System Integration Of Hydride Tanks With PEM Fuel Cells

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Evolution and Integration Objectives

Hydrogen storage technology has evolved significantly over the past decades, transitioning from conventional compressed gas and cryogenic liquid methods to more advanced material-based solutions. The early systems primarily relied on high-pressure tanks (350-700 bar), which presented significant safety concerns and volumetric efficiency limitations. The subsequent development of liquid hydrogen storage offered improved density but introduced challenges related to boil-off losses and energy-intensive liquefaction processes requiring temperatures below 20K.

The emergence of solid-state hydrogen storage materials, particularly metal hydrides, represents a pivotal advancement in this evolution. These materials chemically bind hydrogen atoms within their structure, enabling storage at moderate pressures and temperatures while achieving volumetric densities that surpass compressed gas. The progression from simple metal hydrides to complex hydrides and chemical hydrogen carriers demonstrates the continuous pursuit of higher gravimetric and volumetric capacities.

Integration objectives for hydride tanks with PEM fuel cells focus primarily on optimizing the entire system's efficiency, safety, and practicality. A fundamental objective is achieving seamless thermal management between the exothermic fuel cell operation and the endothermic hydrogen release from metal hydrides. This synergistic thermal integration aims to utilize waste heat from the fuel cell to drive hydrogen desorption from the storage material, thereby enhancing overall system efficiency.

Weight reduction represents another critical integration objective, as current metal hydride systems often contribute significantly to the total system mass. Research targets gravimetric hydrogen capacities exceeding 6 wt% at the system level to achieve competitive energy densities compared to conventional power sources. Simultaneously, integration efforts seek to address kinetic limitations by developing hydride materials with rapid hydrogen absorption/desorption rates that can respond dynamically to varying power demands.

Operational flexibility constitutes a key integration goal, with systems designed to function effectively across diverse environmental conditions and duty cycles. This includes developing storage solutions that maintain performance integrity during cold starts, rapid power fluctuations, and extended idle periods. The integration architecture must also accommodate space constraints in various applications, from stationary power generation to mobile transportation systems.

Long-term integration objectives extend to lifecycle considerations, including the development of hydride materials with enhanced cycling stability, reduced degradation rates, and improved resistance to contaminants. Additionally, integration strategies increasingly incorporate advanced sensors and control systems to optimize hydrogen delivery based on real-time fuel cell demands, further enhancing system responsiveness and efficiency.

The emergence of solid-state hydrogen storage materials, particularly metal hydrides, represents a pivotal advancement in this evolution. These materials chemically bind hydrogen atoms within their structure, enabling storage at moderate pressures and temperatures while achieving volumetric densities that surpass compressed gas. The progression from simple metal hydrides to complex hydrides and chemical hydrogen carriers demonstrates the continuous pursuit of higher gravimetric and volumetric capacities.

Integration objectives for hydride tanks with PEM fuel cells focus primarily on optimizing the entire system's efficiency, safety, and practicality. A fundamental objective is achieving seamless thermal management between the exothermic fuel cell operation and the endothermic hydrogen release from metal hydrides. This synergistic thermal integration aims to utilize waste heat from the fuel cell to drive hydrogen desorption from the storage material, thereby enhancing overall system efficiency.

Weight reduction represents another critical integration objective, as current metal hydride systems often contribute significantly to the total system mass. Research targets gravimetric hydrogen capacities exceeding 6 wt% at the system level to achieve competitive energy densities compared to conventional power sources. Simultaneously, integration efforts seek to address kinetic limitations by developing hydride materials with rapid hydrogen absorption/desorption rates that can respond dynamically to varying power demands.

Operational flexibility constitutes a key integration goal, with systems designed to function effectively across diverse environmental conditions and duty cycles. This includes developing storage solutions that maintain performance integrity during cold starts, rapid power fluctuations, and extended idle periods. The integration architecture must also accommodate space constraints in various applications, from stationary power generation to mobile transportation systems.

