Examining the Role of Isocyanates in Smart Textiles

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanates in Smart Textiles: Background and Objectives

Isocyanates have emerged as a pivotal component in the development of smart textiles, marking a significant advancement in the intersection of chemistry and textile engineering. The evolution of this technology can be traced back to the mid-20th century when isocyanates were first synthesized and their reactive properties discovered. Since then, these versatile compounds have found applications in various industries, with their role in smart textiles becoming increasingly prominent in recent years.

The primary objective of incorporating isocyanates into smart textiles is to enhance the functionality and performance of fabrics beyond their traditional capabilities. This integration aims to create textiles that can respond to environmental stimuli, adapt to changing conditions, or perform specific functions on demand. The unique chemical properties of isocyanates, particularly their ability to form strong covalent bonds with a wide range of substrates, make them ideal candidates for imparting smart features to textiles.

One of the key trends driving the development of isocyanate-based smart textiles is the growing demand for wearable technology and functional clothing. As consumers seek garments that offer more than just aesthetic appeal, the textile industry has been pushed to innovate, leading to the exploration of chemical solutions like isocyanates to meet these evolving needs.

The technological progression in this field has been marked by several milestones. Initially, isocyanates were primarily used for waterproofing and enhancing the durability of fabrics. However, as research advanced, their potential for creating shape-memory textiles, self-healing materials, and temperature-responsive fabrics became apparent. This evolution has opened up new possibilities for applications in sectors such as healthcare, sports, and protective wear.

Current research in isocyanate-based smart textiles is focused on overcoming challenges related to durability, washability, and environmental impact. Scientists and engineers are working on developing more sustainable isocyanate formulations and exploring ways to improve the longevity of smart features in textiles without compromising their performance or safety.

The future trajectory of isocyanates in smart textiles points towards more sophisticated and multifunctional materials. There is a growing interest in creating textiles that can simultaneously respond to multiple stimuli, self-regulate their properties, and even interact with digital devices. This vision aligns with the broader trend of Internet of Things (IoT) and the increasing integration of technology into everyday objects.

As we delve deeper into the role of isocyanates in smart textiles, it becomes clear that this field is at the cusp of significant breakthroughs. The potential applications span from medical textiles that can monitor vital signs and deliver medication, to adaptive sportswear that optimizes performance based on environmental conditions. The ongoing research and development in this area promise to revolutionize not only the textile industry but also how we interact with the fabrics in our daily lives.

The primary objective of incorporating isocyanates into smart textiles is to enhance the functionality and performance of fabrics beyond their traditional capabilities. This integration aims to create textiles that can respond to environmental stimuli, adapt to changing conditions, or perform specific functions on demand. The unique chemical properties of isocyanates, particularly their ability to form strong covalent bonds with a wide range of substrates, make them ideal candidates for imparting smart features to textiles.

One of the key trends driving the development of isocyanate-based smart textiles is the growing demand for wearable technology and functional clothing. As consumers seek garments that offer more than just aesthetic appeal, the textile industry has been pushed to innovate, leading to the exploration of chemical solutions like isocyanates to meet these evolving needs.

The technological progression in this field has been marked by several milestones. Initially, isocyanates were primarily used for waterproofing and enhancing the durability of fabrics. However, as research advanced, their potential for creating shape-memory textiles, self-healing materials, and temperature-responsive fabrics became apparent. This evolution has opened up new possibilities for applications in sectors such as healthcare, sports, and protective wear.

Current research in isocyanate-based smart textiles is focused on overcoming challenges related to durability, washability, and environmental impact. Scientists and engineers are working on developing more sustainable isocyanate formulations and exploring ways to improve the longevity of smart features in textiles without compromising their performance or safety.

The future trajectory of isocyanates in smart textiles points towards more sophisticated and multifunctional materials. There is a growing interest in creating textiles that can simultaneously respond to multiple stimuli, self-regulate their properties, and even interact with digital devices. This vision aligns with the broader trend of Internet of Things (IoT) and the increasing integration of technology into everyday objects.

As we delve deeper into the role of isocyanates in smart textiles, it becomes clear that this field is at the cusp of significant breakthroughs. The potential applications span from medical textiles that can monitor vital signs and deliver medication, to adaptive sportswear that optimizes performance based on environmental conditions. The ongoing research and development in this area promise to revolutionize not only the textile industry but also how we interact with the fabrics in our daily lives.

