Leveraging Isocyanates for Advanced Engineering Solutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the mid-20th century. Initially synthesized by Adolph Wurtz in 1848, these compounds gained significant industrial importance in the 1930s when Otto Bayer developed polyurethanes. This breakthrough marked the beginning of a technological revolution in materials science.

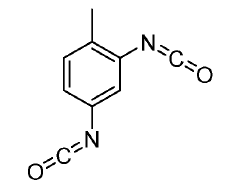

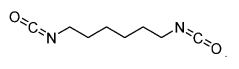

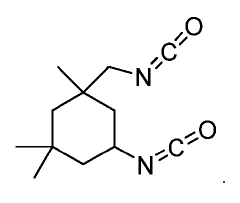

The 1950s and 1960s saw rapid advancements in isocyanate chemistry, with the development of various types including aromatic and aliphatic isocyanates. These innovations expanded the application scope, leading to the creation of flexible and rigid foams, elastomers, and coatings. The 1970s brought about environmental concerns, prompting research into more sustainable production methods and safer handling practices.

In the 1980s and 1990s, the focus shifted towards enhancing the performance characteristics of isocyanate-based products. This period witnessed the emergence of specialized isocyanates tailored for specific applications, such as high-performance adhesives and advanced composite materials. Concurrently, efforts to reduce volatile organic compound (VOC) emissions led to the development of water-based and high-solids formulations.

The turn of the millennium heralded a new era in isocyanate technology. Nanotechnology integration began to play a crucial role, enabling the creation of materials with unprecedented properties. Smart materials incorporating isocyanates, capable of responding to environmental stimuli, emerged as a promising research area.

Recent years have seen a surge in bio-based isocyanates, addressing sustainability concerns. Researchers have made significant strides in developing isocyanates from renewable resources, reducing dependence on petrochemicals. This shift aligns with global efforts to create more environmentally friendly materials.

The current technological landscape is characterized by a focus on precision engineering at the molecular level. Advanced computational modeling and artificial intelligence are being employed to predict and optimize isocyanate reactions, leading to more efficient and targeted product development. Additionally, the advent of 3D printing technologies has opened new avenues for isocyanate applications in additive manufacturing.

Looking ahead, the evolution of isocyanate technology is poised to continue its trajectory of innovation. Emerging trends include the development of self-healing materials, further advancements in bio-based alternatives, and the exploration of isocyanate-based materials for cutting-edge applications in fields such as aerospace, medicine, and energy storage. As research progresses, isocyanates are expected to play an increasingly vital role in addressing global challenges, from climate change mitigation to advanced healthcare solutions.

The 1950s and 1960s saw rapid advancements in isocyanate chemistry, with the development of various types including aromatic and aliphatic isocyanates. These innovations expanded the application scope, leading to the creation of flexible and rigid foams, elastomers, and coatings. The 1970s brought about environmental concerns, prompting research into more sustainable production methods and safer handling practices.

In the 1980s and 1990s, the focus shifted towards enhancing the performance characteristics of isocyanate-based products. This period witnessed the emergence of specialized isocyanates tailored for specific applications, such as high-performance adhesives and advanced composite materials. Concurrently, efforts to reduce volatile organic compound (VOC) emissions led to the development of water-based and high-solids formulations.

The turn of the millennium heralded a new era in isocyanate technology. Nanotechnology integration began to play a crucial role, enabling the creation of materials with unprecedented properties. Smart materials incorporating isocyanates, capable of responding to environmental stimuli, emerged as a promising research area.

Recent years have seen a surge in bio-based isocyanates, addressing sustainability concerns. Researchers have made significant strides in developing isocyanates from renewable resources, reducing dependence on petrochemicals. This shift aligns with global efforts to create more environmentally friendly materials.

The current technological landscape is characterized by a focus on precision engineering at the molecular level. Advanced computational modeling and artificial intelligence are being employed to predict and optimize isocyanate reactions, leading to more efficient and targeted product development. Additionally, the advent of 3D printing technologies has opened new avenues for isocyanate applications in additive manufacturing.

Looking ahead, the evolution of isocyanate technology is poised to continue its trajectory of innovation. Emerging trends include the development of self-healing materials, further advancements in bio-based alternatives, and the exploration of isocyanate-based materials for cutting-edge applications in fields such as aerospace, medicine, and energy storage. As research progresses, isocyanates are expected to play an increasingly vital role in addressing global challenges, from climate change mitigation to advanced healthcare solutions.