Long-term integration objectives extend to lifecycle considerations, including the development of hydride materials with enhanced cycling stability, reduced degradation rates, and improved resistance to contaminants. Additionally, integration strategies increasingly incorporate advanced sensors and control systems to optimize hydrogen delivery based on real-time fuel cell demands, further enhancing system responsiveness and efficiency.

Market Analysis for Hydrogen Fuel Cell Systems

The global hydrogen fuel cell market is experiencing significant growth, with a market value reaching $16.5 billion in 2022 and projected to expand at a CAGR of 21.5% through 2030. This growth is primarily driven by increasing environmental concerns, stringent emission regulations, and the push for clean energy alternatives across various sectors. The transportation sector currently dominates the market application, accounting for approximately 65% of the total market share, followed by stationary power generation at 25%.

Regional analysis reveals that Asia-Pacific, particularly Japan, South Korea, and China, leads the market with substantial government investments in hydrogen infrastructure. Europe follows closely, with Germany, France, and the UK implementing aggressive hydrogen strategies. North America, especially the United States and Canada, is also showing increased adoption rates, particularly in material handling equipment and backup power systems.

The PEM (Proton Exchange Membrane) fuel cell segment holds the largest market share among fuel cell technologies at approximately 60%, due to its higher efficiency, lower operating temperatures, and suitability for transportation applications. The integration of hydride tanks with PEM fuel cells represents a critical market opportunity, addressing key challenges in hydrogen storage and delivery systems.

Consumer demand patterns indicate growing interest in fuel cell electric vehicles (FCEVs), with global sales increasing by 40% year-over-year. However, market penetration remains limited by high costs and insufficient refueling infrastructure. The commercial vehicle segment, including buses and trucks, shows stronger adoption rates compared to passenger vehicles, with fleet operators valuing the quick refueling times and longer range capabilities.

Market barriers include high system costs, with integrated PEM fuel cell systems currently priced at $1,000-1,500 per kW for automotive applications. The cost of metal hydride storage systems remains a significant component, although prices have decreased by approximately 30% over the past five years. Infrastructure limitations also constrain market growth, with fewer than 700 hydrogen refueling stations operational worldwide as of 2022.

Emerging market opportunities include the integration of fuel cell systems with renewable energy sources for grid stabilization and backup power. The maritime and aviation sectors are also exploring hydrogen fuel cell applications, potentially opening new market segments. Additionally, the growing interest in green hydrogen production aligns with the sustainability benefits of fuel cell systems, potentially creating synergistic market growth.

Customer feedback indicates that reliability, system integration simplicity, and total cost of ownership are the primary concerns for potential adopters. Market forecasts suggest that as production scales and technology advances, particularly in hydride tank integration with PEM fuel cells, system costs could decrease by 50-60% by 2030, potentially triggering mass market adoption.

Regional analysis reveals that Asia-Pacific, particularly Japan, South Korea, and China, leads the market with substantial government investments in hydrogen infrastructure. Europe follows closely, with Germany, France, and the UK implementing aggressive hydrogen strategies. North America, especially the United States and Canada, is also showing increased adoption rates, particularly in material handling equipment and backup power systems.

The PEM (Proton Exchange Membrane) fuel cell segment holds the largest market share among fuel cell technologies at approximately 60%, due to its higher efficiency, lower operating temperatures, and suitability for transportation applications. The integration of hydride tanks with PEM fuel cells represents a critical market opportunity, addressing key challenges in hydrogen storage and delivery systems.

Consumer demand patterns indicate growing interest in fuel cell electric vehicles (FCEVs), with global sales increasing by 40% year-over-year. However, market penetration remains limited by high costs and insufficient refueling infrastructure. The commercial vehicle segment, including buses and trucks, shows stronger adoption rates compared to passenger vehicles, with fleet operators valuing the quick refueling times and longer range capabilities.