Market Analysis for Isocyanate-Based Smart Textiles

The market for isocyanate-based smart textiles is experiencing significant growth, driven by increasing demand for advanced functional fabrics across various industries. The global smart textile market, which includes isocyanate-based products, is projected to reach substantial market value in the coming years. This growth is primarily fueled by the unique properties that isocyanates bring to textile applications, such as enhanced durability, flexibility, and responsiveness to environmental stimuli.

In the healthcare sector, isocyanate-based smart textiles are gaining traction for their potential in wound care, drug delivery systems, and biomonitoring applications. The aging population and rising healthcare costs are driving the adoption of these innovative textiles for remote patient monitoring and personalized healthcare solutions. The sports and fitness industry is another key market segment, where isocyanate-based smart textiles are being utilized in performance-enhancing sportswear and wearable technology for athletes.

The automotive industry represents a significant market opportunity for isocyanate-based smart textiles. These materials are being incorporated into vehicle interiors for improved comfort, safety, and energy efficiency. As the trend towards electric and autonomous vehicles continues, the demand for advanced textile solutions is expected to grow further.

Military and defense applications are also driving market growth, with isocyanate-based smart textiles being developed for protective gear, camouflage systems, and communication-integrated uniforms. The increasing focus on soldier safety and battlefield effectiveness is propelling research and development in this sector.

Geographically, North America and Europe are currently leading the market for isocyanate-based smart textiles, owing to their advanced technological infrastructure and strong presence of key industry players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of smart textile applications.

Despite the positive market outlook, challenges such as high production costs and concerns about the environmental impact of isocyanates may hinder market growth. Manufacturers are investing in research to develop more sustainable and eco-friendly alternatives to address these concerns and meet evolving regulatory requirements.

Overall, the market for isocyanate-based smart textiles shows promising growth potential across multiple industries. As technology advances and production costs decrease, wider adoption of these innovative materials is expected, opening up new opportunities for market expansion and product development.

In the healthcare sector, isocyanate-based smart textiles are gaining traction for their potential in wound care, drug delivery systems, and biomonitoring applications. The aging population and rising healthcare costs are driving the adoption of these innovative textiles for remote patient monitoring and personalized healthcare solutions. The sports and fitness industry is another key market segment, where isocyanate-based smart textiles are being utilized in performance-enhancing sportswear and wearable technology for athletes.

The automotive industry represents a significant market opportunity for isocyanate-based smart textiles. These materials are being incorporated into vehicle interiors for improved comfort, safety, and energy efficiency. As the trend towards electric and autonomous vehicles continues, the demand for advanced textile solutions is expected to grow further.

Military and defense applications are also driving market growth, with isocyanate-based smart textiles being developed for protective gear, camouflage systems, and communication-integrated uniforms. The increasing focus on soldier safety and battlefield effectiveness is propelling research and development in this sector.

Geographically, North America and Europe are currently leading the market for isocyanate-based smart textiles, owing to their advanced technological infrastructure and strong presence of key industry players. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing disposable income, and growing awareness of smart textile applications.

Despite the positive market outlook, challenges such as high production costs and concerns about the environmental impact of isocyanates may hinder market growth. Manufacturers are investing in research to develop more sustainable and eco-friendly alternatives to address these concerns and meet evolving regulatory requirements.

Overall, the market for isocyanate-based smart textiles shows promising growth potential across multiple industries. As technology advances and production costs decrease, wider adoption of these innovative materials is expected, opening up new opportunities for market expansion and product development.

Current Challenges in Isocyanate Smart Textile Technology

The integration of isocyanates in smart textile technology presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is the potential health and environmental risks associated with isocyanates. These compounds are known for their high reactivity and can cause respiratory irritation, skin sensitization, and other health issues when not properly handled. This necessitates stringent safety protocols and protective measures during the manufacturing process, which can increase production costs and complexity.

Another challenge lies in achieving consistent and uniform application of isocyanates onto textile substrates. The reactivity of isocyanates can lead to uneven distribution or premature curing, resulting in inconsistent performance of the smart textile. Controlling the reaction kinetics and ensuring proper bonding between the isocyanate-based coatings and the textile fibers remains a technical hurdle that requires further research and development.