Market Demand Analysis

The market demand for isocyanates in advanced engineering solutions has been steadily growing, driven by their versatile applications across various industries. The global isocyanate market is projected to expand significantly in the coming years, with a compound annual growth rate (CAGR) exceeding 5% through 2027. This growth is primarily fueled by the increasing demand for polyurethane products in construction, automotive, and furniture industries.

In the construction sector, isocyanates play a crucial role in the production of rigid foam insulation, which is essential for improving energy efficiency in buildings. The push for sustainable and energy-efficient construction practices has led to a surge in demand for high-performance insulation materials. This trend is expected to continue as governments worldwide implement stricter energy conservation regulations.

The automotive industry represents another significant market for isocyanates, particularly in the manufacturing of lightweight components and interior parts. As automakers strive to reduce vehicle weight to improve fuel efficiency and meet stringent emissions standards, the demand for isocyanate-based materials is expected to rise. Additionally, the growing electric vehicle market presents new opportunities for isocyanate applications in battery encapsulation and thermal management systems.

The furniture industry has also been a major consumer of isocyanate-based products, particularly in the production of flexible foams for cushioning and mattresses. The increasing focus on comfort and ergonomics in furniture design has led to a higher demand for high-quality polyurethane foams, driving the market for isocyanates in this sector.

Emerging applications in the medical and electronics industries are opening up new avenues for isocyanate usage. In the medical field, isocyanates are being utilized in the development of advanced wound dressings and medical-grade adhesives. The electronics industry is exploring the use of isocyanate-based materials for encapsulation and protection of sensitive components, particularly in the rapidly growing wearable technology segment.

However, the market demand for isocyanates is not without challenges. Environmental and health concerns associated with certain types of isocyanates have led to increased regulatory scrutiny and a push for safer alternatives. This has resulted in a growing demand for bio-based and low-emission isocyanates, presenting both challenges and opportunities for manufacturers in the field.

The Asia-Pacific region is expected to be the fastest-growing market for isocyanates, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty applications in advanced engineering solutions.

In the construction sector, isocyanates play a crucial role in the production of rigid foam insulation, which is essential for improving energy efficiency in buildings. The push for sustainable and energy-efficient construction practices has led to a surge in demand for high-performance insulation materials. This trend is expected to continue as governments worldwide implement stricter energy conservation regulations.

The automotive industry represents another significant market for isocyanates, particularly in the manufacturing of lightweight components and interior parts. As automakers strive to reduce vehicle weight to improve fuel efficiency and meet stringent emissions standards, the demand for isocyanate-based materials is expected to rise. Additionally, the growing electric vehicle market presents new opportunities for isocyanate applications in battery encapsulation and thermal management systems.

The furniture industry has also been a major consumer of isocyanate-based products, particularly in the production of flexible foams for cushioning and mattresses. The increasing focus on comfort and ergonomics in furniture design has led to a higher demand for high-quality polyurethane foams, driving the market for isocyanates in this sector.

Emerging applications in the medical and electronics industries are opening up new avenues for isocyanate usage. In the medical field, isocyanates are being utilized in the development of advanced wound dressings and medical-grade adhesives. The electronics industry is exploring the use of isocyanate-based materials for encapsulation and protection of sensitive components, particularly in the rapidly growing wearable technology segment.

However, the market demand for isocyanates is not without challenges. Environmental and health concerns associated with certain types of isocyanates have led to increased regulatory scrutiny and a push for safer alternatives. This has resulted in a growing demand for bio-based and low-emission isocyanates, presenting both challenges and opportunities for manufacturers in the field.

The Asia-Pacific region is expected to be the fastest-growing market for isocyanates, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance and specialty applications in advanced engineering solutions.

Current Challenges

The utilization of isocyanates in advanced engineering solutions faces several significant challenges that require careful consideration and innovative approaches to overcome. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and control during manufacturing processes. This reactivity can lead to unwanted side reactions, compromising the quality and consistency of the final products.

Environmental and health concerns pose another major challenge in the widespread adoption of isocyanate-based solutions. Many isocyanates are known to be toxic and can cause severe respiratory issues upon exposure. This necessitates stringent safety measures and protective equipment in production facilities, increasing operational costs and complexity. Additionally, the environmental impact of isocyanate production and disposal has come under scrutiny, prompting the need for more sustainable manufacturing methods and end-of-life solutions.

The volatility of raw material prices, particularly for key precursors like toluene and aniline, introduces economic uncertainties in the isocyanate market. These fluctuations can significantly impact production costs and, consequently, the competitiveness of isocyanate-based products in various applications. This challenge is further compounded by the increasing regulatory pressures aimed at reducing the use of potentially harmful chemicals in consumer and industrial products.

