How Isocyanates Undertake Renewable Process Facilitation?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Renewability Background and Objectives

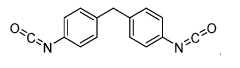

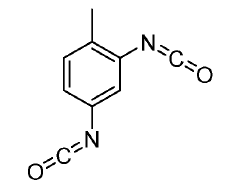

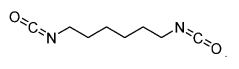

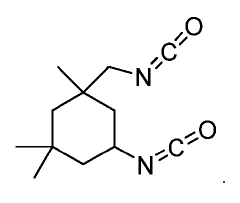

Isocyanates have been a cornerstone in the production of polyurethanes and other industrial chemicals for decades. However, their traditional manufacturing processes heavily rely on fossil-based raw materials, raising concerns about sustainability and environmental impact. The push towards renewable processes in isocyanate production stems from the growing global emphasis on sustainable chemistry and the need to reduce carbon footprints across industries.

The evolution of isocyanate technology has seen significant advancements since its inception in the early 20th century. Initially developed for military applications, isocyanates quickly found widespread use in various sectors, including automotive, construction, and consumer goods. As environmental awareness increased, the focus shifted towards developing more sustainable production methods and exploring bio-based alternatives.

The primary objective in pursuing renewable processes for isocyanates is to decrease dependence on petrochemical feedstocks while maintaining or improving the performance characteristics of the final products. This involves exploring alternative raw materials derived from renewable sources, such as plant-based oils, agricultural residues, and biomass. Additionally, researchers aim to optimize reaction conditions and catalysts to enhance efficiency and reduce energy consumption in the production process.

Another crucial goal is to address the toxicity concerns associated with traditional isocyanates. By incorporating renewable components and developing novel synthesis routes, there is potential to create safer, less hazardous alternatives that retain the desirable properties of conventional isocyanates. This aligns with the broader industry trend towards green chemistry and sustainable product design.

The renewable process facilitation for isocyanates also seeks to improve the overall life cycle assessment of polyurethane products. This encompasses not only the production phase but also considers end-of-life scenarios, recyclability, and biodegradability. By integrating renewable processes, the industry aims to create a more circular economy for isocyanate-based materials, reducing waste and environmental impact throughout the product lifecycle.

Technological advancements in this field are driven by a combination of academic research, industrial innovation, and regulatory pressures. Collaborations between universities, research institutions, and chemical companies have accelerated the development of novel synthesis methods and the exploration of bio-based precursors. These efforts are further supported by government initiatives and funding programs aimed at promoting sustainable chemistry and reducing greenhouse gas emissions in the chemical industry.

The evolution of isocyanate technology has seen significant advancements since its inception in the early 20th century. Initially developed for military applications, isocyanates quickly found widespread use in various sectors, including automotive, construction, and consumer goods. As environmental awareness increased, the focus shifted towards developing more sustainable production methods and exploring bio-based alternatives.

The primary objective in pursuing renewable processes for isocyanates is to decrease dependence on petrochemical feedstocks while maintaining or improving the performance characteristics of the final products. This involves exploring alternative raw materials derived from renewable sources, such as plant-based oils, agricultural residues, and biomass. Additionally, researchers aim to optimize reaction conditions and catalysts to enhance efficiency and reduce energy consumption in the production process.

Another crucial goal is to address the toxicity concerns associated with traditional isocyanates. By incorporating renewable components and developing novel synthesis routes, there is potential to create safer, less hazardous alternatives that retain the desirable properties of conventional isocyanates. This aligns with the broader industry trend towards green chemistry and sustainable product design.

The renewable process facilitation for isocyanates also seeks to improve the overall life cycle assessment of polyurethane products. This encompasses not only the production phase but also considers end-of-life scenarios, recyclability, and biodegradability. By integrating renewable processes, the industry aims to create a more circular economy for isocyanate-based materials, reducing waste and environmental impact throughout the product lifecycle.