Durability and longevity of isocyanate-based smart textiles pose additional challenges. The functional properties imparted by isocyanates, such as water repellency or shape memory, may degrade over time due to wear, washing, or exposure to environmental factors. Enhancing the long-term stability of these properties without compromising the textile's comfort and flexibility is an ongoing area of investigation.

The scalability of isocyanate-based smart textile production is another significant challenge. While laboratory-scale demonstrations have shown promising results, translating these processes to industrial-scale manufacturing while maintaining quality and cost-effectiveness remains difficult. This includes optimizing curing conditions, developing efficient application methods, and ensuring consistent performance across large batches of textiles.

Furthermore, the environmental impact of isocyanate-based smart textiles is a growing concern. The use of petrochemical-derived isocyanates raises questions about sustainability and end-of-life disposal. Developing more eco-friendly alternatives or finding ways to recycle and reuse these materials is crucial for the long-term viability of this technology in an increasingly environmentally conscious market.

Regulatory compliance presents an additional layer of complexity. As smart textiles incorporating isocyanates enter various markets, navigating the diverse and evolving regulatory landscape becomes challenging. Ensuring compliance with different regional standards for chemical use, product safety, and environmental protection requires significant resources and expertise.

Lastly, the integration of isocyanate-based smart functionalities with other electronic components in e-textiles presents unique challenges. Ensuring compatibility between the chemical treatments and embedded electronics, while maintaining the textile's flexibility and washability, requires interdisciplinary collaboration and innovative design approaches.

Another challenge lies in achieving consistent and uniform application of isocyanates onto textile substrates. The reactivity of isocyanates can lead to uneven distribution or premature curing, resulting in inconsistent performance of the smart textile. Controlling the reaction kinetics and ensuring proper bonding between the isocyanate-based coatings and the textile fibers remains a technical hurdle that requires further research and development.

Durability and longevity of isocyanate-based smart textiles pose additional challenges. The functional properties imparted by isocyanates, such as water repellency or shape memory, may degrade over time due to wear, washing, or exposure to environmental factors. Enhancing the long-term stability of these properties without compromising the textile's comfort and flexibility is an ongoing area of investigation.

The scalability of isocyanate-based smart textile production is another significant challenge. While laboratory-scale demonstrations have shown promising results, translating these processes to industrial-scale manufacturing while maintaining quality and cost-effectiveness remains difficult. This includes optimizing curing conditions, developing efficient application methods, and ensuring consistent performance across large batches of textiles.

Furthermore, the environmental impact of isocyanate-based smart textiles is a growing concern. The use of petrochemical-derived isocyanates raises questions about sustainability and end-of-life disposal. Developing more eco-friendly alternatives or finding ways to recycle and reuse these materials is crucial for the long-term viability of this technology in an increasingly environmentally conscious market.

Regulatory compliance presents an additional layer of complexity. As smart textiles incorporating isocyanates enter various markets, navigating the diverse and evolving regulatory landscape becomes challenging. Ensuring compliance with different regional standards for chemical use, product safety, and environmental protection requires significant resources and expertise.

Lastly, the integration of isocyanate-based smart functionalities with other electronic components in e-textiles presents unique challenges. Ensuring compatibility between the chemical treatments and embedded electronics, while maintaining the textile's flexibility and washability, requires interdisciplinary collaboration and innovative design approaches.

Existing Isocyanate-Based Smart Textile Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Some patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel compounds that enhance reaction rates, improve selectivity, or provide specific properties to the final products.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents address safety concerns and improved handling methods. These include storage techniques, exposure prevention, and the development of less hazardous isocyanate derivatives.

