Isocyanate Advances: Forging New Pathways in Research

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their initial discovery in the mid-19th century. The journey began with the synthesis of the first isocyanate compound by Wurtz in 1848, marking the inception of a chemical class that would revolutionize various industries. The early 20th century saw significant advancements in isocyanate chemistry, with Otto Bayer's groundbreaking work in the 1930s leading to the development of polyurethanes, a major milestone in the field.

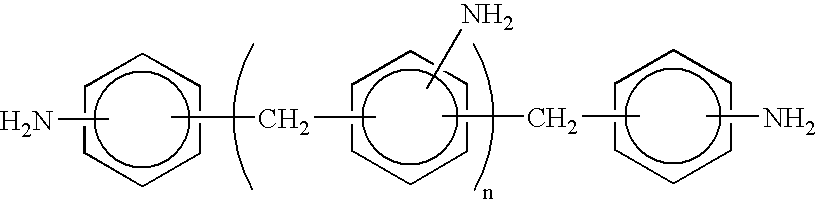

The post-World War II era witnessed an explosion of research and development in isocyanate technology. The 1950s and 1960s were characterized by the rapid commercialization of isocyanate-based products, particularly in the foam and coatings industries. This period also saw the emergence of new isocyanate types, including methylene diphenyl diisocyanate (MDI) and polymeric MDI, which offered improved performance and versatility compared to their predecessors.

The 1970s and 1980s brought increased focus on environmental and health concerns associated with isocyanates. This led to the development of safer handling procedures and the exploration of alternative chemistries. Concurrently, researchers began investigating the potential of isocyanates in novel applications, such as high-performance adhesives and elastomers.

The turn of the millennium marked a new era in isocyanate evolution, characterized by a shift towards sustainability and green chemistry. Efforts to develop bio-based isocyanates and reduce the environmental impact of production processes gained momentum. Additionally, advancements in nanotechnology opened up new avenues for isocyanate applications, particularly in the field of smart materials and coatings.

Recent years have seen a surge in research aimed at addressing the limitations of traditional isocyanates. This includes the development of non-toxic alternatives, such as non-isocyanate polyurethanes (NIPUs), and the exploration of novel catalytic systems for more efficient and selective isocyanate reactions. The advent of computational chemistry and high-throughput screening techniques has accelerated the discovery of new isocyanate compounds and formulations with enhanced properties.

Looking ahead, the evolution of isocyanates is poised to continue its trajectory of innovation. Emerging trends include the integration of isocyanates with other advanced materials, such as graphene and carbon nanotubes, to create hybrid composites with exceptional properties. Furthermore, the ongoing pursuit of sustainable and bio-based isocyanates is expected to yield breakthrough technologies that could reshape the industry landscape in the coming decades.

The post-World War II era witnessed an explosion of research and development in isocyanate technology. The 1950s and 1960s were characterized by the rapid commercialization of isocyanate-based products, particularly in the foam and coatings industries. This period also saw the emergence of new isocyanate types, including methylene diphenyl diisocyanate (MDI) and polymeric MDI, which offered improved performance and versatility compared to their predecessors.

The 1970s and 1980s brought increased focus on environmental and health concerns associated with isocyanates. This led to the development of safer handling procedures and the exploration of alternative chemistries. Concurrently, researchers began investigating the potential of isocyanates in novel applications, such as high-performance adhesives and elastomers.

The turn of the millennium marked a new era in isocyanate evolution, characterized by a shift towards sustainability and green chemistry. Efforts to develop bio-based isocyanates and reduce the environmental impact of production processes gained momentum. Additionally, advancements in nanotechnology opened up new avenues for isocyanate applications, particularly in the field of smart materials and coatings.

Recent years have seen a surge in research aimed at addressing the limitations of traditional isocyanates. This includes the development of non-toxic alternatives, such as non-isocyanate polyurethanes (NIPUs), and the exploration of novel catalytic systems for more efficient and selective isocyanate reactions. The advent of computational chemistry and high-throughput screening techniques has accelerated the discovery of new isocyanate compounds and formulations with enhanced properties.