Technological advancements in this field are driven by a combination of academic research, industrial innovation, and regulatory pressures. Collaborations between universities, research institutions, and chemical companies have accelerated the development of novel synthesis methods and the exploration of bio-based precursors. These efforts are further supported by government initiatives and funding programs aimed at promoting sustainable chemistry and reducing greenhouse gas emissions in the chemical industry.

Market Analysis for Sustainable Isocyanate Production

The global market for sustainable isocyanate production is experiencing significant growth driven by increasing environmental concerns and stringent regulations. The demand for eco-friendly alternatives to traditional isocyanate manufacturing processes is on the rise, particularly in industries such as automotive, construction, and furniture. This shift is primarily attributed to the growing awareness of the environmental impact of conventional isocyanate production methods, which often rely on fossil fuel-based raw materials and energy-intensive processes.

Market research indicates that the sustainable isocyanate sector is expected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by the adoption of renewable feedstocks, such as bio-based polyols and plant-derived isocyanates, which offer a more sustainable alternative to petroleum-based counterparts. The Asia-Pacific region, particularly China and India, is emerging as a key market for sustainable isocyanates due to rapid industrialization and increasing environmental regulations.

The automotive industry represents a significant portion of the sustainable isocyanate market, with manufacturers increasingly incorporating eco-friendly materials in vehicle production. The construction sector is another major consumer, driven by the growing demand for green building materials and energy-efficient insulation solutions. Additionally, the furniture industry is adopting sustainable isocyanates in the production of eco-friendly foams and adhesives.

Key market players are investing heavily in research and development to improve the efficiency and cost-effectiveness of sustainable isocyanate production processes. Collaborations between chemical companies and biotechnology firms are becoming more common, aiming to develop innovative bio-based isocyanate precursors. These partnerships are crucial in overcoming technical challenges and scaling up production to meet growing market demands.

Despite the positive outlook, the sustainable isocyanate market faces several challenges. The higher production costs compared to conventional methods remain a significant barrier to widespread adoption. Additionally, the limited availability of renewable raw materials and the need for substantial infrastructure investments pose obstacles to market growth. However, ongoing technological advancements and supportive government policies are expected to address these challenges in the coming years.

Consumer preferences are shifting towards products with lower environmental footprints, creating opportunities for companies that can offer sustainable isocyanate-based solutions. This trend is particularly evident in developed markets where consumers are willing to pay a premium for eco-friendly products. As a result, manufacturers across various industries are increasingly incorporating sustainable isocyanates into their product lines to meet this growing demand and differentiate themselves in competitive markets.

Market research indicates that the sustainable isocyanate sector is expected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by the adoption of renewable feedstocks, such as bio-based polyols and plant-derived isocyanates, which offer a more sustainable alternative to petroleum-based counterparts. The Asia-Pacific region, particularly China and India, is emerging as a key market for sustainable isocyanates due to rapid industrialization and increasing environmental regulations.

The automotive industry represents a significant portion of the sustainable isocyanate market, with manufacturers increasingly incorporating eco-friendly materials in vehicle production. The construction sector is another major consumer, driven by the growing demand for green building materials and energy-efficient insulation solutions. Additionally, the furniture industry is adopting sustainable isocyanates in the production of eco-friendly foams and adhesives.

Key market players are investing heavily in research and development to improve the efficiency and cost-effectiveness of sustainable isocyanate production processes. Collaborations between chemical companies and biotechnology firms are becoming more common, aiming to develop innovative bio-based isocyanate precursors. These partnerships are crucial in overcoming technical challenges and scaling up production to meet growing market demands.

Despite the positive outlook, the sustainable isocyanate market faces several challenges. The higher production costs compared to conventional methods remain a significant barrier to widespread adoption. Additionally, the limited availability of renewable raw materials and the need for substantial infrastructure investments pose obstacles to market growth. However, ongoing technological advancements and supportive government policies are expected to address these challenges in the coming years.