Market barriers include high system costs, with integrated PEM fuel cell systems currently priced at $1,000-1,500 per kW for automotive applications. The cost of metal hydride storage systems remains a significant component, although prices have decreased by approximately 30% over the past five years. Infrastructure limitations also constrain market growth, with fewer than 700 hydrogen refueling stations operational worldwide as of 2022.

Emerging market opportunities include the integration of fuel cell systems with renewable energy sources for grid stabilization and backup power. The maritime and aviation sectors are also exploring hydrogen fuel cell applications, potentially opening new market segments. Additionally, the growing interest in green hydrogen production aligns with the sustainability benefits of fuel cell systems, potentially creating synergistic market growth.

Customer feedback indicates that reliability, system integration simplicity, and total cost of ownership are the primary concerns for potential adopters. Market forecasts suggest that as production scales and technology advances, particularly in hydride tank integration with PEM fuel cells, system costs could decrease by 50-60% by 2030, potentially triggering mass market adoption.

Technical Barriers in Hydride Tank-PEM Integration

The integration of metal hydride storage tanks with PEM fuel cells presents several significant technical challenges that must be addressed for successful system deployment. One of the primary barriers is thermal management, as the hydrogen absorption process in metal hydrides is exothermic while desorption is endothermic. This creates a complex thermal coupling requirement between the fuel cell and storage system that demands sophisticated heat exchange mechanisms to maintain optimal operating conditions for both components.

Weight optimization remains a persistent challenge, with current metal hydride materials exhibiting relatively low gravimetric hydrogen storage capacity (typically 1-2 wt%). This results in storage systems that are often prohibitively heavy for mobile applications, particularly when compared to compressed hydrogen alternatives. The trade-off between storage capacity, weight, and system complexity continues to limit widespread adoption.

Hydrogen release kinetics pose another significant barrier, as many hydride materials cannot deliver hydrogen at rates sufficient to meet dynamic load demands of PEM fuel cells, especially during rapid power fluctuations. This mismatch between supply and demand rates necessitates buffer storage or hybrid solutions that add complexity and cost to the overall system.

Material degradation over multiple absorption-desorption cycles represents a long-term reliability concern. Most metal hydrides experience capacity fade, particle decrepitation, and structural changes that reduce performance over time. This degradation is often accelerated by impurities in hydrogen feedstock and temperature variations during operation, requiring either frequent material replacement or oversized storage systems.

System integration complexity is further compounded by the need for precise pressure regulation between the hydride tank and fuel cell. PEM fuel cells typically operate at pressures between 1-3 bar, while efficient hydrogen release from many hydrides requires careful pressure management that may necessitate additional components like pressure regulators and safety relief valves.

Cost factors present perhaps the most significant market barrier, with high-performance metal hydrides containing expensive rare earth elements or precious metals. The additional balance-of-plant components required for thermal management and pressure control further increase system costs compared to simpler storage alternatives.

Safety considerations introduce additional design constraints, particularly regarding heat management during rapid charging and potential material reactivity with air or moisture in case of containment breach. These safety requirements often necessitate redundant systems and robust containment solutions that add weight and complexity.

Standardization remains underdeveloped in this field, with various proprietary designs and approaches making system-level integration challenging across different manufacturers and applications. The lack of unified standards for interfaces, safety protocols, and performance metrics hinders broader market adoption and supply chain development.

Weight optimization remains a persistent challenge, with current metal hydride materials exhibiting relatively low gravimetric hydrogen storage capacity (typically 1-2 wt%). This results in storage systems that are often prohibitively heavy for mobile applications, particularly when compared to compressed hydrogen alternatives. The trade-off between storage capacity, weight, and system complexity continues to limit widespread adoption.

Hydrogen release kinetics pose another significant barrier, as many hydride materials cannot deliver hydrogen at rates sufficient to meet dynamic load demands of PEM fuel cells, especially during rapid power fluctuations. This mismatch between supply and demand rates necessitates buffer storage or hybrid solutions that add complexity and cost to the overall system.