Looking ahead, the evolution of isocyanates is poised to continue its trajectory of innovation. Emerging trends include the integration of isocyanates with other advanced materials, such as graphene and carbon nanotubes, to create hybrid composites with exceptional properties. Furthermore, the ongoing pursuit of sustainable and bio-based isocyanates is expected to yield breakthrough technologies that could reshape the industry landscape in the coming decades.

Market Applications

Isocyanates have found widespread applications across various industries due to their versatile chemical properties and reactivity. The polyurethane sector remains the largest consumer of isocyanates, with applications spanning from flexible and rigid foams to coatings, adhesives, sealants, and elastomers. In the automotive industry, isocyanates are crucial for producing lightweight materials, enhancing fuel efficiency, and improving vehicle safety through the use of polyurethane foams in seats, dashboards, and insulation.

The construction industry extensively utilizes isocyanate-based products for insulation, roofing materials, and sealants, contributing to energy-efficient buildings and infrastructure. In the furniture and bedding sector, isocyanates are essential for manufacturing memory foam mattresses and cushions, offering superior comfort and durability. The footwear industry relies on isocyanate-based materials for producing high-performance athletic shoes and durable work boots.

Emerging applications in the medical field include the development of advanced wound dressings, orthopedic supports, and biocompatible materials for implants. Isocyanates are also finding new uses in the electronics industry, particularly in the production of flexible and stretchable electronics, as well as in the development of protective coatings for electronic components.

The textile industry is exploring innovative applications of isocyanates in the creation of water-resistant and breathable fabrics, as well as in the production of synthetic leather. In the aerospace sector, isocyanate-based composites are being used to develop lightweight yet strong materials for aircraft interiors and structural components, contributing to fuel efficiency and reduced emissions.

Environmental concerns have driven research into bio-based isocyanates derived from renewable resources, opening up new market opportunities in sustainable and eco-friendly products. This shift aligns with the growing demand for green chemistry solutions across various industries. Additionally, the packaging industry is exploring isocyanate-based materials for creating high-barrier films and coatings to extend the shelf life of food products and reduce waste.

As nanotechnology advances, isocyanates are being incorporated into nanocomposites, offering enhanced mechanical, thermal, and barrier properties for specialized applications in aerospace, automotive, and electronics industries. The ongoing research in isocyanate chemistry continues to unlock new potential applications, driving innovation and market growth across diverse sectors.

The construction industry extensively utilizes isocyanate-based products for insulation, roofing materials, and sealants, contributing to energy-efficient buildings and infrastructure. In the furniture and bedding sector, isocyanates are essential for manufacturing memory foam mattresses and cushions, offering superior comfort and durability. The footwear industry relies on isocyanate-based materials for producing high-performance athletic shoes and durable work boots.

Emerging applications in the medical field include the development of advanced wound dressings, orthopedic supports, and biocompatible materials for implants. Isocyanates are also finding new uses in the electronics industry, particularly in the production of flexible and stretchable electronics, as well as in the development of protective coatings for electronic components.

The textile industry is exploring innovative applications of isocyanates in the creation of water-resistant and breathable fabrics, as well as in the production of synthetic leather. In the aerospace sector, isocyanate-based composites are being used to develop lightweight yet strong materials for aircraft interiors and structural components, contributing to fuel efficiency and reduced emissions.

Environmental concerns have driven research into bio-based isocyanates derived from renewable resources, opening up new market opportunities in sustainable and eco-friendly products. This shift aligns with the growing demand for green chemistry solutions across various industries. Additionally, the packaging industry is exploring isocyanate-based materials for creating high-barrier films and coatings to extend the shelf life of food products and reduce waste.

As nanotechnology advances, isocyanates are being incorporated into nanocomposites, offering enhanced mechanical, thermal, and barrier properties for specialized applications in aerospace, automotive, and electronics industries. The ongoing research in isocyanate chemistry continues to unlock new potential applications, driving innovation and market growth across diverse sectors.

