Standards And Certification Pathways For Metal Hydride Tanks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Hydride Storage Technology Background and Objectives

Metal hydride storage technology represents a significant advancement in hydrogen storage solutions, evolving from early experimental systems in the 1970s to increasingly sophisticated commercial applications today. This technology leverages the unique ability of certain metal alloys to absorb hydrogen atoms within their crystalline structure, forming stable metal hydrides that can release hydrogen when heated. The fundamental principle involves hydrogen molecules dissociating at the metal surface, with hydrogen atoms subsequently diffusing into the metal lattice and bonding with metal atoms.

The evolution of metal hydride storage has been marked by progressive improvements in storage capacity, operating conditions, and system durability. Early systems suffered from low gravimetric capacity and required extreme temperature conditions, whereas modern materials can operate at near-ambient temperatures with substantially improved storage densities. This progression has been driven by advancements in material science, particularly in the development of complex multi-element alloys and nanostructured materials.

The primary objective of metal hydride storage technology is to provide a safe, efficient, and compact method for hydrogen storage that overcomes the limitations of conventional compressed gas or cryogenic liquid storage. Specific technical goals include achieving DOE targets for volumetric density (>40 g H₂/L), gravimetric capacity (>5.5 wt%), operating temperature range (-40°C to 60°C), and cycle durability (>1500 cycles).

Current research focuses on developing metal hydride systems that balance thermodynamic stability with practical operating conditions. This includes exploring novel alloy compositions, optimizing particle morphology, and enhancing heat transfer characteristics to improve absorption/desorption kinetics. Additionally, significant effort is directed toward reducing system costs, which remain a major barrier to widespread adoption.

The standardization and certification of metal hydride tanks represent a critical step in the technology's commercialization pathway. As hydrogen gains prominence in the global energy transition, establishing comprehensive standards for metal hydride storage systems becomes essential for ensuring safety, reliability, and interoperability across different applications and markets.

Looking forward, metal hydride storage technology is positioned to play a crucial role in enabling hydrogen-based energy systems, particularly in applications where volumetric efficiency and safety are paramount concerns. The technology's continued development aligns with broader trends toward decarbonization and renewable energy integration, with potential applications spanning stationary power, transportation, and portable electronics sectors.

The evolution of metal hydride storage has been marked by progressive improvements in storage capacity, operating conditions, and system durability. Early systems suffered from low gravimetric capacity and required extreme temperature conditions, whereas modern materials can operate at near-ambient temperatures with substantially improved storage densities. This progression has been driven by advancements in material science, particularly in the development of complex multi-element alloys and nanostructured materials.

The primary objective of metal hydride storage technology is to provide a safe, efficient, and compact method for hydrogen storage that overcomes the limitations of conventional compressed gas or cryogenic liquid storage. Specific technical goals include achieving DOE targets for volumetric density (>40 g H₂/L), gravimetric capacity (>5.5 wt%), operating temperature range (-40°C to 60°C), and cycle durability (>1500 cycles).

Current research focuses on developing metal hydride systems that balance thermodynamic stability with practical operating conditions. This includes exploring novel alloy compositions, optimizing particle morphology, and enhancing heat transfer characteristics to improve absorption/desorption kinetics. Additionally, significant effort is directed toward reducing system costs, which remain a major barrier to widespread adoption.

The standardization and certification of metal hydride tanks represent a critical step in the technology's commercialization pathway. As hydrogen gains prominence in the global energy transition, establishing comprehensive standards for metal hydride storage systems becomes essential for ensuring safety, reliability, and interoperability across different applications and markets.

Looking forward, metal hydride storage technology is positioned to play a crucial role in enabling hydrogen-based energy systems, particularly in applications where volumetric efficiency and safety are paramount concerns. The technology's continued development aligns with broader trends toward decarbonization and renewable energy integration, with potential applications spanning stationary power, transportation, and portable electronics sectors.

Market Analysis for Metal Hydride Storage Solutions

The global market for metal hydride hydrogen storage solutions is experiencing significant growth, driven primarily by the increasing focus on clean energy alternatives and the transition towards a hydrogen economy. Current market valuations indicate that the metal hydride storage segment represents approximately 12% of the overall hydrogen storage market, with projections showing potential growth to reach 18% by 2030. This growth trajectory is supported by the expanding applications in both stationary and mobile hydrogen storage systems.