Material degradation over multiple absorption-desorption cycles represents a long-term reliability concern. Most metal hydrides experience capacity fade, particle decrepitation, and structural changes that reduce performance over time. This degradation is often accelerated by impurities in hydrogen feedstock and temperature variations during operation, requiring either frequent material replacement or oversized storage systems.

System integration complexity is further compounded by the need for precise pressure regulation between the hydride tank and fuel cell. PEM fuel cells typically operate at pressures between 1-3 bar, while efficient hydrogen release from many hydrides requires careful pressure management that may necessitate additional components like pressure regulators and safety relief valves.

Cost factors present perhaps the most significant market barrier, with high-performance metal hydrides containing expensive rare earth elements or precious metals. The additional balance-of-plant components required for thermal management and pressure control further increase system costs compared to simpler storage alternatives.

Safety considerations introduce additional design constraints, particularly regarding heat management during rapid charging and potential material reactivity with air or moisture in case of containment breach. These safety requirements often necessitate redundant systems and robust containment solutions that add weight and complexity.

Standardization remains underdeveloped in this field, with various proprietary designs and approaches making system-level integration challenging across different manufacturers and applications. The lack of unified standards for interfaces, safety protocols, and performance metrics hinders broader market adoption and supply chain development.

Current Hydride Tank-PEM Fuel Cell Integration Approaches

01 Metal hydride storage systems for PEM fuel cells

Metal hydride storage systems provide a safe and efficient method for hydrogen storage in PEM fuel cell applications. These systems store hydrogen through absorption into metal alloys, allowing for higher storage density at lower pressures compared to compressed gas. The integration of metal hydride tanks with PEM fuel cells creates a complete power system with improved energy density and operational safety, particularly beneficial for portable and stationary applications.- Metal hydride storage systems for PEM fuel cells: Metal hydride storage systems provide a safe and efficient method for hydrogen storage in PEM fuel cell applications. These systems store hydrogen through absorption into metal alloys, allowing for higher storage density at lower pressures compared to compressed gas. The integration of metal hydride tanks with PEM fuel cells creates a complete power system that offers advantages in terms of safety, energy density, and operational efficiency for various applications including vehicles and portable power systems.

- Thermal management in integrated hydride-PEM systems: Effective thermal management is crucial in integrated hydride storage and PEM fuel cell systems. Heat generated by the fuel cell can be utilized for hydrogen desorption from the metal hydride, creating a synergistic thermal relationship. Advanced thermal management systems incorporate heat exchangers, cooling circuits, and thermal coupling between components to maintain optimal operating temperatures, improve system efficiency, and extend operational lifetime of both the storage system and the fuel cell stack.

- Compact integration designs for mobile applications: Compact integration designs focus on optimizing the spatial arrangement of hydride tanks and PEM fuel cells for mobile applications such as vehicles and portable power units. These designs incorporate modular approaches, innovative tank geometries, and integrated balance-of-plant components to reduce system volume and weight while maintaining performance. Advanced packaging solutions enable efficient hydrogen delivery pathways, simplified maintenance access, and improved safety features for practical deployment in space-constrained applications.

- Control systems for hydrogen flow management: Sophisticated control systems are essential for managing hydrogen flow between hydride storage tanks and PEM fuel cells. These systems incorporate pressure regulators, flow controllers, sensors, and electronic control units that monitor and adjust hydrogen delivery based on power demand. Advanced control algorithms optimize hydrogen release rates from the hydride material, manage system pressures, and coordinate with the fuel cell's power output requirements to ensure stable operation under varying load conditions while maximizing efficiency and system responsiveness.

