Mapping Isocyanate's Role in Future Technology Implementations

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanates have undergone significant technological evolution since their discovery in the mid-20th century. Initially used primarily in the production of polyurethane foams, these versatile compounds have found applications across various industries, driving innovation and technological advancements.

The early stages of isocyanate technology focused on developing basic formulations for flexible and rigid foams. As research progressed, scientists discovered the potential of isocyanates in creating high-performance adhesives, coatings, and elastomers. This diversification led to a rapid expansion of isocyanate applications in automotive, construction, and consumer goods industries.

In the 1970s and 1980s, environmental concerns prompted researchers to explore more sustainable isocyanate technologies. This resulted in the development of water-based polyurethane dispersions and low-VOC formulations, marking a significant shift towards eco-friendly solutions.

The 1990s saw advancements in isocyanate chemistry, with the introduction of aliphatic isocyanates for UV-resistant coatings and the development of blocked isocyanates for improved handling and storage. These innovations expanded the use of isocyanates in outdoor applications and enhanced their industrial processing capabilities.

The turn of the millennium brought about a focus on nanotechnology, leading to the integration of nanoparticles with isocyanate-based materials. This combination resulted in enhanced mechanical properties, improved flame retardancy, and novel functionalities in polyurethane products.

Recent years have witnessed a surge in bio-based isocyanates, driven by the growing demand for sustainable materials. Researchers have successfully developed isocyanates derived from renewable resources, such as vegetable oils and lignin, paving the way for more environmentally friendly polyurethane products.

The ongoing evolution of isocyanate technology is now centered on smart materials and advanced manufacturing techniques. Self-healing polyurethanes, shape-memory materials, and 3D-printable isocyanate formulations are at the forefront of current research, promising revolutionary applications in fields like aerospace, healthcare, and wearable technology.

As we look to the future, the role of isocyanates in emerging technologies is set to expand further. Developments in areas such as energy storage, flexible electronics, and advanced composites are likely to leverage the unique properties of isocyanates, driving continued innovation and technological progress across multiple sectors.

The early stages of isocyanate technology focused on developing basic formulations for flexible and rigid foams. As research progressed, scientists discovered the potential of isocyanates in creating high-performance adhesives, coatings, and elastomers. This diversification led to a rapid expansion of isocyanate applications in automotive, construction, and consumer goods industries.

In the 1970s and 1980s, environmental concerns prompted researchers to explore more sustainable isocyanate technologies. This resulted in the development of water-based polyurethane dispersions and low-VOC formulations, marking a significant shift towards eco-friendly solutions.

The 1990s saw advancements in isocyanate chemistry, with the introduction of aliphatic isocyanates for UV-resistant coatings and the development of blocked isocyanates for improved handling and storage. These innovations expanded the use of isocyanates in outdoor applications and enhanced their industrial processing capabilities.

The turn of the millennium brought about a focus on nanotechnology, leading to the integration of nanoparticles with isocyanate-based materials. This combination resulted in enhanced mechanical properties, improved flame retardancy, and novel functionalities in polyurethane products.

Recent years have witnessed a surge in bio-based isocyanates, driven by the growing demand for sustainable materials. Researchers have successfully developed isocyanates derived from renewable resources, such as vegetable oils and lignin, paving the way for more environmentally friendly polyurethane products.

The ongoing evolution of isocyanate technology is now centered on smart materials and advanced manufacturing techniques. Self-healing polyurethanes, shape-memory materials, and 3D-printable isocyanate formulations are at the forefront of current research, promising revolutionary applications in fields like aerospace, healthcare, and wearable technology.

As we look to the future, the role of isocyanates in emerging technologies is set to expand further. Developments in areas such as energy storage, flexible electronics, and advanced composites are likely to leverage the unique properties of isocyanates, driving continued innovation and technological progress across multiple sectors.

Market Demand Analysis

The market demand for isocyanate-based technologies continues to grow, driven by their versatile applications across various industries. The global isocyanate market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 6% through 2027. This growth is primarily fueled by increasing demand in construction, automotive, and furniture industries, where isocyanates play a crucial role in producing polyurethanes and other advanced materials.

In the construction sector, isocyanates are essential components in the production of rigid foam insulation, sealants, and adhesives. The rising focus on energy-efficient buildings and sustainable construction practices has led to a surge in demand for high-performance insulation materials, where isocyanate-based products excel. This trend is expected to continue as governments worldwide implement stricter energy efficiency regulations for buildings.