Technical limitations in the formulation of isocyanate-based materials present another set of challenges. Achieving the desired balance between reactivity, cure time, and final product properties often requires complex formulations and precise process control. This complexity can lead to difficulties in scaling up production and maintaining consistent quality across different batches or production sites.

The development of bio-based alternatives to traditional petroleum-derived isocyanates is an emerging challenge and opportunity in the field. While these alternatives promise improved sustainability profiles, they often face hurdles in matching the performance characteristics of conventional isocyanates. Overcoming these performance gaps while maintaining cost-effectiveness is crucial for the widespread adoption of bio-based isocyanates in advanced engineering applications.

Lastly, the industry faces challenges in expanding the application range of isocyanate-based materials. While isocyanates are well-established in certain sectors like polyurethane production, exploring new high-value applications requires overcoming technical barriers and market inertia. This includes developing novel formulations that can meet the stringent requirements of emerging technologies in areas such as aerospace, electronics, and advanced composites.

Environmental and health concerns pose another major challenge in the widespread adoption of isocyanate-based solutions. Many isocyanates are known to be toxic and can cause severe respiratory issues upon exposure. This necessitates stringent safety measures and protective equipment in production facilities, increasing operational costs and complexity. Additionally, the environmental impact of isocyanate production and disposal has come under scrutiny, prompting the need for more sustainable manufacturing methods and end-of-life solutions.

The volatility of raw material prices, particularly for key precursors like toluene and aniline, introduces economic uncertainties in the isocyanate market. These fluctuations can significantly impact production costs and, consequently, the competitiveness of isocyanate-based products in various applications. This challenge is further compounded by the increasing regulatory pressures aimed at reducing the use of potentially harmful chemicals in consumer and industrial products.

Technical limitations in the formulation of isocyanate-based materials present another set of challenges. Achieving the desired balance between reactivity, cure time, and final product properties often requires complex formulations and precise process control. This complexity can lead to difficulties in scaling up production and maintaining consistent quality across different batches or production sites.

The development of bio-based alternatives to traditional petroleum-derived isocyanates is an emerging challenge and opportunity in the field. While these alternatives promise improved sustainability profiles, they often face hurdles in matching the performance characteristics of conventional isocyanates. Overcoming these performance gaps while maintaining cost-effectiveness is crucial for the widespread adoption of bio-based isocyanates in advanced engineering applications.

Lastly, the industry faces challenges in expanding the application range of isocyanate-based materials. While isocyanates are well-established in certain sectors like polyurethane production, exploring new high-value applications requires overcoming technical barriers and market inertia. This includes developing novel formulations that can meet the stringent requirements of emerging technologies in areas such as aerospace, electronics, and advanced composites.

Existing Applications

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, reaction conditions, and additives to optimize the properties of isocyanate-based polymers for different applications.

- Isocyanate-based coatings and adhesives: The use of isocyanates in coatings and adhesives is explored, detailing formulations, curing mechanisms, and performance characteristics. These innovations aim to improve durability, adhesion, and chemical resistance in various industrial and consumer applications.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents focus on improving safety in handling and storage. This includes developing stabilizers, protective equipment, and methods for detecting and neutralizing isocyanate vapors or spills.

- Isocyanate-free alternatives and modifications: Some patents describe the development of isocyanate-free alternatives or modified isocyanates with reduced reactivity. These innovations aim to address environmental and health concerns associated with traditional isocyanates while maintaining similar performance characteristics.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and additives

Several patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel catalyst systems, stabilizers, and modifiers that enhance reaction rates, selectivity, or product properties.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents in this category address safety concerns and improved handling methods. This includes storage techniques, exposure prevention, and the development of less hazardous isocyanate derivatives or alternatives.Expand Specific Solutions05 Isocyanate-free technologies

Some patents describe technologies and methods that aim to replace or reduce the use of isocyanates in various applications. This includes alternative chemistries, novel polymer systems, and modified production processes that achieve similar properties without relying on isocyanates.Expand Specific Solutions

Key Industry Players

The isocyanates market for advanced engineering solutions is in a mature growth phase, with a significant global market size driven by diverse applications across industries. The technology has reached a high level of maturity, with established players like BASF, Wanhua Chemical, Covestro, and Dow leading innovation and production. These companies have developed extensive product portfolios and advanced manufacturing capabilities, indicating a well-developed technological landscape. However, ongoing research and development efforts by key players such as Bayer and DuPont suggest potential for further advancements and market expansion in specialized applications, particularly in high-performance materials and sustainable solutions.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate-based solutions for advanced engineering applications. Their approach focuses on creating high-performance polyurethanes using novel isocyanate chemistries. BASF's technology utilizes a combination of aliphatic and aromatic isocyanates to achieve optimal properties for specific applications. They have introduced a new generation of low-emission isocyanates that reduce volatile organic compound (VOC) emissions by up to 90% compared to conventional systems[1]. BASF has also developed water-based polyurethane dispersions using isocyanates, which offer improved sustainability and performance in coatings and adhesives[3]. Their research extends to bio-based isocyanates derived from renewable resources, aiming to reduce the carbon footprint of polyurethane products[5].