- Safety and monitoring features for integrated systems: Safety and monitoring features are critical components in hydride tank and PEM fuel cell integrated systems. These include hydrogen leak detection sensors, pressure relief devices, temperature monitors, and isolation systems that prevent catastrophic failures. Advanced monitoring systems provide real-time data on system status, hydrogen levels, and performance metrics. Integrated safety protocols enable automatic shutdown procedures in case of abnormal operating conditions, ensuring safe operation in various environments and applications while meeting regulatory requirements for hydrogen systems.

02 Thermal management in integrated hydride-PEM systems

Effective thermal management is crucial in integrated hydride tank and PEM fuel cell systems. The hydrogen absorption/desorption process in metal hydrides is highly temperature-dependent, requiring heat during hydrogen release and cooling during storage. Advanced thermal management systems utilize waste heat from the fuel cell to facilitate hydrogen release from the hydride material, creating synergistic thermal integration that improves overall system efficiency and performance.Expand Specific Solutions03 Control systems for hydride-PEM fuel cell integration

Sophisticated control systems are essential for managing the integration between hydride storage tanks and PEM fuel cells. These systems monitor and regulate hydrogen flow rates, system pressures, and temperatures to ensure optimal performance. Advanced controllers incorporate predictive algorithms to anticipate hydrogen demand based on load profiles, optimizing the hydrogen release from hydride materials and maintaining stable fuel cell operation under varying power demands.Expand Specific Solutions04 Compact and lightweight integrated designs

Innovative design approaches focus on creating compact and lightweight integrated hydride tank and PEM fuel cell systems. These designs incorporate space-saving configurations, lightweight structural materials, and optimized component placement to reduce overall system volume and weight. Such compact integrated systems are particularly valuable for mobile applications, including vehicles and portable power generators, where space and weight constraints are significant considerations.Expand Specific Solutions05 Safety features and system durability

Enhanced safety features and durability considerations are critical in hydride tank and PEM fuel cell integrated systems. These include pressure relief mechanisms, hydrogen leak detection, thermal runaway prevention, and robust containment structures. Advanced systems incorporate redundant safety measures and materials resistant to hydrogen embrittlement to ensure long-term reliability. Improved sealing technologies and connection interfaces between the hydride tanks and fuel cells prevent hydrogen leakage and maintain system integrity over extended operational periods.Expand Specific Solutions

Leading Companies in Hydrogen Storage and Fuel Cell Industry

The integration of hydride tanks with PEM fuel cells is currently in a growth phase, with the market expanding due to increasing demand for clean energy solutions. The global market size for this technology is projected to reach significant scale as hydrogen fuel cell vehicles gain traction. Technologically, the field shows varying maturity levels across companies. Industry leaders like Bosch, Siemens, and Mercedes-Benz demonstrate advanced integration capabilities, while specialized players such as Ballard Power Systems, Hydrogenics, and Intelligent Energy focus on optimizing fuel cell performance. Chinese companies including Sunrise Power and Shanghai Shen-Li High Tech are rapidly advancing their technological capabilities. Academic institutions like Tongji University and Auburn University contribute valuable research to bridge remaining technical gaps in system efficiency and safety.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated integration system for hydride tanks with PEM fuel cells that leverages their extensive automotive systems expertise. Their approach centers on a "Unified Thermal Architecture" that creates an intelligent heat management network between the fuel cell stack, hydride storage, and vehicle thermal systems. This integration utilizes a multi-circuit liquid cooling system with electronically controlled valves that direct thermal energy based on real-time system needs. Bosch's solution incorporates advanced sensors throughout the system that provide comprehensive monitoring of temperatures, pressures, and flow rates, enabling precise control of hydrogen release from the hydride materials. Their system achieves approximately 40% reduction in startup time compared to non-integrated approaches by utilizing strategic thermal management during cold starts. The integration includes Bosch's proprietary electronic control units that optimize system performance across varying operational conditions while providing diagnostic capabilities that can predict maintenance needs before failures occur. The system architecture is designed with automotive-grade redundancy and safety features, including isolation protocols and emergency shutdown capabilities that exceed regulatory requirements.