- Isocyanate-free alternatives and substitutes: Some patents explore alternatives to traditional isocyanates, aiming to address environmental and health concerns. These include bio-based substitutes, non-isocyanate polyurethanes, and alternative chemistries that provide similar functionalities.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various formulations, curing methods, and applications of isocyanate-based polymers in coatings, adhesives, and other materials.Expand Specific Solutions03 Isocyanate-modified compounds and materials

Several patents focus on the modification of existing compounds or materials using isocyanates. This includes the creation of isocyanate-terminated prepolymers, isocyanate-functional silanes, and other modified materials with enhanced properties.Expand Specific Solutions04 Handling and safety of isocyanates

Due to the reactive nature of isocyanates, several patents address safety concerns and handling procedures. This includes methods for reducing exposure, improving storage stability, and developing safer alternatives or formulations.Expand Specific Solutions05 Analytical methods for isocyanates

Various analytical techniques and methods for detecting, quantifying, and characterizing isocyanates are described. These include spectroscopic methods, chromatographic techniques, and specialized sensors for monitoring isocyanate levels in different environments.Expand Specific Solutions

Key Players in Isocyanate Smart Textile Industry

The smart textiles market, driven by isocyanate technology, is in a growth phase characterized by increasing adoption and innovation. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, but still evolving, with companies like Wanhua Chemical Group, BASF Corp., and Covestro Deutschland AG leading in isocyanate production. Academic institutions such as South China University of Technology and Ghent University are contributing to research and development. Collaborations between industry players like Adidas and research centers are accelerating the maturation of smart textile technologies, indicating a competitive landscape that balances established chemical companies with innovative textile and technology firms.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed innovative isocyanate-based solutions for smart textiles. Their approach involves incorporating polyurethane (PU) coatings with isocyanate-terminated prepolymers onto fabric substrates. This technology enables the creation of textiles with enhanced properties such as water repellency, breathability, and durability. The company has also explored the use of blocked isocyanates, which remain stable at room temperature but become reactive when heated, allowing for controlled crosslinking in textile applications[1][3]. Wanhua's research has led to the development of bio-based isocyanates derived from renewable resources, addressing sustainability concerns in the smart textile industry[5].

Strengths: Extensive experience in isocyanate chemistry, strong R&D capabilities, and a focus on sustainable solutions. Weaknesses: Potential environmental and health concerns associated with isocyanate use, regulatory challenges in some markets.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has made significant strides in the application of isocyanates for smart textiles. Their approach focuses on developing novel polyurethane formulations that incorporate reactive isocyanate groups. These formulations are designed to create durable, flexible coatings on textiles that can impart various smart functionalities. Dow has particularly emphasized the development of moisture-curing systems that allow for room-temperature processing, reducing energy costs in textile manufacturing[2]. The company has also explored the use of aliphatic isocyanates for UV-resistant coatings, enhancing the longevity of smart textiles exposed to outdoor conditions[4]. Additionally, Dow has invested in research on isocyanate-free alternatives to address potential health and environmental concerns[6].

Strengths: Broad portfolio of polyurethane technologies, strong global presence, and significant R&D resources. Weaknesses: Reliance on petroleum-based raw materials for many isocyanate products, potential regulatory challenges in some regions.

Core Innovations in Isocyanate Smart Textile Research

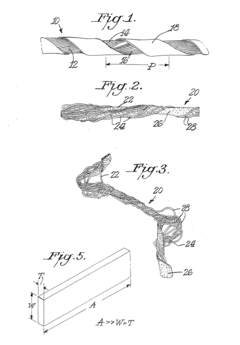

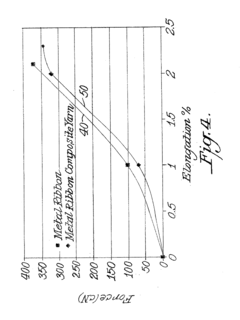

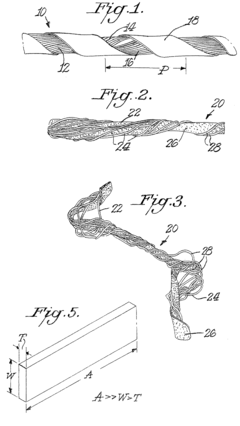

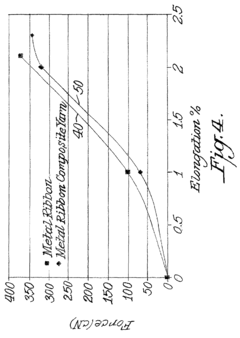

Energy active composite yarn, methods for making the same and articles incorporating the same

PatentInactiveUS20080176073A1

Innovation

- Energy active composite yarns featuring a textile fiber member surrounded by a functional substantially planar filament, which can be elastic or inelastic, allowing for multifunctional properties such as electrical, optical, and magnetic capabilities, while maintaining textile-like stress-strain properties through methods like twisting, wrapping, or entangling the filaments.