Technical Challenges

The field of isocyanate research faces several significant technical challenges that hinder further advancements and applications. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and control in various processes. This reactivity, while beneficial for certain applications, poses safety risks and complicates storage and transportation.

Another major challenge lies in the toxicity of many isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This health concern necessitates stringent safety measures and personal protective equipment, which can increase production costs and limit widespread use in certain industries.

The environmental impact of isocyanate production and use presents another hurdle. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, raising concerns about worker safety and environmental contamination. Developing greener, more sustainable production methods remains a significant challenge for researchers and industry professionals.

Isocyanate-based products, such as polyurethanes, face end-of-life issues related to recycling and disposal. The cross-linked nature of many polyurethane materials makes them difficult to break down and recycle effectively, contributing to waste management problems and environmental concerns.

In the realm of performance, researchers are grappling with the challenge of enhancing the durability and longevity of isocyanate-based materials. Improving resistance to degradation factors such as UV radiation, moisture, and temperature fluctuations is crucial for expanding the application range of these materials in demanding environments.

The development of bio-based isocyanates represents another frontier in research. While there is growing interest in sustainable alternatives to petroleum-based isocyanates, creating bio-based versions that match or exceed the performance of traditional isocyanates remains a significant technical challenge. Issues such as scalability, cost-effectiveness, and consistent quality need to be addressed.

Lastly, the ongoing quest for isocyanate-free alternatives in certain applications poses a challenge to the industry. As regulations tighten and consumer preferences shift towards more environmentally friendly options, researchers must innovate to develop high-performance materials that can replace isocyanates in specific use cases without compromising on quality or functionality.

Another major challenge lies in the toxicity of many isocyanates, particularly their potential to cause respiratory sensitization and occupational asthma. This health concern necessitates stringent safety measures and personal protective equipment, which can increase production costs and limit widespread use in certain industries.

The environmental impact of isocyanate production and use presents another hurdle. Traditional manufacturing processes often involve the use of phosgene, a highly toxic gas, raising concerns about worker safety and environmental contamination. Developing greener, more sustainable production methods remains a significant challenge for researchers and industry professionals.

Isocyanate-based products, such as polyurethanes, face end-of-life issues related to recycling and disposal. The cross-linked nature of many polyurethane materials makes them difficult to break down and recycle effectively, contributing to waste management problems and environmental concerns.

In the realm of performance, researchers are grappling with the challenge of enhancing the durability and longevity of isocyanate-based materials. Improving resistance to degradation factors such as UV radiation, moisture, and temperature fluctuations is crucial for expanding the application range of these materials in demanding environments.

The development of bio-based isocyanates represents another frontier in research. While there is growing interest in sustainable alternatives to petroleum-based isocyanates, creating bio-based versions that match or exceed the performance of traditional isocyanates remains a significant technical challenge. Issues such as scalability, cost-effectiveness, and consistent quality need to be addressed.

Lastly, the ongoing quest for isocyanate-free alternatives in certain applications poses a challenge to the industry. As regulations tighten and consumer preferences shift towards more environmentally friendly options, researchers must innovate to develop high-performance materials that can replace isocyanates in specific use cases without compromising on quality or functionality.

Current Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

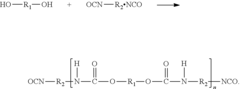

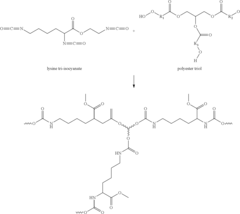

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and foams.

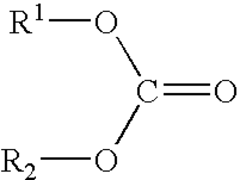

- Isocyanate-free alternatives and environmentally friendly processes: Research into isocyanate-free alternatives and more environmentally friendly processes for producing similar materials is described. This includes bio-based precursors and alternative reaction pathways to reduce environmental impact.