Regional analysis reveals that Asia-Pacific currently dominates the metal hydride storage market, with Japan and South Korea leading in both research and commercial applications. Europe follows closely, particularly with strong market presence in Germany, France, and the Nordic countries where hydrogen infrastructure development is receiving substantial government support. North America, while slightly behind in adoption rates, is showing accelerated interest, particularly in California and the northeastern United States.

The market segmentation for metal hydride storage solutions spans across several key sectors. The automotive industry represents the largest potential market, with particular interest in hydrogen fuel cell vehicles where compact, safe storage remains a critical challenge. Industrial applications form the second largest segment, where metal hydride systems are increasingly utilized for process gas storage and energy backup systems. Stationary power generation and grid-scale energy storage applications constitute a rapidly growing segment, expected to expand at a compound annual growth rate of 24% through 2028.

Consumer demand patterns indicate a strong preference for storage solutions that offer higher volumetric efficiency, improved safety profiles, and cost-effectiveness. Market surveys show that 78% of potential industrial adopters cite safety as their primary concern, followed by storage capacity (65%) and system longevity (59%). These demand drivers are directly influencing the certification pathways being developed for metal hydride tanks.

Economic analysis of the market reveals that while initial capital costs for metal hydride systems remain higher than conventional storage methods, the total cost of ownership over a 10-year lifecycle is becoming increasingly competitive. This is particularly evident in applications requiring frequent cycling and where space constraints are significant considerations. The price sensitivity threshold appears to be approximately 20% premium over conventional technologies, beyond which adoption rates decline sharply.

Market barriers include the current fragmented regulatory landscape, limited standardization across international markets, and the need for specialized manufacturing capabilities. However, these barriers are gradually being addressed through collaborative industry initiatives and international standardization efforts, which are expected to significantly expand market accessibility for metal hydride storage solutions in the coming years.

Regional analysis reveals that Asia-Pacific currently dominates the metal hydride storage market, with Japan and South Korea leading in both research and commercial applications. Europe follows closely, particularly with strong market presence in Germany, France, and the Nordic countries where hydrogen infrastructure development is receiving substantial government support. North America, while slightly behind in adoption rates, is showing accelerated interest, particularly in California and the northeastern United States.

The market segmentation for metal hydride storage solutions spans across several key sectors. The automotive industry represents the largest potential market, with particular interest in hydrogen fuel cell vehicles where compact, safe storage remains a critical challenge. Industrial applications form the second largest segment, where metal hydride systems are increasingly utilized for process gas storage and energy backup systems. Stationary power generation and grid-scale energy storage applications constitute a rapidly growing segment, expected to expand at a compound annual growth rate of 24% through 2028.

Consumer demand patterns indicate a strong preference for storage solutions that offer higher volumetric efficiency, improved safety profiles, and cost-effectiveness. Market surveys show that 78% of potential industrial adopters cite safety as their primary concern, followed by storage capacity (65%) and system longevity (59%). These demand drivers are directly influencing the certification pathways being developed for metal hydride tanks.

Economic analysis of the market reveals that while initial capital costs for metal hydride systems remain higher than conventional storage methods, the total cost of ownership over a 10-year lifecycle is becoming increasingly competitive. This is particularly evident in applications requiring frequent cycling and where space constraints are significant considerations. The price sensitivity threshold appears to be approximately 20% premium over conventional technologies, beyond which adoption rates decline sharply.

Market barriers include the current fragmented regulatory landscape, limited standardization across international markets, and the need for specialized manufacturing capabilities. However, these barriers are gradually being addressed through collaborative industry initiatives and international standardization efforts, which are expected to significantly expand market accessibility for metal hydride storage solutions in the coming years.

Current Standards Landscape and Technical Challenges

The global landscape for metal hydride hydrogen storage tank standards remains fragmented, with significant regional variations in regulatory frameworks. Currently, the International Organization for Standardization (ISO) provides several relevant standards, including ISO 16111 for transportable gas storage devices containing hydrogen absorbed in reversible metal hydride, which serves as the primary international reference. However, this standard primarily addresses transportable applications rather than stationary or vehicular integrated systems, creating a regulatory gap for emerging applications.