Energy active composite yarn, methods for making the same and articles incorporating the same

PatentInactiveUS7665288B2

Innovation

- Energy active composite yarns featuring a textile fiber member surrounded by a functional substantially planar filament, which can be elastic or inelastic, allowing for multifunctional properties such as electrical, optical, and magnetic capabilities, while maintaining textile-like stress-strain properties through methods like twisting, wrapping, or entangling the filaments.

Environmental Impact of Isocyanates in Textiles

The environmental impact of isocyanates in textiles is a critical concern as the smart textile industry continues to grow. Isocyanates, widely used in the production of polyurethane-based materials, play a significant role in enhancing the functionality of smart textiles. However, their potential environmental consequences cannot be overlooked.

One of the primary environmental concerns associated with isocyanates is their toxicity. When released into the environment, these compounds can have detrimental effects on aquatic ecosystems and soil microorganisms. Studies have shown that isocyanates can persist in water bodies, leading to long-term ecological damage. Furthermore, the bioaccumulation of these chemicals in the food chain poses risks to higher-order organisms, including humans.

The production process of isocyanate-based smart textiles also contributes to environmental pollution. The synthesis of isocyanates often involves the use of harmful chemicals and energy-intensive processes, resulting in significant carbon emissions. Additionally, the disposal of textile waste containing isocyanates presents challenges, as improper handling can lead to the release of toxic substances into the environment.

However, it is important to note that the textile industry has been making efforts to mitigate the environmental impact of isocyanates. Research into more environmentally friendly alternatives, such as bio-based isocyanates derived from renewable resources, is gaining momentum. These sustainable alternatives aim to reduce the carbon footprint associated with isocyanate production while maintaining the desired functional properties in smart textiles.

Moreover, advancements in manufacturing technologies have led to improved efficiency in isocyanate usage, reducing waste and emissions. Closed-loop systems and better containment measures are being implemented to minimize the release of isocyanates during production and processing stages. These initiatives not only protect the environment but also enhance worker safety.

The textile industry is also focusing on developing more effective end-of-life solutions for isocyanate-containing smart textiles. Recycling technologies are being explored to recover and repurpose these materials, reducing the need for landfill disposal and minimizing environmental contamination. Additionally, research into biodegradable isocyanate formulations shows promise in addressing the long-term environmental persistence of these compounds.

As regulations become more stringent, manufacturers are increasingly adopting life cycle assessment approaches to evaluate and improve the environmental performance of isocyanate-based smart textiles. This holistic view enables the identification of hotspots in the production chain where environmental impacts can be most effectively reduced, leading to more sustainable product development strategies.

One of the primary environmental concerns associated with isocyanates is their toxicity. When released into the environment, these compounds can have detrimental effects on aquatic ecosystems and soil microorganisms. Studies have shown that isocyanates can persist in water bodies, leading to long-term ecological damage. Furthermore, the bioaccumulation of these chemicals in the food chain poses risks to higher-order organisms, including humans.

The production process of isocyanate-based smart textiles also contributes to environmental pollution. The synthesis of isocyanates often involves the use of harmful chemicals and energy-intensive processes, resulting in significant carbon emissions. Additionally, the disposal of textile waste containing isocyanates presents challenges, as improper handling can lead to the release of toxic substances into the environment.

However, it is important to note that the textile industry has been making efforts to mitigate the environmental impact of isocyanates. Research into more environmentally friendly alternatives, such as bio-based isocyanates derived from renewable resources, is gaining momentum. These sustainable alternatives aim to reduce the carbon footprint associated with isocyanate production while maintaining the desired functional properties in smart textiles.

Moreover, advancements in manufacturing technologies have led to improved efficiency in isocyanate usage, reducing waste and emissions. Closed-loop systems and better containment measures are being implemented to minimize the release of isocyanates during production and processing stages. These initiatives not only protect the environment but also enhance worker safety.