- Isocyanate handling and safety measures: Patents related to the safe handling, storage, and use of isocyanates are included. This covers protective equipment, exposure prevention methods, and risk mitigation strategies for working with these reactive compounds.

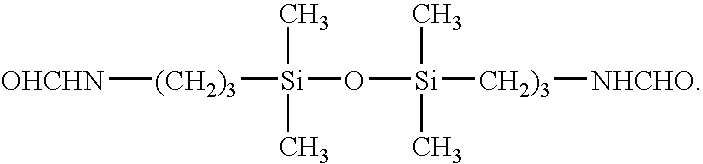

- Specialized isocyanate derivatives and modifications: Development of specialized isocyanate derivatives and modifications for specific applications or improved properties is described. This includes blocked isocyanates, isocyanate-terminated prepolymers, and novel isocyanate-containing compounds with unique characteristics.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in industries such as coatings, adhesives, and foams.Expand Specific Solutions03 Isocyanate-free alternatives and environmentally friendly processes

Research into isocyanate-free alternatives and more environmentally friendly processes for producing similar materials is presented. This includes novel chemistries, bio-based precursors, and alternative reaction pathways to reduce reliance on traditional isocyanates.Expand Specific Solutions04 Isocyanate handling and safety measures

Given the reactive nature of isocyanates, several patents focus on improved handling techniques, safety measures, and storage methods. This includes specialized equipment, protective gear, and protocols for working with these compounds in industrial settings.Expand Specific Solutions05 Modification and functionalization of isocyanates

Various techniques for modifying and functionalizing isocyanates are described. These include the addition of specific functional groups, creation of isocyanate adducts, and development of blocked isocyanates for improved stability or tailored reactivity in different applications.Expand Specific Solutions

Industry Leaders

The isocyanate industry is in a mature growth phase, characterized by steady expansion and technological advancements. The global market size for isocyanates is projected to reach $44 billion by 2025, driven by increasing demand in construction, automotive, and furniture sectors. Major players like BASF, Covestro, and Wanhua Chemical are at the forefront of innovation, focusing on developing eco-friendly and high-performance isocyanates. These companies are investing heavily in R&D to improve production processes and expand applications. The technology is well-established, but there's ongoing research to address environmental concerns and enhance product efficiency, indicating a dynamic competitive landscape with opportunities for differentiation through sustainable solutions and novel applications.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative isocyanate-based solutions for various applications. Their research focuses on improving the performance and sustainability of polyurethanes. They have introduced novel aliphatic isocyanates with enhanced UV stability and durability for coatings applications[1]. BASF has also developed water-based polyurethane dispersions using specialized isocyanates, reducing VOC emissions in adhesives and coatings[2]. Their recent advancements include bio-based isocyanates derived from renewable resources, addressing the growing demand for sustainable materials[3].

Strengths: Wide range of applications, focus on sustainability, strong R&D capabilities. Weaknesses: Dependence on petrochemical feedstocks for some products, regulatory challenges in certain markets.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in isocyanate research, particularly in the development of more sustainable and efficient production processes. They have pioneered a novel gas-phase technology for producing TDI (toluene diisocyanate), which reduces energy consumption by up to 60% compared to conventional methods[4]. Covestro has also developed partially bio-based isocyanates, incorporating up to 70% renewable raw materials, thus reducing the carbon footprint of polyurethane products[5]. Their research extends to novel curing technologies for isocyanate-based coatings, improving performance while reducing environmental impact[6].

Strengths: Leadership in sustainable production processes, strong focus on bio-based materials, innovative curing technologies. Weaknesses: High investment costs for new production technologies, market volatility for specialty chemicals.