Strengths: Exceptional system integration with vehicle electronics and thermal management systems, providing seamless operation within complex automotive architectures. Advanced diagnostics and prognostics capabilities enhance reliability and maintenance planning. Weaknesses: Higher system complexity requires specialized service training and equipment, potentially increasing maintenance costs for service providers without appropriate expertise.

Cummins, Inc.

Technical Solution: Cummins has developed a comprehensive system integration approach for hydride tanks with PEM fuel cells focused on heavy-duty applications. Their solution features a modular architecture that allows for scalable hydrogen storage capacity while maintaining efficient thermal coupling with the fuel cell system. The integration centers around their proprietary "Thermal Bridge Technology" that efficiently transfers waste heat from the fuel cell stack to the metal hydride storage vessels, achieving approximately 85% thermal transfer efficiency. This system incorporates variable-flow cooling circuits that can be dynamically adjusted based on operating conditions and power demands. Cummins' approach includes advanced materials for hydride containment that optimize weight while meeting stringent safety requirements for commercial applications. Their control system architecture integrates both the fuel cell and hydride storage management into a unified platform, allowing for predictive control strategies that anticipate hydrogen demand based on operational patterns. The system achieves start-up times of under 30 seconds in ambient conditions above 0°C, with full power availability within 2 minutes even in colder environments.

Strengths: Exceptional durability and reliability designed for commercial duty cycles exceeding 25,000 hours of operation. Highly scalable architecture allows for customization across different vehicle platforms and power requirements. Weaknesses: The robust design prioritizes reliability over absolute power density, resulting in somewhat larger system footprint compared to some competitors' offerings.

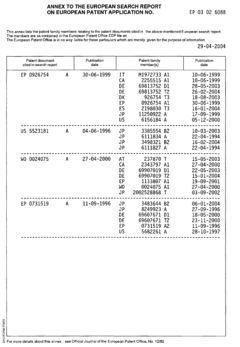

Key Patents in Hydride Storage-Fuel Cell Integration

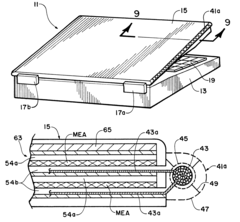

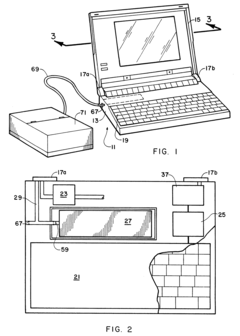

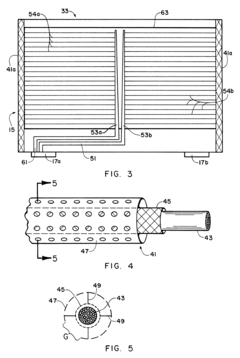

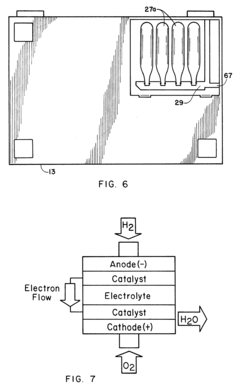

Portable electronic device powered by proton exchange membrane fuel cell

PatentInactiveUS6447945B1

Innovation

- A portable electronic device design incorporating a PEM fuel cell within a two-piece case with a wick system for water removal and an electrolyzer unit for hydrogen recharging, where air is blown past the CPU to supply oxygen to the fuel cells, and hydrogen is generated for recharging purposes, ensuring efficient operation and water evaporation.

Proton exchange membrane (PEM) for a fuel cell

PatentInactiveEP1427044A3

Innovation

- A proton exchange membrane (PEM) comprising a polymer matrix with uniformly dispersed ionically conductive ceramic materials, such as beta aluminum oxide or zirconium phosphate-phosphate/silica composite, creating a superconductive interface to facilitate rapid proton transfer between the anode and cathode, exceeding methanol transfer rates.