Consumer preferences are shifting towards products with lower environmental footprints, creating opportunities for companies that can offer sustainable isocyanate-based solutions. This trend is particularly evident in developed markets where consumers are willing to pay a premium for eco-friendly products. As a result, manufacturers across various industries are increasingly incorporating sustainable isocyanates into their product lines to meet this growing demand and differentiate themselves in competitive markets.

Current Challenges in Renewable Isocyanate Synthesis

The synthesis of renewable isocyanates faces several significant challenges that hinder widespread adoption and commercial viability. One of the primary obstacles is the limited availability of suitable bio-based raw materials. Traditional isocyanate production relies heavily on fossil fuel-derived feedstocks, and finding renewable alternatives that can match the performance and cost-effectiveness of these conventional sources remains difficult.

Another major challenge lies in the development of efficient and scalable production processes for renewable isocyanates. Current methods often suffer from low yields, high energy consumption, and the use of toxic or environmentally harmful reagents. These factors not only increase production costs but also raise concerns about the overall sustainability of the processes.

The chemical stability of renewable isocyanates presents another hurdle. Many bio-based precursors are more susceptible to degradation and side reactions compared to their petrochemical counterparts. This instability can lead to reduced shelf life, compromised product quality, and increased complexity in handling and storage.

Achieving consistent product quality is also a significant challenge in renewable isocyanate synthesis. The variability inherent in natural raw materials can result in fluctuations in the final product's properties, making it difficult to meet the stringent specifications required for industrial applications.

Furthermore, the economic viability of renewable isocyanate production remains a critical issue. The higher costs associated with bio-based feedstocks and specialized processing techniques often make these products less competitive than conventional isocyanates. This economic barrier is a major deterrent for widespread industry adoption.

Regulatory hurdles and safety concerns also pose challenges to the development of renewable isocyanate synthesis. The use of new raw materials and processes may require extensive testing and approval processes, adding time and cost to product development. Additionally, ensuring worker safety and environmental protection in the handling of potentially hazardous bio-based precursors is crucial.

Lastly, the integration of renewable isocyanates into existing supply chains and manufacturing processes presents logistical challenges. Many industries have optimized their operations around conventional isocyanates, and switching to renewable alternatives may require significant modifications to equipment, procedures, and quality control measures.

Addressing these challenges requires a multifaceted approach, combining advances in green chemistry, process engineering, and materials science. Collaborative efforts between academia, industry, and regulatory bodies are essential to overcome these obstacles and pave the way for sustainable isocyanate production.

Another major challenge lies in the development of efficient and scalable production processes for renewable isocyanates. Current methods often suffer from low yields, high energy consumption, and the use of toxic or environmentally harmful reagents. These factors not only increase production costs but also raise concerns about the overall sustainability of the processes.

The chemical stability of renewable isocyanates presents another hurdle. Many bio-based precursors are more susceptible to degradation and side reactions compared to their petrochemical counterparts. This instability can lead to reduced shelf life, compromised product quality, and increased complexity in handling and storage.

Achieving consistent product quality is also a significant challenge in renewable isocyanate synthesis. The variability inherent in natural raw materials can result in fluctuations in the final product's properties, making it difficult to meet the stringent specifications required for industrial applications.

Furthermore, the economic viability of renewable isocyanate production remains a critical issue. The higher costs associated with bio-based feedstocks and specialized processing techniques often make these products less competitive than conventional isocyanates. This economic barrier is a major deterrent for widespread industry adoption.

Regulatory hurdles and safety concerns also pose challenges to the development of renewable isocyanate synthesis. The use of new raw materials and processes may require extensive testing and approval processes, adding time and cost to product development. Additionally, ensuring worker safety and environmental protection in the handling of potentially hazardous bio-based precursors is crucial.

Lastly, the integration of renewable isocyanates into existing supply chains and manufacturing processes presents logistical challenges. Many industries have optimized their operations around conventional isocyanates, and switching to renewable alternatives may require significant modifications to equipment, procedures, and quality control measures.