In North America, the regulatory framework is led by ASME's Boiler and Pressure Vessel Code (BPVC) and the Canadian Standards Association (CSA), while the European Union relies on the Pressure Equipment Directive (PED) and specific EN standards. These regional differences create compliance challenges for manufacturers targeting global markets, as certification in one region does not automatically ensure acceptance in others.

A significant technical challenge lies in the lack of standardized testing protocols specifically designed for metal hydride materials and systems. Current standards often apply conventional pressure vessel testing methodologies that fail to address the unique thermodynamic and kinetic properties of metal hydrides. This includes inadequate consideration of heat management during hydrogen absorption/desorption cycles, which is critical for metal hydride tank performance and safety.

Material degradation assessment presents another major challenge, as existing standards provide limited guidance on evaluating long-term cycling stability and potential embrittlement effects specific to metal hydride systems. The absence of standardized accelerated aging tests makes lifetime predictions difficult, creating uncertainty for manufacturers and end-users alike.

Safety certification pathways remain particularly problematic due to the unique failure modes of metal hydride systems. Unlike conventional compressed gas storage, metal hydride tanks exhibit complex behavior during thermal excursions or physical damage. Current standards inadequately address these scenarios, leaving certification bodies without clear evaluation criteria for these emerging technologies.

Harmonization efforts are further complicated by the rapid evolution of metal hydride materials themselves. As researchers develop novel compositions with improved storage capacities and kinetics, standards struggle to keep pace with defining appropriate testing and certification requirements for these new materials.

The integration of metal hydride tanks into larger systems, particularly vehicles and stationary power applications, faces additional regulatory challenges. Current standards provide limited guidance on system-level integration requirements, creating uncertainty regarding interfaces, controls, and safety systems that must work cohesively with the metal hydride storage component.

In North America, the regulatory framework is led by ASME's Boiler and Pressure Vessel Code (BPVC) and the Canadian Standards Association (CSA), while the European Union relies on the Pressure Equipment Directive (PED) and specific EN standards. These regional differences create compliance challenges for manufacturers targeting global markets, as certification in one region does not automatically ensure acceptance in others.

A significant technical challenge lies in the lack of standardized testing protocols specifically designed for metal hydride materials and systems. Current standards often apply conventional pressure vessel testing methodologies that fail to address the unique thermodynamic and kinetic properties of metal hydrides. This includes inadequate consideration of heat management during hydrogen absorption/desorption cycles, which is critical for metal hydride tank performance and safety.

Material degradation assessment presents another major challenge, as existing standards provide limited guidance on evaluating long-term cycling stability and potential embrittlement effects specific to metal hydride systems. The absence of standardized accelerated aging tests makes lifetime predictions difficult, creating uncertainty for manufacturers and end-users alike.

Safety certification pathways remain particularly problematic due to the unique failure modes of metal hydride systems. Unlike conventional compressed gas storage, metal hydride tanks exhibit complex behavior during thermal excursions or physical damage. Current standards inadequately address these scenarios, leaving certification bodies without clear evaluation criteria for these emerging technologies.

Harmonization efforts are further complicated by the rapid evolution of metal hydride materials themselves. As researchers develop novel compositions with improved storage capacities and kinetics, standards struggle to keep pace with defining appropriate testing and certification requirements for these new materials.

The integration of metal hydride tanks into larger systems, particularly vehicles and stationary power applications, faces additional regulatory challenges. Current standards provide limited guidance on system-level integration requirements, creating uncertainty regarding interfaces, controls, and safety systems that must work cohesively with the metal hydride storage component.

Current Certification Methodologies and Requirements

01 Safety standards and certification for metal hydride storage tanks

Metal hydride storage tanks must meet specific safety standards and certifications to ensure their safe operation. These standards cover aspects such as pressure resistance, leak testing, and structural integrity. Certification processes typically involve rigorous testing under various conditions to verify compliance with international safety regulations. These standards help minimize risks associated with hydrogen storage and ensure consistent quality across manufacturers.- Safety standards and certification for metal hydride tanks: Metal hydride tanks must meet specific safety standards and certifications to ensure their safe operation. These standards typically cover aspects such as pressure resistance, leak testing, and structural integrity. Certification processes often involve rigorous testing under various conditions to verify that the tanks can safely store and release hydrogen without failure. International standards organizations have developed specific guidelines for metal hydride storage systems that manufacturers must adhere to.