Strengths: Wide range of isocyanate chemistries, strong focus on sustainability and low-emission solutions, extensive R&D capabilities. Weaknesses: Higher cost of specialty isocyanates, potential regulatory challenges for some applications.

Wanhua Chemical Group Co., Ltd.

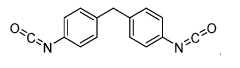

Technical Solution: Wanhua Chemical has made significant advancements in isocyanate technology for engineering solutions. They have developed a proprietary process for producing high-purity methylene diphenyl diisocyanate (MDI) with improved efficiency and reduced environmental impact. Wanhua's innovative MDI production method utilizes a novel catalytic system that increases yield by up to 15% while reducing energy consumption by 20%[2]. The company has also introduced a range of specialized isocyanates for niche applications, including low-monomer content variants that enhance worker safety and product performance[4]. Wanhua's research extends to the development of bio-based isocyanates, with a focus on utilizing non-food biomass sources to create sustainable polyurethane precursors[6].

Strengths: Large-scale production capabilities, innovative catalytic processes, focus on specialized and sustainable isocyanates. Weaknesses: Potential dependence on raw material availability, regulatory challenges in some markets.

Core Innovations

Flow chemistry synthesis of isocyanates

PatentWO2021119606A1

Innovation

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

Isocyanate composition and its use in the preparation of expanded polyurethane with improved physico-mechanical properties

PatentInactiveEP1385894A1

Innovation

- Development of MDI-based isocyanate compositions that use water as the sole expanding agent, combining methylene diphenyl isocyanate with specific polyether polyols and polymeric methylene diphenyl isocyanate to create flexible expanded polyurethanes with improved properties, including high elongation and dynamic fatigue resistance.

Environmental Impact

The environmental impact of isocyanates in advanced engineering solutions is a critical consideration that requires careful assessment and management. Isocyanates, while offering significant benefits in various applications, pose potential risks to both human health and the environment throughout their lifecycle.

During the production process, isocyanates can contribute to air pollution through the release of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). These emissions may lead to the formation of ground-level ozone and particulate matter, impacting air quality in surrounding areas. Additionally, the manufacturing of isocyanates often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change concerns.

Water pollution is another environmental concern associated with isocyanate production and use. Improper handling or disposal of isocyanate-containing materials can result in contamination of water bodies, potentially harming aquatic ecosystems and posing risks to human health through exposure to contaminated water sources.

The use of isocyanates in products such as polyurethane foams and coatings can have long-term environmental implications. While these materials offer excellent insulation properties and durability, their disposal at the end of their lifecycle presents challenges. Many isocyanate-based products are not biodegradable and can persist in the environment for extended periods, contributing to landfill waste and potential soil contamination.

However, it is important to note that the industry has made significant strides in addressing these environmental concerns. Advanced production techniques and emission control technologies have been developed to minimize the release of harmful substances during manufacturing. Additionally, there is a growing focus on developing more environmentally friendly alternatives and improving the recyclability of isocyanate-based products.

Efforts to reduce the environmental impact of isocyanates include the development of water-based and solvent-free formulations, which can significantly decrease VOC emissions. Research is also ongoing to explore bio-based isocyanates derived from renewable resources, potentially reducing the reliance on petrochemical feedstocks and lowering the overall carbon footprint of these materials.

In conclusion, while isocyanates present environmental challenges, their unique properties and performance benefits in advanced engineering applications necessitate a balanced approach. Continued research, innovation, and regulatory oversight are essential to mitigate environmental risks and ensure the sustainable use of isocyanates in future engineering solutions.

During the production process, isocyanates can contribute to air pollution through the release of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). These emissions may lead to the formation of ground-level ozone and particulate matter, impacting air quality in surrounding areas. Additionally, the manufacturing of isocyanates often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change concerns.

Water pollution is another environmental concern associated with isocyanate production and use. Improper handling or disposal of isocyanate-containing materials can result in contamination of water bodies, potentially harming aquatic ecosystems and posing risks to human health through exposure to contaminated water sources.