The textile industry is also focusing on developing more effective end-of-life solutions for isocyanate-containing smart textiles. Recycling technologies are being explored to recover and repurpose these materials, reducing the need for landfill disposal and minimizing environmental contamination. Additionally, research into biodegradable isocyanate formulations shows promise in addressing the long-term environmental persistence of these compounds.

As regulations become more stringent, manufacturers are increasingly adopting life cycle assessment approaches to evaluate and improve the environmental performance of isocyanate-based smart textiles. This holistic view enables the identification of hotspots in the production chain where environmental impacts can be most effectively reduced, leading to more sustainable product development strategies.

Safety Regulations for Isocyanate Use in Smart Textiles

The use of isocyanates in smart textiles has raised significant safety concerns, prompting regulatory bodies worldwide to establish stringent guidelines for their handling and application. These regulations aim to protect workers, consumers, and the environment from potential hazards associated with isocyanate exposure.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates used in textile manufacturing. These limits typically range from 0.005 to 0.02 parts per million (ppm) for an 8-hour time-weighted average. Additionally, OSHA mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure during the production of smart textiles incorporating isocyanates.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which imposes strict requirements on the use of isocyanates in consumer products, including smart textiles. Under REACH, manufacturers must assess and manage the risks associated with isocyanates, provide safety information to users, and in some cases, seek authorization for their use.

Japan's Ministry of Health, Labour and Welfare has established similar exposure limits and safety protocols for isocyanate use in textile manufacturing. These regulations emphasize proper ventilation, worker training, and regular health monitoring for employees involved in the production of smart textiles containing isocyanates.

To ensure compliance with these regulations, manufacturers of smart textiles must implement comprehensive safety management systems. These systems typically include regular air quality monitoring, proper storage and handling procedures for isocyanate-containing materials, and detailed emergency response plans in case of accidental exposure or spills.

Furthermore, many regulatory bodies require extensive documentation and reporting on the use of isocyanates in smart textile production. This includes maintaining detailed records of isocyanate inventory, worker exposure levels, and any incidents or near-misses related to isocyanate handling.

As the field of smart textiles continues to evolve, regulatory agencies are closely monitoring developments and adjusting safety regulations accordingly. There is an increasing focus on promoting the use of safer alternatives to isocyanates where possible, and encouraging research into less hazardous smart textile technologies.

In response to these regulatory pressures, many companies in the smart textile industry are investing in advanced production technologies that minimize isocyanate exposure. This includes the development of closed-system manufacturing processes, automated application methods, and improved ventilation systems.

In the United States, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits (PELs) for various isocyanates used in textile manufacturing. These limits typically range from 0.005 to 0.02 parts per million (ppm) for an 8-hour time-weighted average. Additionally, OSHA mandates the use of personal protective equipment (PPE) and engineering controls to minimize worker exposure during the production of smart textiles incorporating isocyanates.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which imposes strict requirements on the use of isocyanates in consumer products, including smart textiles. Under REACH, manufacturers must assess and manage the risks associated with isocyanates, provide safety information to users, and in some cases, seek authorization for their use.

Japan's Ministry of Health, Labour and Welfare has established similar exposure limits and safety protocols for isocyanate use in textile manufacturing. These regulations emphasize proper ventilation, worker training, and regular health monitoring for employees involved in the production of smart textiles containing isocyanates.

To ensure compliance with these regulations, manufacturers of smart textiles must implement comprehensive safety management systems. These systems typically include regular air quality monitoring, proper storage and handling procedures for isocyanate-containing materials, and detailed emergency response plans in case of accidental exposure or spills.

Furthermore, many regulatory bodies require extensive documentation and reporting on the use of isocyanates in smart textile production. This includes maintaining detailed records of isocyanate inventory, worker exposure levels, and any incidents or near-misses related to isocyanate handling.

As the field of smart textiles continues to evolve, regulatory agencies are closely monitoring developments and adjusting safety regulations accordingly. There is an increasing focus on promoting the use of safer alternatives to isocyanates where possible, and encouraging research into less hazardous smart textile technologies.

In response to these regulatory pressures, many companies in the smart textile industry are investing in advanced production technologies that minimize isocyanate exposure. This includes the development of closed-system manufacturing processes, automated application methods, and improved ventilation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!