The automotive industry represents another significant market for isocyanates, particularly in the manufacture of lightweight components, seat cushions, and interior trim. As the automotive sector shifts towards electric vehicles and emphasizes weight reduction for improved fuel efficiency, the demand for isocyanate-based materials is likely to increase. These materials offer excellent strength-to-weight ratios and contribute to enhanced vehicle performance and energy efficiency.

In the furniture and bedding industry, isocyanates are widely used in the production of flexible foams for mattresses, sofas, and other upholstered products. The growing consumer preference for comfortable and durable furniture, coupled with the expansion of the hospitality sector in emerging economies, is driving the demand for isocyanate-based materials in this segment.

The electronics industry is emerging as a promising new market for isocyanates, particularly in the production of protective coatings and encapsulants for electronic components. As electronic devices become more compact and sophisticated, the need for advanced protective materials that can withstand harsh environments and ensure long-term reliability is increasing.

However, the market demand for isocyanates is not without challenges. Growing environmental concerns and regulatory pressures regarding the potential health hazards associated with isocyanate exposure are prompting industries to seek safer alternatives. This has led to increased research and development efforts focused on bio-based isocyanates and isocyanate-free technologies, which may impact the traditional isocyanate market in the long term.

Despite these challenges, the overall market outlook for isocyanates remains positive, with opportunities for growth in both established and emerging applications. The key to sustaining this growth will be the development of safer handling practices, more environmentally friendly production methods, and novel applications that leverage the unique properties of isocyanates in addressing future technological challenges.

In the construction sector, isocyanates are essential components in the production of rigid foam insulation, sealants, and adhesives. The rising focus on energy-efficient buildings and sustainable construction practices has led to a surge in demand for high-performance insulation materials, where isocyanate-based products excel. This trend is expected to continue as governments worldwide implement stricter energy efficiency regulations for buildings.

The automotive industry represents another significant market for isocyanates, particularly in the manufacture of lightweight components, seat cushions, and interior trim. As the automotive sector shifts towards electric vehicles and emphasizes weight reduction for improved fuel efficiency, the demand for isocyanate-based materials is likely to increase. These materials offer excellent strength-to-weight ratios and contribute to enhanced vehicle performance and energy efficiency.

In the furniture and bedding industry, isocyanates are widely used in the production of flexible foams for mattresses, sofas, and other upholstered products. The growing consumer preference for comfortable and durable furniture, coupled with the expansion of the hospitality sector in emerging economies, is driving the demand for isocyanate-based materials in this segment.

The electronics industry is emerging as a promising new market for isocyanates, particularly in the production of protective coatings and encapsulants for electronic components. As electronic devices become more compact and sophisticated, the need for advanced protective materials that can withstand harsh environments and ensure long-term reliability is increasing.

However, the market demand for isocyanates is not without challenges. Growing environmental concerns and regulatory pressures regarding the potential health hazards associated with isocyanate exposure are prompting industries to seek safer alternatives. This has led to increased research and development efforts focused on bio-based isocyanates and isocyanate-free technologies, which may impact the traditional isocyanate market in the long term.

Despite these challenges, the overall market outlook for isocyanates remains positive, with opportunities for growth in both established and emerging applications. The key to sustaining this growth will be the development of safer handling practices, more environmentally friendly production methods, and novel applications that leverage the unique properties of isocyanates in addressing future technological challenges.

Current Challenges

The implementation of isocyanates in future technologies faces several significant challenges that require careful consideration and innovative solutions. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and store safely. This reactivity, while beneficial for certain applications, poses risks in terms of occupational health and safety, necessitating stringent control measures and protective equipment.

Environmental concerns also present a major challenge. Isocyanates are known to have potential harmful effects on ecosystems, particularly aquatic environments. As global environmental regulations become more stringent, the use of isocyanates in various applications may face increased scrutiny and restrictions. This necessitates the development of more environmentally friendly alternatives or improved methods for containment and disposal.

The toxicity of isocyanates, especially their potential to cause respiratory sensitization and occupational asthma, remains a significant hurdle. Long-term exposure to even low levels of isocyanates can lead to chronic health issues, making their widespread use in consumer products problematic. This challenge extends to the manufacturing process, where worker safety is paramount and requires extensive protective measures.

Another technical challenge lies in the optimization of isocyanate-based materials for specific applications. While isocyanates offer versatility in polymer chemistry, fine-tuning their properties for emerging technologies such as advanced composites, smart materials, or biomedical applications requires extensive research and development. Achieving the right balance of reactivity, durability, and functionality remains an ongoing challenge for material scientists and engineers.

