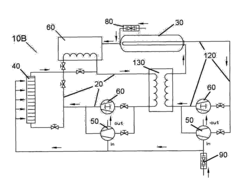

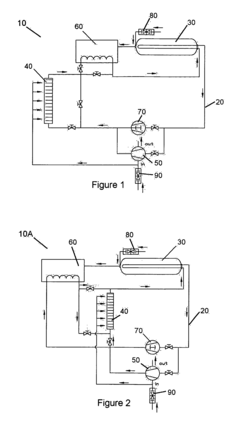

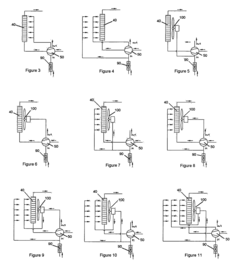

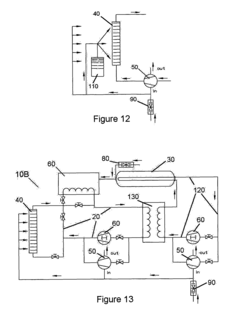

Apparatus for refueling on-board metal hydride hydrogen storage tank

PatentActiveUS7727492B2

Innovation

- An onboard hydrogen storage unit with a gas-driven heat transfer system that uses compressed air to circulate a primary heat transfer fluid through a primary heat transfer loop, which removes heat from the hydrogen storage material during refueling and supplies heat during vehicle operation, incorporating a radiator for cooling and an air-driven pump system to facilitate efficient hydrogen absorption and release.

Improved method and system for tank refilling using active fueling speed control

PatentWO2014200959A2

Innovation

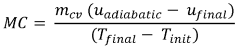

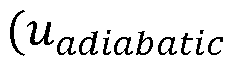

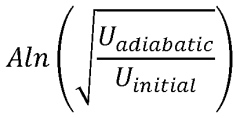

- A modified method and system using a new tank filling model based on the total heat capacity of the hydrogen fueling system and an advanced algorithm that adjusts fueling speed and pressure ramp rate in real-time, utilizing sensors to measure pressure, temperature, and flow rate, allowing for improved fill speed and quality while maintaining safety margins.

Safety Standards and Compliance for Hydrogen Storage

Safety standards for hydrogen storage systems, particularly in the context of hydride tanks with rapid refueling capabilities, are governed by comprehensive regulatory frameworks established by international and national bodies. The International Organization for Standardization (ISO) has developed ISO 16111, which specifically addresses portable hydrogen storage systems integrated with metal hydrides. This standard outlines critical safety parameters including pressure vessel requirements, thermal management specifications, and testing protocols for hydrogen storage systems.

In the United States, the Department of Energy (DOE) has established stringent technical targets for onboard hydrogen storage systems, emphasizing safety as a paramount concern alongside performance metrics. These standards mandate that hydride tanks must withstand extreme conditions, including fire exposure, drop tests, and penetration tests without catastrophic failure. The Code of Federal Regulations (CFR) Title 49 Parts 171-180 further regulates the transportation of hazardous materials, including hydrogen storage systems.

European regulations, particularly through the European Industrial Gases Association (EIGA) and the European Integrated Hydrogen Project, have developed complementary standards focusing on the unique safety challenges of rapid refueling protocols. These standards address thermal management during accelerated hydrogen absorption, which generates significant heat that must be efficiently dissipated to prevent dangerous pressure buildups or material degradation.

The Society of Automotive Engineers (SAE) has published J2579 for fuel systems in fuel cell vehicles, which includes specific provisions for hydride storage systems. This standard addresses the integration of heat sink designs with safety systems, ensuring that thermal management failures trigger appropriate safety responses before dangerous conditions develop.

Japanese and South Korean regulatory frameworks have pioneered standards specifically addressing the unique safety requirements of rapid refueling systems, including mandatory cooling systems, temperature monitoring, and emergency pressure relief mechanisms. These standards have been particularly influential in the development of commercial hydrogen refueling infrastructure.

Compliance testing for hydride tanks with advanced heat sink designs typically involves cyclic pressure testing, thermal cycling, and accelerated refueling simulations to verify system integrity under worst-case scenarios. Certification processes require extensive documentation of materials compatibility, thermal management efficiency, and failure mode analysis.

Recent developments in safety standards have begun to address the specific challenges of scaling up hydride tank technologies from laboratory to commercial applications, with particular emphasis on standardizing safety protocols for rapid refueling across different system architectures and material compositions. These evolving standards will play a crucial role in facilitating the widespread adoption of hydrogen storage technologies while ensuring public safety.

In the United States, the Department of Energy (DOE) has established stringent technical targets for onboard hydrogen storage systems, emphasizing safety as a paramount concern alongside performance metrics. These standards mandate that hydride tanks must withstand extreme conditions, including fire exposure, drop tests, and penetration tests without catastrophic failure. The Code of Federal Regulations (CFR) Title 49 Parts 171-180 further regulates the transportation of hazardous materials, including hydrogen storage systems.

European regulations, particularly through the European Industrial Gases Association (EIGA) and the European Integrated Hydrogen Project, have developed complementary standards focusing on the unique safety challenges of rapid refueling protocols. These standards address thermal management during accelerated hydrogen absorption, which generates significant heat that must be efficiently dissipated to prevent dangerous pressure buildups or material degradation.