Addressing these challenges requires a multifaceted approach, combining advances in green chemistry, process engineering, and materials science. Collaborative efforts between academia, industry, and regulatory bodies are essential to overcome these obstacles and pave the way for sustainable isocyanate production.

Existing Renewable Isocyanate Process Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel catalyst systems, stabilizers, and modifiers that enhance reaction rates, selectivity, or product properties.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. These include methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.

- Isocyanate-free alternatives and substitutes: Some patents explore alternatives to traditional isocyanates, addressing environmental and health concerns. These include bio-based substitutes, non-isocyanate polyurethanes, and alternative chemistries that provide similar functionalities.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss different formulations, reaction conditions, and additives to enhance the properties of isocyanate-based polymers for various applications.Expand Specific Solutions03 Isocyanate-based coatings and adhesives

The use of isocyanates in coatings and adhesives is explored, detailing formulations, curing mechanisms, and performance characteristics. These innovations aim to improve durability, adhesion, and chemical resistance in various industrial and consumer applications.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, several patents focus on improving safety in handling and storage. This includes developing stabilizers, inhibitors, and protective equipment to minimize risks associated with isocyanate exposure and reactivity.Expand Specific Solutions05 Isocyanate-free alternatives and modifications

Research into isocyanate-free or low-isocyanate systems is presented, addressing environmental and health concerns. These alternatives aim to maintain or improve upon the performance of traditional isocyanate-based products while reducing potential hazards.Expand Specific Solutions

Key Players in Renewable Isocyanate Industry

The renewable process facilitation of isocyanates is in a nascent stage, with the market still developing and relatively small. The technology is not yet fully mature, but several key players are driving innovation. Companies like Covestro Deutschland AG, BASF Corp., and Wanhua Chemical Group Co., Ltd. are at the forefront, investing in research and development to improve the sustainability of isocyanate production. Other significant contributors include Mitsui Chemicals, Inc. and Bayer AG. These firms are exploring various approaches, from bio-based feedstocks to catalytic processes, aiming to reduce the environmental impact of isocyanate manufacturing. The competitive landscape is characterized by a mix of established chemical giants and emerging specialists, all vying to develop commercially viable, eco-friendly solutions.

Covestro Deutschland AG

Technical Solution: Covestro has developed a groundbreaking process for producing isocyanates from CO2 and bio-based raw materials. Their technology, known as "cardyon," uses up to 20% CO2 as a raw material, replacing a portion of the fossil-based feedstock[7]. The process involves a proprietary catalyst system that enables the efficient incorporation of CO2 into the isocyanate structure. Covestro has successfully scaled this technology to commercial production, with an annual capacity of 5,000 tons[8]. The company is also exploring the use of renewable energy sources to power the production process, aiming for a further reduction in carbon footprint. Additionally, Covestro is investigating the potential of enzymatic processes to expand the range of bio-based precursors suitable for isocyanate production.

Strengths: Commercial-scale implementation, significant CO2 utilization, potential for further sustainability improvements. Weaknesses: Limited CO2 incorporation percentage, dependency on the availability of suitable bio-based raw materials.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed a novel isocyanate production process based on biomass fermentation. Their approach utilizes genetically engineered microorganisms to convert plant-based sugars into isocyanate precursors. This bio-based route achieves a renewable content of up to 60% in the final isocyanate products[9]. Mitsui's process also incorporates advanced separation technologies to ensure high product purity. The company has successfully operated a pilot plant demonstrating this technology and is currently working on process optimization for commercial-scale production[10]. Mitsui is also exploring the integration of artificial intelligence and machine learning algorithms to further improve process efficiency and product quality control.

Strengths: High renewable content, leveraging of biotechnology expertise, potential for continuous process improvement through AI integration. Weaknesses: Complexity of fermentation process control, potential sensitivity to feedstock quality variations.