The cost-effectiveness of isocyanate-based technologies is also a concern, particularly in light of fluctuating raw material prices and the need for specialized handling equipment. As alternative materials and technologies emerge, the economic viability of isocyanate-based solutions may be challenged, necessitating continuous innovation to maintain their competitive edge.

Lastly, the regulatory landscape surrounding isocyanates is complex and evolving. Different countries and regions have varying regulations regarding the use, transport, and disposal of isocyanates. Navigating this regulatory environment and ensuring compliance across global markets presents a significant challenge for companies looking to implement isocyanate-based technologies on a large scale.

Environmental concerns also present a major challenge. Isocyanates are known to have potential harmful effects on ecosystems, particularly aquatic environments. As global environmental regulations become more stringent, the use of isocyanates in various applications may face increased scrutiny and restrictions. This necessitates the development of more environmentally friendly alternatives or improved methods for containment and disposal.

The toxicity of isocyanates, especially their potential to cause respiratory sensitization and occupational asthma, remains a significant hurdle. Long-term exposure to even low levels of isocyanates can lead to chronic health issues, making their widespread use in consumer products problematic. This challenge extends to the manufacturing process, where worker safety is paramount and requires extensive protective measures.

Another technical challenge lies in the optimization of isocyanate-based materials for specific applications. While isocyanates offer versatility in polymer chemistry, fine-tuning their properties for emerging technologies such as advanced composites, smart materials, or biomedical applications requires extensive research and development. Achieving the right balance of reactivity, durability, and functionality remains an ongoing challenge for material scientists and engineers.

The cost-effectiveness of isocyanate-based technologies is also a concern, particularly in light of fluctuating raw material prices and the need for specialized handling equipment. As alternative materials and technologies emerge, the economic viability of isocyanate-based solutions may be challenged, necessitating continuous innovation to maintain their competitive edge.

Lastly, the regulatory landscape surrounding isocyanates is complex and evolving. Different countries and regions have varying regulations regarding the use, transport, and disposal of isocyanates. Navigating this regulatory environment and ensuring compliance across global markets presents a significant challenge for companies looking to implement isocyanate-based technologies on a large scale.

Existing Applications

01 Synthesis and properties of isocyanates

Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or its derivatives. Various methods have been developed to control the reactivity and improve the handling of isocyanates in industrial applications.- Synthesis and modification of isocyanates: This category focuses on methods for synthesizing and modifying isocyanates. It includes processes for producing various types of isocyanates, as well as techniques for altering their chemical structure or properties. These methods can be used to create isocyanates with specific characteristics for different applications.

- Isocyanate-based polymers and coatings: This category covers the use of isocyanates in the production of polymers and coatings. It includes formulations and methods for creating polyurethanes, polyureas, and other isocyanate-based materials. These polymers and coatings can be used in various industries, such as automotive, construction, and electronics.

- Isocyanate curing and crosslinking: This category focuses on the use of isocyanates as curing agents or crosslinking agents in various materials. It includes methods for improving the mechanical properties, chemical resistance, and durability of polymers and composites through isocyanate-based curing or crosslinking reactions.

- Isocyanate-free alternatives and substitutes: This category explores alternatives and substitutes for isocyanates in various applications. It includes the development of new materials and processes that aim to replace isocyanates due to health, safety, or environmental concerns. These alternatives may offer similar performance characteristics while reducing potential risks associated with isocyanate use.

- Isocyanate handling and safety measures: This category addresses the safe handling and use of isocyanates in industrial settings. It includes methods for reducing exposure risks, improving storage and transportation safety, and developing protective equipment or systems for workers handling isocyanates. These measures aim to minimize potential health hazards associated with isocyanate exposure.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a crucial role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. Modified isocyanates and blocked isocyanates are used to control curing rates and improve storage stability in coating systems. The versatility of isocyanates allows for the development of a wide range of products with tailored properties for specific applications.Expand Specific Solutions03 Isocyanate-based foam technologies

Isocyanates are essential components in the production of polyurethane foams, which find applications in insulation, packaging, and automotive industries. The reaction of isocyanates with water or specific blowing agents generates carbon dioxide, creating the cellular structure of the foam. Advancements in isocyanate chemistry have led to the development of low-density, high-performance foams with improved thermal insulation properties and fire resistance.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity and potential health hazards, proper safety measures and handling procedures are crucial when working with isocyanates. This includes the use of personal protective equipment, adequate ventilation, and specialized storage conditions. Research has focused on developing less volatile and less hazardous isocyanate formulations, as well as improving detection methods for isocyanate exposure in industrial settings.Expand Specific Solutions05 Isocyanate-free alternatives and sustainable technologies