Safety Standards and Regulatory Framework for Hydrogen Systems

The integration of hydrogen storage systems with PEM fuel cells necessitates adherence to comprehensive safety standards and regulatory frameworks due to hydrogen's unique properties. Currently, several international standards govern hydrogen systems, with ISO/TC 197 specifically addressing hydrogen technologies. Key standards include ISO 16111 for transportable hydrogen storage systems, ISO 19880 for hydrogen fueling stations, and ISO 22734 for hydrogen generators using water electrolysis.

In the United States, NFPA 2 (Hydrogen Technologies Code) provides fundamental safeguards for hydrogen infrastructure, while DOE Technical Standards establish specific requirements for hydrogen systems in energy applications. The European Union implements regulations through directives like 2014/94/EU for alternative fuels infrastructure and the Pressure Equipment Directive (2014/68/EU) for pressurized hydrogen components.

Regulatory compliance for hydride tank integration with PEM fuel cells requires addressing multiple safety aspects. Material compatibility standards ensure that all components resist hydrogen embrittlement and degradation. Pressure management regulations mandate appropriate pressure relief devices, monitoring systems, and emergency shutdown capabilities. Ventilation requirements specify proper airflow rates in enclosed spaces to prevent hydrogen accumulation.

Leak detection and monitoring standards require implementation of hydrogen sensors with specific sensitivity thresholds and response times. Fire protection regulations mandate separation distances, fire-resistant barriers, and specialized fire suppression systems. Electrical classification standards address potential ignition sources near hydrogen systems, requiring intrinsically safe components in hazardous areas.

Risk assessment methodologies like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are mandated for system design validation. Certification processes typically involve third-party verification of compliance with applicable standards before commercial deployment. For transportation applications, additional regulations apply, including UN GTR No. 13 for hydrogen vehicles and ADR regulations for dangerous goods transport.

Recent regulatory trends show movement toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in system design while maintaining safety. Harmonization efforts between different regional standards are progressing, though significant variations remain in implementation details across jurisdictions. Emerging regulations increasingly address lifecycle considerations, including decommissioning and recycling of hydride materials and system components.

In the United States, NFPA 2 (Hydrogen Technologies Code) provides fundamental safeguards for hydrogen infrastructure, while DOE Technical Standards establish specific requirements for hydrogen systems in energy applications. The European Union implements regulations through directives like 2014/94/EU for alternative fuels infrastructure and the Pressure Equipment Directive (2014/68/EU) for pressurized hydrogen components.

Regulatory compliance for hydride tank integration with PEM fuel cells requires addressing multiple safety aspects. Material compatibility standards ensure that all components resist hydrogen embrittlement and degradation. Pressure management regulations mandate appropriate pressure relief devices, monitoring systems, and emergency shutdown capabilities. Ventilation requirements specify proper airflow rates in enclosed spaces to prevent hydrogen accumulation.

Leak detection and monitoring standards require implementation of hydrogen sensors with specific sensitivity thresholds and response times. Fire protection regulations mandate separation distances, fire-resistant barriers, and specialized fire suppression systems. Electrical classification standards address potential ignition sources near hydrogen systems, requiring intrinsically safe components in hazardous areas.

Risk assessment methodologies like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are mandated for system design validation. Certification processes typically involve third-party verification of compliance with applicable standards before commercial deployment. For transportation applications, additional regulations apply, including UN GTR No. 13 for hydrogen vehicles and ADR regulations for dangerous goods transport.

Recent regulatory trends show movement toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in system design while maintaining safety. Harmonization efforts between different regional standards are progressing, though significant variations remain in implementation details across jurisdictions. Emerging regulations increasingly address lifecycle considerations, including decommissioning and recycling of hydride materials and system components.

Thermal Management Strategies for Integrated Systems

Thermal management represents a critical aspect in the integration of hydride tanks with PEM fuel cells, as both components have distinct thermal requirements that must be harmonized for optimal system performance. Metal hydride tanks release heat during hydrogen absorption (charging) and require heat during desorption (discharging), while PEM fuel cells generate heat during operation that must be efficiently removed to maintain performance and durability.