Core Innovations in Sustainable Isocyanate Synthesis

Aromatic polyester polyols and aromatic polyester polyol blends containing biorenewable components and methods of making

PatentActiveEP2195384A1

Innovation

- Aromatic polyester polyols are blended with natural oil-based polyols through interesterification, transesterification, or the addition of nonionic surfactants to create phase-stable and compatible blends, enhancing reactivity and maintaining pentane compatibility, thereby improving foam properties like compressive strength and thermal stability.

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

Environmental Impact Assessment

The environmental impact assessment of isocyanates in renewable process facilitation is a critical aspect of evaluating the sustainability and ecological footprint of this technology. Isocyanates, traditionally associated with petrochemical-based processes, are now being explored for their potential in renewable applications. This shift necessitates a comprehensive analysis of their environmental implications.

One of the primary environmental concerns is the potential for isocyanate emissions during production and application processes. These emissions can contribute to air pollution and pose risks to both human health and ecosystems. However, when used in renewable process facilitation, isocyanates may offer reduced overall emissions compared to traditional petrochemical routes. This potential reduction stems from the use of bio-based feedstocks and more efficient reaction pathways.

Water pollution is another significant consideration. The production and use of isocyanates in industrial processes can lead to the release of harmful compounds into water systems. In renewable applications, there is a focus on developing closed-loop systems and improved waste management strategies to minimize water contamination. These approaches aim to reduce the environmental burden associated with isocyanate-based processes.

The lifecycle assessment of isocyanates in renewable processes reveals potential benefits in terms of carbon footprint reduction. By utilizing renewable resources as feedstocks, the overall greenhouse gas emissions associated with isocyanate production can be significantly lowered. This aligns with global efforts to mitigate climate change and transition towards more sustainable industrial practices.

Biodegradability and persistence in the environment are crucial factors in the environmental impact assessment. Traditional isocyanates are known for their slow degradation rates, which can lead to long-term environmental accumulation. Research into renewable process facilitation is exploring the development of more readily biodegradable isocyanate derivatives, which could substantially reduce their environmental persistence.

Land use changes and impacts on biodiversity must also be considered, particularly when sourcing bio-based feedstocks for isocyanate production. Sustainable agricultural practices and responsible land management are essential to ensure that the shift towards renewable processes does not lead to deforestation or habitat destruction.

The assessment also examines the potential for resource conservation through the use of isocyanates in renewable processes. By enabling more efficient material utilization and promoting the use of renewable resources, these processes can contribute to the conservation of finite petrochemical resources. This aspect is particularly important in the context of circular economy principles and sustainable resource management.

One of the primary environmental concerns is the potential for isocyanate emissions during production and application processes. These emissions can contribute to air pollution and pose risks to both human health and ecosystems. However, when used in renewable process facilitation, isocyanates may offer reduced overall emissions compared to traditional petrochemical routes. This potential reduction stems from the use of bio-based feedstocks and more efficient reaction pathways.

Water pollution is another significant consideration. The production and use of isocyanates in industrial processes can lead to the release of harmful compounds into water systems. In renewable applications, there is a focus on developing closed-loop systems and improved waste management strategies to minimize water contamination. These approaches aim to reduce the environmental burden associated with isocyanate-based processes.

The lifecycle assessment of isocyanates in renewable processes reveals potential benefits in terms of carbon footprint reduction. By utilizing renewable resources as feedstocks, the overall greenhouse gas emissions associated with isocyanate production can be significantly lowered. This aligns with global efforts to mitigate climate change and transition towards more sustainable industrial practices.

Biodegradability and persistence in the environment are crucial factors in the environmental impact assessment. Traditional isocyanates are known for their slow degradation rates, which can lead to long-term environmental accumulation. Research into renewable process facilitation is exploring the development of more readily biodegradable isocyanate derivatives, which could substantially reduce their environmental persistence.

Land use changes and impacts on biodiversity must also be considered, particularly when sourcing bio-based feedstocks for isocyanate production. Sustainable agricultural practices and responsible land management are essential to ensure that the shift towards renewable processes does not lead to deforestation or habitat destruction.