Growing environmental and health concerns have driven research into isocyanate-free alternatives and more sustainable technologies. This includes the development of bio-based isocyanates, non-isocyanate polyurethanes (NIPUs), and alternative crosslinking chemistries. These innovations aim to reduce the reliance on petroleum-based isocyanates while maintaining or improving the performance characteristics of traditional isocyanate-based products.Expand Specific Solutions

Key Industry Players

The isocyanate technology market is in a mature growth phase, characterized by steady expansion and ongoing innovation. The global market size is substantial, estimated to be in the billions of dollars, driven by diverse applications across industries such as automotive, construction, and electronics. Technologically, isocyanates are well-established, with major players like Wanhua Chemical, Covestro, and BASF leading in research and development. These companies are focusing on enhancing product performance, sustainability, and exploring new applications. Emerging trends include bio-based isocyanates and low-emission formulations, reflecting the industry's response to environmental concerns and regulatory pressures. The competitive landscape is intense, with established firms investing heavily in capacity expansion and technological advancements to maintain their market positions.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group is at the forefront of isocyanate technology implementation. They have developed a novel approach to produce bio-based isocyanates from renewable resources, reducing reliance on fossil fuels[1]. Their process involves the conversion of biomass-derived feedstocks into isocyanate precursors, followed by a catalytic transformation to yield high-purity isocyanates. This method achieves a carbon footprint reduction of up to 30% compared to traditional petrochemical routes[2]. Additionally, Wanhua has invested in advanced polyurethane formulations that incorporate these bio-based isocyanates, resulting in materials with enhanced biodegradability and reduced environmental impact[3].

Strengths: Sustainable production methods, reduced carbon footprint, and innovative bio-based materials. Weaknesses: Higher production costs compared to traditional methods and potential scalability challenges for large-scale implementation.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in isocyanate technology, focusing on sustainable and efficient production methods. They have developed a groundbreaking gas-phase technology for producing TDI (toluene diisocyanate), which reduces energy consumption by up to 60% and carbon dioxide emissions by up to 80% compared to conventional liquid-phase processes[4]. This technology also minimizes solvent use, enhancing overall process safety. Furthermore, Covestro has pioneered the use of carbon dioxide as a raw material for polyols, which are then combined with isocyanates to create innovative polyurethanes. This CO2 utilization technology can replace up to 20% of petroleum-based raw materials, contributing to a more circular economy[5].

Strengths: Energy-efficient production, significant reduction in carbon emissions, and innovative CO2 utilization. Weaknesses: High initial investment costs for new technology implementation and potential limitations in raw material availability for CO2-based processes.

Core Innovations

Environmental attributes for isocyanate compositions

PatentPendingUS20250053159A1

Innovation

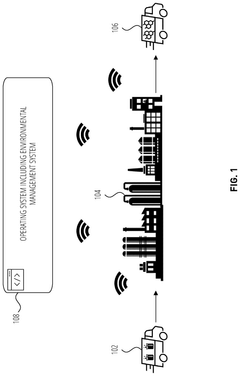

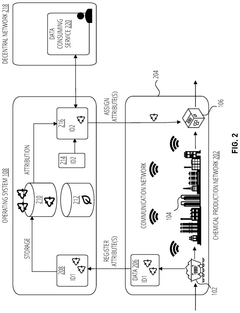

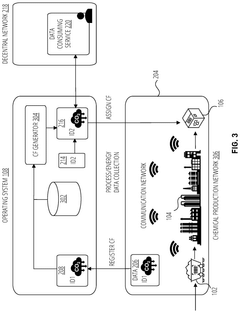

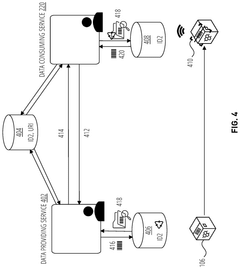

- A system is developed that produces isocyanate compositions associated with an isocyanate composition passport or digital asset. This system includes a chemical production network that produces isocyanate compositions from input materials through chemical processes, and a production operating apparatus that generates a decentral identifier linked to environmental attributes of the input materials and chemical processes, creating a digital asset that tracks environmental impact.