- Design specifications for metal hydride storage systems: Metal hydride tanks require specific design considerations to optimize hydrogen storage capacity and safety. These specifications include appropriate material selection, internal structure design, heat exchange mechanisms, and pressure management systems. The design must account for the expansion and contraction of metal hydrides during hydrogen absorption and desorption cycles while maintaining structural integrity. Proper thermal management is essential to control the heat generated during hydrogen absorption and required for desorption.

- Testing protocols for metal hydride storage tanks: Comprehensive testing protocols are established to evaluate the performance and safety of metal hydride tanks. These tests include cycling stability, thermal response, pressure resistance, and leak detection. Accelerated aging tests are conducted to predict long-term performance and identify potential failure modes. Environmental testing assesses the tanks' resistance to various conditions such as temperature extremes, vibration, and impact. These protocols ensure that metal hydride tanks meet the required standards before certification.

- Material requirements for metal hydride tanks: The materials used in metal hydride tanks must meet specific requirements to ensure safety and efficiency. These materials need to have high hydrogen absorption capacity, good thermal conductivity, and resistance to hydrogen embrittlement. The container materials must withstand the pressure and temperature conditions during operation while being compatible with the metal hydride alloys inside. Corrosion resistance is also crucial for long-term durability. Advanced alloys and composites are being developed to improve the performance characteristics of metal hydride storage systems.

- Integration standards for hydrogen storage systems: Standards for integrating metal hydride tanks into larger hydrogen systems address compatibility, connectivity, and system-level safety. These standards ensure that metal hydride storage components can be safely and effectively connected to hydrogen production, distribution, and utilization equipment. Interface specifications define the requirements for connections, controls, and monitoring systems. System-level certification considers the interaction between the storage tank and other components to prevent cascading failures and ensure overall system reliability.

02 Design specifications for metal hydride hydrogen storage systems

Design specifications for metal hydride tanks include considerations for material compatibility, thermal management systems, and pressure regulation mechanisms. These specifications ensure optimal hydrogen absorption and desorption rates while maintaining structural integrity. Key design elements include heat exchange systems to manage the exothermic absorption process, pressure relief devices, and appropriate container materials that resist hydrogen embrittlement. Proper design is essential for efficient and safe hydrogen storage.Expand Specific Solutions03 Testing protocols for metal hydride storage containers

Testing protocols for metal hydride tanks involve cycling tests, thermal stability assessments, and pressure resistance evaluations. These tests verify the tank's ability to withstand repeated hydrogen charging and discharging cycles without degradation. Testing also includes environmental exposure tests, vibration resistance, and impact resistance to simulate real-world conditions. Standardized testing methods ensure consistency in evaluating performance and safety across different manufacturers and applications.Expand Specific Solutions04 Material requirements for metal hydride storage vessels

Material requirements for metal hydride tanks focus on hydrogen compatibility, corrosion resistance, and thermal conductivity. The container materials must withstand hydrogen embrittlement while providing adequate heat transfer properties to manage the thermal effects of hydrogen absorption and desorption. Advanced alloys and composite materials are often specified to balance weight considerations with strength requirements. Material selection also considers manufacturing processes and cost-effectiveness while maintaining safety standards.Expand Specific Solutions05 Certification processes for commercial metal hydride applications

Certification processes for commercial metal hydride tanks involve third-party verification, documentation requirements, and compliance with industry-specific regulations. These processes typically include design review, manufacturing quality assessment, and performance validation testing. For automotive and transportation applications, additional certifications related to crash safety and environmental exposure may be required. Regular recertification may be necessary to ensure continued compliance as standards evolve and technology advances.Expand Specific Solutions