The Society of Automotive Engineers (SAE) has published J2579 for fuel systems in fuel cell vehicles, which includes specific provisions for hydride storage systems. This standard addresses the integration of heat sink designs with safety systems, ensuring that thermal management failures trigger appropriate safety responses before dangerous conditions develop.

Japanese and South Korean regulatory frameworks have pioneered standards specifically addressing the unique safety requirements of rapid refueling systems, including mandatory cooling systems, temperature monitoring, and emergency pressure relief mechanisms. These standards have been particularly influential in the development of commercial hydrogen refueling infrastructure.

Compliance testing for hydride tanks with advanced heat sink designs typically involves cyclic pressure testing, thermal cycling, and accelerated refueling simulations to verify system integrity under worst-case scenarios. Certification processes require extensive documentation of materials compatibility, thermal management efficiency, and failure mode analysis.

Recent developments in safety standards have begun to address the specific challenges of scaling up hydride tank technologies from laboratory to commercial applications, with particular emphasis on standardizing safety protocols for rapid refueling across different system architectures and material compositions. These evolving standards will play a crucial role in facilitating the widespread adoption of hydrogen storage technologies while ensuring public safety.

Sustainability Impact of Advanced Hydride Refueling Technologies

The advancement of hydride refueling technologies represents a significant step toward sustainable energy systems, particularly in the transportation and energy storage sectors. These technologies offer substantial environmental benefits compared to conventional fossil fuel systems, primarily through the reduction of greenhouse gas emissions. When hydrogen is produced from renewable energy sources, the entire fuel cycle approaches carbon neutrality, creating a truly sustainable energy pathway.

Advanced hydride refueling systems contribute to resource conservation by enabling more efficient use of materials. The improved heat sink designs in modern hydride tanks reduce material degradation during rapid refueling cycles, extending tank lifespans and decreasing the need for frequent replacements. This longevity directly translates to reduced raw material consumption and manufacturing energy requirements over system lifetimes.

Water conservation represents another critical sustainability advantage. Unlike traditional fossil fuel production, which can require significant water resources for extraction and refining processes, hydrogen production methods—particularly electrolysis powered by renewable energy—can be designed with minimal water footprints. The closed-loop cooling systems in advanced hydride refueling stations further minimize water consumption during operation.

From an air quality perspective, hydrogen fuel cell vehicles produce zero tailpipe emissions beyond water vapor, eliminating particulate matter, nitrogen oxides, and other harmful pollutants associated with internal combustion engines. This benefit is particularly valuable in urban environments where air quality concerns are most acute.

The sustainability impact extends to noise pollution reduction as well. Hydrogen refueling infrastructure operates with significantly lower noise levels compared to conventional gas stations, contributing to healthier urban soundscapes and reduced environmental stress on surrounding ecosystems.

Long-term ecological benefits include reduced risk of environmental contamination. Unlike fossil fuel storage and distribution systems, hydrogen storage in hydride tanks presents minimal risk of soil or groundwater contamination in the event of leaks or system failures, as hydrogen rapidly dissipates into the atmosphere rather than persisting as a contaminant.

The circular economy potential of hydride-based systems further enhances their sustainability profile. Many metal hydride materials can be reclaimed and recycled at end-of-life, creating closed material loops that minimize waste and resource extraction demands. Research into standardized recycling protocols for spent hydride materials shows promising recovery rates exceeding 90% for critical metals.

Advanced hydride refueling systems contribute to resource conservation by enabling more efficient use of materials. The improved heat sink designs in modern hydride tanks reduce material degradation during rapid refueling cycles, extending tank lifespans and decreasing the need for frequent replacements. This longevity directly translates to reduced raw material consumption and manufacturing energy requirements over system lifetimes.

Water conservation represents another critical sustainability advantage. Unlike traditional fossil fuel production, which can require significant water resources for extraction and refining processes, hydrogen production methods—particularly electrolysis powered by renewable energy—can be designed with minimal water footprints. The closed-loop cooling systems in advanced hydride refueling stations further minimize water consumption during operation.

From an air quality perspective, hydrogen fuel cell vehicles produce zero tailpipe emissions beyond water vapor, eliminating particulate matter, nitrogen oxides, and other harmful pollutants associated with internal combustion engines. This benefit is particularly valuable in urban environments where air quality concerns are most acute.

The sustainability impact extends to noise pollution reduction as well. Hydrogen refueling infrastructure operates with significantly lower noise levels compared to conventional gas stations, contributing to healthier urban soundscapes and reduced environmental stress on surrounding ecosystems.

Long-term ecological benefits include reduced risk of environmental contamination. Unlike fossil fuel storage and distribution systems, hydrogen storage in hydride tanks presents minimal risk of soil or groundwater contamination in the event of leaks or system failures, as hydrogen rapidly dissipates into the atmosphere rather than persisting as a contaminant.

The circular economy potential of hydride-based systems further enhances their sustainability profile. Many metal hydride materials can be reclaimed and recycled at end-of-life, creating closed material loops that minimize waste and resource extraction demands. Research into standardized recycling protocols for spent hydride materials shows promising recovery rates exceeding 90% for critical metals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!