Key Innovations

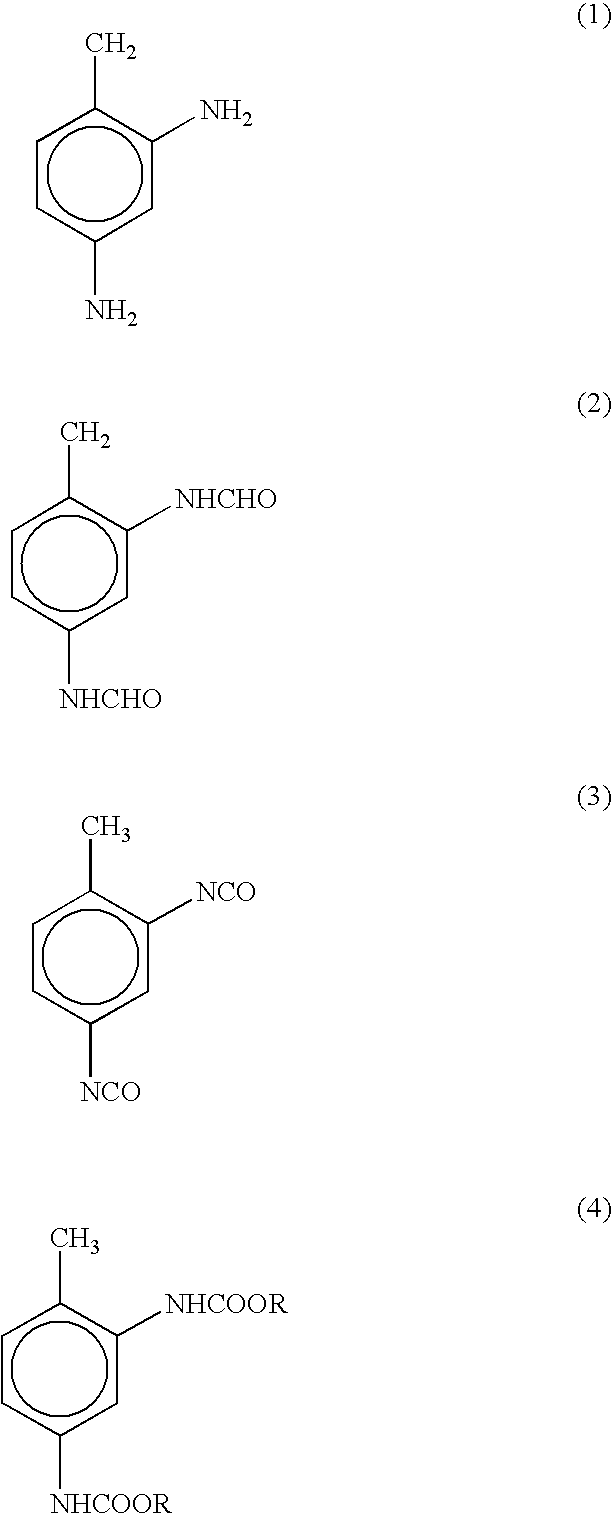

Non-phosgene route to the manufacture of organic isocyanates

PatentInactiveUS6781010B1

Innovation

- The synthesis of organic isocyanates through the reaction of formamides with diorganocarbonates, where the major byproducts can be thermolyzed to additional isocyanates or recycled to generate raw materials, resulting in a high-yield, efficient process with minimal waste.

Isocyanate manufacture

PatentActiveUS20120202961A1

Innovation

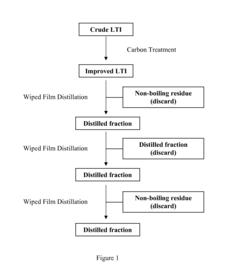

- The use of diphosgene (ClCO2CCl3) as a substitute for phosgene, allowing for the production of isocyanates at elevated temperatures, either through a two-reactor system or directly in a one-reactor system with a catalyst, to generate isocyanates like lysine ester triisocyanate (LTI) with high purity by reacting an amine with disphosgene.