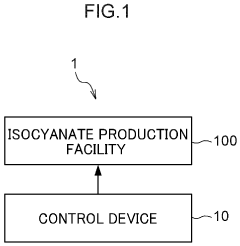

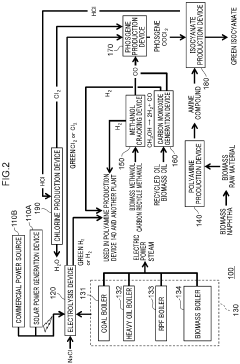

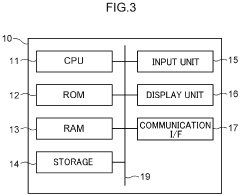

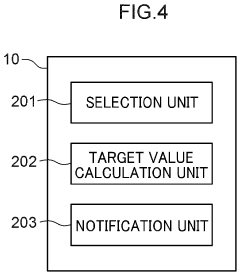

Isocyanate production system, isocyanate composition, polymerizable composition, resin, and molded article

PatentPendingEP4371974A1

Innovation

- An isocyanate production system that utilizes biomass-based energy sources, recycled materials, and carbon monoxide and hydrogen generated from renewable sources to produce phosgene and polyamine compounds, with a control device optimizing energy and material usage to minimize environmental load and carbon dioxide emissions.

Environmental Impact

Isocyanates, widely used in the production of polyurethanes, have significant environmental implications that must be carefully considered in future technology implementations. The production, use, and disposal of isocyanate-based products can have far-reaching effects on ecosystems, air quality, and human health.

During the manufacturing process, the release of isocyanates into the environment poses potential risks to air and water quality. Strict emission controls and advanced filtration systems are essential to mitigate these impacts. Additionally, the energy-intensive nature of isocyanate production contributes to greenhouse gas emissions, necessitating the development of more sustainable manufacturing methods.

The use phase of isocyanate-containing products presents another set of environmental challenges. While polyurethanes offer excellent insulation properties that can improve energy efficiency in buildings and appliances, the potential for off-gassing of volatile organic compounds (VOCs) remains a concern. Ongoing research is focused on developing low-VOC formulations and improving indoor air quality monitoring systems.

End-of-life management of isocyanate-based products is a critical environmental consideration. Many polyurethane products are not easily recyclable, contributing to landfill waste. However, innovative recycling technologies are emerging, such as chemical depolymerization and mechanical recycling, which could significantly reduce the environmental footprint of these materials.

The persistence of isocyanates and their breakdown products in the environment is an area of ongoing study. While some isocyanates degrade relatively quickly in the presence of moisture, others may persist longer, potentially affecting soil and aquatic ecosystems. Research into biodegradable alternatives and environmentally friendly catalysts is crucial for minimizing long-term environmental impacts.

Occupational and public health concerns related to isocyanate exposure have led to stricter regulations and improved safety protocols. Future technology implementations must prioritize the development of safer handling procedures, personal protective equipment, and exposure monitoring systems to protect workers and communities.

As the demand for polyurethane products continues to grow, balancing the benefits of isocyanate-based technologies with their environmental impact becomes increasingly important. Future research and development efforts should focus on green chemistry principles, exploring bio-based alternatives, and improving the overall lifecycle assessment of isocyanate-containing products to ensure a more sustainable future for this versatile class of chemicals.

During the manufacturing process, the release of isocyanates into the environment poses potential risks to air and water quality. Strict emission controls and advanced filtration systems are essential to mitigate these impacts. Additionally, the energy-intensive nature of isocyanate production contributes to greenhouse gas emissions, necessitating the development of more sustainable manufacturing methods.

The use phase of isocyanate-containing products presents another set of environmental challenges. While polyurethanes offer excellent insulation properties that can improve energy efficiency in buildings and appliances, the potential for off-gassing of volatile organic compounds (VOCs) remains a concern. Ongoing research is focused on developing low-VOC formulations and improving indoor air quality monitoring systems.

End-of-life management of isocyanate-based products is a critical environmental consideration. Many polyurethane products are not easily recyclable, contributing to landfill waste. However, innovative recycling technologies are emerging, such as chemical depolymerization and mechanical recycling, which could significantly reduce the environmental footprint of these materials.

The persistence of isocyanates and their breakdown products in the environment is an area of ongoing study. While some isocyanates degrade relatively quickly in the presence of moisture, others may persist longer, potentially affecting soil and aquatic ecosystems. Research into biodegradable alternatives and environmentally friendly catalysts is crucial for minimizing long-term environmental impacts.