Key Industry Players and Certification Bodies

The metal hydride tank market is in an early growth phase, characterized by increasing demand for hydrogen storage solutions but still evolving standards and certification pathways. The market is expanding with the hydrogen economy, projected to reach significant scale as clean energy transitions accelerate. Technologically, the field shows varying maturity levels across players. Research institutions like CEA, CNRS, and IFP Energies Nouvelles are advancing fundamental technologies, while automotive manufacturers (Toyota, Hyundai, Kia) are integrating solutions into commercial applications. Industrial players such as thyssenkrupp Marine Systems, JFE Steel, and GRZ Technologies are developing specialized storage solutions, with companies like ULVAC and Shin-Etsu Chemical contributing materials expertise. The certification landscape remains fragmented, requiring harmonized international standards to facilitate broader market adoption.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed comprehensive certification frameworks for metal hydride hydrogen storage systems. Their approach focuses on fundamental materials science combined with engineering safety principles. CEA has established testing protocols for various metal hydride compositions, including AB5, AB2, and body-centered cubic (BCC) alloys, evaluating their performance across temperature ranges from -40°C to +85°C[2]. Their certification pathway addresses the unique challenges of metal hydride systems through specialized testing for thermal management, cycling stability (>1000 cycles), and material compatibility. CEA's methodology incorporates both European standards (EN 13648 for cryogenic vessels and EN ISO 7866 for gas cylinders) and international frameworks like ISO 16111 for transportable gas storage devices containing hydrogen absorbed in reversible metal hydrides[4]. The organization has pioneered non-destructive testing methods specifically adapted for metal hydride tanks, including acoustic emission testing during hydrogen cycling and specialized ultrasonic techniques to detect material degradation or hydride formation in tank walls[7].

Strengths: CEA brings strong scientific expertise in materials science and hydrogen storage mechanisms, enabling fundamental understanding of degradation mechanisms and safety factors. Their comprehensive testing protocols address both material and system-level certification requirements. Weaknesses: As a research organization rather than a commercial manufacturer, CEA's certification pathways may require additional validation in mass production environments and real-world applications.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered certification pathways for metal hydride storage systems through their NEXO fuel cell vehicle program. Their approach focuses on developing tanks that meet both automotive and stationary storage standards. Hyundai's metal hydride systems utilize AB5-type alloys (primarily LaNi5-based compounds) with modified compositions to enhance absorption/desorption kinetics and cycling stability[2]. Their certification process addresses the unique challenges of metal hydride systems, including thermal management during hydrogen absorption (an exothermic process) and material degradation over multiple cycles. Hyundai's tanks undergo pressure vessel certification according to EC79/2009 and EU 406/2010 regulations in Europe, while also meeting KGS AC411 standards in Korea and relevant DOT regulations in the US[4]. The company has established a comprehensive testing protocol that includes permeation testing, hydraulic pressure cycling (>100,000 cycles), extreme temperature exposure tests, and bonfire testing to validate safety under catastrophic conditions[6].

Strengths: Hyundai has successfully commercialized hydrogen vehicles with certified storage systems, demonstrating practical implementation of certification pathways. Their dual-focus on both mobile and stationary applications provides versatility. Weaknesses: Current metal hydride systems still face challenges with weight penalties and thermal management requirements during rapid refueling, which can complicate certification processes.

Critical Technical Standards and Testing Protocols

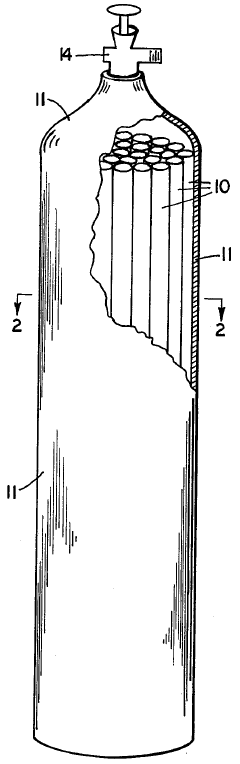

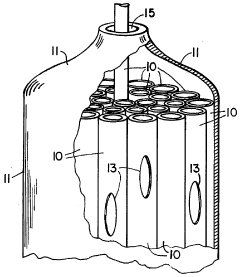

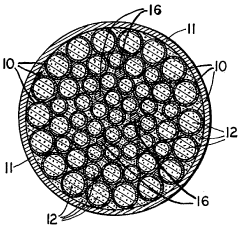

Method and apparatus for providing increased thermal conductivity and heat capacity to a pressure vessel containing a hydride-forming metal material

PatentInactiveUS4187092A

Innovation

- Incorporating a tightly packed bundle of aluminum, magnesium, or copper tubes within a certified pressure vessel, filled with particulate hydride-forming metal material, to enhance thermal conductivity and capacity, while maintaining the vessel's certification.