Environmental Impact

Isocyanates, while crucial in various industrial applications, have long been associated with significant environmental concerns. The production, use, and disposal of isocyanate-containing products can lead to the release of harmful substances into the environment, affecting air, water, and soil quality. Recent advances in isocyanate research have focused on mitigating these environmental impacts through innovative approaches and sustainable practices.

One of the primary environmental challenges associated with isocyanates is their potential to contribute to air pollution. When released into the atmosphere, isocyanates can react with other compounds to form secondary pollutants, including ozone and particulate matter. These pollutants can have detrimental effects on both human health and ecosystems. To address this issue, researchers have been developing new formulations with reduced volatile organic compound (VOC) content and improved stability, minimizing the release of harmful emissions during production and application processes.

Water contamination is another significant concern in isocyanate-related industries. Improper disposal or accidental spills can lead to the presence of isocyanates and their byproducts in water bodies, posing risks to aquatic life and potentially entering the food chain. Recent research has focused on developing advanced water treatment technologies specifically designed to remove isocyanate compounds from industrial wastewater. These include novel filtration systems, advanced oxidation processes, and bioremediation techniques that utilize specialized microorganisms to break down isocyanate contaminants.

The persistence of isocyanates and their degradation products in soil has also been a subject of intensive study. Researchers are exploring new approaches to enhance the biodegradability of isocyanate-based materials, aiming to reduce their long-term environmental impact. This includes the development of bio-based isocyanates derived from renewable resources, which not only offer improved environmental profiles but also contribute to the circular economy by reducing reliance on fossil fuel-based raw materials.

In the realm of product design, there is a growing emphasis on creating isocyanate-based materials that are more easily recyclable or reusable at the end of their lifecycle. This involves developing new chemical structures and bonding techniques that allow for the efficient separation and recovery of isocyanate components from finished products. Such advancements not only reduce waste but also minimize the need for new raw material production, further decreasing the overall environmental footprint of isocyanate-related industries.

The environmental impact of isocyanates extends beyond their direct effects on ecosystems to include broader considerations such as energy consumption and greenhouse gas emissions associated with their production and use. To address these challenges, researchers are exploring more energy-efficient synthesis methods and investigating the potential of carbon capture and utilization technologies in isocyanate manufacturing processes. These efforts aim to significantly reduce the carbon footprint of isocyanate production while maintaining or even improving product performance.

One of the primary environmental challenges associated with isocyanates is their potential to contribute to air pollution. When released into the atmosphere, isocyanates can react with other compounds to form secondary pollutants, including ozone and particulate matter. These pollutants can have detrimental effects on both human health and ecosystems. To address this issue, researchers have been developing new formulations with reduced volatile organic compound (VOC) content and improved stability, minimizing the release of harmful emissions during production and application processes.

Water contamination is another significant concern in isocyanate-related industries. Improper disposal or accidental spills can lead to the presence of isocyanates and their byproducts in water bodies, posing risks to aquatic life and potentially entering the food chain. Recent research has focused on developing advanced water treatment technologies specifically designed to remove isocyanate compounds from industrial wastewater. These include novel filtration systems, advanced oxidation processes, and bioremediation techniques that utilize specialized microorganisms to break down isocyanate contaminants.

The persistence of isocyanates and their degradation products in soil has also been a subject of intensive study. Researchers are exploring new approaches to enhance the biodegradability of isocyanate-based materials, aiming to reduce their long-term environmental impact. This includes the development of bio-based isocyanates derived from renewable resources, which not only offer improved environmental profiles but also contribute to the circular economy by reducing reliance on fossil fuel-based raw materials.

In the realm of product design, there is a growing emphasis on creating isocyanate-based materials that are more easily recyclable or reusable at the end of their lifecycle. This involves developing new chemical structures and bonding techniques that allow for the efficient separation and recovery of isocyanate components from finished products. Such advancements not only reduce waste but also minimize the need for new raw material production, further decreasing the overall environmental footprint of isocyanate-related industries.