Occupational and public health concerns related to isocyanate exposure have led to stricter regulations and improved safety protocols. Future technology implementations must prioritize the development of safer handling procedures, personal protective equipment, and exposure monitoring systems to protect workers and communities.

As the demand for polyurethane products continues to grow, balancing the benefits of isocyanate-based technologies with their environmental impact becomes increasingly important. Future research and development efforts should focus on green chemistry principles, exploring bio-based alternatives, and improving the overall lifecycle assessment of isocyanate-containing products to ensure a more sustainable future for this versatile class of chemicals.

Safety Regulations

The safety regulations surrounding isocyanates play a crucial role in shaping their future technological implementations. As these compounds are known for their potential health hazards, particularly respiratory sensitization, stringent safety measures are essential for their continued use in various industries.

Regulatory bodies worldwide have established comprehensive guidelines for the handling, storage, and use of isocyanates. In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for different types of isocyanates. Similarly, the European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which include specific provisions for isocyanates.

These safety regulations have a significant impact on the development and adoption of isocyanate-based technologies. Manufacturers and end-users must invest in advanced engineering controls, personal protective equipment, and monitoring systems to ensure compliance. This has led to the emergence of innovative technologies aimed at reducing worker exposure and improving overall safety in isocyanate-related processes.

One notable trend is the development of low-free monomer (LFM) isocyanates, which contain significantly reduced levels of unreacted monomers. These formulations offer improved safety profiles while maintaining the desirable properties of traditional isocyanates. Additionally, there is a growing focus on the development of non-isocyanate polyurethanes (NIPUs) as alternative technologies that can potentially circumvent some of the safety concerns associated with isocyanates.

The implementation of safety regulations has also driven advancements in detection and monitoring technologies. Real-time isocyanate monitors and personal exposure devices have become increasingly sophisticated, allowing for more accurate and timely detection of potential hazards. These technologies not only enhance workplace safety but also provide valuable data for further improving safety protocols and regulations.

As environmental concerns gain prominence, safety regulations are expanding to encompass the entire lifecycle of isocyanate-based products. This includes considerations for sustainable production, safe disposal, and potential environmental impacts. Future technological implementations will need to address these broader safety and environmental considerations, potentially leading to the development of more eco-friendly isocyanate alternatives or improved recycling methods for isocyanate-containing materials.

The ongoing evolution of safety regulations will continue to shape the landscape of isocyanate technology. As our understanding of the long-term effects of isocyanate exposure grows, regulations are likely to become more stringent. This regulatory pressure will drive further innovation in safer handling methods, exposure mitigation technologies, and potentially the development of entirely new classes of materials that can replicate the beneficial properties of isocyanates without the associated safety concerns.

Regulatory bodies worldwide have established comprehensive guidelines for the handling, storage, and use of isocyanates. In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for different types of isocyanates. Similarly, the European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which include specific provisions for isocyanates.

These safety regulations have a significant impact on the development and adoption of isocyanate-based technologies. Manufacturers and end-users must invest in advanced engineering controls, personal protective equipment, and monitoring systems to ensure compliance. This has led to the emergence of innovative technologies aimed at reducing worker exposure and improving overall safety in isocyanate-related processes.

One notable trend is the development of low-free monomer (LFM) isocyanates, which contain significantly reduced levels of unreacted monomers. These formulations offer improved safety profiles while maintaining the desirable properties of traditional isocyanates. Additionally, there is a growing focus on the development of non-isocyanate polyurethanes (NIPUs) as alternative technologies that can potentially circumvent some of the safety concerns associated with isocyanates.

The implementation of safety regulations has also driven advancements in detection and monitoring technologies. Real-time isocyanate monitors and personal exposure devices have become increasingly sophisticated, allowing for more accurate and timely detection of potential hazards. These technologies not only enhance workplace safety but also provide valuable data for further improving safety protocols and regulations.

As environmental concerns gain prominence, safety regulations are expanding to encompass the entire lifecycle of isocyanate-based products. This includes considerations for sustainable production, safe disposal, and potential environmental impacts. Future technological implementations will need to address these broader safety and environmental considerations, potentially leading to the development of more eco-friendly isocyanate alternatives or improved recycling methods for isocyanate-containing materials.

The ongoing evolution of safety regulations will continue to shape the landscape of isocyanate technology. As our understanding of the long-term effects of isocyanate exposure grows, regulations are likely to become more stringent. This regulatory pressure will drive further innovation in safer handling methods, exposure mitigation technologies, and potentially the development of entirely new classes of materials that can replicate the beneficial properties of isocyanates without the associated safety concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!