Regulatory Compliance and Safety Considerations

Metal hydride storage systems are subject to rigorous regulatory frameworks that vary significantly across global jurisdictions. In the United States, the Department of Transportation (DOT) and the Code of Federal Regulations (49 CFR) govern the transportation of hazardous materials, including hydrogen storage systems. The National Fire Protection Association (NFPA) provides additional safety standards through NFPA 2 and NFPA 55, specifically addressing hydrogen technologies and compressed gases.

European regulations are primarily governed by the Pressure Equipment Directive (PED 2014/68/EU) and the ADR for international transport of dangerous goods. The EU has also developed specific technical standards through CEN/TC 268 for cryogenic vessels and hydrogen technologies. Japan's High Pressure Gas Safety Act and KHK standards provide another regulatory model with particular emphasis on seismic considerations relevant to metal hydride storage systems.

Safety considerations for metal hydride tanks encompass multiple dimensions beyond regulatory compliance. Thermal management represents a critical safety factor due to the exothermic nature of hydrogen absorption and endothermic desorption processes. Inadequate thermal management can lead to dangerous pressure buildups or structural degradation of the storage medium.

Pressure relief mechanisms must be incorporated into tank designs to prevent catastrophic failures during abnormal operating conditions. These systems must respond appropriately to both gradual and sudden pressure increases while maintaining system integrity. Material compatibility issues present another safety challenge, as hydrogen embrittlement can compromise structural components, particularly at connection points and seals.

Certification pathways typically involve third-party testing and validation against established standards such as ISO 16111 for transportable gas storage devices or SAE J2579 for fuel systems in fuel cell vehicles. The certification process generally includes design validation, prototype testing, production quality assurance, and periodic inspection protocols.

Risk assessment methodologies have evolved specifically for hydrogen storage systems, incorporating Failure Mode and Effects Analysis (FMEA), Hazard and Operability Study (HAZOP), and quantitative risk assessment techniques. These methodologies help identify potential failure scenarios and establish appropriate mitigation measures throughout the product lifecycle.

End-of-life considerations and decommissioning procedures represent an emerging regulatory focus, with requirements for safe disposal or recycling of metal hydride materials. This aspect is particularly important given the potential environmental impacts of certain rare earth elements commonly used in advanced metal hydride formulations.

European regulations are primarily governed by the Pressure Equipment Directive (PED 2014/68/EU) and the ADR for international transport of dangerous goods. The EU has also developed specific technical standards through CEN/TC 268 for cryogenic vessels and hydrogen technologies. Japan's High Pressure Gas Safety Act and KHK standards provide another regulatory model with particular emphasis on seismic considerations relevant to metal hydride storage systems.

Safety considerations for metal hydride tanks encompass multiple dimensions beyond regulatory compliance. Thermal management represents a critical safety factor due to the exothermic nature of hydrogen absorption and endothermic desorption processes. Inadequate thermal management can lead to dangerous pressure buildups or structural degradation of the storage medium.

Pressure relief mechanisms must be incorporated into tank designs to prevent catastrophic failures during abnormal operating conditions. These systems must respond appropriately to both gradual and sudden pressure increases while maintaining system integrity. Material compatibility issues present another safety challenge, as hydrogen embrittlement can compromise structural components, particularly at connection points and seals.

Certification pathways typically involve third-party testing and validation against established standards such as ISO 16111 for transportable gas storage devices or SAE J2579 for fuel systems in fuel cell vehicles. The certification process generally includes design validation, prototype testing, production quality assurance, and periodic inspection protocols.

Risk assessment methodologies have evolved specifically for hydrogen storage systems, incorporating Failure Mode and Effects Analysis (FMEA), Hazard and Operability Study (HAZOP), and quantitative risk assessment techniques. These methodologies help identify potential failure scenarios and establish appropriate mitigation measures throughout the product lifecycle.