The environmental impact of isocyanates extends beyond their direct effects on ecosystems to include broader considerations such as energy consumption and greenhouse gas emissions associated with their production and use. To address these challenges, researchers are exploring more energy-efficient synthesis methods and investigating the potential of carbon capture and utilization technologies in isocyanate manufacturing processes. These efforts aim to significantly reduce the carbon footprint of isocyanate production while maintaining or even improving product performance.

Safety Regulations

The safety regulations surrounding isocyanates have become increasingly stringent in recent years, reflecting growing concerns about their potential health and environmental impacts. Regulatory bodies worldwide have implemented comprehensive frameworks to govern the production, handling, and use of isocyanates across various industries. These regulations primarily focus on minimizing exposure risks and ensuring proper containment and disposal practices.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE). The Environmental Protection Agency (EPA) also regulates isocyanates under the Toxic Substances Control Act (TSCA), mandating reporting, record-keeping, and testing requirements for companies involved in isocyanate production and use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which places strict controls on the manufacture, import, and use of isocyanates. Under REACH, companies must register isocyanate substances and provide detailed safety information. Additionally, the EU has introduced specific restrictions on certain diisocyanates, requiring professional and industrial users to undergo training on safe handling practices.

In Asia, countries like China and Japan have also strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has included isocyanates in its list of priority controlled chemicals, imposing stricter monitoring and reporting requirements. Japan's Industrial Safety and Health Law sets exposure limits and mandates regular health check-ups for workers handling isocyanates.

These regulations have significantly impacted isocyanate research and development. Researchers are now focusing on developing safer alternatives and improving existing isocyanate formulations to reduce health and environmental risks. This has led to innovations in low-emission and water-based isocyanate systems, as well as the exploration of bio-based isocyanates derived from renewable resources.

The regulatory landscape has also driven advancements in safety equipment and monitoring technologies. Companies are investing in sophisticated air quality monitoring systems, improved PPE designs, and more effective containment solutions. These developments not only ensure compliance with regulations but also contribute to overall workplace safety and environmental protection.

As research in isocyanate chemistry progresses, it is likely that safety regulations will continue to evolve. Future regulatory trends may include more stringent exposure limits, expanded training requirements, and increased focus on lifecycle management of isocyanate-containing products. This dynamic regulatory environment will continue to shape the direction of isocyanate research, driving innovation towards safer and more sustainable solutions in the coming years.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate exposure in the workplace. These include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE). The Environmental Protection Agency (EPA) also regulates isocyanates under the Toxic Substances Control Act (TSCA), mandating reporting, record-keeping, and testing requirements for companies involved in isocyanate production and use.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which places strict controls on the manufacture, import, and use of isocyanates. Under REACH, companies must register isocyanate substances and provide detailed safety information. Additionally, the EU has introduced specific restrictions on certain diisocyanates, requiring professional and industrial users to undergo training on safe handling practices.

In Asia, countries like China and Japan have also strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has included isocyanates in its list of priority controlled chemicals, imposing stricter monitoring and reporting requirements. Japan's Industrial Safety and Health Law sets exposure limits and mandates regular health check-ups for workers handling isocyanates.

These regulations have significantly impacted isocyanate research and development. Researchers are now focusing on developing safer alternatives and improving existing isocyanate formulations to reduce health and environmental risks. This has led to innovations in low-emission and water-based isocyanate systems, as well as the exploration of bio-based isocyanates derived from renewable resources.

The regulatory landscape has also driven advancements in safety equipment and monitoring technologies. Companies are investing in sophisticated air quality monitoring systems, improved PPE designs, and more effective containment solutions. These developments not only ensure compliance with regulations but also contribute to overall workplace safety and environmental protection.

As research in isocyanate chemistry progresses, it is likely that safety regulations will continue to evolve. Future regulatory trends may include more stringent exposure limits, expanded training requirements, and increased focus on lifecycle management of isocyanate-containing products. This dynamic regulatory environment will continue to shape the direction of isocyanate research, driving innovation towards safer and more sustainable solutions in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!