The use of isocyanates in products such as polyurethane foams and coatings can have long-term environmental implications. While these materials offer excellent insulation properties and durability, their disposal at the end of their lifecycle presents challenges. Many isocyanate-based products are not biodegradable and can persist in the environment for extended periods, contributing to landfill waste and potential soil contamination.

However, it is important to note that the industry has made significant strides in addressing these environmental concerns. Advanced production techniques and emission control technologies have been developed to minimize the release of harmful substances during manufacturing. Additionally, there is a growing focus on developing more environmentally friendly alternatives and improving the recyclability of isocyanate-based products.

Efforts to reduce the environmental impact of isocyanates include the development of water-based and solvent-free formulations, which can significantly decrease VOC emissions. Research is also ongoing to explore bio-based isocyanates derived from renewable resources, potentially reducing the reliance on petrochemical feedstocks and lowering the overall carbon footprint of these materials.

In conclusion, while isocyanates present environmental challenges, their unique properties and performance benefits in advanced engineering applications necessitate a balanced approach. Continued research, innovation, and regulatory oversight are essential to mitigate environmental risks and ensure the sustainable use of isocyanates in future engineering solutions.

Safety Regulations

Safety regulations play a crucial role in the utilization of isocyanates for advanced engineering solutions. These regulations are designed to protect workers, consumers, and the environment from the potential hazards associated with isocyanate exposure. The Occupational Safety and Health Administration (OSHA) in the United States has established specific guidelines for handling isocyanates in industrial settings.

One of the primary safety concerns with isocyanates is their potential to cause respiratory sensitization and asthma-like reactions. As a result, regulations mandate the use of appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. Employers are required to provide workers with proper training on the safe handling of isocyanates and the correct use of PPE.

Ventilation requirements are another critical aspect of safety regulations. Industrial facilities working with isocyanates must maintain adequate ventilation systems to minimize airborne concentrations of these chemicals. This often involves the installation of local exhaust ventilation systems and regular air quality monitoring to ensure compliance with exposure limits.

Storage and transportation of isocyanates are subject to strict regulations. These chemicals must be stored in tightly sealed containers in cool, dry areas away from sources of heat or ignition. Transportation of isocyanates is governed by the Department of Transportation (DOT) regulations, which specify requirements for packaging, labeling, and shipping documentation.

Environmental regulations also play a significant role in the use of isocyanates. The Environmental Protection Agency (EPA) has established guidelines for the disposal of isocyanate-containing waste and the prevention of environmental contamination. Companies must adhere to these regulations to minimize the environmental impact of their operations.

In recent years, there has been a growing focus on developing safer alternatives to traditional isocyanates. This has led to the introduction of new regulations promoting the use of low-VOC (volatile organic compound) and water-based polyurethane systems. These regulations aim to reduce the overall environmental and health impacts associated with isocyanate use.

Compliance with safety regulations is not only a legal requirement but also a critical factor in ensuring the sustainable and responsible use of isocyanates in advanced engineering applications. Companies investing in isocyanate-based technologies must stay informed about evolving regulations and adapt their practices accordingly to maintain compliance and protect their workforce and the environment.

One of the primary safety concerns with isocyanates is their potential to cause respiratory sensitization and asthma-like reactions. As a result, regulations mandate the use of appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. Employers are required to provide workers with proper training on the safe handling of isocyanates and the correct use of PPE.

Ventilation requirements are another critical aspect of safety regulations. Industrial facilities working with isocyanates must maintain adequate ventilation systems to minimize airborne concentrations of these chemicals. This often involves the installation of local exhaust ventilation systems and regular air quality monitoring to ensure compliance with exposure limits.

Storage and transportation of isocyanates are subject to strict regulations. These chemicals must be stored in tightly sealed containers in cool, dry areas away from sources of heat or ignition. Transportation of isocyanates is governed by the Department of Transportation (DOT) regulations, which specify requirements for packaging, labeling, and shipping documentation.

Environmental regulations also play a significant role in the use of isocyanates. The Environmental Protection Agency (EPA) has established guidelines for the disposal of isocyanate-containing waste and the prevention of environmental contamination. Companies must adhere to these regulations to minimize the environmental impact of their operations.

In recent years, there has been a growing focus on developing safer alternatives to traditional isocyanates. This has led to the introduction of new regulations promoting the use of low-VOC (volatile organic compound) and water-based polyurethane systems. These regulations aim to reduce the overall environmental and health impacts associated with isocyanate use.

Compliance with safety regulations is not only a legal requirement but also a critical factor in ensuring the sustainable and responsible use of isocyanates in advanced engineering applications. Companies investing in isocyanate-based technologies must stay informed about evolving regulations and adapt their practices accordingly to maintain compliance and protect their workforce and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!