End-of-life considerations and decommissioning procedures represent an emerging regulatory focus, with requirements for safe disposal or recycling of metal hydride materials. This aspect is particularly important given the potential environmental impacts of certain rare earth elements commonly used in advanced metal hydride formulations.

International Harmonization of Certification Processes

The global nature of hydrogen technology development necessitates a coordinated approach to certification standards for metal hydride storage tanks. Currently, significant disparities exist between certification processes across major markets including North America, Europe, and Asia-Pacific regions. These differences create substantial barriers to market entry and increase compliance costs for manufacturers seeking multi-regional deployment.

Recent efforts toward international harmonization have been spearheaded by organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC). The ISO/TC 197 committee specifically focuses on hydrogen technologies and has made progress in developing unified standards for hydrogen storage systems, including metal hydride tanks. Their work on ISO 16111 represents a significant step toward global standardization for transportable hydrogen storage systems.

The Global Technical Regulation No. 13 (GTR-13) under the United Nations Economic Commission for Europe (UNECE) provides another framework for harmonization, particularly for hydrogen-powered vehicles. This regulation includes provisions for on-board hydrogen storage systems that incorporate metal hydride technologies, creating a pathway for consistent safety requirements across participating nations.

Mutual recognition agreements (MRAs) between certification bodies represent another promising approach to harmonization. These agreements allow for test results and certifications from one jurisdiction to be recognized in another, reducing redundant testing requirements. The European Union's agreements with countries like Japan, the United States, and South Korea demonstrate the potential of this approach to streamline market access while maintaining safety standards.

Challenges to harmonization include differing national safety philosophies, existing regulatory infrastructures, and varying technical requirements. For example, pressure vessel codes in North America (ASME) differ significantly from those in Europe (PED) and Japan (KHK), creating fundamental compatibility issues for metal hydride tank certification. Additionally, some regions emphasize performance-based standards while others focus on prescriptive requirements.

Economic considerations also impact harmonization efforts. Developing nations may lack the technical infrastructure to implement sophisticated testing regimes, while established markets may resist changes that could disrupt existing certification ecosystems. Finding a balance that ensures safety while enabling global market access remains a central challenge.

Future harmonization pathways will likely involve a tiered approach, with core safety requirements standardized globally while allowing for regional adaptations where necessary. Digital certification systems and blockchain technology may facilitate transparent cross-border recognition of compliance documentation, streamlining the verification process for metal hydride storage systems in international markets.

Recent efforts toward international harmonization have been spearheaded by organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC). The ISO/TC 197 committee specifically focuses on hydrogen technologies and has made progress in developing unified standards for hydrogen storage systems, including metal hydride tanks. Their work on ISO 16111 represents a significant step toward global standardization for transportable hydrogen storage systems.

The Global Technical Regulation No. 13 (GTR-13) under the United Nations Economic Commission for Europe (UNECE) provides another framework for harmonization, particularly for hydrogen-powered vehicles. This regulation includes provisions for on-board hydrogen storage systems that incorporate metal hydride technologies, creating a pathway for consistent safety requirements across participating nations.

Mutual recognition agreements (MRAs) between certification bodies represent another promising approach to harmonization. These agreements allow for test results and certifications from one jurisdiction to be recognized in another, reducing redundant testing requirements. The European Union's agreements with countries like Japan, the United States, and South Korea demonstrate the potential of this approach to streamline market access while maintaining safety standards.

Challenges to harmonization include differing national safety philosophies, existing regulatory infrastructures, and varying technical requirements. For example, pressure vessel codes in North America (ASME) differ significantly from those in Europe (PED) and Japan (KHK), creating fundamental compatibility issues for metal hydride tank certification. Additionally, some regions emphasize performance-based standards while others focus on prescriptive requirements.

Economic considerations also impact harmonization efforts. Developing nations may lack the technical infrastructure to implement sophisticated testing regimes, while established markets may resist changes that could disrupt existing certification ecosystems. Finding a balance that ensures safety while enabling global market access remains a central challenge.

Future harmonization pathways will likely involve a tiered approach, with core safety requirements standardized globally while allowing for regional adaptations where necessary. Digital certification systems and blockchain technology may facilitate transparent cross-border recognition of compliance documentation, streamlining the verification process for metal hydride storage systems in international markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!