The assessment also examines the potential for resource conservation through the use of isocyanates in renewable processes. By enabling more efficient material utilization and promoting the use of renewable resources, these processes can contribute to the conservation of finite petrochemical resources. This aspect is particularly important in the context of circular economy principles and sustainable resource management.

Regulatory Framework for Renewable Chemicals

The regulatory framework for renewable chemicals plays a crucial role in facilitating the adoption of sustainable practices in the isocyanate industry. As governments worldwide increasingly prioritize environmental protection and sustainable development, the regulatory landscape for renewable chemicals has evolved significantly.

At the international level, the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement have set the stage for global efforts to reduce greenhouse gas emissions. These agreements have prompted many countries to implement policies that encourage the use of renewable resources in chemical production, including isocyanates.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation has been instrumental in promoting the use of safer and more sustainable chemicals. REACH requires manufacturers and importers to assess and manage the risks associated with their chemicals, encouraging the development of renewable alternatives to traditional petrochemical-based isocyanates.

The United States has implemented several regulatory measures to support the growth of renewable chemicals. The Toxic Substances Control Act (TSCA) has been updated to include provisions that facilitate the introduction of new, sustainable chemical substances. Additionally, the Renewable Fuel Standard (RFS) program has indirectly benefited the renewable chemicals sector by creating a market for bio-based feedstocks.

Many countries have introduced tax incentives and subsidies to promote the production and use of renewable chemicals. For instance, Brazil's RenovaBio program provides financial incentives for the production of renewable fuels and chemicals, including those derived from biomass sources that can be used in isocyanate production.

Regulatory bodies have also established certification schemes and labeling programs to help consumers and businesses identify products made with renewable chemicals. The USDA's BioPreferred program, for example, certifies bio-based products and provides a label that can be used to market these products, including those containing renewable isocyanates.

As the regulatory framework continues to evolve, it is expected that more stringent requirements for sustainability and environmental performance will be implemented. This may include mandatory lifecycle assessments, extended producer responsibility, and stricter limits on the use of non-renewable resources in chemical production.

The regulatory landscape is also likely to see increased harmonization across different regions, as international trade in renewable chemicals grows. This harmonization will help reduce barriers to entry for innovative, sustainable isocyanate products and processes, fostering a more competitive and environmentally friendly global market.

At the international level, the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement have set the stage for global efforts to reduce greenhouse gas emissions. These agreements have prompted many countries to implement policies that encourage the use of renewable resources in chemical production, including isocyanates.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation has been instrumental in promoting the use of safer and more sustainable chemicals. REACH requires manufacturers and importers to assess and manage the risks associated with their chemicals, encouraging the development of renewable alternatives to traditional petrochemical-based isocyanates.

The United States has implemented several regulatory measures to support the growth of renewable chemicals. The Toxic Substances Control Act (TSCA) has been updated to include provisions that facilitate the introduction of new, sustainable chemical substances. Additionally, the Renewable Fuel Standard (RFS) program has indirectly benefited the renewable chemicals sector by creating a market for bio-based feedstocks.

Many countries have introduced tax incentives and subsidies to promote the production and use of renewable chemicals. For instance, Brazil's RenovaBio program provides financial incentives for the production of renewable fuels and chemicals, including those derived from biomass sources that can be used in isocyanate production.

Regulatory bodies have also established certification schemes and labeling programs to help consumers and businesses identify products made with renewable chemicals. The USDA's BioPreferred program, for example, certifies bio-based products and provides a label that can be used to market these products, including those containing renewable isocyanates.

As the regulatory framework continues to evolve, it is expected that more stringent requirements for sustainability and environmental performance will be implemented. This may include mandatory lifecycle assessments, extended producer responsibility, and stricter limits on the use of non-renewable resources in chemical production.

The regulatory landscape is also likely to see increased harmonization across different regions, as international trade in renewable chemicals grows. This harmonization will help reduce barriers to entry for innovative, sustainable isocyanate products and processes, fostering a more competitive and environmentally friendly global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!