The most effective thermal management strategies leverage this complementary thermal behavior through integrated cooling/heating circuits. Advanced systems implement plate heat exchangers or cooling jackets surrounding the hydride tanks, connected to the fuel cell cooling loop. This configuration allows waste heat from the fuel cell to be directed to the hydride tanks during hydrogen release, improving overall system efficiency by reducing parasitic energy losses.

Temperature control precision represents a significant challenge, as PEM fuel cells typically operate at 60-80°C, while metal hydride materials have varying optimal temperature ranges depending on their composition. Multi-zone thermal management systems with independent temperature control for different system components have demonstrated superior performance in laboratory settings, allowing for optimized operation across varying load conditions.

Phase change materials (PCMs) are emerging as promising passive thermal management solutions, particularly for transient operations. These materials can absorb excess heat during peak loads and release it during startup or low-power operation, effectively dampening thermal fluctuations without requiring active control systems. Recent research indicates that PCMs with melting points between 65-75°C show particular promise for integrated hydride-PEM systems.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal management system designs. Three-dimensional models incorporating detailed heat transfer mechanisms within both the hydride beds and fuel cell stacks enable precise prediction of temperature distributions and hotspots. These models have revealed that non-uniform temperature distributions within hydride tanks can significantly reduce hydrogen storage capacity and release rates.

Advanced control algorithms implementing predictive models and machine learning techniques are being developed to anticipate thermal management needs based on expected load profiles. These systems can preemptively adjust cooling parameters before temperature excursions occur, maintaining both components within their optimal operating windows while minimizing energy consumption for thermal management.

For mobile applications, weight and volume constraints have driven innovation toward multifunctional thermal management components. Examples include structural heat exchangers that simultaneously provide mechanical support and thermal management, and integrated cooling plates that serve as bipolar plates within the fuel cell stack while also managing heat transfer to the hydride tanks.

The most effective thermal management strategies leverage this complementary thermal behavior through integrated cooling/heating circuits. Advanced systems implement plate heat exchangers or cooling jackets surrounding the hydride tanks, connected to the fuel cell cooling loop. This configuration allows waste heat from the fuel cell to be directed to the hydride tanks during hydrogen release, improving overall system efficiency by reducing parasitic energy losses.

Temperature control precision represents a significant challenge, as PEM fuel cells typically operate at 60-80°C, while metal hydride materials have varying optimal temperature ranges depending on their composition. Multi-zone thermal management systems with independent temperature control for different system components have demonstrated superior performance in laboratory settings, allowing for optimized operation across varying load conditions.

Phase change materials (PCMs) are emerging as promising passive thermal management solutions, particularly for transient operations. These materials can absorb excess heat during peak loads and release it during startup or low-power operation, effectively dampening thermal fluctuations without requiring active control systems. Recent research indicates that PCMs with melting points between 65-75°C show particular promise for integrated hydride-PEM systems.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal management system designs. Three-dimensional models incorporating detailed heat transfer mechanisms within both the hydride beds and fuel cell stacks enable precise prediction of temperature distributions and hotspots. These models have revealed that non-uniform temperature distributions within hydride tanks can significantly reduce hydrogen storage capacity and release rates.

Advanced control algorithms implementing predictive models and machine learning techniques are being developed to anticipate thermal management needs based on expected load profiles. These systems can preemptively adjust cooling parameters before temperature excursions occur, maintaining both components within their optimal operating windows while minimizing energy consumption for thermal management.

For mobile applications, weight and volume constraints have driven innovation toward multifunctional thermal management components. Examples include structural heat exchangers that simultaneously provide mechanical support and thermal management, and integrated cooling plates that serve as bipolar plates within the fuel cell stack while also managing heat transfer to the hydride tanks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!